Arc Flash Boundary Table by Incident Energy Explained

NFPA 70e Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 3873 Fact Sheet – Minimum Approach Distance and Training Requirements

- Calculate MAD using voltage and overvoltage values

- Ensure proper communication between host and contract employers

- Meet OSHA training requirements for qualified electrical workers

An arc flash boundary table by incident energy helps determine safe working distances based on calculated energy levels in cal/cm². It supports NFPA 70E compliance and protects workers from arc flash hazards by specifying PPE and approach boundaries.

What is an "arc flash boundary table by incident energy"?

An arc flash boundary table by incident energy provides essential safety guidance:

✅ Defines boundary distances based on incident energy levels

✅ Helps select appropriate PPE for each risk category

✅ Aids in NFPA 70E arc flash risk assessments and compliance

Incident energy determination is based on the level of incident energy, measured in calories per square centimetre (cal/cm²), which indicates the severity of potential heat exposure during an arc flash event. Using this calculation, electricians and safety professionals can establish the proper boundary to protect workers from the dangers of arc flashes, ensuring that they are positioned far away to avoid serious burns or injuries. This plays a vital role in selecting the appropriate personal protective equipment (PPE) and following proper safety protocols in compliance with electrical safety standards. Learn how pressure waves form during arc flash events by visiting our arc blast definition guide.

Request a Free Training Quotation

How is an arc flash boundary table based on incident energy?

An arc flash boundary table defines the minimum safe distance from an electrical fault source where the incident energy falls to 1.2 cal/cm²—the threshold at which second-degree burns can occur. Beyond this point, the use of arc-rated personal protective equipment (PPE) is mandatory to ensure the safety of workers. For step-by-step hazard evaluation procedures, see our arc flash assessment article.

This boundary is influenced by multiple factors, including system voltage, available fault current, and the clearing time of overcurrent protection devices. Accurate determination of this distance often requires an incident energy analysis, as outlined in IEEE 1584. This standard offers detailed formulas and modelling guidance to calculate arc flash boundaries based on real-world electrical system configurations. Additionally, NFPA 70E Section 130.5 provides further direction for identifying safe working distances for various tasks and equipment setups.

Test Your Knowledge About Arc Flash!

Think you know Arc Flash? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

| Incident Energy (cal/cm²) | Minimum Arc Flash Boundary (inches) | Minimum Arc Flash Boundary (mm) | PPE Category |

|---|---|---|---|

| 1.2 | 18 | 457 | Minimum PPE Required |

| 4.0 | 24 | 610 | Category 1–2 (8 cal/cm²) |

| 8.0 | 36 | 914 | Category 3 (25 cal/cm²) |

| 25 | 60 | 1524 | Category 4 (40 cal/cm²) |

| 40 | 72 | 1829 | Custom PPE Required |

Arc Flash Boundary Table By Incident Energy

Notes:

-

1.2 cal/cm² is the threshold for second-degree burns, establishing the arc flash protection boundary.

-

Actual boundaries depend on system-specific variables including voltage, fault current, clearing time, and working distance.

-

Always refer to an incident energy analysis and IEEE 1584 calculations for precise arc flash boundary determinations.

Frequently Asked Questions

How Does Energy Affect the Electrical Boundary?

The amount of energy released during a fault directly impacts the size of the boundary. Higher energy levels result in a greater distance that must be maintained for safety, as the risk of burns increases with the intensity of the energy.

Energy is determined by several factors, including the system's design, such as arcing faults, and the fault-clearing time. Another important variable is the distance between the worker and the equipment, known as the working distance. The closer the worker is to the fault, the higher the energy exposure; therefore, the boundary must be adjusted accordingly.

Energy is typically calculated using the incident energy calculation method or the flash PPE categories method, which assigns protective clothing based on potential exposure levels. The arc flash incident energy table 130.7(c)(15), helps guide workers in choosing the right protective equipment based on energy levels and tasks. If you’re working with 480V systems, explore the specific risks on our 480V arc flash page.

What Are the Typical Working Distances for Different Voltages?

The working distance is critical in determining how far away a worker should stay from electrical equipment. For systems operating at different voltage levels, typical distances vary:

- For low-voltage equipment, such as 480V panels, an 18-inch working distance is common.

- For medium-voltage equipment, such as switchgear, distances often range from 24 to 36 inches.

- For high-voltage systems, working distances can extend beyond 36 inches, depending on the equipment and risk assessment.

Energy exposure decreases as the worker and the equipment distance increase, leading to smaller required boundaries. To understand how fault current and clearing time determine safe distances, read our arc flash boundary calculation guide.

How Do Electrode Configurations Affect the Electrical Boundary?

Electrode configurations influence the behaviour of electrical faults and, therefore, the size of the boundary. The way conductors are arranged inside an enclosure impacts how energy is dispersed. Some typical configurations defined in IEEE 1584 include:

-

Vertical conductors in a box are the most common setup for electrical panels.

-

Horizontal conductors tend to disperse energy toward the worker, potentially increasing the size of the safety boundary.

Each configuration alters how energy is released, and these variations must be taken into account when determining safe distances.

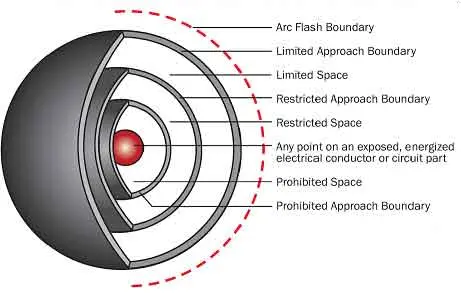

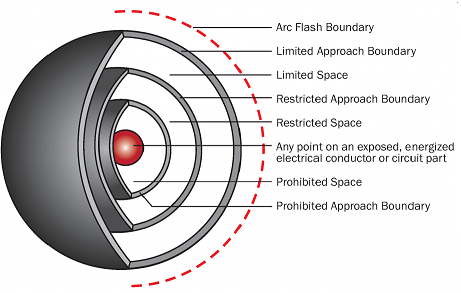

Why is the Electrical Boundary Different from the Limited and Restricted Approach Boundaries?

The safety boundary protects workers from heat and energy exposure during electrical work. In contrast, the limited and restricted approach boundaries are based on shock risks rather than energy exposure. The limited approach boundary marks the distance within which only qualified personnel can enter. In contrast, the restricted approach boundary requires additional controls and specialized protective gear due to the heightened risk of electric shock. Discover how modeling tools improve compliance in our arc flash assessment software page.

The boundary for energy exposure may extend farther than shock-related boundaries, especially in cases involving high energy levels. Both risk factors should be evaluated during a thorough risk assessment to ensure that workers are adequately protected from multiple hazards.

Calculating safe electrical boundaries based on energy levels is essential for maintaining workplace safety in environments with high electrical risks. Guidelines from IEEE 1584 and workplace electrical safety standards provide essential tools for accurately calculating these distances. Employing methods such as the incident energy analysis method or PPE categories can help ensure workers are protected from hazardous energy levels. See the human impact of arc events by reviewing our arc flash injuries overview.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Additionally, understanding how factors such as electrode configuration, fault clearing time, and arc-rated clothing requirements affect boundaries is crucial for designing safe systems. Proper planning and adherence to safety guidelines reduce the risk of arc flash injuries and equipment damage in the workplace, thereby creating a safer environment for all involved.

Related Pages

What's the Arc Flash Boundary for 8 cal/cm²?