Power Quality

Apparent Power Formula: Definition, Calculation, and Examples

Apparent power formula is important for calculating Apparent Power (AP) in AC circuits that represent the total power consumed by a circuit, including both the real and reactive power. The formula for calculating AP is S = V x I, where S is the AP in VA, V is the rms voltage in volts, and I is the rms current in amperes.

The power factor measures how effectively the circuit uses the power supplied and is expressed as a decimal or a percentage. The power factor (PF) affects the calculation of AP, as a high PF means that the circuit uses most of the power supplied to it to do useful work. In contrast, a low PF indicates that a significant portion of the power is being wasted due to reactive components.

Power Quality Analysis Training

Request a Free Power Quality Training Quotation

To calculate the total power a circuit consumes, you need to measure the rms voltage and current and use the apparent power formula. Other formulas related to AP include the reactive power formula, the complex power formula, the power factor formula, the volt-amperes formula, the AC power formula, and the electrical power formula. By understanding these formulas, you can analyze and optimize the performance of electrical systems and reduce energy costs and power quality issues.

What is Apparent Power?

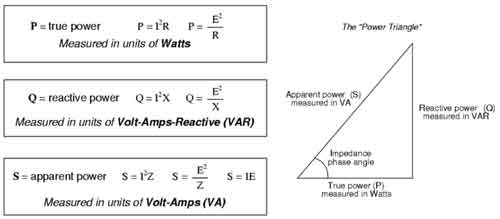

AP is the total power that an AC circuit consumes, both the real power (RP) used to do useful work and the reactive power required to maintain the voltage and current phase relationship. AP is measured in volt-amperes (VA) and is calculated as the product of the root-mean-square (RMS) voltage and current in an AC circuit. The formula for calculating apparent power is:

AP = Voltage × Current

or

S = V x I

where S is the AP in VA, V is the rms voltage in volts, and I is the rms current in amperes.

AP is called "apparent" because it is not the actual power used by the circuit. Instead, it is a measure of the total power that is required to run the circuit, including the power that is lost due to reactive components like capacitors and inductors.

What is the difference between RP and AP?

RP, also known as active power or true power, is the power that is used to do useful work in a circuit, such as powering a motor, heating a room, or lighting a bulb. RP is measured in watts (W) and is the part of the AP that is in phase with the voltage. The formula gives real power:

Real Power = Voltage × Current × cos φ

or

P = V x I x cos φ

Where P is the RP in watts, φ is the phase angle between the voltage and current waveforms, and cos φ is the PF.

PF is a measure of how effectively the circuit uses the power that is supplied to it. It is the ratio of the RP to the AP and is expressed as a decimal or a percentage. A high PF means that the circuit uses most of the power supplied to it to do useful work. In contrast, a low PF indicates that a significant portion of the power is being wasted due to reactive components.

Reactive power, on the other hand, is the power that is required to maintain the voltage and current phase relationship in a circuit but needs to do more useful work. Reactive power is measured in volt-amperes reactive (VAR) and is given by the formula:

Reactive Power = Voltage × Current × sin φ

or

Q = V x I x sin φ

Where Q is the reactive power in VAR. Reactive power is necessary to maintain the magnetic and electric fields in the circuit and is stored and released by capacitors and inductors.

What is the unit of measurement for apparent power?

The unit of measurement for AP is volt-amperes (VA), which is the product of the rms voltage and current in an AC circuit. VA represents the total power required to run the circuit, including the RP used for useful work and the reactive power required to maintain the voltage and current phase relationship.

How does the PF affect the calculation?

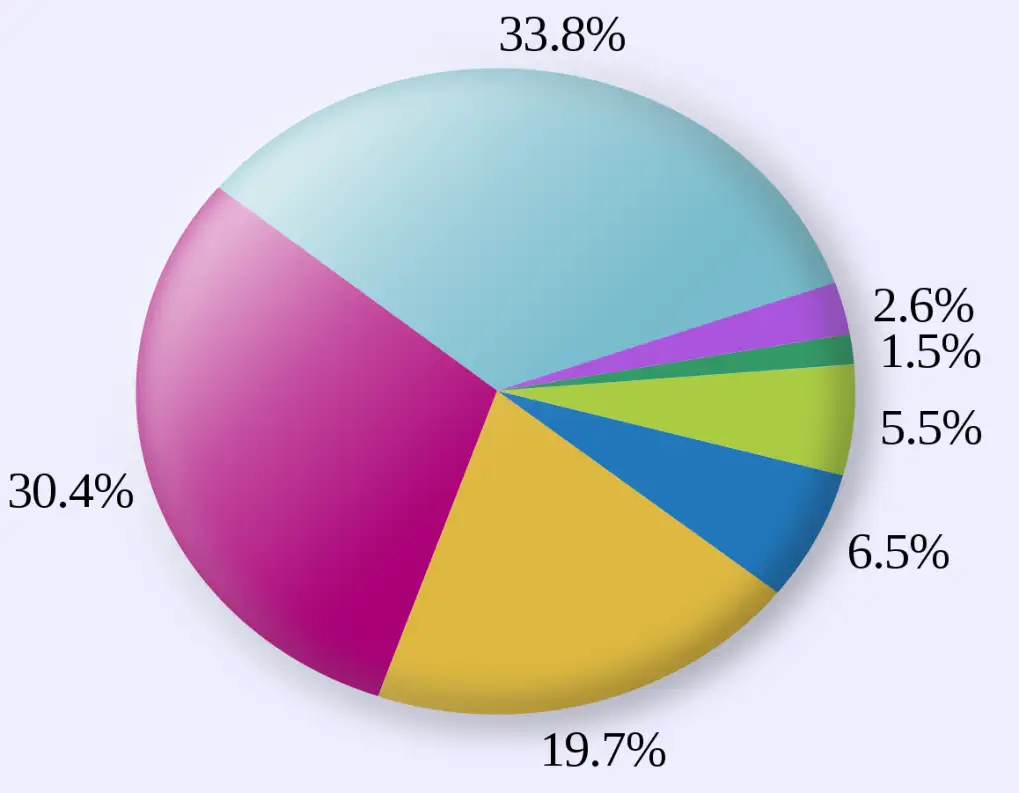

PF affects the apparent power calculation because the total power a circuit consumes is the sum of the real and reactive power. Therefore, the AP is the hypotenuse of the power triangle, where the RP is the adjacent side and the reactive power is the opposite side. Therefore, the PF is the ratio of the adjacent side to the hypotenuse of the power triangle, as shown below:

As the PF approaches 1, the circuit becomes more efficient and uses less reactive power to maintain the voltage and current phase relationship. This reduces the AP and the overall power consumption of the circuit. On the other hand, a low PF means that the circuit consumes more apparent power than necessary, leading to increased energy costs, reduced efficiency, and other power quality issues. Therefore, it is important to measure and improve the PF of electrical systems, especially in commercial and industrial applications where the power demand is high.

How do you calculate apparent power in a circuit?

To calculate the APin a circuit, you need to measure the rms voltage and current and multiply them together. The RMS voltage and current can be measured using a digital multimeter or a power analyzer. The RMS value accounts for the AC waveform, which is not constant like DC. Once you have the voltage and current RMS values, you can use the apparent power formula to calculate the total power consumed by the circuit, including both the real and reactive power.

What is the formula for calculating apparent power?

The formula for calculating apparent power is:

AP = Voltage × Current

or

S = V x I

Where S is the AP in VA, V is the rms voltage in volts, and I is the rms current in amperes. This formula gives the total power consumed by the circuit, including the power used to do useful work and the power required to maintain the voltage and current phase relationship.

Reactive Power Formula

The formula for calculating reactive power is:

Reactive Power = Voltage × Current × sin φ

or

Q = V x I x sin φ

Where Q is the reactive power in VAR, V is the rms voltage in volts, I is the rms current in amperes, and φ is the phase angle between the voltage and current waveforms. Reactive power is necessary to maintain the circuit's voltage and current phase relationship but does not do any useful work.

Complex Power Formula

The formula for calculating complex power is:

Complex Power = Real Power + j × Reactive Power

or

S = P + jQ

Where S is the complex power in VA, P is the RP in watts, Q is the reactive power in VAR, and j is the imaginary unit (√-1). Complex power is a mathematical concept representing the combination of real and reactive power in a circuit. The real power is the horizontal component, and the reactive power is the vertical component.

Power Factor Formula

The formula for calculating power factor is:

Power Factor = Real Power / Apparent Power

or

PF = P / S

Where PF is the power factor, P is the RP in watts, and S is the AP in VA. The PF measures how effectively the circuit uses the power supplied and is expressed as a decimal or a percentage.

Volt-Amperes Formula

The formula for calculating volt-amperes is:

Volt-Amperes = Voltage × Current

or

VA = V x I

Where VA is the AP in volt-amperes, V is the rms voltage in volts, and I is the rms current in amperes. Volt-amperes is the unit of measurement for AP, which is the total power an AC circuit consumes, including both the real and reactive power.

AC Power Formula

The formula for calculating AC power is:

AC Power = Voltage × Current × cos φ

or

P = V x I x cos φ

Where P is the RP in watts, V is the rms voltage in volts, I is the rms current in amperes, and φ is the phase angle between the voltage and current waveforms. AC power is used to do useful work in a circuit, such as powering a motor, heating a room, or lighting a bulb.

Electrical Power Formula

The formula for calculating electrical power is:

Electrical Power = Voltage × Current

or

P = V x I

Where P is the RP in watts, V is the voltage in volts, and I is the current in amperes. Electrical power is the rate at which energy is transferred in an electrical circuit and is measured in watts.

Download Our FREE Power Quality Handbook

Power Quality, Grounding and UPS Handbook Vol 10

Our all-new Power Quality, Electrical Grounding, UPS Handbook Volume 10 covers all the information you need to create a safe and secure grounding environment for your integrated electrical and electronic systems - a special section on UPS systems. ALL NEW INFORMATION!!

In this comprehensive guide, readers will find expert insights into the challenges and solutions related to power disturbances, grounding practices, and UPS systems, including detailed methodologies for improving power quality, designing effective grounding systems, and selecting the right UPS for different applications. The content is structured to offer both foundational knowledge and advanced technical guidance, making it suitable for engineers, electricians, system designers, and maintenance professionals who are tasked with ensuring the integrity of electrical infrastructure.

Volume 10 emphasizes the importance of understanding the interplay between power quality, grounding, and UPS systems to prevent costly downtime, equipment damage, and potential safety hazards. It also covers modern technologies, emerging trends, and best practices that can be applied to enhance system performance and mitigate electrical issues in a wide range of industries. Whether for industrial plants, commercial facilities, or critical infrastructure, this handbook serves as an indispensable tool for those dedicated to safeguarding power reliability and maintaining smooth operations in an increasingly digital and power-dependent world.

Latest Power Quality Articles

Ground Grid: Important Electrical Design

Ground grid provides a buried earthing mesh for substations, managing fault current, reducing ground resistance, controlling step-and-touch voltage, and ensuring equipotential bonding per IEEE Std 80 for personnel and equipment safety.

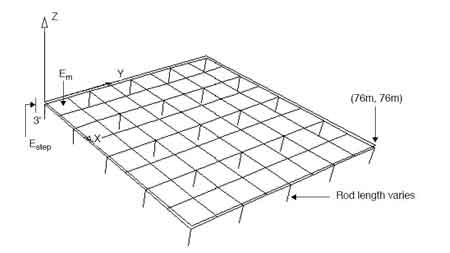

What Is a Ground Grid in Electrical Substations?

A ground grid is a conductor network managing fault current and touch/step voltages to protect equipment and personnel.

✅ Limits touch and step voltages per IEEE Std 80

✅ Copper conductor meshes and ground rods lower resistance

✅ Design uses soil resistivity, fault current, and clearance

A ground grid is a critical component in electrical systems, especially in high-voltage environments like substations and power plants. This system ensures that electrical faults are safely dissipated into the earth, reducing the risk of equipment damage and protecting personnel. The ground grid provides a low-resistance path for fault currents, preventing the buildup of dangerous voltages. Understanding its design, installation, and maintenance is essential for ensuring the safe and efficient operation of electrical systems. For readers new to the topic, understanding electrical grounding provides essential context about the principles that underpin ground grid performance.

What is a Ground Grid in Electrical Systems?

A ground grid refers to a network of conductors buried underground to create a low-resistance path for electrical fault currents. It is an essential part of grounding systems, designed to safely direct excess electricity into the earth. These systems are typically installed in electrical substations, power plants, and large industrial facilities where grounding is required to prevent electrical hazards. The grid also helps to create a solid and stable foundation for electrical equipment by stabilizing the soil and enhancing the structural integrity of the installation. In broader practice, effective grounding system strategies help ensure these networks integrate safely with adjacent facilities and equipment.

Why is a Ground Grid Important for Electrical Safety?

The primary function of a ground grid is to ensure the safety of electrical installations. Without a proper grounding system, electrical faults could result in dangerous voltage levels on equipment and structures, posing significant risks to both personnel and equipment. The grid helps maintain stable voltage levels by quickly dissipating fault currents, making it a crucial safety measure in power systems. Properly installed systems also allow water to flow through mineral infill or gravel, preventing water accumulation that could cause further electrical hazards. If you need a refresher on fundamentals, what is electrical grounding explains how grounding manages fault energy and touch potentials in practical settings.

How Do You Design and Install a Ground Grid for a Substation?

Designing and installing a ground grid requires careful planning. Engineers must consider factors such as soil resistivity, the size of the installation, and the fault current levels expected in the system. Typically, the grid is constructed using conductors that form a mesh or honeycomb structure. These conductors are buried underground and connected to key equipment in the substation. Fill materials such as gravel, soil, or sand are often used to stabilize the installation and improve the grid’s effectiveness. Creating a stable surface for the installation is important for ensuring long-term performance.

In certain networks, adopting high-resistance grounding can limit fault current magnitude while maintaining service continuity during single-line-to-ground events.

The layout must be designed to cover a large area to distribute fault currents evenly, and grounding stabilization techniques such as using mineral infill may be employed to enhance soil conductivity. These materials ensure that the grid remains effective over time, providing a reliable path for fault currents. Complementary grounding and bonding practices also reduce potential differences between structures and cable trays, improving overall safety.

What Materials are Commonly Used for Ground Grids?

Ground grids are usually made from highly conductive materials, with copper and galvanized steel being the most common choices. Copper is favored for its superior conductivity and corrosion resistance, while galvanized steel is often used in cost-sensitive installations. In some cases, a combination of materials is used to create a durable and efficient grounding system. When backup power is present, best practices for grounding a generator help ensure neutral references and fault clearing remain consistent with the facility grid.

Gravel, soil, and sand are typically used as infill materials to stabilize the ground grid. The honeycomb structure formed by the grid allows water to flow easily through the system, preventing water buildup and enhancing grounding performance. These materials also provide a stable surface for heavy equipment, such as transformers and circuit breakers, to be placed on top of the grid.

How Do You Test and Maintain a Ground Grid to Ensure Effectiveness?

Once installed, regular testing and maintenance are critical to ensuring the effectiveness of a ground grid. Over time, corrosion, soil movement, and other factors can degrade the system’s performance. Testing typically involves measuring the system’s resistance and verifying that it remains within acceptable limits. Periodic visual inspections are also necessary to ensure that the conductors and fill materials are in good condition. As part of commissioning or periodic checks, methods on how to check if an area is grounded can guide field teams in verifying compliance and documenting results.

Ground stabilization methods like using mineral infill can extend the life of the system, but ongoing monitoring is necessary to catch potential issues before they become dangerous. Regular maintenance ensures that the grid continues to provide a stable surface and effective fault current dissipation, protecting both equipment and personnel.

In summary, a well-designed and maintained ground grid is crucial for ensuring electrical safety in high-voltage environments. These systems create a solid and stable foundation for electrical equipment while providing an efficient path for fault currents to flow safely into the earth. With proper design, materials, and maintenance, a ground grid can significantly reduce the risk of electrical hazards in substations, power plants, and other industrial settings. By regularly testing and maintaining the system, engineers can ensure its long-term effectiveness and reliability.

Related Articles

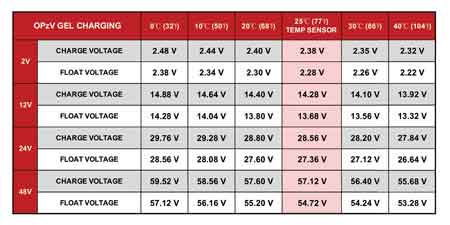

An Acceptable Charging Circuit Voltage on a 12-volt Battery System

An Acceptable Charging Circuit Voltage On refers to safe alternator output for 12V/24V systems, ensuring battery health, regulator accuracy, minimal ripple, correct float voltage, and reliable performance under varying loads and temperatures.

What Is an Acceptable Charging Circuit Voltage On?

The target voltage range an alternator/regulator holds to charge 12V/24V batteries correctly across load and temperature.

