Circuit Breaker In Substation Explained

Substation Maintenance Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3873 Fact Sheet – Minimum Approach Distance and Training Requirements

- Calculate MAD using voltage and overvoltage values

- Ensure proper communication between host and contract employers

- Meet OSHA training requirements for qualified electrical workers

A circuit breaker in substation systems protects transformers and grid infrastructure by interrupting faults like overloads or short circuits. Learn how they work, their types, maintenance, and evolving technology.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

What is a circuit breaker in a substation?

It is a critical protective device that interrupts electrical current during fault conditions like short circuits or overloads.

✅ Automatically interrupts electrical current during faults to protect substation equipment like transformers and busbars.

✅ Ensures grid reliability by isolating faulted sections and maintaining power flow to unaffected areas.

✅ Works with protective relays and control systems to detect overloads, short circuits, and abnormal conditions.

These high-performance switches are crucial for maintaining power system stability, protecting expensive equipment such as transformers, and preventing widespread power outages. Whether in a utility-scale transmission yard or an industrial distribution hub, the breaker’s ability to detect faults and isolate problems makes it the backbone of substation protection systems.

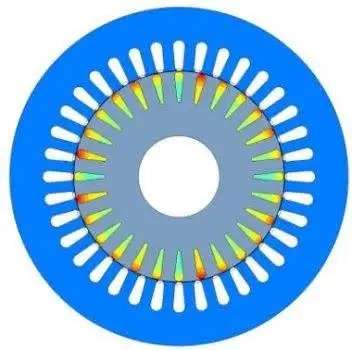

A circuit breaker in substation is a key component in electrical power systems, designed to interrupt the flow of electricity when a fault occurs, such as a short circuit or overload. Depending on system design, these devices can operate manually or automatically and come in various types, including air, vacuum, oil, and SF₆ gas. When triggered, the breaker relies on arc extinguishing mechanisms that either cool the arc with insulating materials or eliminate it entirely through vacuum or gas-based solutions. Their high dielectric strength enables them to withstand and effectively isolate high-voltage currents. Substations ensure system stability, minimize downtime, and protect equipment, such as transformers and busbars, from damage while supporting real-time monitoring and automated grid responses.

Test Your Knowledge About Electrical Substations!

Think you know Electrical Substations? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Role of the Circuit Breaker in Substation Protection

In substations, circuit breakers serve as the first line of defence. When abnormal current is detected—due to equipment failure, insulation breakdown, or lightning—a breaker opens its contacts to interrupt the current flow. This rapid response prevents severe equipment damage, minimizes safety hazards, and ensures reliable power delivery.

Circuit breakers work in conjunction with protective relays and disconnectors to isolate faults while allowing the rest of the system to remain operational. This selectivity is especially crucial in interconnected grid environments where continuity of supply must be preserved.

To explore how these systems are integrated, see our page on electrical substation design.

Types of Substation Circuit Breakers

Substation circuit breakers vary based on their arc-quenching medium and voltage rating. Each type is suited to specific applications and offers advantages and limitations:

-

Air (ACB): Use compressed air to extinguish arcs. These are typically used in low-voltage systems and offer simple construction but require regular inspection.

-

Vacuum (VCB): Suitable for medium-voltage levels (up to 38 kV), VCBs extinguish arcs in a vacuum, ensuring minimal wear and extended service life.

-

Oil (OCB) use insulating oil to suppress arcs. They are more common in legacy systems and require ongoing maintenance due to oil degradation.

-

SF₆: These breakers, employed in high-voltage substations, use sulphur hexafluoride gas for superior arc quenching and insulation. While highly effective, they present environmental concerns due to the gas’s impact on greenhouse gases.

To understand how different transformer systems pair with circuit breakers, visit our electrical substation transformer overview.

Protection, Control, and Grid Stability

Circuit breakers form part of a broader substation protection and control system that includes current transformers, voltage transformers, and digital protection relays. When a relay detects an abnormality, it sends a signal to the breaker to open, thereby isolating the faulty section. This automated coordination is crucial in modern substations, particularly as grids integrate renewable energy sources and smart grid technologies.

Many modern substations now use digital relays, IEDs (Intelligent Electronic Devices), and SCADA systems for real-time monitoring and automation. Learn how circuit breakers integrate with these systems in our article on

substation automation systems.

These control systems allow breakers to be operated remotely, analyze fault data, and optimize asset performance, thereby enhancing substation responsiveness and reliability.

Maintenance and Inspection Practices

Routine maintenance is vital to ensure breaker reliability. The type of breaker determines specific servicing needs:

-

Oil and SF₆ breakers require careful monitoring of fluid or gas levels to prevent insulation failure.

-

Vacuum and air breakers require less maintenance but still need to be inspected for wear and mechanical issues.

Key inspection tasks include:

-

Verifying insulation resistance

-

Testing trip and close mechanisms

-

Checking for leakage or contamination

-

Reviewing control circuitry and relay coordination

Explore our electrical substation maintenance programs, which outline testing techniques and predictive diagnostics, for practical guidance on these procedures.

Environmental and Safety Considerations

Safety is paramount when working around high-voltage circuit breakers. Operators must use appropriate PPE and follow strict lockout/tagout procedures to prevent arc flash injuries and electrical shock. Circuit breakers, particularly those using SF₆ gas, also carry environmental risks.

To understand how breakers help mitigate shock hazards and arc incidents, refer to our

Electrical Substation Components Safety Guide.

Growing concerns about SF₆’s environmental impact push the industry toward eco-friendly alternatives. Dry air and vacuum interrupters are gaining traction for their reduced greenhouse footprint.

Future Trends in Breaker Technology

The future lies in digitalization, remote diagnostics, and sustainability. Innovations include:

-

IoT-connected sensors for condition-based maintenance

-

AI algorithms for predictive failure detection

-

Eco-efficient breakers using clean-air technologies

As utilities adapt to the demands of electrification and renewable integration, they will continue to evolve, ensuring safety, reliability, and efficiency in the next generation of power grids.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Frequently Asked Questions

What is the main function of a circuit breaker in substation?

To detect and interrupt fault currents, protecting transformers and maintaining system reliability.

How often should they be inspected?

Maintenance intervals vary by type, but annual testing and inspection are generally recommended.

Are SF₆ breakers still widely used?

Yes, but many utilities are shifting toward more environmentally friendly alternatives due to SF₆'s global warming potential.

Related Articles