Grounding and Bonding

By William Conklin, Associate Editor

Power Quality Analysis Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA FS3529 Fact Sheet – Lockout/Tagout Safety Procedures

- Learn how to disable machines and isolate energy sources safely

- Follow OSHA guidelines for developing energy control programs

- Protect workers with proper lockout devices and annual inspections

Grounding and bonding ensure electrical safety by directing fault currents safely to earth and preventing voltage differences. Essential for shock protection, fire prevention, and system stability in homes, commercial buildings, and industrial electrical systems.

What is Grounding and Bonding?

✅ Prevents electric shock and fire hazards by stabilizing voltage and directing fault current

✅ Connects conductive parts to ground for system safety and continuity

✅ Required by NEC and CSA codes in residential, commercial, and industrial settings

Grounding and bonding are crucial for ensuring your electrical system operates safely and efficiently, while also meeting the National Electrical Code (NEC) requirements.

This means they are connecting electrical equipment to the earth or ground. This is typically achieved through the use of grounding electrodes, which are conductive rods or plates that are buried in the earth. Bonding is the process of connecting metal parts of electrical equipment to ensure that they are at the same electrical potential. Bonding is achieved using equipment bonding conductors, wires or cables that connect metal parts. For a deeper understanding of how grounding affects overall system performance, see our electrical grounding guide.

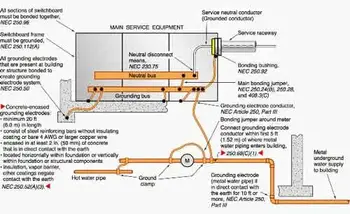

NEC Article 250 Requirements

Grounding and bonding are governed by NEC Article 250, which outlines detailed requirements for electrical safety, performance, and system integrity. Understanding these code sections is critical for proper system design, installation, and inspection.

The NEC has specific requirements designed to ensure the safety and effectiveness of electrical systems. For example, the NEC requires that all electrical equipment be grounded and that grounding electrodes be installed at specific intervals based on the type of electrode being used. The NEC also requires that bonding connections be made at specific points within the electrical system, such as metal conduits and enclosures.

Test Your Knowledge About Power Quality!

Think you know Power Quality? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

To meet the NEC requirements, it's essential to have practical ground fault current paths in place. An effective ground fault protection system ensures that fault currents are quickly detected and that power is shut off to prevent injury or damage. This is achieved through overcurrent protective devices, such as circuit breakers and fuses, designed to trip or blow if a fault current is detected. To ensure compliance with Canadian and U.S. standards, review our comparison of grounding and bonding code requirements under CSA and NEC.

NEC 250.4 – General Performance Requirements

The NEC Article 250.4 establishes the fundamental purpose and performance expectations for both grounding and bonding:

-

Earthing must stabilize system voltage under normal operation and provide a low-impedance path for fault currents or lightning surges.

-

Grounded conductors (e.g., neutrals) must connect to the grounding electrode system to establish a reference to earth.

-

Ungrounded systems must be bonded and monitored to detect ground faults.

-

Systems must be grounded in a manner that limits voltage to ground and facilitates the effective operation of overcurrent devices during faults.

This section ensures that electrical systems are protected from both system transients and lightning-induced surges by properly earthing them through grounding electrodes. Discover how a properly installed grounding electrode conductor facilitates the dissipation of fault current and stabilizes voltage.

NEC 250.92 – Bonding Requirements for Services

Section 250.92(A) and (B) specify how metal enclosures and service equipment must be bonded to ensure electrical continuity and fault-current return paths:

-

Bonding jumpers (main, supply-side, and equipment) must be used to ensure electrical continuity between service equipment, enclosures, raceways, and conduits.

-

Acceptable bonding methods include:

-

Listed bonding jumpers

-

Threaded couplings (where metal-to-metal continuity is assured)

-

Bonding bushings or earthing bushings

-

Bonding locknuts

-

Listed lugs or pressure connectors

-

The goal of bonding is to equalize the electrical potential between conductive parts, thereby eliminating the risk of shock and allowing circuit breakers or fuses to trip quickly in the event of a fault.

Additional Key Sections in NEC Article 250:

-

250.52: Defines acceptable grounding electrodes (ground rods, building steel, water pipe, concrete-encased electrodes, etc.)

-

250.66: Specifies grounding electrode conductor (GEC) sizing based on service-entrance conductor size.

-

250.102(C): Covers sizing of bonding jumpers for fault-current capacity.

-

250.30(A): Rules for separately derived systems (like transformers), which must also be grounded and bonded properly.

