Hand Safety - Protective Gloves

By Larry J. Loizzo, LabSafety

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

Insulating rubber gloves protect electricians from shock with dielectric PPE, ASTM/IEC class ratings, arc-flash compatibility, and OSHA compliance, enabling safe high-voltage maintenance, live-line work, and substation testing when paired with leather protectors and regular recertification.

What Are Insulating Rubber Gloves?

Dielectric PPE gloves rated by class to prevent electrical shock during high-voltage work and testing.

✅ Rated Class 00–4 per ASTM D120; inspect, air test, and date-stamp.

✅ Use with leather protectors; store cuff-up in ventilated bags.

✅ Re-test every 6 months; keep dry, clean, and away from hydrocarbons.

Rubber insulating gloves are among the most important articles of personal protection for electrical workers. To be effective, the gloves must incorporate high dielectric and physical strength, along with flexibility and durability. For superior performance they should meet and/or exceed the requirements of current American Society for Testing and Materials (ASTM) D120 specifications. Gloves should also be electrically tested following ASTM D120/IEC903 specifications.

A glove system usually consists of:

Rubber Insulating Gloves: Classified by the level of voltageand protection they provide.

Liner Gloves: Are used to reduce the discomfort of wearing rubber insulating gloves in all seasons, for year round use.

Liners: provide warmth in cold weather, while they absorb perspiration in the warm months. These can have a straight cuff or knit wrist.

Leather Protector Gloves: Should always be worn over rubber insulating gloves to provide the mechanical protection needed against cuts, abrasions and punctures. Look for those that are steam pressed on curved hand forms to ensure proper fit over rubber gloves. For a broader overview of compatible personal protective equipment, see the guidance on lineman safety equipment to ensure system-level protection.

Sign Up for Electricity Forum’s Lineman Safety Newsletter

Stay informed with our FREE Lineman Safety Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

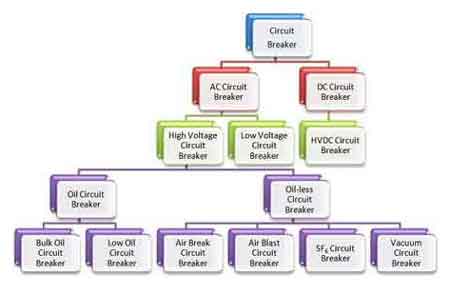

ELECTRICAL-PROTECTIVE GLOVE CLASSIFICATION

Employees who work in close proximity to live electrical current may require a variety of electrically insulating protective equipment. The Occupational Safety and Health Administration (OSHA) outlines this in their Electrical Protective Equipment Standard (29 CFR 1910.137) which provides the design requirements and in-service care and use requirements for electricalinsulating gloves and sleeves as well as insulating blankets, matting,

covers and line hoses. Electrical-protective gloves are categorized by the level of voltage protection they provide and whether or not they’re resistant to ozone. Voltage protection is broken down into the following classes: Because electrical work often also involves arc-flash hazards, practitioners should review advanced protection measures against electromagnetic exposures and electric arc to align gloves with a coordinated PPE plan.

For gloves, ozone resistance is covered by the “Type” designation. A Type I glove is not ozone-resistant, while a Type II is ozone-resistant. Once the gloves have been issued, OSHA requires that “protective equipment shall be maintained in a safe, reliable condition”. This requires that gloves be inspected for any damage before each day’s use. Gloves must also be inspected immediately following any incident that may have caused damage. OSHA requires that insulating gloves be given an air test along with the inspection. For program planning, a concise overview of electrical testing methods and best practices can help define inspection intervals and documentation.

OSHA requires air testing, but doesn’t explain how to perform the test. The test method is described in ASTM F 496, Specification for In-Service Care of Insulating Gloves and Sleeves. Basically, the glove is filled with air, either manually or by an inflator, and then checked for leakage. The leakage is detected by either listening for escaping air or holding the glove against the tester’s cheek to feel air releasing. Beyond air checks, understanding the principles of an electrical insulation resistance test can inform decisions about when to escalate to laboratory diagnostics.

As stated in ASTM specifications for In-Service Care and Use of Rubber Gloves and Sleeves, gloves and sleeves should be expanded no more than 1.5 times their normal size for type I, and 1.25 times normal for type II during the air test. The procedure should then be repeated with the glove turned inside out. In addition to this daily testing, OSHA requires “Electrical protective equipment shall be subjected to periodic electrical tests.” OSHA does not elaborate on a time frame for these tests, but ASTM F 496 does provide direction. It states that gloves being used in the field must be electrically retested every six months. When deeper diagnostics are warranted, selecting an appropriate insulation resistance tester ensures measurements are reliable and traceable.

Gloves that have not been placed into service after an electrical test shall not be placed into service unless they have been electrically tested within the previous 12 months. See reference below for Testing Agency information. OSHA recognizes that gloves meeting ASTM D 120-87, Specification for Rubber Insulating Gloves, and ASTM F 496, Specification for In-Service Care of Insulating Gloves and Sleeves, meet their requirements. Facilities may also standardize procedures for checking insulation resistance to complement scheduled retesting.

INSPECTION

In order to maintain the highest level of insulating protectionand ensure long life, it is essential that gloves (and sleeves) are properly cared for and stored.

Before each use, gloves and sleeves should be inspected for holes, rips or tears, ozone cutting, UV checking and signs of chemical deterioration. Refer to ASTM F 1236, Standard Guide for Visual Inspection of Electrical Protective Rubber Products for Additional Information.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Gloves and Sleeves should also be examined to determine if they show any damage as a result of chemical contamination, particularly from petroleum products. The first sign of exposure is swelling in the area of contamination. Should any rubber equipment be exposed to chemical contaminants or be suspect of any other physical damage, it should be turned in for inspection, cleaning and electrical testing.

Since sleeves cannot be inflated, they are inspected along the edge as they are rolled. Rolling will stretch the sleeve along the edge, making cuts, tears and ozone cutting more visible. After the outside of the sleeve is inspected, the procedure should also be repeated with the sleeve turned inside out.

COMMONLY ASKED QUESTIONS

Q. Can I just use the rubber glove only, and not have to buy the leather part?

A. Leather protective gloves should always be worn over rubber insulating gloves to provide the needed mechanical protection against cuts, abrasions, and punctures. For tasks with arc-flash exposure, consult current guidance on arc-flash clothing for electricians so glove selection integrates with garment ATPV ratings.

Q. Would re-testing be needed if I don’t use the gloves very often and visually see no damage?

A. Yes, re-testing is still needed to verify the integrity of the material and to ensure electrical safety is maintained for the user.

Q. If I find a hole, can I just “patch it” - like a tire inner tube?

A. No - because this would not comply with ASTM or OSHA Standards for Electrical Protective Gloves, and it would not pass Accredited Laboratory Testing.

From: Electrical Safety & Arc Flash Handbook Handbook, Volume 3, The Electricity Forum