Transformer Cutout Fuse Explained

Protective Relay Training - Basic

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

A transformer cutout fuse is a critical component in electrical distribution systems, providing essential protection against overcurrent conditions and preventing damage to transformers and other equipment.

What is "transformer cutout fuse"?

A transformer cutout fuse is a protective device mounted on power poles to safeguard distribution transformers.

✅ Interrupts power during short circuits or overload conditions

✅ Allows linemen to isolate and safely service transformers

✅ Prevents transformer damage and enhances grid reliability

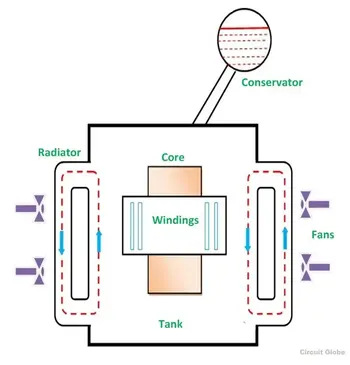

This device acts as a safeguard by disconnecting the transformer from the system in the event of a fault or surge, ensuring the safety and reliability of power supply networks. Distribution transformers is important in delivering electricity from the power grid to end users, especially in overhead distribution systems commonly seen in suburban and rural areas.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

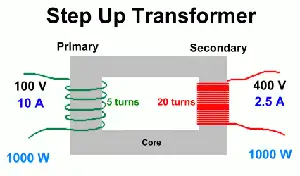

To ensure safety and protect equipment from faults, these systems often rely on a power fuse, which acts as a first line of defence against overcurrent conditions. One widely used design in such applications is the Type XS overcurrent protector, known for its reliability and compatibility with standard transformer cutout mounts, providing consistent performance in a variety of field conditions. Whether used in residential, commercial, or industrial settings, the transformer cutout overcurrent protector plays a vital role in minimizing the impact of electrical faults, reducing downtime, and protecting valuable infrastructure from catastrophic failures. Understanding the operation and maintenance of a transformer cutout overcurrent protector is key to ensuring long-term system efficiency and safety. For a comprehensive discussion on the different Types of Fuses and Overcurrent Protection Devices in electrical systems, you can check the dedicated page on overcurrent protection technologies.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

A pole-mounted fuse is a critical component of distribution protection systems in overhead electrical networks, designed to safeguard transformers and other equipment from overload conditions. At the heart of this setup is the fuse link, a replaceable element that melts when excessive current flows through, thereby breaking the circuit and preventing further damage. One common type used in these applications is the expulsion fuse, which extinguishes the arc by releasing gases generated from the fuse element itself. The fuse holder secures the fuse in place, allowing for easy inspection and replacement. Together, these components ensure effective fault current interruption, minimizing downtime and enhancing electrical safety in utility environments.

Types of Transformer Cutout Fuses

Transformer cutout fuses are available in two primary types: expulsion fuses and current-limiting fuses.

-

Expulsion fuses are widely used in overhead distribution systems. They interrupt overcurrents by creating an arc inside a tube, which is then extinguished by gases expelled from the burning fuse link material.

-

Current-limiting fuses, on the other hand, are designed to respond quickly to high fault currents. They limit the peak let-through current by opening the circuit before the fault reaches its maximum level. This makes them suitable for installations where rapid fault current interruption is required to protect sensitive equipment. Choosing the right fuse type depends on system voltage, fault current levels, and coordination with upstream and downstream devices.

How to Choose the Right Fuse Rating

Selecting the correct fuse rating is essential for reliable operation and transformer protection. The rating should be based on the transformer's full-load current, inrush characteristics, and the maximum short-circuit current at the point of installation. Underrated fuses may cause nuisance trips, while overrated fuses could fail to interrupt dangerous fault currents. Consult the manufacturer’s coordination tables and distribution protection guidelines to determine the optimal balance between protection sensitivity and equipment tolerance. Factors like kVA rating, system voltage, and the fuse link speed class (e.g., slow-blow vs. fast-acting) all play a role in proper selection.

Installation and Safety Tips

Proper installation of pole-mounted fuses is critical for system reliability and lineman safety.

-

Always de-energize the circuit before installation.

-

Use insulated tools and personal protective equipment (PPE) that comply with local safety standards.

-

Ensure that the fuse holder is clean, securely mounted, and aligned with the cutout arm.

