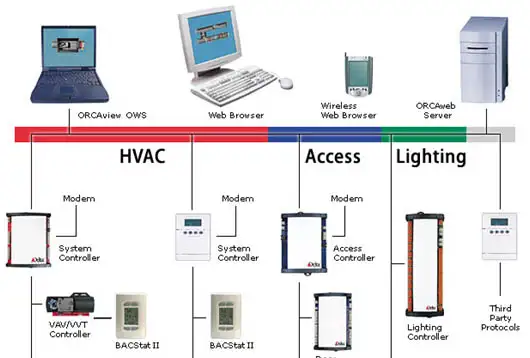

Energy Management Controls - HVAC Systems

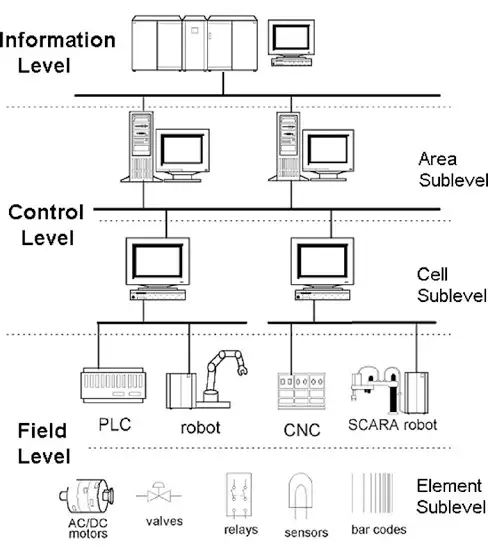

Energy management controls are conservation tools implemented to control heating, energy consumption, lighting systems, heathing ventilation and air conditioning (HVAC) systems. Modern Direct Digital Control (DDC) systems, which can accurately control building systems, have become very cost-effective in recent years. As a result, they are replacing traditional manual and electromechanical building control systems in retrofitted buildings and being installed in almost all new commercial and institutional facilities. However, maximizing energy efficiency requires strategic facility management control methods for controlling the HVAC, power and communications systems.

Regardless of the technology used, deciding which energy management control mode to apply is important. It is important to understand that these modes can be implemented using many available technology types. In many cases, simple on-off control is adequate and very appropriate. In other cases, the desired effect can be on with modulating controllers. The following are basic control modes. The accompanying diagrams will illustrate typical system performance.

The term system capacitance refers to the rate of response of a system to a stimulus. Systems with a large capacitance tend to resist change, and the effects of control are felt more slowly than with systems of smaller capacitance. Comparing the effect to a flywheel or relative mass is a good way to describe this concept. Another useful example to illustrate system capacitance is an instantaneous electric water heater (small volume of water) compared to a standard residential tank-type water heater. Upon energizing the heater elements, the water temperature in the tank unit changes much more slowly because it has more mass, and we say it has greater system capacitance.

The term gain is a control term synonymous with sensitivity and is usually an adjustable amplification value used to tune the devices. For example, if a quicker response is desired for a small input change, the gain is increased in a stronger output reaction from the controller.

On-off Energy Management Controls

Also called two-position control, this rudimentary mode is used with either on or off equipment. A nominal setpoint exists but is only achieved in passing. A range of control values must be tolerated to avoid short-cycling the equipment, and temperature ranges are often fairly wide. In the case of equipment that cannot be modulated, this is often the only choice. The smoothness of control depends strongly upon the system capacitance; systems with very low capacitance can experience short cycling problems using two-position control.

Floating Energy Management Controls

This hybrid combination of on-off and modulating control is also called incremental control. As with on-off control, there is a control range (cut-in/cut out). However, unlike on-off control, floating control systems can maintain a mid-position of the controlled device instead of being limited to full-on or full-off. The controlled device holds its last position between the cut-in and cut-out thresholds. The process variable is not under control within this range, and it floats with the load until it crosses a threshold to get another incremental nudge in the correcting direction. This control is tighter than simple on-off control, and although tight than true modulating control, it is inexpensive and reliable. Equipment items from small HVAC terminal units to 1000 HP water chiller inlet vanes are controlled in this manner with good success. Note that floating control is limited to processes that change slowly, and floating control actuators are usually selected as slow-moving.

Proportional-only Control (P)

This is the basic modulating control and what most commercial pneumatic and analog electronic systems utilize. It is an error-sensing device with an adjustable gain or amplification. A control output is issued to regulate a process, and the magnitude of the output is directly proportional to the size of the error. This type of control is economical and reliable. However, a characteristic offset (residual error) is natural with this type of controller, and the size of the offset will increase with load. This offset occurs because an error must increase (further off setpoint) before an output increase can occur.

If the proportional energy management controls are too sensitive (gain set too high), the controller’s response will be excessive, and oscillation or hunting will occur. When this occurs, the controller output (and the equipment connected) will oscillate up and down, open and closed, etc., and the control action will not settle out.

Conclusion

Automatic energy management controls are useful for basic regulation and quality control of processes and environments. They can also be leveraged for energy savings through optimization. Properly applied, these systems are reliable and cost-effective. Returning to the chapter's intent, the stated purpose of this chapter was to focus on the application of automatic system controllers as a tool to achieve energy savings. The reader should review the titles of each section, reflect on the key topics taken away, and decide if the stated objective was met. It is hoped that the reader has gained insight into how automatic energy management controls can help achieve energy goals. Therefore, they will endeavour to put these systems to work, optimizing processes and saving energy.

From: Energy Management Handbook, 7th Edition, The Fairmont Press