What is a Synchronous Motor? Explained

By R.W. Hurst, Editor

VFD Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3873 Fact Sheet – Minimum Approach Distance and Training Requirements

- Calculate MAD using voltage and overvoltage values

- Ensure proper communication between host and contract employers

- Meet OSHA training requirements for qualified electrical workers

A synchronous motor is an AC motor that rotates at a constant speed, matching the frequency of the AC power supply. Its rotor locks in step with the stator’s rotating magnetic field, delivering constant speed, high efficiency, and power factor correction.

What is a Synchronous Motor?

A synchronous motor is a type of AC device that operates at a constant speed, which is directly proportional to the frequency of the AC phase supply and the number of poles in the device. Unlike induction motors, which run with slip, synchronous motors maintain perfect synchronism between the rotor and stator fields. To fully understand the role of synchronous motors, it is helpful to explore the basics of electric motors and drives, as well as their function in modern electrical systems.

A synchronous machine is more than just a fixed-speed device. In industrial environments where precision is crucial, this fixed-speed device ensures equipment operates reliably without the slip often seen in induction types. Because it locks exactly with the rotating magnetic field, it is especially valuable in applications requiring accurate timing and consistency, such as compressors, pumps, and high-precision tools.

Another important feature is its ability to act as a power factor correction unit within an electrical system. By operating at either unity power factor or leading power factor, it offsets lagging loads and improves overall system efficiency. Proper rotor and stator alignment is essential in achieving these benefits, since any misalignment can compromise performance. This balance of efficiency, stability, and system support explains why synchronous machines remain a vital choice for engineers seeking both energy savings and grid reliability.

How Does a Synchronous Motor Work?

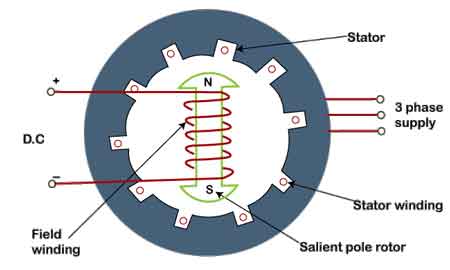

To understand the principle of operation, one must know the roles of the stator and rotor.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

-

Stator: The stationary part of the device, consisting of windings that produce a rotating magnetic field when connected to an AC supply.

-

Rotor: The rotating part, which may contain wound field windings or permanent magnets.

When the rotor poles align with the stator’s magnetic field, torque is produced, driving the mechanical load at constant speed. The fundamentals of electric motor design directly influence the construction of synchronous motors and their ability to maintain constant speed.

Advantages of Synchronous Motors

Synchronous motors are widely chosen for their performance benefits:

-

Constant speed operation, regardless of load changes

-

High efficiency and lower energy losses

-

Ability to operate at unity or leading power factor, correcting system lag

Improving electric motor efficiency is often a key reason why engineers choose synchronous motors in industrial applications.

Disadvantages of Synchronous Motors

Despite their advantages, they have some drawbacks:

-

Not self-starting; requires an external starter or VFD

-

More complex construction compared to induction machines

-

Higher initial cost and additional components are needed for starting

How Do Synchronous Motors Differ from Induction Motors?

While both are AC machines, key differences exist:

-

Rotor construction: Synchronous motors utilize wound fields or permanent magnets, while induction motors typically employ squirrel-cage rotors.

-

Starting: Synchronous motors are not self-starting, while induction fixed-speed devices start on their own.

-

Power factor: Synchronous motors can operate at unity or leading power factor, thereby improving efficiency; in contrast, induction devices typically run at a lagging power factor. Comparing synchronous motors with other types, such as the induction motor, highlights their unique ability to maintain exact synchronism with the power supply.

Since many synchronous motors are started or controlled with variable-frequency drives (VFDs), it is essential to understand how a VFD works and its impact on performance.

EF Partner Media

Applications of Synchronous Motors

Synchronous motors are used wherever constant speed, precision, and efficiency are required:

-

Compressors, pumps, and fans for constant-speed drives

-

Machine tools and robotics for high precision

-

Power plants, where they operate as synchronous motors

-

Industrial settings that benefit from power factor correction

Speed Control of Synchronous Motors

Synchronous Motor speed control can be achieved in two primary ways:

-

Frequency adjustment: Changing the supply frequency alters the constant speed.

-

Pole variation: Adjusting the number of poles in the stator.

Modern systems typically utilize variable frequency drives (VFDs), which provide smooth and efficient speed control by varying the input frequency. Learning how electric motor control works provides context for how synchronous motors achieve precise operation compared to other types.

Contribution to Power Factor Correction

Synchronous motors are valuable in power systems because they can operate at unity or leading power factor. This allows them to offset lagging power factors caused by other loads, lowering energy costs and improving system efficiency.

Frequently Asked Questions

Can a synchronous motor operate without a VFD?

Yes, but they require other starting methods, such as pony devices or damper windings, since they are not self-starting.

Why are they important in robotics?

Their precise, constant-speed operation and ability to maintain synchronism make them ideal for robotics and automation applications requiring accuracy.

Can a synchronous machine generate electricity?

Yes, when driven mechanically, synchronous motors can function as constant-speed generators, converting mechanical energy into electrical energy.

What limits the starting of synchronous motors?

They cannot develop starting torque on their own, which limits direct-on-line starting. This is why auxiliary devices, VFDs, or other methods are used.

Are synchronous machines used in renewable energy?

Yes, constant-speed generators are widely used in hydroelectric and wind power plants, where stable frequency and power factor control are critical.

For a more detailed guide covering design, performance curves, standards, and industrial applications, see our in-depth resource on synchronous motors.

Test Your Knowledge About Motors and Drives!

Think you know Motors and Drives? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics