Electrical Insulator

By R.W. Hurst, Editor

Download Our NFPA 70E Fact Sheet – 2024 Electrical Safety Edition

- Understand how NFPA 70E works with NEC and NFPA 70B standards

- Clarify the shared responsibility between employers and employees

- Learn how NFPA 70E supports OSHA compliance

An electrical insulator prevents the unwanted flow of current by providing high resistance between conductive parts. Essential in power transmission systems, these materials ensure isolation, enhance safety, and protect equipment from arcing and short circuits.

What is an Electrical Insulator?

An electrical insulator is a vital component in T&D systems, ensuring safety and reliability. However, it comes in various materials and types, each with advantages and disadvantages.

✅ Provides electrical isolation in high-voltage systems

✅ Made from dielectric materials like porcelain or polymer

✅ Prevents arcing and protects conductors from short circuits

Understanding the insulating properties of dielectric materials, resistance, and breakdown voltage is essential for selecting the most suitable non-conductive material for a specific application. By making informed choices, engineers can ensure the longevity and safety of transmission and distribution (T&D) installations and equipment.

An electrical insulator is a material that restricts the flow of electric current, ensuring that electric charge does not easily pass through it. They are essential components in power systems, as they help protect equipment, structures, and people from electric shocks and short circuits. A high-quality electrical insulator possesses high resistivity, which means it can withstand high voltages without allowing current to flow unimpeded.

High Voltage Transmission Uses

High-voltage power transmission insulating devices are typically made from materials such as glass, porcelain, or composite polymers. Porcelain types consist of clay, quartz or alumina, and feldspar and feature a smooth glaze that allows water to run off easily. When high mechanical strength is required, porcelain rich in alumina is utilized. Porcelain ones have a dielectric strength of around 4–10 kV/mm. Glass types possess a higher dielectric strength; however, they tend to attract condensation, which can result in thick, irregular shapes that are necessary for non-conductive insulating devices. These shapes can lead to internal strains.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Consequently, some manufacturers ceased producing glass ones in the late 1960s, opting instead for ceramic materials.

Electric utilities sometimes use polymer composite materials for certain types of insulators. These typically consist of a central rod of fibre-reinforced plastic and an outer weather shield made of silicone rubber or ethylene propylene diene monomer (EPDM) rubber. Composite non-conductive materials are more cost-effective and lightweight, exhibiting exceptional hydrophobic properties. This combination makes them ideal for use in areas with high pollution levels. However, these materials have not demonstrated the same long-term service life as their glass and porcelain counterparts.

Different Materials

Different types of electrical insulator are designed to cater to various applications and environments. They are classified based on the material used, such as ceramic, glass, and polymer insulators. Each type has specific insulating properties that make it suitable for certain uses.

Dielectric materials are a crucial component of any electrical insulator. They function by inhibiting the electric field within their structure, preventing the flow of a charge. A dielectric material's insulating properties are primarily determined by its dielectric constant, which measures its ability to store energy without conducting it.

Ceramic ones, such as porcelain, have been used for many years due to their excellent insulating properties, mechanical strength, and resistance to high temperatures. They are typically used in high-voltage applications, including power transmission and distribution systems. However, they can be heavy and brittle, which reduces durability and increases maintenance costs.

Materials such as glass paper, on the other hand, offer excellent transparency and a smooth surface that helps prevent dirt accumulation. They also have high dielectric strength, meaning they can withstand high voltage without breaking down. However, like ceramic ones, they are fragile and prone to breakage.

Polymer insulators are a recent innovation made from silicone rubber or epoxy resins. They are lightweight, durable, and have good insulating properties. Additionally, polymer devices exhibit increased resistance to environmental factors, including UV radiation and pollution. However, their long-term performance still needs to be studied, and they may be more expensive than traditional ceramic or glass insulators.

Performance is affected by its resistance and breakdown voltage. Resistance measures a material's ability to prevent the flow of electric current. A higher resistance means that the insulating device is more effective at blocking the flow of electricity. On the other hand, the breakdown voltage is the maximum voltage an insulator can withstand before it fails and allows electric current to flow through it. Therefore, a higher breakdown voltage indicates better insulating capabilities.

Electrical insulators play a crucial role in power transmission and distribution systems. They support and separate conductors, ensuring that the electric field and current remain confined within the conductors. They also help maintain the integrity of the wiring and prevent short circuits or leakage currents that may cause equipment damage or pose safety risks.

Several factors should be considered when selecting an electrical insulator for a specific application, including the operating voltage, environmental conditions, and mechanical stresses. The non-conductive material should possess a high dielectric constant, good resistance to temperature changes, and adequate mechanical strength. Additionally, it should resist environmental factors such as moisture, pollution, and UV radiation.

Various Types

Pin Insulator - This type is attached to a pin mounted on the cross-arm of a utility pole. It features a groove near its top, just below the crown, through which the conductor runs and is fastened using an annealed wire made of the same material as the conductor. Pin insulators are commonly used to transmit communication signals and electric power at voltages of up to 33 kV. However, they can become bulky and uneconomical for operating voltages between 33 kV and 69 kV.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Post Insulator - Introduced in the 1930s, they are more compact than traditional pin-types. They have rapidly replaced many pin-types in lines with voltages up to 69 kV and, in some configurations, can be designed for operation at up to 115 kV.

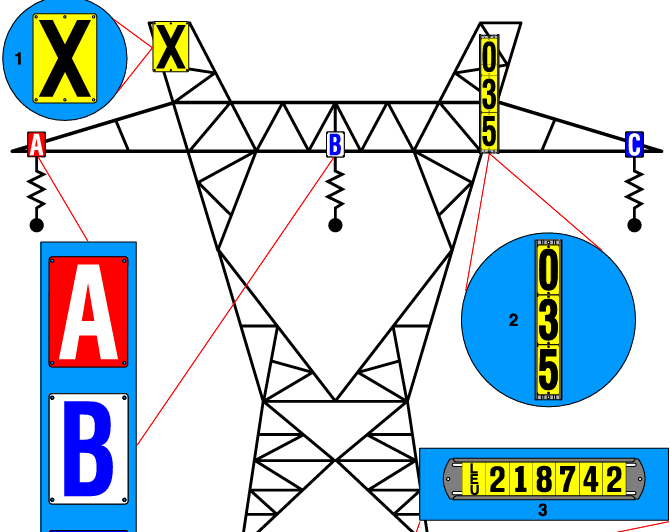

Suspension Insulator - Suspension devices are typically utilized for voltages exceeding 33 kV. They consist of a series of glass or porcelain discs linked together with metal connectors, forming a string. The conductor is suspended from the bottom of this string, while the top is secured to the tower's cross-arm. The number of disc units required depends on the voltage.

Strain Insulator - When a straight section of a transmission line ends or changes direction, a dead-end or anchor pole or tower is employed. These structures must withstand the lateral (horizontal) tension from the long straight section of wire. Strain devices are used to support this load. For low-voltage lines (under 11 kV), shackle ones are strain insulators. For high-voltage transmission lines, cap-and-pin (suspension) insulator strings are used, mounted horizontally to the crossarm. In cases of extremely high tension, such as long river spans, two or more parallel strings may be necessary.

Shackle Insulator - Initially, shackle types were employed as strain insulators. Nowadays, they are predominantly used for low-voltage distribution lines. These can be installed in horizontal or vertical orientation and can be directly fastened to the pole with a bolt or to the crossarm.

Related Articles