Buck Boost Transformer

Power Transformer Maintenance Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3873 Fact Sheet – Minimum Approach Distance and Training Requirements

- Calculate MAD using voltage and overvoltage values

- Ensure proper communication between host and contract employers

- Meet OSHA training requirements for qualified electrical workers

A buck boost transformer adjusts voltage by increasing or decreasing it within a small range to match equipment needs. It improves voltage stability, energy efficiency, and protects sensitive electrical systems from over-voltage or under-voltage issues.

What is a Buck Boost Transformer?

A buck boost transformer is an essential device for industrial and commercial electrical systems, designed to fine-tune voltage levels and prevent damage to sensitive equipment.

✅ Regulates voltage by boosting or reducing levels for precise equipment operation.

✅ Enhances energy efficiency and prevents equipment damage from power fluctuations.

✅ Ideal for HVAC, lighting, and other electrical systems requiring minor voltage correction.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Purpose, Design, and Applications

It can either increase (boost) or decrease (buck) voltage by a small amount—typically between 5% and 20%—to ensure that equipment receives stable and optimal power. This precise voltage control helps bridge the gap between supply voltage and the operational requirements of devices, reducing the risk of malfunctions, overheating, or premature equipment failure.

By maintaining correct voltage levels, buck boost transformers improve energy efficiency and system performance while protecting machinery from fluctuations that could otherwise lead to costly downtime. For electricians, understanding how these transformers function is crucial for troubleshooting voltage-related issues and ensuring reliable power delivery.

To understand the basic function of transformers, see our guide on what is a transformer.

Comparison of Buck Boost Transformers vs Other Transformer Types

| Feature | Buck Boost Transformer | Step-Up/Step-Down Transformer | Isolation Transformer |

|---|---|---|---|

| Voltage Adjustment | Small (5–20%) up or down | Large voltage changes (e.g., 120V to 480V) | Minimal voltage change, provides isolation |

| Purpose | Fine-tunes voltage for equipment like HVAC or lighting | Converts voltage for distribution and machinery | Provides safety and noise isolation for sensitive systems |

| Size & Cost | Compact and cost-effective | Larger and more expensive | Moderate size and cost |

| Applications | HVAC units, UPS, motors, lighting | Utility grids, industrial equipment | Medical equipment, audio systems, electronics |

Voltage Regulation and Precision

The primary function of a buck boost transformer is voltage regulation. Electrical systems often encounter mismatches between supply voltage and equipment requirements. For example, a motor designed to run on 230 volts may receive only 208 volts from the supply. In such cases, a buck boost transformer raises the voltage to the correct level, allowing the motor to operate efficiently. Conversely, if the supply voltage exceeds the equipment’s rating, the transformer can reduce the voltage to prevent potential damage. This ability to make minor but critical adjustments ensures that connected systems remain safe and stable. Learn how power distribution systems utilize 3-phase to single-phase transformers to meet various voltage requirements.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Versatile Applications Across Industries

Buck boost transformers are widely used in industrial, commercial, and residential settings where voltage inconsistencies can affect performance. In industrial facilities, they support heavy machinery, conveyor systems, and motor-driven equipment by maintaining steady voltage levels. In commercial environments, they are commonly used for lighting circuits, HVAC systems, and other building infrastructure to prevent interruptions caused by voltage fluctuations.

They are also valuable in specialized applications such as uninterruptible power supplies (UPS), renewable energy systems, and agricultural equipment. For instance, air conditioning units often require 230 volts, but many power supplies provide only 208 volts. A buck boost transformer can easily correct this discrepancy, ensuring optimal performance. For insight into adjusting voltage levels efficiently, explore our article on step-down transformers.

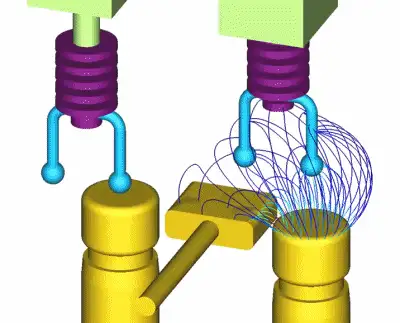

Design and Construction

A distinctive feature of buck boost transformers is their autotransformer configuration. Unlike isolating transformers, the primary and secondary windings of an autotransformer are electrically connected, allowing for highly efficient voltage adjustments within a compact design. While this configuration does not provide electrical isolation, it is ideal for applications requiring small voltage corrections.

These transformers are typically single-phase, dry-type units, although three-phase models are also available for larger systems. Common secondary voltages include 12, 16, 24, 32, or 48 volts, with dual-voltage primary and secondary windings that can be configured to meet various needs. Their compact and lightweight design makes installation simple, whether indoors or outdoors, and they are built to withstand a wide range of environmental conditions. See how autotransformers offer cost-effective voltage regulation for industrial applications.

Energy Efficiency and Equipment Longevity

By precisely matching the voltage supply to the equipment’s requirements, buck boost transformers help minimize energy waste and improve system efficiency. Without proper voltage regulation, equipment may draw excessive current or operate inefficiently, resulting in higher energy consumption and unnecessary wear. Understand system protection and monitoring with our resource on current transformers.

Over time, exposure to incorrect voltage levels can shorten the lifespan of electrical components, causing overheating or permanent damage. By preventing these issues, buck boost transformers not only reduce the likelihood of costly repairs but also extend the operational life of connected devices. Dive into detailed transformer types in our section on electrical power transformers.

Advantages and Limitations

Buck boost transformers offer several key advantages:

-

Compact and cost-effective: They are smaller and less expensive than full-scale step-up or step-down transformers.

-

High efficiency: Their design ensures minimal power loss during voltage adjustment.

-

Versatility: Suitable for a wide range of applications requiring small voltage corrections.

However, there are limitations to consider. These transformers are not designed for large voltage changes and do not provide electrical isolation. They are most effective for low to medium-power systems that require only minor voltage adjustments.

Frequently Asked Questions

How does a buck boost transformer work?

It operates by using a specific turns ratio between the primary and secondary windings, enabling it to step the voltage up or down by a small percentage. It is typically wired in series or parallel with the load to achieve the desired voltage correction.

What are the common applications?

They are used in HVAC systems, lighting, UPS systems, and industrial motors where slight voltage adjustments are necessary to maintain performance and protect equipment.

Buck boost transformer vs isolating transformer?

A buck boost transformer adjusts voltage without providing electrical isolation. An isolating transformer, on the other hand, separates the primary and secondary circuits for safety and noise reduction but does not perform fine voltage corrections.

Can it handle large voltage changes?

No, it is designed for minor voltage corrections (typically 5–20%). For major voltage conversions, step-up or step-down transformers are required.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

What are the main benefits?

Improved system performance, reduced energy loss, extended equipment lifespan, and cost savings due to fewer repairs or replacements.

Related Articles