NFPA 70E Arc Flash Requirements

NFPA 70e Training - Arc Flash

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our NFPA 70E Fact Sheet – 2024 Electrical Safety Edition

- Understand how NFPA 70E works with NEC and NFPA 70B standards

- Clarify the shared responsibility between employers and employees

- Learn how NFPA 70E supports OSHA compliance

NFPA 70E Arc Flash Requirements outline how employers must assess electrical hazards, set approach boundaries, train qualified workers, and maintain a documented safety program to prevent shock, burn injuries, and arc flash incidents while ensuring OSHA and CSA Z462 compliance.

What are the NFPA 70E Arc Flash Requirements?

NFPA 70E Arc Flash Requirements outline the employer’s duty to create a safe electrical work environment through risk assessment, boundary determination, and the development of documented procedures. These standards ensure that workers understand potential hazards, apply protective controls, and follow safe work practices.

✅ Employers must establish and maintain a documented electrical safety program

✅ Risk assessments are required to identify arc flash and shock hazards

✅ Safe work practices, boundaries, and training must be implemented and reviewed

NFPA 70E provides a framework for reducing the likelihood of electrical injuries by combining engineering controls, administrative procedures, and personal protective measures. It serves as a bridge between OSHA’s performance-based regulations and practical implementation in the field.

Request a Free Training Quotation

NFPA 70E is a foundational component of any electrical safety program, guiding organizations in identifying and controlling hazards associated with energized electrical systems. The standard, developed by the National Fire Protection Association (NFPA), gives employers a clear methodology for assessing risk, training workers, and maintaining OSHA compliance under 29 CFR 1910. It promotes a proactive safety culture focused on hazard prevention rather than reaction.

Meeting NFPA 70E requirements involves more than paperwork. It means building an environment where every task begins with a safety mindset — assessing equipment condition, confirming boundaries, and ensuring workers are protected before performing any energized work. When applied correctly, the standard reduces injuries, downtime, and liability while strengthening operational reliability. For a broader introduction to the standard, see our NFPA 70E Overview. To understand the hazard itself, visit our What is Arc Flash? page.

Sign Up for Electricity Forum’s Arc Flash Newsletter

Stay informed with our FREE Arc Flash Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

NFPA 70E 2024 Edition

The most recent edition of NFPA 70E introduces several important updates to strengthen worker protection and clarify employer obligations:

-

Mandatory hearing protection for anyone inside the arc flash boundary

-

Stronger emphasis on establishing an Electrically Safe Work Condition (ESWC)

-

Expanded guidance for DC systems and updated PPE selection tables

-

Revised definitions and additional clarity for risk assessment documentation

Including these changes in your electrical safety program ensures continued compliance with the latest industry best practices.

General Employer Requirements

Employers bear the responsibility for developing and maintaining a documented Electrical Safety Program under NFPA 70E. This program must clearly define responsibilities, safe work procedures, and employee training requirements. It must also be reviewed at least every three years or after major system changes.

Key elements include:

-

Hazard identification and incident energy analysis

-

Written safe work procedures and job planning documents

-

Regular employee training and retraining

-

Job briefings before electrical work begins

-

Ongoing compliance with OSHA 29 CFR 1910 Subpart S and I

A well-documented program demonstrates due diligence and creates consistency in how electrical hazards are managed throughout the organization.

Arc Flash Risk Assessment Requirements

NFPA 70E 130.5 requires a formal risk assessment before employees perform any task near exposed energized parts. This process identifies hazards, estimates risk severity, and determines the protective boundaries necessary to prevent injury.

A complete assessment must include:

-

Identifying both arc flash and shock hazards

-

Calculating incident energy in cal/cm²

-

Defining approach boundaries (limited, restricted, and arc flash)

-

Documenting results with updated arc flash labels

-

Reviewing and updating every five years or when system changes occur

Arc flash labels must display voltage, incident energy, and PPE requirements so workers can easily understand the risk level. Arc flash labels communicate hazards and PPE requirements. Learn more.

Boundary Requirements

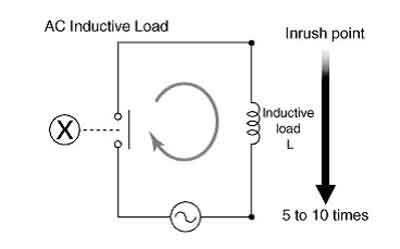

NFPA 70E defines specific approach boundaries to protect workers from electrical hazards. These boundaries determine how close a person can approach energized conductors or circuit parts without additional protective measures.

| Boundary | Purpose | Who May Enter | Requirements |

|---|---|---|---|

| Limited Approach | Prevent accidental contact | Qualified or escorted persons | Awareness + PPE as required |

| Restricted Approach | Higher shock risk | Qualified persons only | PPE + risk assessment |

| Arc Flash Boundary | Risk of second-degree burn | Qualified persons only | Full arc-rated PPE |

Safe Work Practice Requirements

NFPA 70E requires employers to enforce work practices that reduce exposure:

-

NFPA 70E requires employers to implement safe work practices that reduce exposure to electrical hazards and reinforce preventive safety culture.

Key practices include:

-

Lockout/Tagout (LOTO) and verification of de-energized equipment

-

Establishing an Electrically Safe Work Condition (ESWC) before maintenance or inspection

-

Conducting job briefings and hazard discussions before each task

-

Using insulated tools, barriers, and test equipment rated for the voltage involved

-

Requiring energized work permits only when de-energizing is not feasible

Following these practices ensures that workers understand their tasks, risks, and protective measures before performing any work around energized systems. See our article on verification steps.

-

OSHA and CSA Z462 Alignment

While NFPA 70E itself is not a federal law, it provides the technical roadmap for compliance with OSHA 29 CFR 1910 electrical safety requirements. In Canada, CSA Z462 mirrors NFPA 70E, harmonizing safety expectations across North America.

Employers that follow NFPA 70E demonstrate due diligence in preventing electrical injuries and reducing liability exposure. Proper implementation supports a compliant, safer, and more productive workplace.

Why Compliance Matters

Compliance with NFPA 70E Arc Flash Requirements is essential to:

-

Protect employees from life-threatening electrical incidents

-

Reduce costly downtime and equipment damage

-

Ensure regulatory compliance with OSHA and CSA Z462

-

Strengthen a culture of safety and accountability

Failure to comply exposes workers to preventable harm and employers to potential legal and financial consequences.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Frequently Asked Questions

What are the basic NFPA 70E arc flash requirements?

Employers must establish an electrical safety program, perform hazard and risk assessments, set approach boundaries, train workers, and enforce safe work practices to prevent arc flash and shock injuries.

How often must NFPA 70E training be completed?

Training is required initially for all qualified employees and must be refreshed at least every three years, or sooner if new equipment, updated standards, or workplace changes occur.

How are arc flash boundaries determined?

Boundaries are calculated based on system voltage, fault current, and clearing time to establish safe approach distances that prevent thermal or shock injury.

What changed in the 2024 edition of NFPA 70E?

New updates include mandatory hearing protection within the arc flash boundary, stronger ESWC requirements, clarified DC system provisions, and revised PPE and risk assessment tables.

Related Articles: