Power Transformers Health Check- Human Analogy

By Ali Naderian, PhD, PEng, Int. PE,<BR>METSCO Energy Solutions

Substation Maintenance Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA FS3529 Fact Sheet – Lockout/Tagout Safety Procedures

- Learn how to disable machines and isolate energy sources safely

- Follow OSHA guidelines for developing energy control programs

- Protect workers with proper lockout devices and annual inspections

Power transformers health check leverages condition monitoring, diagnostics, DGA oil analysis, thermography, and predictive maintenance to assess insulation integrity, detect faults, optimize reliability, reduce risk, and extend asset life-cycle across critical grids.

What Is Power Transformers Health Check?

A diagnostic assessment using DGA and thermography to evaluate transformer condition, reliability, and risk.

✅ DGA, oil quality, and moisture analysis

✅ Infrared thermography and partial discharge testing

✅ Risk scoring, compliance, and maintenance planning

Power transformers are static electric machines used to step-up or step-down voltage in electric power applications. The capital cost of a power transformer in the range of 100MVA can be $1M or more and by the time it is under operation, the price is increased. The average age of installed large power transformers (LPTs) in the United States is approximately 45 years, with 70 percent of LPTs being 30 years or older. The lead time of LPTs can vary from 1 year to 2 years. Many transformers are approaching the end of their technical life and most have reached the end of their financial life. While the life expectancy of a power transformer varies depending on the design and how it is used, aging power transformers are subject to an increased risk of failure. Utilities increasingly apply health index based asset management to prioritize replacements and justify risk-informed investment plans.

The challenge facing today’s power industry, especially during the COVID-19 era, is in leveraging the most out of existing assets without reducing customer service. The funds for replacing the assets may be subjected to adjustment which can cause delays in new installations or refurbishment. This requires the asset owners, operations, and maintenance to fully understand the condition of old and often highly loaded LPTs. Effective planning starts with structured evaluation of transformers that aligns testing programs with system reliability objectives.

Test Your Knowledge About Utility Transformers!

Think you know Utility Transformers? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

There have been several analogies associated with the human body in the electrical and mechanical world. As an example, the human body is like an engine that continuously generates large quantities of heat, and its radiator disperses heat least effectively in hotter climes. It is likely that most of the readers of this article have personal experience with basic human body diagnostics and are familiar with some of the health tests. I have used the analogy of human test to explain or teach power transformer diagnostics and it has been a success. Here I try to provide a summary of using the human analogy for diagnostics of power transformers.

The objective of this article is to help younger engineers, non-engineers, and others in the energy sector who do not have extensive background on power transformers to understand the importance of the diagnostics and testing concepts used for power transformers condition assessment. It is not meant to explain the details of the diagnostic tests; rather giving a high-level introduction.

Transformer DGA v.s. Blood Test.

Dissolved Gas Analysis (DGA) is a diagnostic technique like your medical blood test check-up that is applied to power transformers. DGA is a very effective and strong and has been used for more than 50 years to prevent thermal and electrical failures. Degeneration of transformer oil generates various types of gases, most important gases include H2 – hydrogen, CH4 – methane, C2H4 – ethylene, C2H6 – ethane, C2H2 – acetylene, CO – carbon monoxide, and CO2 – carbon dioxide. DGA is done on a yearly basis for healthy large power transformers. The more frequent test may be required if there is any defect detected. Understanding the chemistry of transformer oil helps interpret gas generation mechanisms and set appropriate sampling intervals.

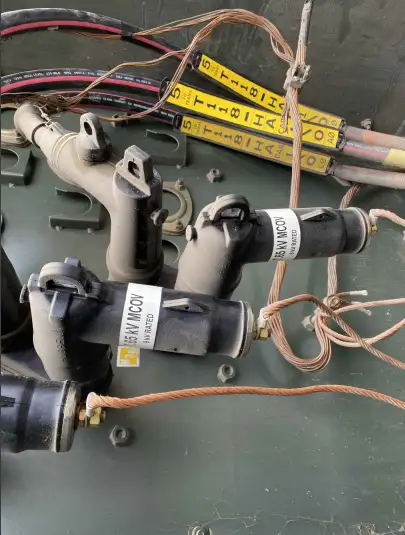

Similar to the blood test, a syringe of oil sample is taken from the transformer to be sent to a laboratory for analysis. A larger oil sample in a jar is also taken along with the syringe sample for further analysis. The analogy for the jar sample could be the urine sample that is used to reveal other health information. Field sampling and visual checks are supported by inspection windows and maintenance access practices that improve safety and data quality.

DGA is one of the most widely used diagnostic tools for transformer condition assessment because experience has proven it to be a very effective tool. The newly revised IEEE C57.104-2019 provides the latest best industry practice for interpretation of DGA. Similar to a blood test, DGA has limitations that one has to be careful to get a meaningful test result. Collecting samples incorrectly, misidentification, inaccuracy of test equipment, and multiple phenomena occurring at the same time can affect the test results. Modern analytics leverage feature selection techniques for health indices to combine DGA with other test results for stronger diagnostics.

Heat Run Test v.s. Exercise Stress Test

Heat run test, also called temperature rise test, is a part of the Factory Acceptance Test (FAT) conducted in an HV laboratory equipped with large power sources to verify the performance of the transformer at full-load or simulate short overload conditions. This test is also common for many other electrical assets such as motors, generators, switchgear, cables, etc. Test outcomes also inform transformer design considerations around cooling, windings, and materials for future procurements.

One can notice the similarity of heat run test with the human exercise stress test. An exercise (cardiac) stress test is used to determine how well your heart responds during times when it is working its hardest. Like heat run that several sensors are attached to the transformer tank to monitor the transformer, during cardiac test the heart's ability to respond to external stress in a controlled clinical environment is measured.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Transformer Heat Run Test vs Cardiac Stress Test

Furan Test v.s. Urine Protein Test

Furan test is a diagnostic technique to estimate the degradation of transformer paper insulation. The cellulosic insulation degradation produces furan (2-furaldehyde) and other byproducts that is released to oil. On the other hand, urine protein test measures the amount of protein present in urine. Healthy people don't have a significant amount of protein in their urine. However, protein may be excreted in the urine when the kidneys are not working correctly or when high levels of specific proteins are present in the bloodstream. Similar to a urine protein test, an oil sample is collected in a jar and the sample is sent to the lab for byproduct analysis. As a rule of thumb, a transformer with 0.1 ppm furan has a normal thermal aging and a healthy insulation condition. If the furan gets to 1ppm, further investigation is required. If the measured furan is 10 ppm, the transformer is probably close to the end of life. Furan trends should be correlated with transformer insulation fundamentals to estimate paper aging and residual life.

Summary of Power Transformer & Human Body Analogy

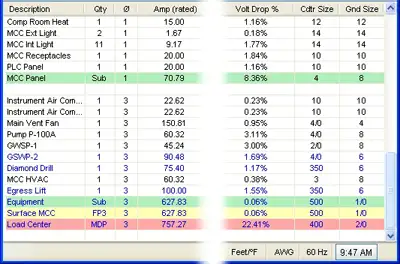

There are several other basic or advanced diagnostic tests for power transformer condition assessment which are similar to human body. The summary is presented in the table below, including oil voltage breakdown, SFRA, DFR, partial discharge test, and degree of polymerization (DP).

Similar to a medical doctor, a transformer specialist more likely to recommend starting the condition assessment with basic tests and then do more advanced tests if required. By putting the results of multiple tests, the transformer specialist can determine the possible defect, fault, or health condition of the power transformer.

In many cases, this requires "re-rating" the transformer's planned loading capacity for normal and contingent operation. In many cases, use of these planned loading limits may be dependent on the condition of the unit. Refurbishment or options for enhancing transformer performance to reduce temperature, increase life and/or increase load capability are often considered as O&M options to defer capital spending on new equipment.

600MVA Generating Plant Transformer, Acoustic Emission PD simulation based on actual onsite AE monitoring to reveal internal faults

The health check and condition assessment of power transformers is critical to the security and stability of power system operation. Similar to human, the frequency of checkup and attention required can naturally increase by the age of the asset. During the last decades, major works have been being carried out for the development of reliable and accurate condition assessment techniques such as online monitoring. It is recommended to consider such techniques for the critical assets.

It is expected that some of the utility and government funds allocated for power equipment replacement and refurbishment gets affected or put on hold due to the COVID-19 condition. Therefore, it is more crucial than before to consider the health of existing aged power transformer. It is recommended to use classic and advanced diagnostics techniques to aim for extending the life of the existing valuable assets.