What Is An Arc Flash Study?

What is an Arc Flash Study? It is a comprehensive analysis of an electrical distribution system aimed at identifying potential hazards associated with electrical explosions. These arc flash incidents, which involve a rapid release of electrical energy, can lead to severe injuries and damage due to the resulting electrical explosion. The study is essential for establishing safe work practices, informing protective device coordination, and ensuring the correct implementation of arc flash boundaries to protect workers. Incident energy, defined by IEEE 1584, calculates the potential energy that a worker might be exposed to in an arc flash event. This calculation is a critical aspect of the study, as it directly influences the type and level of personal protective equipment (PPE) needed to protect individuals in proximity to electrical equipment.

Visit Our Arc Flash Study Training Page

Incident Energy and NFPA 70E Compliance

Conducting an arc flash study is required for facilities to comply with safety standards, specifically NFPA 70E. NFPA 70E is a key reference for defining the practices and precautions necessary to protect workers from electrical hazards. By assessing incident energy, the study evaluates the potential severity of exposure to an electrical explosion, helping companies determine the proper PPE that workers need. NFPA 70E guidelines outline the importance of reducing exposure risks by defining boundaries around electrical equipment that are critical for maintaining safety. Incident energy assessments provide the foundation for identifying areas within an electrical distribution system where PPE is essential for safe work practices.

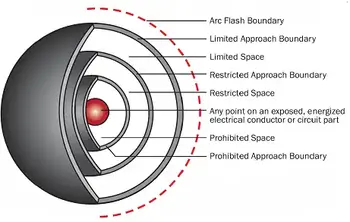

Defining Boundaries

An essential outcome of the study is the establishment of boundaries. These are zones around electrical equipment where the risk of injury from an electrical explosion is significant. By identifying these boundaries, the study ensures that personnel are aware of the distances necessary to remain safe and when the use of PPE is mandatory. The boundary is determined through calculations that consider the electrical system’s configuration and operating conditions. Ensuring compliance with these boundaries is crucial for maintaining safety in environments with high electrical risk, as it directly affects where workers should stand or operate.

Personal Protective Equipment and Risk Assessment

One of the primary goals of conducting an arc flash study is to define and mandate the proper personal protective equipment required for employees who may be exposed to a hazard. By understanding the severity of potential hazards through a detailed arc flash risk assessment, companies can specify the appropriate PPE levels for different areas within the facility. This includes establishing the types of protective clothing, face shields, gloves, and other necessary gear based on the incident energy level identified in the study. This careful matching of PPE to hazard levels allows for more effective protection against injuries in the event of an electrical explosion.

Short Circuit and Coordination Studies

An arc flash study typically incorporates two additional studies that enhance safety and ensure effective operation of the electrical distribution system: short circuit and coordination studies. A short circuit study assesses potential fault currents and helps verify that circuit breakers and other protective devices are appropriately rated to handle the current levels that might occur. Coordination studies include evaluating how protective devices interact and respond during a fault condition to ensure that they trip correctly, thus limiting the extent and duration of an electrical fault. Together, these studies include essential data that support safe and efficient operation, minimizing the risks posed by incidents.

Labeling for Electrical Equipment

Once the study is completed, labels are placed on electrical equipment to clearly indicate the level of hazard and the necessary precautions. These labels inform workers about the boundary, PPE requirements, and other safety measures based on the arc flash study’s findings. Proper labeling is essential to help workers quickly identify equipment with high-risk potential and to promote adherence to established safety protocols. By clearly marking equipment with labels, the workplace becomes more informed and prepared, reducing the likelihood of accidents due to unawareness of electrical hazards.

Questions & Answers

What is an arc flash study, and why is it necessary?

An arc flash study analyzes the electrical system to assess potential electrical hazards. It identifies high-risk areas and helps in implementing safety measures to protect personnel from electrical explosions. The study is crucial for compliance with industry standards and for ensuring workplace safety.

How is an arc flash study conducted?

This process involves data collection, system modeling, fault current calculations, and hazard analysis. Specialized software simulates electrical faults, determining energy levels and hazard zones, which are then used to recommend personal protective equipment (PPE) and safety practices.

What information is needed to perform an arc flash study?

Essential data includes one-line diagrams, equipment ratings (like transformers, circuit breakers, and fuses), operating conditions, and fault current information. Accurate and up-to-date system data ensures reliable analysis results.

How often should an arc flash study be updated?

Generally, updates are recommended every five years or after significant changes to the electrical system. Regular updates help maintain accurate hazard assessments and ensure compliance with safety standards like NFPA 70E.

What are the benefits of conducting an arc flash study?

Key benefits include enhanced worker safety, regulatory compliance, optimized PPE requirements, and reduced risks of equipment damage. The study also fosters a safer working environment and can help lower incident-related costs.

EF PARTNER MEDIA

Product Showcases

Shared Media