Grounding vs Bonding: NEC Requirements, Applications, and Safety Roles

| Category | Grounding | Bonding |

|---|---|---|

| Definition | Connecting an electrical system or equipment to earth | Connecting metal parts to ensure equal electrical potential |

| Primary Objective | Direct fault or surge currents safely into the ground | Eliminate voltage differences between conductive parts |

| Key Components | Grounding electrodes, electrode conductors, ground rods | Bonding jumpers, bushings, locknuts, earthing lugs |

| NEC Code References | 250.4(A), 250.52, 250.66 | 250.4(B), 250.92, 250.102(C) |

| Installation Requirements | Rods ≥ 8 ft, ≤25 ohm resistance, #6 or #4 AWG conductor, 6 ft spacing for rods | Bonding at enclosures, panels, metal piping, telecom systems |

| Types and Applications | System earthing, equipment earthing, and lightning protection | Main bonding, supplementary bonding, equipotential bonding (pools, HVAC) |

| Role in Surge/EMI Protection | Dissipates lightning, transients, and static buildup | Ensures SPDs and sensitive equipment have low-impedance bonding paths |

| Testing Methodology | Ground resistance testing (fall-of-potential, clamp-on meters) | Continuity tests between bonded components |

| Failure Consequences | System instability, ineffective surge protection, and electric shock | Fault currents may not return, equipment damage, increased shock/fire risk |

Practical Installation Details

Meeting NEC requirements involves more than just compliance — proper installation ensures real-world effectiveness.

-

Ground rods must be at least 8 feet long (NEC 250.52(A)(5)).

-

When two or more electrodes are used, they must be spaced at least 6 feet apart (NEC 250.53(A)(3)).

-

Grounding electrode conductors should be minimum #6 AWG copper, or #4 AWG in higher-risk or commercial installations.

-

Ground resistance should not exceed 25 ohms; if it does, a second rod is often required.

-

Earthing clamps must be corrosion-resistant and listed for the type of conductor used.

-

Routine testing (e.g., ground resistance testing) helps ensure the long-term effectiveness of the system and should be performed annually or after lightning events or system alterations. Explore our overview of electrical grounding definitions and how they apply across residential, commercial, and industrial settings.

Types of Bonding and Their Applications

Ensuring that electrical equipment is properly grounded and bonded is also essential. This includes using equipment bonding jumper conductors to connect metal parts of equipment and ensuring that grounding electrodes are correctly installed and maintained. If you're troubleshooting issues with unstable voltage or harmonic distortion, visit our power quality troubleshooting section.

Bonding ensures that metal components remain at the same potential, preventing electric shock and facilitating the return of fault current.

Main Bonding

Links service equipment, neutral conductors, and metallic enclosures together. Typically installed at the main panel.

Supplementary Bonding

Used where additional protection is needed — for instance, between water pipes, HVAC equipment, or in kitchens and bathrooms.

Sign Up for Electricity Forum’s Power Quality Newsletter

Stay informed with our FREE Power Quality Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Equipotential Bonding

Applied in hazardous locations like pools or spas, ensuring that all accessible conductive parts (e.g., rebar, ladders, handrails) are equalized to prevent shock during faults.

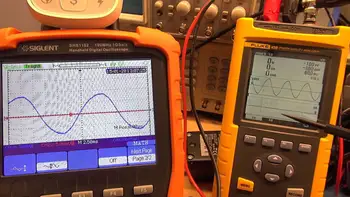

Grounding Beyond Fault Current: Surge, EMI, and System Stabilization

Another critical aspect of earthing is protecting equipment from damage. For example, the equipment can be damaged if there is a voltage difference between different parts. Bonding ensures that all metal parts of equipment have the same electrical potential, reducing the risk of damage due to voltage differences.

Earthing does more than provide a fault path; it also serves as a protective measure. It also:

-

Mitigates lightning strikes and static buildup

-

Reduces electromagnetic interference (EMI) in sensitive electronics

-

Stabilizes voltage under transient conditions

-

Enhances the performance of surge protection devices (SPDs), which must be bonded to the same earthing system to operate correctly

For systems vulnerable to atmospheric surges, grounding plays a vital role—learn more in our lightning protection guide.

Standards Beyond the NEC

While NEC Article 250 is the U.S. gold standard, additional standards improve system design and cross-discipline integration:

-

TIA-607-B: Addresses bonding infrastructure for telecommunications systems, ensuring continuity between telecom racks, conduits, and main earthing points

-

IEC 60364 and BS 7671 (UK): Provide international guidance for earthing and bonding, especially for systems installed outside North America

Frequently Asked Questions

What is the purpose of grounding and bonding?

The purpose is to provide safe and reliable power by minimizing risks such as fire, shock, and equipment failure resulting from electrical faults.

What methods are used?

Methods include equipment grounding conductors, GFCIs, overcurrent devices, grounding electrodes, bonding jumpers, and metal conduit systems.

What does the NEC require for commercial systems?

NEC requires proper grounding electrodes, bonding connections at service equipment, overcurrent protection, and installation per Article 250.

How do you size grounding conductors?

Based on service size, electrode type, and conductor length. NEC Tables (e.g., 250.66) guide sizing.

What happens with poor grounding?

Risks include electric shock, fire, electrocution, and equipment damage due to voltage differentials.

How is grounding tested?

By measuring ground resistance, checking insulation, and verifying bonding continuity.

What’s the difference between grounding and bonding?

Earthing stabilizes voltage and provides a safe path for fault current. Bonding equalizes potential between conductive parts. Both are essential for safety and performance. Discover how understanding electrical grounding helps improve equipment lifespan, minimize shock hazards, and meet code requirements.

Related Articles