Transformer Overcurrent Protection Explained

Substation Maintenance Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3075 Fact Sheet – Understanding Electrical Hazards in the Workplace

- Learn the effects of electric current on the human body

- Understand OSHA safety standards and protective devices

- Discover essential lockout/tagout and grounding practices

Transformer overcurrent protection safeguards windings, insulation, and conductors from overloads and short circuits. Using fuses, relays, and circuit breakers ensures electrical safety, NEC compliance, and reliable performance in utility and industrial power systems.

What is Transformer Overcurrent Protection?

Transformer overcurrent protection is a safety system that interrupts excessive current in transformers, preventing damage and ensuring reliable operation.

✅ Prevents winding damage from overloads and short circuits

✅ Uses fuses, circuit breakers, and protective relays

✅ Ensures NEC/ANSI compliance and system reliability

Short Circuit Study & Protective Device Coordination

Arc Flash Analysis/Study - IEEE 1584 Update

Transformer overcurrent protection is a safety system designed to interrupt excessive current before it can damage transformer windings or insulation. Unlike general circuit protection, transformer protection must account for both gradual overloads and sudden short circuits, which can create thermal and magnetic stresses that can destroy equipment within milliseconds. To understand how transformer faults contribute to system hazards, see What is Fault Current.

To maintain safe and reliable operation, it is essential to ensure that only qualified personnel perform installation and maintenance on protection systems. When selecting protective devices, engineers must evaluate the primary current of the transformer and apply the proper primary OCPD to avoid hazards. Using a device that is larger than required can compromise coordination and reduce effectiveness. For this reason, only qualified persons should assess both the primary voltage and current conditions of the system to guarantee that protection settings align with equipment ratings and industry standards.

Why Transformers Require Overcurrent Protection

Transformers are mission-critical assets in power systems, and both the primary and secondary windings must be protected. The primary winding is vulnerable to short circuits and overloads, while the secondary winding must be protected against sustained overloads. Without proper devices, overheating or fault currents could lead to severe damage, fire hazards, or extended downtime.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Section 450.3 of the National Electrical Code (NEC) establishes detailed requirements for overload protection of transformers. The rules vary depending on several important conditions:

Overcurrent protection requirements depend on the following factors:

-

Operating voltage: Section 450.3(A) applies to transformers rated over 600 V; Section 450.3(B) applies to those rated 600 V or less.

-

Location of the overcurrent device: Rules differ depending on whether only the primary winding is protected or both the primary and secondary are protected.

-

Conditions of maintenance (for >600 V): If supervised by qualified personnel, Table 450.3(A) permits primary-only protection.

-

Transformer impedance: For higher-voltage units, impedance is used to refine protection sizing when both windings are protected.

-

Manufacturer design: When a transformer is built with coordinated thermal overload protection, NEC allowances may change.

For a step-by-step approach to sizing devices, review our guide on Maximum Fault Current Calculation.

NEC Rules for Sizing Overcurrent Protection

The NEC provides explicit percentage limits for overcurrent protective devices (OCPDs) based on voltage class. These percentages are applied to the transformer’s full-load current (FLC) and dictate maximum allowable device ratings.

NEC Overcurrent Protection Requirements for Transformers

| Voltage Class | Primary-Only Protection (Supervised) | With Primary & Secondary Protection | NEC Reference |

|---|---|---|---|

| Over 600 V | Fuses ≤ 250% FLC; Breakers ≤ 300% FLC | Based on transformer impedance and coordination | NEC 450.3(A), Table 450.3(A) |

| 600 V or less | OCPD ≤ 125% of full-load current | Primary up to 250% (fuse) or next smaller size; Secondary ≤ 125% FLC | NEC 450.3(B), Table 450.3(B) |

Transformers rated over 600 volts (NEC 450.3(A))

When only primary protection is provided in a supervised location:

-

Fuses may be rated up to 250% of the primary FLC.

-

Circuit breakers may be rated up to 300% of the primary FLC.

-

If the calculated value does not match a standard device size, the next larger size is permitted.

-

When both primary and secondary protection are provided, transformer impedance must be taken into account for proper coordination. For a broader look at transformer defense strategies, visit Transformer Protection Explained.

Transformers rated 600 volts or less (NEC 450.3(B))

When only primary protection is provided, stricter limits apply:

-

OCPDs may not exceed 125% of the full-load primary current.

-

If secondary protection is included, the primary device can be rated up to 250% of FLC (for fuses) or the next smaller standard size.

-

Secondary devices cannot exceed 125% of the secondary full-load current (or the next larger size if no exact match exists).

These requirements strike a balance between adequate safety and practical operation, ensuring that transformers are protected without experiencing nuisance tripping. To understand how overloads and short circuits fit into the broader context, explore Overcurrent Protection.

Example Application

It is often easier to understand NEC rules by applying them to a real transformer. Consider a 15 kVA, 480 V to 208/120 V transformer operating at a voltage of less than 600 V.

-

The primary full-load current is 18 A. Applying NEC 450.3(B), the OCPD must not exceed 125%:

18 × 1.25 = 22.5 A → The next standard rating is a 25 A fuse. -

The secondary full-load current at 208 V is approximately 42 A. At 125%, this equals 52.5 A.

→ The next standard rating is a 60 A breaker.

This example shows how NEC percentages translate into practical device ratings that protect both primary and secondary windings. A deeper dive into methods and formulas can be found in Fault Current Calculation.

Overloads vs Short Circuits

Overcurrent in transformers can result from two distinct conditions, and protection must address both.

-

Overloads occur when a transformer delivers more current than its rated capacity for an extended period, typically 1 to 6 times the normal load. Current remains on its intended path, but heat builds up in the windings, leading to insulation breakdown if not cleared.

-

Short circuits are much more severe, sending current outside normal load paths and reaching magnitudes hundreds of times greater than rated current. The resulting thermal and magnetic forces can warp busbars, vaporize conductors, and rupture insulation.

Because overloads are gradual and short circuits are instantaneous, different devices are required: overload relays or thermal devices for slow heating, and high-interrupting fuses or breakers for catastrophic faults. The transformer’s impedance is always used to calculate potential fault current and size protective devices appropriately. For the fundamentals of safeguarding electrical systems, read What is Electrical Protection.

Sign Up for Electricity Forum’s Utility Transformers Newsletter

Stay informed with our FREE Utility Transformers Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

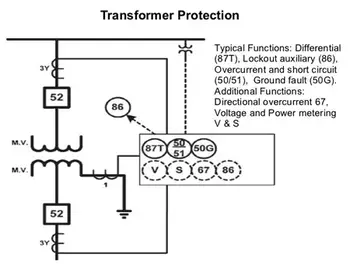

Advanced Protection Methods

While NEC rules establish minimum standards, modern installations often incorporate advanced schemes for higher reliability and selectivity. Before listing them, it is helpful to understand that these methods are designed to isolate only the faulty section of a system while keeping the rest in service.

-

Differential protection compares the current entering and leaving the transformer; any imbalance trips the device immediately.

-

Directional overcurrent relays determine the direction of fault current, crucial in networks with distributed generation or multiple sources.

-

Buchholz relays detect gas buildup in oil-filled transformers, giving early warning of internal arcing faults.

-

Coordination studies analyze time-current curves of fuses and breakers to ensure that faults are cleared by the closest protective device, rather than by upstream equipment.

These approaches provide extra assurance beyond basic NEC compliance, minimizing disruption and extending transformer life.

Related Articles