✅ 12V spec: 13.8-14.7 V at 25C with engine ~1500 rpm

✅ 24V spec: 27.6-29.4 V; ripple under load <0.5 V p-p

✅ Check with a calibrated multimeter; consider temperature compensation

An acceptable charging circuit voltage on a 12-volt battery system is crucial for maintaining the health and performance. Keeping the charging system voltage within the proper range ensures that the battery remains adequately charged, the vehicle’s electrical components function properly, and the system operates efficiently. It’s essential for vehicle owners and technicians to recognize what makes a charging circuit work effectively, the risks associated with improper voltage levels, and how to measure and maintain it for long-term battery life. Understanding these principles aligns with foundational concepts of what is power quality in automotive electrical systems.

What is an acceptable charging circuit voltage for a 12-volt battery system?

An acceptable range for a 12-volt system is typically between 13.5 and 15 volts. This ensures that the battery stays adequately charged while the vehicle is running. The charging components, including the ac generator and the voltage regulator, help maintain this range. Staying within this range prevents any adverse effects on the battery or other systems in the vehicle. Real-world readings can be affected by voltage dropping across connections and loads.

Why is it important to maintain an acceptable charging circuit voltage?

Maintaining the proper charging circuit values is vital for the overall health of the battery and the vehicle. If the system delivers too much power, it can cause overcharging, generating excess heat that damages the battery. On the other hand, if the levels fall below the required threshold, undercharging occurs, leading to reduced power availability. Ensuring the system stays within acceptable parameters helps prevent these issues and extends the battery's lifespan. Stable charging contributes to overall quality of electricity delivered to sensitive onboard electronics.

What happens if the charging circuit voltage is too high or too low?

If the system delivers power exceeding 15 volts, it can cause the battery to overheat and sustain permanent damage. This can lead to early failure and potential safety hazards. Conversely, if the levels fall below 13.5 volts, the battery may not charge adequately, reducing its efficiency and the power available for the vehicle’s systems. In both cases, proper management of the charging process is critical to avoid damage. Overvoltage also risks exceeding a component’s capacitor voltage rating in control modules, leading to premature failure.

How do I check the charging circuit voltage?

To check the system's performance, a multimeter can be used to measure the values. Attach the multimeter to the battery terminals while the engine is running. A healthy system should show values between 13.5 and 15 volts. If the readings are outside this range, it may indicate an issue with the charging components, such as the voltage regulator, which should be addressed immediately. Accurate measurement practices depend on proper grounding and bonding of the vehicle’s electrical system to minimize noise.

What components regulate the charging circuit voltage?

The ac generator and voltage regulator are the main components responsible for managing the charging process. The ac generator produces the necessary power for the vehicle, while the regulator ensures that the levels remain within the required range. Both components work together to ensure the battery stays charged without exceeding safe limits. The regulator’s control strategy is conceptually similar to managing a linear power transformer under varying loads, maintaining stable output.

An acceptable range is essential for maintaining battery health and ensuring the vehicle's electrical systems perform optimally. By understanding how to measure and monitor the system, you can prevent both overcharging and undercharging, ultimately extending the life of the battery and ensuring smooth operation. When diagnosing anomalies, understanding how short-circuit calculations vary with power factor and voltage can inform safe testing and repair decisions.

Related Articles

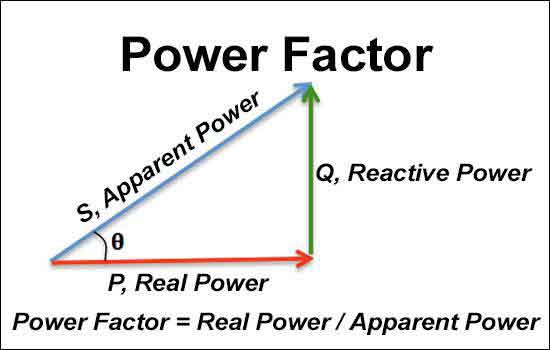

Understanding How Power Factor is Calculated

How Power Factor is Calculated? By PF = kW/kVA = cos φ, using real power, apparent power, and phase angle in AC circuits to assess efficiency, reactive power, voltage, current, and load balance.

How Power Factor Is Calculated?

Power factor equals kW/kVA = cos φ, from the phase angle between voltage and current in AC circuits.

✅ Formula: PF = kW/kVA; ratio of real to apparent power.

✅ Cosine method: PF = cos φ from voltage-current phase angle.

✅ Measure kW, kVA with meters; estimate angle via V and I waveforms.

How Power Factor is Calculated - Calculating PF is crucial for understanding the efficiency of power use in AC circuits. In electrical systems, power factor (PF) represents the ratio between real power, which performs actual work, and apparent power (S), which is the total power supplied. A precise PF calculation can help optimize energy use, reduce costs, and enhance overall system performance. For a step-by-step overview, consult the how to calculate power factor guide to confirm each stage aligns with best practice.

Power Quality Analysis Training

Request a Free Power Quality Training Quotation

Understanding PF Components

To calculate PF, it’s essential first to understand the types of power involved: real power (active power), otherwise known as "P", reactive power (Q), and apparent power (S). Real power, measured in kilowatts (kW), is the power that does useful work. Reactive power, measured in kilovolt-amperes reactive (kVAR), is necessary for creating and sustaining magnetic fields, especially with inductive loads like motors or capacitive loads such as capacitors. Apparent power, expressed in kilovolt-amperes (kVA), combines both real and reactive power. A concise derivation is outlined in the power factor formula reference for quick review.

PF is the ratio of P to S, indicating how efficiently the electrical energy is used. The formula for PF is:

PF = P (kW) / S (kVA)

Practical examples in the power factor calculation article illustrate how different load types shift this ratio.

This ratio shows how much of the S is effectively converted into useful work, with a PF of 1 indicating perfect efficiency. In field audits, technicians often use the how to find power factor workflow to corroborate instrument readings.

The Process of Calculating PF

To calculate PF, you need measurements of both P and S. An analyzer or quality analyzer is typically used in electrical systems to capture these values accurately. A dedicated power factor meter streamlines this task by computing PF from real-time voltage and current.

Measure Real Power (kW): This is the actual power consumed by the system to perform work, like running machinery or lighting. Real power is what you aim to maximize within the limits of efficiency.

Measure Apparent Power (kVA): S is the product of the circuit’s voltage (V) and current (A). The equation for S in an AC circuit is:

kVA = Voltage (V) × Current (A)

When sizing equipment, the power factor calculator helps validate kVA values against measured kW and PF.

Calculate the PF: With P and S measured, PF can be calculated by dividing P by S:

PF = kW / kVA

Consider Phase Angle and Q:

In AC circuits, the phase angle between current and voltage affects the PF. Inductive loads, which create a lagging PF, result in a larger phase angle, increasing reactive power. This reactive power doesn’t perform useful work but influences the PF calculation by affecting the total apparent power. For remediation planning, the power factor correction formula provides capacitor sizing estimates that target a specified PF.

Why Power Factor Calculation Matters

A poor PF means higher S consumption, which can lead to inefficiencies and increased operational costs. Understanding how PF is calculated allows companies to implement PF correction measures, typically by adding capacitive loads to balance inductive loads. PF correction reduces the need for Q, thereby improving the ratio of real power to apparent power.

Improving Power Factor in Electrical Systems

Investing in PQ analyzers and implementing PF correction can help maintain a high PF, ensuring efficient usage and reducing costs. Proper correction methods, such as adding capacitors to counterbalance inductive loads, help improve PF and lower the overall electrical consumption.

Calculating PF accurately is essential for optimizing electricity consumption in AC circuits. By focusing on the ratio of P to S and understanding the effects of Q and phase angle, businesses can achieve more efficient energy use and reduce costs associated with poor PF.

Related Articles

Grounding Electrode Conductor - NEC Section 250 Definition

A grounding electrode conductor (GEC) connects the grounding system to a grounding electrode, helping stabilize voltage and ensure electrical safety. It protects people and equipment by dissipating fault current safely into the earth, following NEC and power quality standards.

What is a Grounding Electrode Conductor?

A Grounding electrode conductor is a critical component in electrical systems, serving as the backbone of effective earthing practices.

✅ Connects an electrical system to a grounding electrode (earth rod or plate)

✅ Safely carries fault current during short circuits or surges

✅ Required by NEC and other power quality standards

For those new to these concepts, our article on Understanding Electrical Grounding provides a beginner-friendly explanation of how earthing and GECs work to protect people and equipment.

Understanding its role is essential for electrical engineering and maintenance professionals to ensure system safety, reliability, and compliance with the National Electrical Code (NEC). This ground (or earthing) conductor provides a direct path for fault currents to dissipate into the earth, reducing the risk of electrical surges and protecting both equipment and personnel. Proper implementation and sizing are not just regulatory requirements; they are vital for preventing failures, minimizing downtime, and ensuring the longevity of electrical installations in residential, commercial, and industrial settings. To understand how electrical grounding systems function in fault conditions, it’s essential to examine how they interact with electrode conductors to dissipate current safely.

While both the GEC and the equipment grounding conductor play roles in electrical safety compliance, they serve distinct functions within the NEC grounding system. The GEC connects the electrical system to the earth through a grounding electrode, providing a low-impedance path for ground fault dissipation during surge events or lightning strikes. In contrast, equipment grounding conductors bond non-current-carrying metal parts of equipment to the system ground to prevent shock hazards. Understanding this distinction is essential for ensuring proper installation and code-compliant system design.

How GECs Work in Fault Current Dissipation

Visit our Grounding and Bonding and The NEC - Section 250 Course

NEC Table 250.66: Ground Wire Sizing Rules

The size of the grounding electrode conductor is crucial, and its determination often follows the guidelines outlined in Table 250.66 of the National Electrical Code (NEC). This table establishes the required conductor size based on the largest ungrounded service entrance conductor or equivalent area of parallel conductors. For example, systems with AWG copper conductors often require specific sizes to maintain effective current dissipation. Ensuring the correct size prevents overheating and provides an adequate fault current path, a critical safety feature in any electric service installation. For NEC-specific rules on conductor sizing and compliance, refer to our detailed guide on NEC ground wire size charts, which outlines key requirements, including Section 250.66.

Grounding Electrode Conductor Sizing NEC Table 250.66

| Largest Ungrounded Conductor or Equivalent Area (Copper) | Minimum Copper GEC Size | Minimum Aluminum GEC Size |

|---|---|---|

| 2 AWG or smaller | 8 AWG | 6 AWG |

| 1 or 1/0 AWG | 6 AWG | 4 AWG |

| 2/0 or 3/0 AWG | 4 AWG | 2 AWG |

| 4/0 – 350 kcmil | 2 AWG | 1/0 AWG |

| 400 – 600 kcmil | 1/0 AWG | 3/0 AWG |

| 700 – 1,100 kcmil | 2/0 AWG | 4/0 AWG |

| Over 1,100 kcmil | 3/0 AWG | 250 kcmil |

NEC Compliance and Safety Standards

Compliance with the NEC is non-negotiable in designing and implementing these systems. The NEC mandates that a grounding electrode conductor must meet specific safety standards to protect against overvoltage conditions. By adhering to these regulations, electrical systems achieve consistency, ensuring that they function as intended and provide safety during fault conditions. The use of an overcurrent protective device adds another layer of security, safeguarding equipment and personnel from potential hazards. If you're looking to explore the broader role of earthing in electrical design, our grounding and bonding page offers insight into how different components must be interconnected for safety and compliance.

