Different Types of Transformers

Substation Relay Protection Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

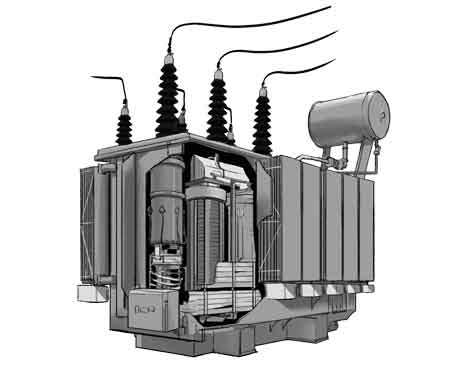

Different types of transformers include power, distribution, isolation, and instrument transformers. Each type serves unique roles in voltage regulation, electrical isolation, and energy transmission within power systems for industrial, commercial, and residential applications.

What are the different types of transformers?

Different types of transformers play a critical role in electrical engineering and maintenance, serving as essential components for power generation, transmission, and distribution systems.

✅ Power, distribution, and isolation transformers optimize voltage and power flow.

✅ Instrument transformers enhance accurate measurement and protection.

✅ Each type supports safe and efficient energy transmission across electrical networks.

Understanding the different types of transformers is vital for professionals responsible for designing, operating, and maintaining electrical infrastructure. Each type of transformer is engineered to perform specific functions, such as stepping up or stepping down voltage, isolating circuits, or providing accurate measurement and protection in substations. Mastering the differences between them enables electrical engineers and maintenance teams to enhance system efficiency, ensure operational safety, and reduce the risk of costly downtime. If you want to understand the inner components, read about the construction of a transformer.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Voltage Conversion and Magnetic Core Design

In different types of transformers, efficient voltage conversion is crucial to ensure that electricity can be safely transmitted from power generation sites to end-users. This process relies on devices built with a magnetic core that facilitates electromagnetic induction, allowing energy to be transferred between the primary winding and secondary winding. By adjusting the number of coil turns, these devices can step the voltage up or down while maintaining system stability. In high-voltage equipment, managing core saturation is critical to prevent performance loss and overheating, especially when loads fluctuate under real-world conditions.

Test Your Knowledge About Electrical Transformers!

Think you know Electrical Transformers? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Reliable electrical insulation further enhances safety and performance, particularly in environments like an electrical substation, where exposure to high voltages poses significant risks. Additionally, AC to DC conversion is often required in industrial control systems and renewable energy applications, where consistent and regulated direct current is needed. As energy demands rise, advancements in power regulation technologies continue to play a key role in supporting scalable and resilient infrastructure across residential, commercial, and utility-scale networks.

Applications and Uses in Different Types of Transformers

In modern power distribution systems, selecting the right transformer is crucial for efficient energy transfer, particularly when powering electronic devices. A step-down transformer is commonly used to reduce high voltage to a safer level suitable for delicate components. Among the various designs, ferrite core types are favoured in high-frequency circuits due to their low core losses, while toroidal core models are known for their compact size and minimal electromagnetic interference. Both types rely on a clear understanding of the primary and secondary windings, which determine how voltage is transformed and delivered to the load with precision and safety.

One of the most fundamental ways to categorize a transformer type is based on the number of phases. Single-phase ones are widely used in residential and small commercial applications, where lower power demands are present. They consist of a primary winding and a secondary coil, which work together to transfer electrical energy. In contrast, three-phase ones are more common in industrial and large commercial environments, as they can handle higher voltages and larger power loads more efficiently. The decision between single-phase and three-phase types is determined by the specific power supply requirements of the facility or application. Learn how a 3-phase transformer efficiently delivers power to industrial and commercial facilities.

Different Types of Transformers – Function, Application, and Key Features

| Transformer Type | Primary Function | Application | Key Features |

|---|---|---|---|

| Power Transformer | Step-up/step-down at high voltages | Transmission substations | High efficiency, full-load performance |

| Distribution Transformer | Reduce voltage for end users | Homes, offices, small industries | Operates at low loads, compact design |

| Isolation Transformer | Electrical isolation | Medical devices, industrial controls | Prevents shock, eliminates ground loops |

| Instrument Transformer | Voltage/current measurement and protection | Substations, metering systems | Safe measurement, supports protective relays |

| Step-Up Transformer | Increase voltage | Power plants to transmission lines | Boosts voltage for long-distance power delivery |

| Step-Down Transformer | Decrease voltage | Commercial and residential use | Converts high voltage to usable levels |

| Toroidal Core Transformer | Reduce EMI, compact design | Audio gear, sensitive electronics | Low noise, space-saving, high efficiency |

| Ferrite Core Transformer | High-frequency energy transfer | Electronic devices, SMPS circuits | Lightweight, low core losses, compact |

Transformer Classifications

Another important classification is according to their role in power systems. Power units are typically used in transmission networks to step up or step down the voltage of electricity, enabling the efficient transmission of power over long distances. These are essential for minimizing power loss as electricity travels from power plants to distribution substations. Once the energy reaches a substation, distribution types come into play. Distribution transformers reduce the voltage to safer, more usable levels for end users. This step down in voltage ensures that homes, offices, and commercial establishments receive the appropriate power levels for their electrical devices and appliances. Our guide on distribution transformers explains how these units step down voltage for safe residential and commercial use.

Instrument transformers, such as current and voltage types, are another category used for measuring and protection purposes. Instrument units connect to measuring instruments, such as voltmeters, ammeters, and protective relays. They enable accurate monitoring of electrical quantities without requiring direct connection to high-voltage power lines. Voltage types for instance, reduce the high voltage to a lower, measurable level that can be safely handled by measuring instruments. This approach provides critical information for system operators to maintain system stability and safety. High-voltage applications often require specialized designs, as detailed in our high-voltage transformers article.

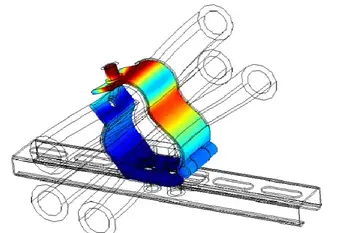

Construction and Design of Different Types of Transformers

The construction and design are also key aspects of their classification. They can be categorized based on the type of core used in their construction. The magnetic core serves as the central structure that supports the electromagnetic induction process. Two common designs are core-type and shell-type. In a core-type design, the windings surround the magnetic core, whereas in a shell-type design, the core encases the windings. These construction differences affect the efficiency, cost, and physical size of the transformer. Materials like laminated steel or ferrite are used in the construction of the magnetic core to minimize energy loss due to eddy currents and hysteresis. Discover how the core material impacts performance by reviewing our transformer core resource.

Sign Up for Electricity Forum’s Electrical Transformers Newsletter

Stay informed with our FREE Electrical Transformers Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Isolation ones form another important category. Unlike power ones that are designed to transfer electrical energy, isolation tones are used to decouple two electrical circuits. The primary and secondary windings in an isolation transformer are physically separated, preventing direct electrical contact between the two circuits. This separation ensures safety by providing protection against electric shock and eliminating ground loops. Isolation units are commonly used in medical equipment, sensitive electronics, and industrial control systems where enhanced electrical isolation is necessary.

Operating Principles

The operating principle of a transformer revolves around the phenomenon of electromagnetic induction. When an alternating current (AC) passes through the primary winding, it generates a magnetic field that induces a voltage in the secondary coil. The voltage induced depends on the turns ratio between the primary and secondary windings. This principle enables step-up or step-down voltage conversion, which is essential for effective power transmission and distribution. Understanding how the magnetic field interacts with the windings underscores the critical role of the transformer in electrical networks.

Advantages and Disadvantages of Different Types of Transformers

Each type of transformer comes with its own set of advantages and disadvantages. Power ones, for example, offer high efficiency and are well-suited for long-distance transmission; however, they come with high costs and a large physical size. Distribution ones, on the other hand, are smaller, less expensive, and suitable for localized power delivery, but they are not designed to handle extremely high voltages. Isolation ones provide safety benefits and reduce the risk of electric shock, but they also have limitations in terms of efficiency and size. These trade-offs play a vital role in selecting the right transformer for specific applications.

Frequently Asked Questions

What is the difference between Type 1 and Type 2?

The main difference lies in their design and application.

-

Type 1: These are typically dry-type ones that use air as a cooling medium. They are commonly used indoors or in environments where fire safety is a concern because they do not contain combustible fluids. Type 1 units are commonly found in commercial and industrial buildings, where safety and environmental considerations are of the utmost importance.

-

Type 2: These are usually liquid-immersed ones, where the transformer windings are submerged in an insulating fluid, such as mineral oil or synthetic fluids, to provide better cooling and insulation. They are more efficient at handling larger loads and are commonly used outdoors, especially in substations or utility grids.

Which are used in substations?

Substations utilize various types, depending on their role in power transmission and distribution. The primary types include:

-

Power: These handle large amounts of electrical power and are used to step up or step down high voltages at transmission substations.

-

Distribution: These are used to reduce the high voltage from power units to a lower voltage suitable for distribution to residential, commercial, and industrial users.

-

Instrument: These include current ones (CTs) and potential ones (PTs) used for measuring, protection, and control purposes in substations.

-

Auxiliary: These supply power for internal substation operations, such as control rooms, HVAC systems, and lighting.

What are the 2 main classes of different types of transformers?

The two main classes are:

-

Power: These are used in transmission networks to step up or step down voltage levels for efficient power transmission over long distances. They operate at high voltage and high power ratings and are designed to be highly efficient under full-load conditions.

-

Distribution: These operate at lower voltage levels to supply power directly to end users (residential, commercial, and industrial customers). Distribution ones are designed for high efficiency at low load conditions, as the load can fluctuate throughout the day. For insights into safe and efficient transformer operation, check out electrical substation transformers.

What are the 3 different types of transformers?

Different types of transformers can be classified into three main types based on their construction, design, or function:

-

Step-Up: Increases voltage from the primary winding to the secondary winding. It is used at generating stations to increase voltage for long-distance transmission.

-

Step-Down: Reduces voltage from the primary winding to the secondary winding. It is used at substations to lower voltage for local distribution to end users.

-

Isolation: Provides electrical isolation between its primary and secondary windings without changing the voltage level. It is used to protect sensitive equipment from electrical surges, noise, and ground loops.

These classifications are essential for understanding the different types of transformers in electrical power systems and their roles in facilitating power generation, transmission, and distribution.

Related Articles