40 Cal Arc Flash Suit Explained

By R.W. Hurst, Editor

CSA Z462 Arc Flash Training - Electrical Safety Essentials

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 3873 Fact Sheet – Minimum Approach Distance and Training Requirements

- Calculate MAD using voltage and overvoltage values

- Ensure proper communication between host and contract employers

- Meet OSHA training requirements for qualified electrical workers

40 Cal Arc Flash Suit provides maximum electrical hazard protection, meeting NFPA 70E and ASTM F1506 standards. Designed for comfort and mobility, it shields workers from arc flash burns with a 40 cal/cm² arc rating for high-risk tasks.

What is a 40 cal Arc Flash Suit?

A 40 cal arc flash suit is specialized personal protective equipment (PPE) designed to shield electrical workers from electrical explosions with incident energy levels up to 40 cal/cm². Constructed from flame-resistant materials like Nomex and Kevlar, it ensures compliance with NFPA 70E and ASTM F1506 standards.

✅ Comprehensive Protection: This includes an arc-rated hood, face shield, jacket, bib overalls, gloves, and balaclava for full-body coverage.

✅ High Thermal Resistance: Withstands temperatures exceeding 35,000°F, reducing severe burns and injuries risks.

✅ Regulatory Compliance: It meets NFPA 70E and ASTM F1506 standards and is suitable for Hazard Risk Category (HRC) Level 4 tasks.

Request a Free Training Quotation

It is designed to protect electrical workers exposed to extreme flashover hazards. Built for tasks involving high incident energy levels, these suits offer full-body coverage using flame-resistant materials such as Nomex and Kevlar. Rated to withstand 40 cal/cm² of thermal energy, they meet NFPA 70E and ASTM F1506 requirements for workplace electrical safety. A 40 cal suit is critical for personnel working on energized equipment, such as switchgear and motor control centers.

40 Cal Arc Flash Suit Specifications and Standards

| Feature | Specification | Purpose | Compliance Standard |

|---|---|---|---|

| Arc Rating | 40 cal/cm² | Protects against high-energy arc flash burns | NFPA 70E, ASTM F1506 |

| Material | Flame-resistant multi-layer fabric | Withstands extreme heat and flame exposure | ASTM F1506 |

| Design | Hood, coat, bib overalls, gloves | Provides full body coverage for maximum safety | NFPA 70E PPE Category 4 |

| Weight | Lightweight construction (8–12 lbs) | Reduces fatigue, improves mobility | Meets comfort and safety guidelines |

| Visibility | High-visibility colors, reflective trim | Improves worker visibility in low-light areas | ANSI/ISEA 107 (optional) |

| Durability | Reinforced seams, tear-resistant stitching | Extends lifespan under tough conditions | ASTM F1506 durability criteria |

Components of a 40 Cal Arc Flash Suit

A 40 cal arc flash suit is designed to serve as comprehensive electrical PPE, safeguarding workers from arc fault exposure, arc blast risks, and extreme heat generated during high-energy incidents. These suits go beyond standard flame-resistant apparel by offering advanced protective gear for electricians who face elevated incident energy levels. Every component works together to ensure compliance with national PPE standards, helping organizations meet OSHA-referenced safety codes and 70E requirements for the safe operation of energized equipment. For tasks involving extreme incident energy levels, workers may require a higher level of protection, such as a 100 cal arc flash suit, which offers advanced thermal shielding beyond the limits of 40 cal gear.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

See our guide to PPE clothing for a full overview of arc flash categories and how a 40-cal suit fits into a comprehensive protection plan.

A complete 40 cal suit kit typically includes:

-

Arc-rated hood with face shield

-

Flame-resistant jacket and bib overalls

-

Rubber insulating gloves with leather protectors

-

Safety glasses and a balaclava

-

Storage and carry bag

These components provide full-body coverage to protect against skin exposure to incident energy exceeding 35,000°F.

Compliance and Certification: Every 40 cal arc flash suit must comply with:

-

NFPA 70E – For workplace electrical safety

-

ASTM F1506 – For flame-resistant protective clothing

These standards ensure suits can withstand incident energy levels of up to 40 cal/cm², reducing the risk of second-degree burns and electrical injuries.

Material and Design Improvements

Modern suits are made from lightweight, breathable fabrics with moisture-wicking properties, which help reduce heat stress. Materials like Nomex, Kevlar, and CarbonX provide both strength and comfort. Suits may include vented hoods, lift-front face shields, and ergonomic tailoring for better mobility during complex tasks. The 40-cal suit is one of the highest-rated options for extreme-risk environments.

Selecting the right arc flash clothing is essential for compliance with NFPA 70E and CSA Z462 standards.

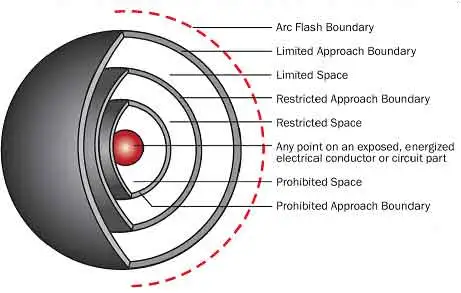

When to Use a 40 Cal Suit

These suits are required when hazard analysis identifies an incident energy exposure exceeding 25 cal/cm². A 40-cal suit is necessary in environments with a high potential incident energy level, typically in industrial settings with significant electrical equipment. According to the Hazard Risk Category (HRC) system, HRC Level 4 indicates situations where incident energy exceeds 25 cal/cm², necessitating a suit with an arc rating of 40 cal/cm². Common scenarios include work on switchgear, motor control centers, and other high-energy electrical systems.

Common high-risk environments include:

-

Motor control centers

-

Switchgear rooms

-

Transformer vaults

-

Industrial substations

This suit meets the most stringent protective thresholds outlined by NFPA 70E. For full details on what’s required at each risk level, visit Arc Flash PPE Requirements. The NFPA 70E PPE requirements help define the proper protective equipment for various electrical tasks. Gain deeper insights into the protective ratings of PPE by exploring our Arc Flash PPE Requirements Chart.

Note: Limitations of a 40-cal Arc Flash Suit

While highly protective, 40-cal arc flash suits can be bulky, limiting mobility. They are not substitutes for insulated tools or safe work practices and must be paired with risk assessments and lockout/tagout procedures.

How to Choose the Right Outfit

Choosing the right size and type of 40 cal suit involves several factors:

-

Fit: Ensure the suit fits comfortably over regular clothing and does not restrict movement. Proper sizing charts from manufacturers can help you select the correct size.

-

Components: Look for suits that include essential components, such as a hood, face shield, insulating gloves, and other protective clothing. Some suits are sold as complete kits to ensure compatibility.

-

Certification: Verify that the suit meets relevant safety standards, such as NFPA 70E or ASTM F1506, to ensure it provides the necessary protection.

-

Comfort Features: Opt for suits with moisture-wicking fabrics and ventilation to enhance comfort during extended wear.

-

Make sure the clothing matches the arc flash ppe category.

The 40 cal/cm² rating is part of a broader spectrum of ppe protection levels. Explore the full range of arc flash safety gear required to minimize injuries from electrical incidents.

Maintenance and Inspection Guidelines

How Often Should a 40 Cal Suit Be Inspected and Replaced?

-

A 40-cal suit should be inspected before each use and thoroughly inspected periodically, as recommended by the manufacturer. Regular inspections help identify wear and tear that can compromise protection. The suit should be replaced if it shows any signs of damage, has been exposed to an explosion, or reaches the end of its service life, typically determined by the manufacturer based on usage and care.

-

PPE is a crucial piece of personal protective equipment for workers exposed to high-voltage electrical hazards. Understanding its capabilities, limitations, and proper usage can significantly enhance safety. By following guidelines for selection, maintenance, and regular inspection, you can ensure your suit provides optimal protection, safeguarding you against the severe consequences of electrical incidents.

Test Your Knowledge About Arc Flash!

Think you know Arc Flash? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

What Are the Proper Procedures for Wearing and Maintaining this PPE?

Proper procedures for wearing and maintaining a 40 cal suit are crucial for ensuring its effectiveness:

-

Inspection: Before use, inspect the suit for any signs of damage, such as tears, burns, or contamination.

-

Donning: Wear flame-resistant undergarments, followed by the suit, ensuring it covers all exposed skin. Secure all fastenings, and wear the face shield and insulating gloves.

-

Maintenance: Follow the manufacturer's guidelines for cleaning and storing the suit. Avoid using harsh chemicals that can degrade the flame-resistant properties.

-

Storage: Store the suit in a cool, dry place away from direct sunlight and chemicals.

Learn how PPE performance is evaluated and rated for personal protection to ensure worker safety in high-risk environments.

Frequently Asked Questions

What does a 40 cal arc flash suit protect against?

It protects against thermal burns, light exposure, and pressure from arc blasts.

Can a 40 cal garment protect against all electrical incidents?

It significantly reduces risk but does not guarantee full protection. Proper use and safety procedures must also be followed.

How often should a 40 cal suit be replaced?

Inspect before each use and follow the manufacturer’s guidelines on service life. Replace if damaged or after a known arc incident.

Related Articles:

Explore our electrical safety Training Programs or contact us to Request a Free Training Quotation for group safety sessions and PPE consultation.