ArizonaÂ’s last new coal plant?

SPRINGERVILLE, ARIZONA - Salt River Project customers will begin paying about $6 more on their monthly bills this spring, most of which will pay for a new $1 billion coal-fired power plant near Springerville in northern Arizona.

Unit 4 at the Springerville Generating Station began commercial operations in December and has been running at full throttle since then, burning about 60 rail cars' worth of coal a day from the Powder River Basin in Wyoming.

The plant supplies low-cost electricity to the non-profit utility, but because of the stiff fight required to get it built, cost overruns and threat of global warming, some experts wonder if it will be the last new coal plant built in Arizona.

Not only did the plant overshoot its original cost estimate by $350 million, but legislation proposed by Congress to limit greenhouse-gas pollution could also make running the plant even more expensive, because coal has more of those emissions than natural gas or other power sources.

David Areghini, SRP's associate general manager of power, said it would be nearly impossible to permit another coal-fired plant.

Arizona Public Service Co. has ruled out more power from coal unless there is a way to handle the carbon-dioxide emissions that contribute to climate change. Tucson Electric Power Co. also is proposing ways to meet energy demand without new coal plants.

"Most people will tell you, unless something changes, there probably won't be another coal plant," said Bill Rihs, the manager of major projects for SRP who oversaw Unit 4's construction. "That depends a lot on future regulations like cap-and-tax (greenhouse-gas legislation), which doesn't make it attractive for us or anyone else to develop a coal plant."

It's clear from the way SRP announced the Springerville plant that utilities view coal as a necessary evil needed to provide around-the-clock power, while generating environmental controversy.

When SRP announced Unit 4's commercial operations in December, it simply sent a press release stating the coal plant was up and running.

It hardly compared with the fanfare that greeted the state's first wind farm a couple of months prior, even though the coal plant cost 10 times as much and will generate about 25 times the amount of power throughout the year.

The Dry Lake Wind Power Project is in the same area and also sends all its electricity to SRP. The dedication ceremony drew political dignitaries from across the state and even U.S. Secretary of the Interior Ken Salazar. But getting Unit 4 built at Springerville was arguably a much larger accomplishment for SRP, considering the effort it took.

SRP and Tri-State Generation and Transmission of Denver had to pay to add environmental controls to Springerville's Units 1 and 2 before getting the required Environmental Protection Agency permits to build Units 3 and 4. SRP's share of the upgrades was $28.8 million.

Tucson Electric Power finished the first two units in 1985 and 1990, and the third opened for Tri-State in 2006.

SRP takes 100 megawatts from Unit 3 and all 400 from Unit 4, which is enough to power about 100,000 homes.

With the power from Unit 4, SRP has been able to shut down some of its natural-gas burning plants in the Phoenix area for the winter because their power is not needed.

"This is much less expensive to run," Rihs said.

Electricity from Unit 4 costs 30 to 50 percent less than energy SRP would have to buy on the market, according to SRP.

Unit 4 also has a $2 million silo that will use a carbon-injection system to clean mercury emissions from the plant, but it is not used yet because it is not required. The expansion with Units 3 and 4 faced opposition from environmental groups such as the Grand Canyon Trust in Flagstaff.

To get the new plant built, SRP also agreed to set aside a $5 million fund for renewable-energy projects in northern Arizona, and the Grand Canyon Trust is helping the utility decide which projects the money will fund.

"Even though we intervened to stop the construction and we lost, the settlement contained important concessions," said Roger Clark, a program director with the Grand Canyon Trust, which fought the permit at the Arizona Corporation Commission and also challenged the permit in court.

"They had to clean up the old plants and make the new ones less dirty, and create the renewable-energy investment fund," he said.

Unit 4 was originally estimated at $643 million but it was built during a time when labor and material prices escalated quickly, Areghini said.

First SRP added about $78 million in design improvements from the similar Unit 3 that had just been constructed.

SRP also paid about $100 million more to build the plant on a short schedule, and the escalating price of labor and materials during the 2005-06 timeframe cost an additional $188 million, he said.

When compared with coal-fired plants that were commissioned and completed in the same time period, from Arkansas, Wyoming, Kansas, Colorado, Texas and other locations, Areghini said Springerville's costs were average and that overruns were common at the time because of labor and material prices.

"The industry was extremely busy," Areghini said. "Even (Hurricane) Katrina carryover was sopping up labor."

But critics said the plant was a poor choice.

"From a cost standpoint, they never get it right... and it is not currently needed to meet the needs on SRP's system," said Tim Hogan, director of the Arizona Center for Law in the Public Interest.

Hogan's group acts as a watchdog of SRP's power rates and he also served as the attorney for the Grand Canyon Trust and the Land and Water Fund of the Rockies when they challenged the permit for Unit 4 in the early 2000s.

"At the time, it was clear there was going to be some form of additional expense associated with carbon, and they didn't factor that in at all," Hogan said.

Clark said that with coal-fired plants in New Mexico, Nevada and Pennsylvania struggling with their permits or being canceled, it's unlikely Arizona will see another after Springerville.

"The cumulative risk associated with carbon that includes everything from mercury to the water needed to run the plant, to liabilities to deal with coal combustion waste all are uncertain and increasing liabilities to existing plants' future," he said. "And they certainly are there in spades for new plants."

Related News

Idaho gets vast majority of electricity from renewables, almost half from hydropower

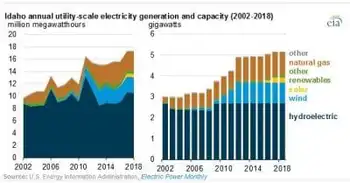

BOISE - More than 80% of Idaho’s in-state utility-scale electricity generation came from renewable resources in 2018, behind only Vermont, according to recently released data from the U.S. Energy Information Administration’s Electric Power Monthly.

Idaho generated 17.4 million MWh of electricity in 2018, of which 14.2 million MWh came from renewable sources. Idaho uses a variety of renewable resources to generate electricity:

Hydroelectricity. Idaho ranked seventh in the U.S. in electricity generation from hydropower in 2018. About half of Idaho’s electricity generating capacity is at hydroelectric power plants and seven of the state’s 10 largest power plants (in terms of electricity generation)…