Arc Flash Study Requirements

By R.W. Hurst, Editor

CSA Z462 Arc Flash Training - Electrical Safety Essentials

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 3873 Fact Sheet – Minimum Approach Distance and Training Requirements

- Calculate MAD using voltage and overvoltage values

- Ensure proper communication between host and contract employers

- Meet OSHA training requirements for qualified electrical workers

Arc flash study requirements define the steps needed to assess electrical hazards, including fault current study, device coordination, and labeling. These studies help ensure NFPA 70E and OSHA compliance to protect workers from arc flash risks and improve electrical safety.

What are Arc Flash Study Requirements?

Arc flash study requirements are essential for ensuring electrical hazard compliance with OSHA and NFPA 70E. They:

✅ Include fault current, equipment labeling, and protective device coordination

✅ Ensure NFPA 70E and OSHA compliance for workplace safety

✅ Protect workers from arc flash and shock hazards

These studies identify safety risks, calculate incident energy, and define boundaries to help protect workers from serious injuries. A properly executed arc flash risk assessment determines PPE categories, short circuit energy levels, and mitigation strategies that reduce exposure during energized work. Conducting regular studies supports electrical safety programs across industrial, commercial, and utility environments. Visit our Arc Flash Study Training Course Page

Request a Free Training Quotation

Understanding Arc Flash

Arc flashes release extreme heat and energy that can cause serious injury or death. While this page explains the requirements for conducting an arc flash study, the detailed process of identifying hazards and evaluating risks is covered in our Arc Flash Hazard Analysis guide. For more on energy levels and hazard thresholds, see our Incident Energy guide.

Regulatory Requirements for Arc Flash Studies

While OSHA does not explicitly require an arc flash study, compliance with OSHA 29 CFR 1910.333 and 1910.269 indirectly mandates the identification and mitigation of hazards. NFPA 70E provides a structured approach to electrical safety risk evaluation, including a proper risk evaluation.

Under NFPA 70E:

-

Risk Assessment

Employers must assess potential arc hazards and implement controls to minimize exposure to them. This includes identifying energized equipment, estimating incident energy, and determining the likelihood of the incident occurring. -

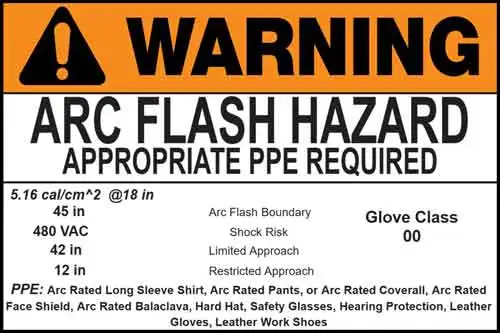

Labeling of Electrical Equipment

All electrical panels and gear likely to require inspection or servicing while energized must be labelled with the arc flash boundary and incident energy level, as per Section 130.5(H). -

Five-Year Review Cycle

NFPA 70E requires a review of studies at least every five years, or more frequently if significant electrical changes occur.

For a deeper breakdown of these requirements, refer to our incident energy analysis resource.

Sign Up for Electricity Forum’s Arc Flash Newsletter

Stay informed with our FREE Arc Flash Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Key Components of an Arc Flash Study

An effective arc flash study includes several interconnected technical steps that comply with NFPA 70E. These steps form the foundation of a documented safety evaluation:

1. Data Collection

-

Purpose: Gather system-specific information to model real-world fault scenarios accurately.

-

Includes: Equipment ratings, protective device settings, transformer data, conductor lengths, and grounding details.

-

Why it matters: Incomplete or outdated data can lead to incorrect incident energy results and ineffective safety labeling.

2. System Modelling

-

Purpose: Digitally represent the facility's electrical distribution system in specialized software like SKM or ETAP.

-

Includes: Development of a one-line diagram showing all critical power distribution paths and components.

-

Why it matters: A clear system model enables the simulation of how electricity flows under both normal and fault conditions.

3. Short Circuit and Coordination Study

-

Purpose: Establish the available fault current and ensure protective devices operate in the correct sequence.

-

Includes: Calculating bolted fault currents and analyzing breaker trip curves.

-

Why it matters: Accurate short circuit study directly impacts incident energy calculations and breaker coordination.

4. Incident Energy and Boundary Calculations

-

Purpose: Quantify the thermal energy that would be released at specific working distances.

-

Includes: Use of IEEE 1584 formulas to calculate calories per square centimetre (cal/cm²).

-

Why it matters: These values determine boundaries and required PPE, forming the basis for all field labelling.

5. Hazard Category Determination

-

Purpose: Assign a PPE category based on the calculated incident energy.

-

Includes: Comparing energy levels to NFPA 70E tables to define if Category 1 (low) or Category 4 (high) PPE is needed.

-

Why it matters: PPE selection must align with risk level to ensure adequate protection during energized work.

6. Recommendations and Mitigation

-

Purpose: Suggest ways to reduce risk and improve system safety.

-

Includes: Adjusting protection settings, improving coordination, installing remote racking systems, or relocating control panels.

-

Why it matters: These proactive steps reduce the likelihood or severity of incidents, lowering the overall electrical hazard severity.

PPE Selection and Arc Flash Boundaries

The results of an arc flash study guide the selection of arc-rated clothing and equipment. Incident energy calculations and hazard category determine proper PPE.

EF Partner Media

-

Category 1 (4 cal/cm²): Long-sleeved flame-resistant (FR) clothing, hard hat with arc-rated face shield, leather gloves.

-

Category 2 (8 cal/cm²): Adds arc-rated balaclava and heavier FR gear.

-

Category 3–4 (25–40+ cal/cm²): Includes multi-layer protective clothing and insulated gloves.

According to industry data, thousands of arc flash injuries occur each year in North America alone. That's why identifying and mitigating arc flash risk is not only a best practice but an essential safety obligation.

In addition to PPE, an arc flash study defines the approach boundaries:

-

Limited Approach Boundary: Distance where shock hazards require limited access.

-

Restricted Approach Boundary: Closer zone requiring special training and PPE.

-

Arc Flash Boundary: The outer perimeter where exposure exceeds 1.2 cal/cm².

To explore the differences between boundary distances and gear selection, visit our Arc Flash Gear Guide.

Who Can Perform an Arc Flash Study?

It must be conducted by qualified individuals with experience in electrical system modelling and safety compliance:

-

Electrical Engineers: Typically licensed Professional Engineers (PEs) or Certified Electrical Safety Compliance Professionals (CESCP).

-

Consultants: Often possess training in IEEE 1584 modelling and use of SKM/ETAP.

-

Qualified Personnel: Must understand NFPA 70E, OSHA regulations, and utility fault current contribution.

For training and certification opportunities, see our arc flash study training.

How Often Must Arc Flash Studies Be Conducted?

The NFPA 70E standard requires updates to arc flash studies:

-

Every 5 Years: To ensure accuracy and continued compliance.

-

After Major System Changes: Including transformer upgrades, panel additions, or relay setting adjustments.

-

Post-Incident or Fault Event: If a near-miss or arc incident occurs, the study should be revalidated.

A current report ensures an accurate arc flash study, helping reduce insurance risk and liability.

Arc flash study requirements play a pivotal role in safeguarding electrical systems and personnel from hazardous incidents. In conjunction with a proper risk assessment, these studies empower electrical engineering and maintenance professionals to design safer work environments, comply with regulatory standards, and minimize operational disruptions. Adhering to these requirements ensures not only the protection of workers but also the longevity and reliability of electrical equipment, making them a cornerstone of modern electrical safety practices.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience