Substation Grounding - Ensuring Electrical Safety

Substation Maintenance Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

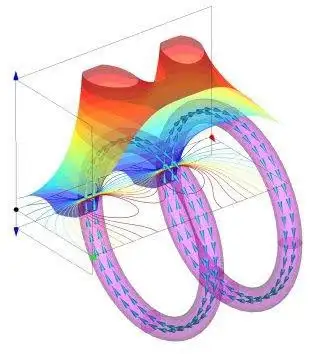

Substation grounding ensures electrical safety by directing fault currents into the earth, stabilizing voltage, and protecting equipment. This process reduces shock risks, enhances reliability, and supports safe operation of utility systems in substations.

What is Substation Grounding?

Substation grounding is the method of connecting electrical systems to earth to ensure safety, stability, and equipment protection.

✅ Provides fault current dissipation into the earth

✅ Stabilizes voltage levels and system operation

✅ Protects personnel, transformers, and equipment

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Substation grounding is a critical aspect of electrical engineering that ensures the safety and reliability of power systems. At its core, substation grounding refers to interconnected conductors designed to safely dissipate fault currents and maintain equipment at a common potential. This process is crucial for protecting personnel and equipment from electrical hazards, ensuring an uninterrupted power supply, and minimizing the risk of damage in the event of electrical faults or lightning strikes. Proper systems in electrical substations enhance operational stability, prevent voltage surges, and ensure compliance with regulatory standards. Understanding the principles and importance of electrical systems is key to designing efficient, safe, and compliant power systems. Proper electrical substation design must always incorporate effective substation grounding to ensure safe dissipation of fault currents.

Advanced Protective Relays and IEDs

One of the most significant advancements in substation protection is the use of microprocessor-based protective relays and Intelligent Electronic Devices (IEDs). These advanced control systems rapidly detect and isolate faults, preventing damage to critical infrastructure. Unlike traditional electromechanical relays, modern protective relays provide real-time data collection, communication capabilities, and adaptive settings that enhance their performance. By integrating these devices, substations can protect and control power flow more efficiently, reducing downtime and enhancing reliability.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Substation Automation and Virtualization

Substation automation has further transformed the operation of protection systems. Automation and virtualization enable centralized control, minimizing the need for extensive hardware and on-site interventions. Virtual protection schemes allow engineers to monitor electrical substations remotely, quickly identifying issues and deploying corrective measures without physically accessing the site. This automation improves the adaptability of power system management, ensuring that substations respond dynamically to changes in load demand and grid conditions. Regular electrical substation maintenance helps verify that grounding systems remain effective against faults and lightning strikes.

Essential Protection Equipment

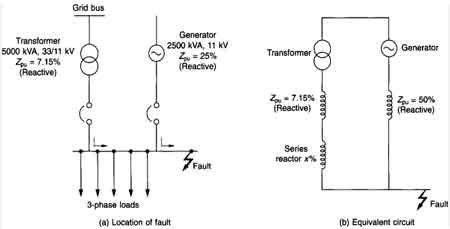

Comprehensive protection equipment is vital for maintaining the integrity of a substation. Circuit breakers play a critical role in interrupting fault currents and preventing cascading failures within the electrical grid. Proper coordination of circuit breakers with other protective devices ensures that faults are isolated at the right locations, minimizing disruptions. Additionally, surge arresters, insulators, transformers, and grounding systems contribute to shielding substations from overvoltages, short circuits, and unexpected electrical anomalies. Reliable electrical substation components, including grounding grids and rods, are essential for stabilizing voltage and protecting equipment.

Preventing Animal Intrusions

Another challenge in substation protection is mitigating the risks posed by wildlife. Animal intrusion is a frequent cause of electrical faults, leading to power disruptions and costly repairs. Birds, rodents, and climbing animals can inadvertently bridge high voltages, causing short circuits or equipment damage. To counter this, substations implement physical barriers, insulated covers, and laser deterrent systems to keep animals away from sensitive components. These preventive measures significantly reduce outage risks while ensuring the long-term safety of electrical substations.

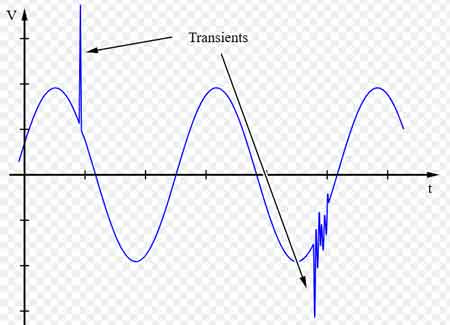

Protection Against Overvoltages and Lightning Strikes

Substations must also be protected against transient overvoltages caused by lightning strikes and switching operations. Without adequate defences, these sudden voltage spikes can severely damage equipment, leading to costly failures. High-performance surge arresters and robust grounding techniques are crucial for safely dissipating excess energy. By directing fault currents into the ground, these protective measures help maintain system stability and prevent disruptions to transmission and distribution networks. Grounding is closely tied to substation protection, which safeguards personnel and equipment from electrical hazards.

The Future of Substation Protection

Effective substation protection involves a combination of advanced technologies and strategic design. The ability to detect and isolate faults quickly, deploy automation for enhanced monitoring, and implement robust protective equipment ensures the reliability of the power system. Substations must continuously adapt to new challenges, integrating state-of-the-art solutions that enhance their resilience against faults, environmental threats, and operational inefficiencies. As the demand for electrical power grows, so does the need for comprehensive and intelligent protection strategies that safeguard the backbone of modern energy infrastructure.

Frequently Asked Questions

Why is substation grounding important for electrical safety?

A substation system is essential for electrical safety because it provides a safe pathway for fault currents to travel to the earth, thereby preventing dangerous electrical shocks to personnel and damage to equipment. Without a proper system, fault currents can cause dangerous voltages to build up in the equipment and surrounding areas, increasing the risk of electric shock. Systems also help in controlling step and touch voltage hazards, ensuring that electrical equipment remains safe for workers. In the event of an electrical fault, the system helps to quickly and safely direct the current to the ground, reducing the risk of injury and ensuring the safe operation of the electrical system. Engineers often conduct ground grid testing of substation cost sheet analysis to evaluate soil resistivity and grounding effectiveness.

What are the key components of a substation grounding system?

The key components of an electrical system include the grounding grid, grounding rods, connections, and conductors. The grid is typically composed of metal conductors buried in the soil surrounding the substation. It forms a network that provides a low-resistance path for fault currents to travel. Rods, also known as earth rods, are metal rods driven into the ground to improve the dissipation of fault currents into the earth. These rods are typically placed at strategic locations throughout the substation to ensure the system remains effective in various environmental conditions. Connections link all components of the system, ensuring that they work together to create a continuous conductive path. Conductors carry the fault currents from the equipment to the grid or rods. Together, these components ensure that electrical faults are safely dissipated, allowing the system to operate reliably and safely.

Test Your Knowledge About Electrical Substations!

Think you know Electrical Substations? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

How is ground resistance measured in a substation grounding system?

Ground resistance is measured using instruments like a ground resistance tester, which applies a small current to the system and measures the voltage drop across the system. The result is a value of resistance (measured in ohms) that indicates how easily fault currents can flow through the earth. Low ground resistance is essential for a system to effectively dissipate fault currents and prevent dangerous voltage buildup. High ground resistance can lead to insufficient dissipation of electrical energy, increasing the risk of electric shock and equipment damage. It can also cause increased heating in the system, potentially leading to fires or system failure. Therefore, achieving an optimal level of ground resistance is crucial for the safety and reliability of the substation.

What are the best practices for a substation grounding system?

Designing an effective electrical system requires careful consideration of several factors, including the layout of the substation, soil resistivity, the type of equipment used, and potential fault currents. The grid should be designed to cover the entire substation area, ensuring that all equipment is well-connected to the system. The rods should be placed at locations that optimize the flow of fault currents into the ground, taking into account factors like soil type and moisture content. The system should be designed to minimize ground resistance by utilizing materials with good conductivity and by considering the depth and arrangement of the rods. Regular testing and ongoing maintenance should be part of the design process to ensure the system remains effective over time. Additionally, safety considerations, such as mitigating step and touch voltages, should guide the placement of components to protect personnel working in or near the substation.

How do regulations and standards impact substation grounding?

Regulations and standards play a crucial role in electrical system design and maintenance, ensuring that systems meet safety and performance criteria. Standards such as IEEE P80 provide detailed guidelines for the installation, design, and maintenance of systems, ensuring that systems are both safe and reliable. Compliance with these standards helps minimize the risk of electrical hazards, such as electric shock or equipment failure and improves the overall reliability of the substation. These standards also ensure that electrical systems are designed to handle fault currents effectively, taking into account local soil resistivity, environmental conditions, and the specific requirements of the system. Regular updates to regulations help keep systems in line with technological advances and industry best practices. By following these standards, substations can ensure that their systems operate effectively and comply with safety regulations, thereby reducing risks and enhancing operational efficiency. Training in electrical substation grounding is a vital part of broader electrical substation training programs for utility and industrial staff.

Substation grounding is a critical element of electrical system safety and performance, ensuring that electrical substations are properly protected against electrical faults. It involves creating a safe pathway for fault currents to travel into the earth, preventing hazardous voltages that could lead to electric shocks or equipment damage. Key components of a system include grids, rods, and conductors, which work together to minimize ground resistance and safely dissipate fault currents. Proper design and maintenance are essential to maintaining a reliable system, with factors like soil resistivity, equipment type, and safety considerations playing a key role. Adherence to industry standards, such as IEEE P80, ensures compliance with safety regulations and optimal system performance, ultimately safeguarding both personnel and the substation equipment.

Related Articles