Resistive Load In Power Systems

By R.W. Hurst, Editor

Substation Grounding Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3873 Fact Sheet – Minimum Approach Distance and Training Requirements

- Calculate MAD using voltage and overvoltage values

- Ensure proper communication between host and contract employers

- Meet OSHA training requirements for qualified electrical workers

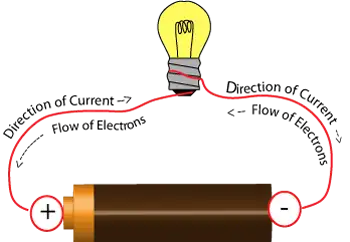

A resistive load consumes electrical energy without storing it, converting it entirely into heat or light. Power factor for resistive loads is 1.0, as voltage and current remain in phase, indicating maximum efficiency and no reactive power.

What is "Resistive Load"?

A resistive load uses electrical power with no reactive components like inductance or capacitance.

✅ Converts energy directly into heat or light (e.g., heaters, incandescent bulbs)

✅ Voltage and current are always in phase

✅ Power factor equals 1.0, ensuring full energy efficiency

Power Quality Analysis Training

Request a Free Power Quality Training Quotation

Common applications of resistive components include heating elements, incandescent light bulbs, and some types of electric motors. To understand how components differ from magnetic or coiled devices, you need to check the explanation of inductive loads. Electric motors are a prime example of devices that involve both inductive and capacitive components, making them important to consider in power system analysis. When electric motors operate, they not only consume real power but also draw reactive power, which can distort current and voltage sine waves if not properly managed. In a steady-state condition, understanding the balance between inductive and capacitive components helps engineers optimize performance and minimize energy loss. Proper analysis of these parameters ensures efficient operation and reduced strain on the electrical infrastructure.

One of the essential principles governing components is Ohm's Law, which states that the current (I) passing through a resistor is directly proportional to the voltage (V) across it and inversely proportional to its resistance (R). Mathematically, this can be represented as I = V/R. This law helps us understand the relationship between voltage, current, and resistance in a purely resistive component.

Test Your Knowledge About Power Quality!

Think you know Power Quality? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Power dissipation is a critical aspect of components. In these components, electrical energy is primarily converted into heat. Power dissipation (P) can be calculated using the formula P = V x I, where V is the voltage across the component, and I is the current flowing through it. Another useful formula for power dissipation is P = I² x R, which highlights the relationship between power, current, and resistance.

A resistive load (RL) comes with its own set of advantages and disadvantages. One significant advantage is their simplicity: as they follow Ohm's Law, the behaviour of components is more predictable and easier to analyze than other component types. Additionally, they exhibit a power factor of one, indicating that power flows smoothly and efficiently throughout the system.

On the downside, components generate more heat than other types, leading to energy loss and potential hazards. Furthermore, resistive heating can cause devices to wear out more quickly, necessitating more frequent maintenance. Since the component affects power factor differently than other component types, engineers and technicians need to understand motor power factor and how to improve it.

Energy efficiency is an essential consideration when working with a RL. Due to their nature of consuming electrical energy without storing it, resistive components typically have a lower energy efficiency than other component types. However, this drawback can be mitigated through proper design and management of the power system, such as incorporating circuit breakers and monitoring power flows to minimize losses.

Safety is a crucial aspect when dealing with component banks. The heat generated can cause burns, fires, or damage to nearby components. To ensure safety, it is essential to employ appropriate protective measures, such as proper insulation and temperature monitoring, and to avoid overloading the system.

Common Resistive Load Examples in Real-World Applications

Resistive loads are widespread in both residential and industrial settings. Understanding common examples helps clarify their role in power systems.

-

Electric heaters and toasters are classic household devices that convert electrical energy directly into heat.

-

Incandescent light bulbs are another example, producing light via the resistive heating of a filament.

-

In industrial applications, resistance welding machines and electric ovens are powered by high-resistance elements for heat generation.

These examples demonstrate how a RL operates without significant reactive components, thereby simplifying energy calculations and system design.

Devices like electric heaters, toasters, and incandescent bulbs fall under the category of ohmic or components, where electrical energy is transformed directly into heat. These elements operate in perfect phase with current and voltage, resulting in a power factor of 1.0. Due to this simplicity, they play a crucial role in systems where precise power calculations and thermal output are crucial. Their behaviour contrasts with inductive or capacitive loads, which introduce complexity through reactive elements.

Electrical Heating Elements and Their Role

Electrical heating elements are purpose-built resistive devices that convert electrical energy into thermal energy.

-

Typically made from materials like nichrome, these elements are found in water heaters, space heaters, and industrial furnaces.

-

They are designed to maintain stable resistance even under high temperatures, which ensures consistent energy output.

The efficiency and predictability of electrical heating elements make them essential in temperature control systems and power quality management.

How Resistive Loads Affect Power Factor

Unlike inductive or capacitive loads, a resistive load does not cause a phase shift between voltage and current.

-

As a result, the power factor in purely resistive circuits is unity (1.0), meaning all power drawn from the source is used effectively.

-

This characteristic makes RLs ideal for simplifying power quality analysis and reducing energy losses.

In mixed-load environments, managing power factor often involves balancing resistive loads with corrective measures, such as capacitor banks. Capacitive loads can also play a major role in balancing out the effects of resistive and inductive components— capacitive load behavior.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Comparing Resistive Loads with Inductive and Capacitive Loads

To grasp RL behaviour, it helps to contrast it with other common load types:

-

Inductive loads (e.g., motors, transformers) introduce a lagging power factor due to energy stored in magnetic fields.

-

Capacitive loads (e.g., capacitor banks, certain electronic devices) can result in a leading power factor.

-

RLs, by contrast, consume power directly as heat or light without storing it.

Understanding these distinctions is crucial for system designers aiming to optimize performance and efficiency across varied electrical environments.

Challenges and Considerations When Managing Resistive Loads

Though simple in behavior, resistive loads present unique considerations in electrical system design.

-

Large RLs can cause high inrush currents during startup, necessitating the use of protective devices.

-

Continuous use may lead to overheating or thermal fatigue in components, especially in high-power systems.

-

Managing load distribution and ensuring adequate wiring and fuse protection are essential for safe operation.

Careful planning around these challenges ensures reliability and compliance with electrical safety standards.

They are vital in various electrical systems and applications. Therefore, understanding their properties, such as Ohm's Law, power dissipation, and energy efficiency, is crucial for engineers and technicians. Furthermore, by carefully considering the advantages and disadvantages of components and implementing safety measures, it is possible to harness their full potential while minimizing potential risks. For a broader understanding of how different types of resistive components impact power quality, engineers and technicians should review the fundamentals of power quality and system design.

It is essential to note that components are inefficient and consume a significant amount of energy. Therefore, understanding the different types of electrical components is essential for managing power consumption and ensuring the efficient operation of electrical systems. In addition, other components require different management strategies, and power factor correction may be necessary to optimize energy efficiency.If you're curious about how components compare to other electrical loads used in real-world settings, don’t miss our overview of examples of load devices in electrical systems.