Glass Electrical Insulators in T&D

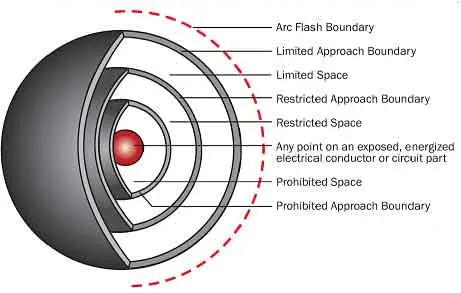

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

Glass electrical insulators support and separate conductors in power lines, preventing unwanted current flow. Known for high dielectric strength and durability, they resist weathering and mechanical stress, ensuring reliable performance in transmission and distribution.

What are Glass Electrical Insulators?

Glass electrical insulators are non-conductive components used in power systems to suspend and isolate energized conductors.

✅ Provide strong dielectric insulation and mechanical stability

✅ Resist environmental stress, UV exposure, and contaminants

✅ Commonly used in high-voltage transmission and distribution networks

Glass insulators are essential components in modern power systems, ensuring the safe and reliable flow of electricity from generating stations to consumers. Their role is not only to hold conductors but also to prevent leakage currents and flashovers. Understanding their properties, applications, and maintenance is crucial for utility professionals who design and operate reliable networks. To understand the role of glass electrical insulators in the grid, begin with an overview of long-distance power transmission and the planning and maintenance of transmission lines.

Comparison of Electrical Insulator Types

| Feature | Glass | Porcelain | Polymer |

|---|---|---|---|

| Material Composition | Toughened glass | Clay, quartz, feldspar | Composite (fiberglass & silicone) |

| Dielectric Strength | Very high | High | Moderate to high |

| Mechanical Strength | Excellent tensile strength | Strong, brittle under impact | Flexible, resistant to breakage |

| Weather Resistance | Excellent UV and water resistance | Good, can degrade over time | Excellent, designed for outdoors |

| Weight | Heavier than polymer | Heaviest of all | Lightest option |

| Contamination Performance | Self-cleaning via surface runoff | May require maintenance | Hydrophobic, sheds water easily |

| Visibility of Damage | Fractures are easy to detect | Hidden internal cracks possible | External sheath may hide damage |

| Cost | Moderate | Moderate to high | Low to moderate |

| Lifespan | 40–50 years | 30–50 years | 25–35 years |

| Typical Application | Transmission & sub-transmission | Substations & older installations | Distribution lines & coastal areas |

Dielectric and Mechanical Properties

Glass insulators excel due to their high dielectric strength, which enables them to withstand elevated voltages without breaking down. This reduces the risk of short circuits and ensures safe operation. Their performance depends on glass composition, thickness, and surface condition. Equally important is mechanical strength. Toughened glass offers high tensile resistance, withstanding conductor loads, wind pressure, and ice accumulation. These combined properties make glass insulators particularly reliable in high-voltage environments. For fundamentals and material choices that influence glass, porcelain, and polymer, review the primer on electrical insulators.

Electric Field and Creepage Distance

A key design factor is creepage distance—the surface path along the insulator that leakage current might follow. Contamination reduces creepage performance, increasing the risk of flashover. For transmission systems, the design typically requires creepage ratios of 25–31 mm/kV. Voltage distribution across insulator strings must also be balanced; otherwise, stress concentrates on certain discs. Utilities often use grading rings to improve field distribution and reduce corona. Because leakage and flashover risks grow with span length and voltage, compare insulation needs on AC transmission lines.

Test Your Knowledge About Overhead T&D!

Think you know Overhead T&D? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Failure Modes and Reliability Issues

Despite their strengths, glass insulators are not immune to failures. A well-documented phenomenon is self-blast—spontaneous shattering due to internal impurities or thermal stress. Microcracks, aging, and partial discharge can also degrade performance. While shattering does not usually cause outages—because the cap-and-pin hardware still holds—the damaged “stub” alters electrical behavior and increases stress on the remaining discs. Utilities rely on infrared thermography, UV cameras, and periodic inspection to detect defects early and avoid cascading failures.