-

Check for visible signs of wear or corrosion, especially on contact surfaces.

-

When replacing a blown fuse, verify the cause of the fault before re-energizing the system.

Regular maintenance checks can prevent unplanned outages and extend the lifespan of the fuse assembly.

Common Failure Modes and Troubleshooting

Although transformer cutout fuses are robust, failures can occur due to improper sizing, environmental conditions, or mechanical wear. Common issues include:

-

Premature fuse link melting from misapplied ratings or transformer inrush

-

Mechanical fatigue in the hinge or fuse holder leads to poor connections

-

Contamination from dust or wildlife interfering with the operation

-

Corrosion in humid or coastal environments causes contact resistance

Troubleshooting should begin with a visual inspection and a review of the load conditions before the failure. Replace the fuse with one of the same rating and check for recurring problems that may indicate upstream issues or load imbalance.

Frequently Asked Questions

What Is the Purpose of a Transformer Cutout Fuse?

The primary function of an overcurrent protector cutout is to protect distribution lines from surges and overloads that can occur during faults. When excessive current flows through the system, the fuse element within the device melts, interrupting the electrical path and preventing further damage to connected equipment.

Installed on feeder lines, the cutout acts as the first line of defence against dangerous conditions. By disconnecting the fuse holder, the system isolates the affected section, preventing damage from spreading across the entire network. This selective disconnection ensures that only the faulty area is impacted, which helps maintain stability in the larger distribution system. Fuse Cutouts and Their Functionality are important to understand the flow of electricity well.

Test Your Knowledge About Electrical Protection!

Think you know Electrical Protection? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

How Does a Transformer Cutout Fuse Work?

A fuse cutout operates through several key components, including the fuse tube, fuse link, and polymer insulator. When a fault occurs, the overcurrent protector link melts, interrupting the flow of current. This process prevents the electrical surge from damaging other critical elements in the system.

To safely remove the overcurrent protector holder for replacement, technicians often use a hot stick, allowing them to avoid direct contact with live electrical parts. Once the faulty overcurrent protector is removed, the system is ready for maintenance or inspection, preventing further risks from live components.

What Are the Typical Ratings?

The ratings for an overcurrent protector cutout depend on the specific application, including the current and voltage requirements of the system it protects. For example, cutouts typically range from 10 to 100 amps, with voltage ratings ranging from 5 kV to 35 kV. The correct rating ensures that the protection device responds appropriately to faults without disrupting normal system operations.

The ratings must align with the system's needs to ensure that it can handle both regular operations and fault conditions. Selecting the right overcurrent protector element is crucial for balancing the system's safety with operational efficiency.

When Should a Transformer Cutout Overcurrent Protector Be Replaced?

An overcurrent protector cutout requires replacement when the fuse element has melted due to an overcurrent condition. This indicates that the overcurrent protector has successfully protected the system, but a new one must be installed to restore protection. Routine inspections of the cutout and other components, such as the polymer insulator and upper contact, ensure that the system remains in good working order.

Maintenance should also include checking for signs of wear, corrosion, or damage to ensure reliable performance. Replacement is critical when any signs of degradation are detected.

What Are the Consequences of a Blown Transformer Cutout Overcurrent Protector?

A blown-overcurrent protector cutout leads to an interruption in power to the affected area of the distribution line. The cutout isolates the faulted section, allowing the rest of the system to function normally. However, power will remain disconnected in the impacted area until the overcurrent protector is replaced.

If the blown-overcurrent protector is not replaced promptly, it can lead to extended outages and potential operational issues. In some cases, a blown overcurrent protector can indicate an underlying fault, such as a transformer overload or short circuit, that needs further investigation before power can be safely restored.

The overcurrent protector cutout is an indispensable protection device in electrical systems, ensuring that feeder lines and distribution equipment are safeguarded from faults and surges. By understanding how this device works, when it needs to be replaced, and how it interacts with the larger electrical network, system operators can ensure reliable and safe operations.

Regular inspections, selecting the appropriate overcurrent protector rating, and promptly replacing blown overcurrent protectors are essential for ensuring that electrical systems remain efficient and safe. Proper management of these devices helps minimize downtime and protects both equipment and personnel from dangerous conditions.

For a more detailed explanation of transformer protection devices, visit our article on the role of transformer protection and short circuit protection in safeguarding electrical equipment.

Related Articles