The primary purpose of the grounding electrode conductor is to ensure safety by providing a low-resistance ground fault path to the earth. This path is designed to carry fault current away from sensitive equipment, thereby mitigating the risks associated with electrical surges. It also protects the grounded conductor and ensures that the earthing conductors of connected equipment function correctly. A well-implemented system enhances the safety of an electrical installation, reducing the likelihood of catastrophic failures and ensuring a stable operation.

Grounding Electrode Conductor Material Requirements (Copper vs Aluminum)

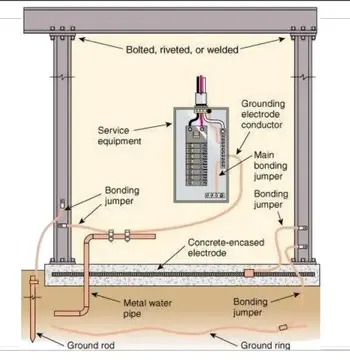

NEC requires that, where available on the premises at each building or structure served, all electrodes, including “made” electrodes, be bonded together to form the “Grounding Electrode System.” Learn how grounding systems support stable voltage conditions across service entrances, generators, and building frames in both residential and industrial installations.

Visit our Electrical Grounding Training Page

The “Grounding Electrode System” includes metal underground water pipes, metal frames of buildings, concrete-encased electrodes and ground rings. See how the grounding bonding CSA/NEC comparison highlights the similarities and differences between Canadian and U.S. earthing requirements.

Bonding and Grounding Systems

The general requirement is that a bonding jumper must be installed between the earthing conductor and the GEC installation to ensure they are bonded together.

-

Grounding electrode conductor is run from the service equipment to one of the electrodes that are bonded together.

-

NEC Section 250-24(c) is a requirement to connect the equipment conductors, the service-equipment enclosures, and, where the system is grounded, the grounded service conductor to an electrode. The conductor used to make this connection is considered the “Grounding Electrode Conductor.”

-

Grounding electrode conductor from an electrical service to a ground rod, pipe or plate electrode is never required to be larger than 6 AWG copper or 4 AWG aluminum unless the grounding electrode conductor continues on from the rod, pipe or plate to connect another electrode that may require a larger GEC such as a concrete encased electrode building steel or metal underground water pipe that qualifies as an earthing electrode.

Common Misconceptions About Grounding Electrode Conductor

NEC Section 250 Requirements

The requirements of NEC Section 250.2 states that an effective ground fault current path is an intentionally constructed, permanent, low impedance, electrically conductive path designed and intended to carry current under a ground fault conditions from the point of a ground fault (like an overcurrent device) on a wiring system to the electrical supply source and that facilitated the operation of the overcurrent protective device. This is the function of a “Bonding Conductor” and not the function of a grounding electrode conductor.

With that assumption, and based on that incorrect interpretation, many electricians assume that in a properly functioning electrical system, currents in grounding electrode conductors are only present during faults, and only for a very short time.

NEC 250.4 and Fault Current Paths

Although further examination of 250.4(A)(5) should clarify that the earth shall not be considered an effective ground-fault current path, misconceptions still persist.

-

Grounding electrode conductors from an electrical service to a ground rod, metal water pipe, or plate must be no larger than 6 AWG copper.

-

Aluminum grounding electrode conductors can not be in contact with earth, masonry or subjected to corrosive conditions.

-

A grounding electrode conductor is permitted to “supply” or “serve” any number of electrodes, but must be sized for the largest grounding electrode conductor required.

-

You can also explore the electrical grounding code to better understand how national regulations define safe earthing conductor practices.

Frequently Asked Questions

Can a single grounding electrode conductor serve multiple buildings or systems?

Yes, a single grounding electrode conductor can serve multiple systems if properly sized and installed. However, each system must still meet bonding requirements, and local codes may require individual electrical connection to earth arrangements in some cases.

What happens if a grounding electrode conductor is too small?

An undersized grounding electrode conductor may overheat or fail to carry fault current effectively, increasing the risk of equipment damage, fire, or shock hazard. It also violates NEC requirements and could lead to code violations or failed inspections.

Does the type of soil affect grounding electrode conductor performance?

Yes. Soil resistivity impacts how effectively current dissipates into the earth. High-resistance soil (like dry sand or rock) may reduce earthing effectiveness, which is why supplemental electrodes or soil conditioning methods are sometimes used.

Is there a difference between earthing for lightning protection and a GEC system?

Yes. While both direct current to earth, lightning protection systems often use separate electrodes specifically designed to handle high-frequency surges. These must be bonded to the GEC to maintain potential equalization but follow different design principles.

When should a grounding electrode conductor be replaced or upgraded?

Replacement is recommended if the GEC shows corrosion, mechanical damage, improper sizing, or poor terminations. Upgrading may also be required if the electrical service is expanded or reconfigured.

Related Articles

Power Factor Correction Capacitor

A power factor correction capacitor improves energy efficiency by reducing reactive power in AC systems. It lowers utility costs, boosts voltage levels, and reduces electrical losses, making it essential for commercial and industrial power quality and load management.

What is a Power Factor Correction Capacitor?

It is used to improve the power factor in electrical systems by offsetting inductive loads. It is commonly applied in industrial facilities to optimize energy use and reduce utility charges.

✅ Reduces reactive power to improve energy efficiency

✅ Stabilizes voltage and supports electrical system reliability

✅ Cuts demand charges and lowers electrical energy costs

Power Quality Analysis Training

Request a Free Power Quality Training Quotation

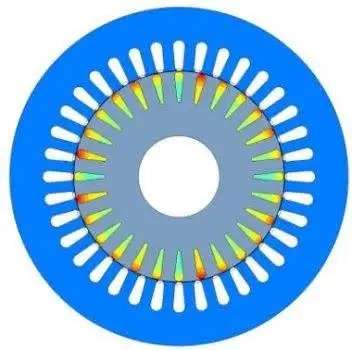

Power Factor Correction Capacitors (PFCC) are an essential component in electrical systems, designed to enhance efficiency by addressing the issue of reactive power (RP). Electrical systems often experience inefficiencies due to inductive loads, which cause excess reactive power (Q). This is where PFCCs come into play, as they reduce the amount of reactive power (RP) and improve the power factor (PF). Understanding how these capacitors work, their benefits, and best practices for their use is crucial for electrical workers aiming to enhance system performance and reduce energy costs.

PFCCs help electrical systems run more efficiently by reducing reactive energy and optimizing current flow. By compensating for phase shifts between voltage and current, they enhance energy efficiency and reduce utility charges. Businesses often use capacitors to meet energy standards and avoid penalties associated with low efficiency.

How Correction Capacitors Work

Power factor correction capacitors introduce leading current to offset the lagging current caused by inductive loads such as motors or transformers. This balance reduces strain on electrical infrastructure, improves voltage stability, and helps businesses manage peak demand costs more effectively.

For a deeper understanding of how efficiency impacts electrical systems, visit our Power Factor Correction guide.

Capacitor Sizing Basics: How Much kVAR Do You Need?

Choosing the right capacitor size is essential for successful correction. A simple formula to estimate the required kVAR rating is:

kVAR needed = kW × (tan φ1 – tan φ2)

Where:

-

φ1 is the current phase angle

-

φ2 is the desired phase angle

Example:

A facility operating at 100 kW with an initial phase angle of 36.87° (PF 0.8) aims to increase its PF to 0.95 (phase angle 18.19°).

Using the formula:

-

tan(36.87°) ≈ 0.75

-

tan(18.19°) ≈ 0.33

kVAR = 100 × (0.75 – 0.33) = 42 kVAR

Thus, a 42 kVAR capacitor bank would be appropriate.

Need help with calculations? Try our Power Factor Calculator.

Types of Correction Capacitors

Not all capacitors are the same. Different types serve different electrical loads:

-

Low-Voltage Capacitors: Typically rated up to 1,000V, suitable for commercial buildings and smaller industries.

-

Medium-Voltage Capacitors: Rated above 1,000V, ideal for large industrial plants or utility applications.

They also come in control methods:

-

Fixed Capacitors: Always connected to the system, best for constant loads.

-

Automatic Capacitors: Switched on or off as needed through controllers, ideal for fluctuating loads.

For automated solutions, see our Automatic Power Factor Controller article.

Real-World Example: Savings from PFCC Installation

An industrial plant consuming 800,000 kWh annually noticed high demand charges due to inefficient load management. After installing a 300 kVAR automatic correction system, their monthly bills decreased by 12%, resulting in approximately $14,400 in annual savings.

Improving system efficiency not only reduced costs but also enhanced voltage stability, which protected sensitive machinery from fluctuations.

For a deeper dive into calculations, see How to Calculate Power Factor.

Installation and Maintenance Best Practices

Proper setup and regular care are critical to maximizing the lifespan and effectiveness of PFCCs:

-

Correct Placement: Install as close as possible to large inductive loads.

-

Overcurrent Protection: Use appropriate fuses or circuit breakers.

-

Periodic Inspection: Check for signs of overheating, bulging, or insulation breakdown.

-

Environment Control: Store power factor correction capacitors in cool, dry areas to extend their operating life.

If you're planning upgrades, consider reading about Capacitor Sizing and Installation Techniques.

Why PFCCs Matter

Correction capacitors are a cost-effective way to enhance electrical system performance, avoid demand penalties, and ensure stable operations. Whether using fixed banks or dynamic controllers, properly installed capacitors are crucial to modern load management strategies.

Frequently Asked Questions

What are the Benefits of Using a Power Factor Correction Capacitor?

There are numerous advantages to using PFCCs. First, they help reduce the amount of RP, resulting in a decrease in the electricity consumed by the system. This reduction results in lower electricity bills and improved energy efficiency. Additionally, by improving the PF, capacitors reduce the stress on the electrical infrastructure, minimizing energy loss and enhancing the overall PQ of the system. Furthermore, these capacitors contribute to a more reliable electrical system by reducing the load on transformers and other components, thereby prolonging their operational life.

How Do You Determine the Correct Size and Type of Power Factor Correction Capacitor?

Choosing the right PFCC depends on several factors, including the size of the inductive load, the system's electrical requirements, and the desired level of PF correction. Electrical engineers often perform calculations based on the system’s current consumption and AP to determine the appropriate size of the capacitance device. In many cases, automatic switched capacitors are utilized in systems with varying loads, enabling the dynamic adjustment of capacitance as needed. It’s essential to ensure that the capacitors are properly sized and designed to meet the specific needs of the electrical system.

What Common Issues or Problems?

Common issues include overvoltage, harmonic distortion, and improper sizing of capacitance devices. Overvoltage can occur if the device is too large for the system, potentially damaging both the cap and other system components. Harmonic distortion, caused by non-linear loads, can affect the performance of the cap and reduce the system’s overall PQ. To prevent these problems, it is essential to conduct regular maintenance and testing, ensuring that the caps are operating within the system’s parameters and that automatic switched caps are functioning correctly.

What are Some Best Practices?

Proper maintenance is critical for ensuring the long-term performance of a PFCC. Regular inspections are necessary to ensure that the caps require minimal cleaning and replacement of components. In addition, systems should be tested periodically to measure the amount of RP and ensure that the correction PFC is effectively improving the PF. Installing protection systems, such as surge protectors, can also safeguard caps from electrical faults. Lastly, in systems where loads vary significantly, using automatic switched caps can optimize the cap's performance by adjusting to changing energy requirements, ensuring maximum efficiency and reliability.

A power factor correction capacitor is an essential tool for electrical systems seeking to reduce energy loss, enhance efficiency, and maintain optimal PQ. By reducing the amount of RP, these caps help increase the PF, resulting in lower energy costs and improved system performance. Understanding how to select, install, and maintain correct PFC caps is crucial for optimizing electrical systems and ensuring long-term reliability. Regular maintenance and dynamic adjustments, utilizing automatic switched caps, further enhance the system's efficiency and sustainability.

Related Articles

High Resistance Grounding

High resistance grounding limits fault current to a low level in electrical systems, reducing arc flash hazards and equipment damage. It enhances system reliability, safety, and uptime in industrial power distribution networks.

What is High Resistance Grounding?

High resistance grounding (HRG) is an advanced electrical grounding method designed to limit fault current in industrial and commercial power systems, offering enhanced safety and operational reliability.

✅ Limits ground fault current to safe levels, reducing arc flash and equipment damage.

✅ Improves system uptime by allowing continued operation even in the event of a single ground fault.

✅ Supports fault detection and coordination with grounding and bonding systems.

Grounding and Bonding and the NEC 250 Training

Electrical Grounding and the CE Code Training

Request a Free Power Quality Training Quotation

By connecting the system's neutral point to the ground through a neutral ground resistor, HRG restricts fault current to a low, manageable level during ground faults. This reduces the risk of equipment damage, minimizes downtime, and protects against dangerous conditions such as arc flash energy and arcing ground faults. HRG systems are particularly beneficial in environments where continuous operation is critical, as they enable the detection and localization of faults without interrupting the entire system. This method is a preferred solution in modern electrical distribution, striking a balance between safety and system efficiency.

Frequently Asked Questions

What Is High Resistance Grounding, and How Does It Work?

HRG is a system that connects the neutral point of an electrical power system to the ground through a neutral ground resistor. This resistor limits the current during an arcing ground fault, reducing the risk of equipment damage and increasing system reliability. Unlike solidly grounded systems, which allow high fault currents, HRG systems maintain low fault currents, making it easier to detect and locate ground faults without shutting down the entire system.

In HRG systems, when a fault occurs, the neutral voltage rises, allowing fault detection equipment to identify the issue. These systems work well with detection techniques such as how to check if an area is grounded. The key component, the neutral ground resistor, is designed to handle the fault current until the fault is cleared.

What Are the Advantages of Using High Resistance Grounding in Electrical Systems?

One of the main benefits of HRG systems is their ability to limit arc flash energy during faults. In solidly grounded or ungrounded systems, ground faults can generate high fault currents, resulting in hazardous conditions such as phase-to-phase faults and substantial equipment damage. By using HRG, the fault current is controlled, minimizing the chance of catastrophic failures and improving safety for personnel.

Another advantage is continuous operation. Since HRG systems limit the fault current, they enable the system to continue running during a fault, providing operators with time to safely locate ground faults and address the issue without incurring costly downtime. This makes HRG especially valuable in grounding systems where shutting down the power supply could lead to significant financial losses.

HRG also reduces stress on the system, improving equipment longevity. By limiting fault currents, the wear and tear on electrical components are minimized, reducing the risk of damage during faults.

How Does High Resistance Grounding Differ from Other Methods?

HRG differs significantly from both solidly grounded and ungrounded systems. In a solidly grounded system, the neutral is directly connected to the ground, allowing for large fault currents during a ground fault. While this method provides good fault detection, the high fault currents can cause extensive damage.

In contrast, ungrounded systems lack a direct connection between the neutral and the ground. This can lead to unpredictable fault conditions, where fault currents fluctuate, causing difficulty in ground fault detection and increasing the risk of insulation breakdown and multiple faults.

HRG systems strike a balance by using a resistor to limit fault current, reducing the risks associated with both methods. In terms of energy delivery, HRG interacts with the system’s apparent power, maintaining balance during faults.

What Types of Electrical Systems Are Best Suited for High Resistance Grounding?

HRG systems are ideal for capacitive load scenarios and earthing of industrial and commercial power systems, particularly where line-to-neutral loads are minimal. Industrial settings, such as manufacturing plants, chemical facilities, and power generation plants, benefit from HRG due to the need for continuous operation and safety during fault conditions.

In these environments, HRG helps prevent hazardous situations, such as arcing ground faults, which can lead to equipment failure and injuries. By reducing the fault current, HRG systems protect expensive machinery and ensure that operations continue even when a fault is detected. High-resistance grounded power systems are particularly useful in industries where electrical faults can lead to fires or explosions.

What Are the Maintenance and Monitoring Requirements for High Resistance Grounding Systems?

To ensure that an HRG system functions properly, regular maintenance and monitoring are essential. This includes inspecting the neutral ground resistor for signs of wear or damage, ensuring it functions correctly to limit fault current.

Monitoring includes evaluating apparent power vs. real power to track system stability, as well as routine testing of fault detection systems. These checks are vital to ensure the electrical grounding infrastructure remains reliable over time.

Maintaining HRG systems requires attention to fault-detection equipment, like ground fault relays, which should be calibrated to ensure precise fault detection. Proper monitoring allows for early fault detection, minimizing downtime and preventing damage to equipment.

High resistance grounding systems offer significant advantages for industrial and commercial power applications. By limiting fault current and controlling arc flash energy, HRG systems enhance safety, reduce the risk of damage, and allow operations to continue during fault conditions. Compared to solidly grounded and ungrounded systems, HRG offers a balanced solution that minimizes both the risk of high fault currents and the unpredictability associated with ungrounded systems.

For industries where operational continuity and safety are crucial, high-resistance grounding is the ideal solution. Regular maintenance and monitoring ensure the system operates correctly, enabling the quick detection and resolution of faults. As a result, high-resistance grounded power systems remain a trusted and effective method for fault protection in modern electrical distribution networks.

Related Pages