Testing and Standards

Glass insulators undergo rigorous testing under IEC and ANSI/IEEE standards. Key tests include:

-

Power-frequency withstand voltage (IEC 60383)

-

Lightning and switching impulse tests

-

Pollution performance tests (IEC 60507, IEC 60815)

-

Mechanical tensile and bending strength tests

-

Thermal cycle and aging tests

-

Salt fog and dust chamber contamination tests

These assessments ensure long-term reliability under electrical, mechanical, and environmental stresses.

Applications of Glass Insulators in Different Voltage Levels

Glass insulators are widely used from low-voltage distribution to ultra-high-voltage transmission. Pin-type insulators serve lower voltages, while suspension discs—linked in strings of 10–12 discs for a 400 kV line—handle higher voltages. Strain insulators manage tensile forces at line ends and angles. Post insulators are common in substations. Each design addresses specific electrical and mechanical demands. On the distribution side, insulator selection is directly tied to topology and contamination levels, as covered in electric power distribution and deeper system design in electrical distribution systems.

Environmental Impact of Glass Insulators

Glass offers environmental advantages compared to porcelain and polymers. It is made from abundant raw materials and is 100% recyclable. Although energy-intensive to produce, its long service life and recyclability reduce its lifecycle impact. Studies also show that glass insulators maintain their surface properties over decades, thereby reducing the need for maintenance. A foundational overview of materials and construction can be found in the article on the electrical insulator.

Innovations and Coatings

Modern developments include glass insulators with hydrophobic surface coatings to improve pollution performance, hybrid assemblies combining glass and polymer, and anti-pollution profiles tailored for coastal or desert regions. These innovations extend lifespan, reduce cleaning cycles, and lower the risk of self-blast.

Case Studies and Field Experience

Long-term field studies, such as GCCIA’s evaluation of coated glass insulators after 15 years of service, report low failure rates and excellent resistance to contamination. Utilities note that visible breakage makes inspection easier than with porcelain or polymer, where hidden defects can persist unnoticed.

Economics and Market Trends

Global demand for glass insulators is increasing with the growth of renewable energy integration and transmission expansion. While initial costs are moderate, lifecycle benefits—long lifespan, low maintenance, and recyclability—make glass attractive compared to polymers that may degrade faster. Market reports indicate glass remains dominant in transmission, while polymers expand in distribution. Utilities also consider using monitoring devices, such as fault indicators, to complement insulator inspection and maintenance.

Installation and Maintenance

Proper installation ensures maximum performance. Insulators must be aligned to minimize mechanical stress and installed with the correct torque on the hardware. Best practices include live-line inspection, periodic cleaning in polluted areas, and prompt replacement of shattered units. Preventive maintenance is critical to sustaining high reliability.

Best Practices

Glass insulators combine high dielectric strength, mechanical durability, and environmental resilience. Their visible failure modes simplify inspection, while their recyclability supports sustainability goals. Challenges include weight, impact vulnerability, and risk of self-blast, but innovations and coatings are reducing these limitations. For high-voltage transmission, glass remains one of the most reliable insulator options, provided utilities follow rigorous installation, testing, and maintenance protocols. In AC networks, insulators play a vital role in supporting AC transmission lines and preventing leakage currents under high stress.

Sign Up for Electricity Forum’s Overhead T&D Newsletter

Stay informed with our FREE Overhead T&D Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Frequently Asked Questions

What are the advantages and disadvantages of glass insulators?

Glass insulators provide high dielectric strength, long lifespan, and recyclability. Drawbacks include weight, brittleness, and susceptibility to vandalism.

What is creepage distance, and why is it important?

Creepage distance is the surface path along the insulator that leakage current can travel. Adequate creepage ensures resistance to flashover in polluted or wet environments.

What tests ensure the reliability of glass insulators?

Tests include power-frequency withstand, impulse tests, tensile and bending strength, and pollution performance under IEC 60383 and related standards.

What happens when a glass insulator shatters?

The insulator becomes a stub. The line remains mechanically intact, but electrical stress increases on adjacent discs, so damaged units must be replaced.

When should glass be chosen over porcelain or polymer?

Glass is preferred for high-voltage lines where durability, recyclability, and the ability to detect visible failures are priorities. Polymers are better suited for lightweight distribution applications or in regions with heavy salt fog.

Related Articles