Incident Energy Explained

By R.W. Hurst, Editor

CSA Z462 Arc Flash Training - Electrical Safety Essentials

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 3873 Fact Sheet – Minimum Approach Distance and Training Requirements

- Calculate MAD using voltage and overvoltage values

- Ensure proper communication between host and contract employers

- Meet OSHA training requirements for qualified electrical workers

Incident energy is the heat released during an arc flash, measured in cal/cm². It defines arc flash boundaries, sets PPE levels, and ensures NFPA 70E compliance. Reducing incident energy lowers burn risk, improves safety, and supports safe electrical practices.

What is Incident Energy?

Incident energy is a critical metric used to measure the thermal energy released during an arc flash incident, expressed in calories per square centimetre (cal/cm²).

✅ Measures arc flash thermal energy in cal/cm²

✅ Determines proper PPE level and arc flash protection boundaries

✅ Used in NFPA 70E and CSA Z462 arc flash studies and risk assessments

Request a Free Training Quotation

This value determines the appropriate level of personal protective equipment (PPE) required to prevent serious injuries such as second- and third-degree burns. Accurate calculations of incident energy exposure are the foundation of any effective arc flash safety program, enabling employers to establish arc flash boundaries, apply compliant warning labels, and enforce safe work practices.

A reliable arc flash study must include an incident energy evaluation to ensure worker safety and compliance with both NFPA 70E and CSA Z462 standards. For step-by-step calculations and case studies, check our incident energy analysis page.

Why Incident Energy Matters

Arc flash incidents are among the most dangerous electrical hazards. Thousands of incidents occur annually, causing hundreds of serious injuries and fatalities. Beyond personal harm, arc flash events lead to costly downtime, equipment loss, and legal liability.

By defining incident energy, safety professionals can:

-

Protect workers from severe burns.

-

Ensure compliance with NFPA 70E and CSA Z462.

-

Reduce insurance costs and operational risk.

Understanding and applying these principles is crucial for creating safer workplaces.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Arc flash incidents pose a serious threat to electrical workers, often resulting in severe arc flash injuries such as second- and third-degree burns.

Within this arc flash boundary, the use of personal protective equipment PPE is not optional—it’s essential.

See our Arc Flash PPE article for more information.

Implementing effective OSHA electrical safety protocols starts with conducting a formal hazard analysis that considers system voltage, fault current, and clearing time.

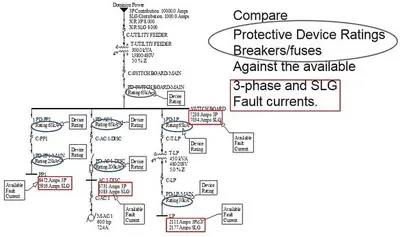

How Incident Energy Is Calculated Using IEEE 1584

To determine the amount of incident energy that can be released during an arc flash, electrical professionals rely on the IEEE 1584-2018 standard. This calculation takes into account a range of system and environmental variables.

Accurate assessment depends on understanding the following core inputs:

-

Arcing Current: The actual current that sustains the arc during the fault event.

-

System Voltage: The operating voltage of the equipment under evaluation.

-

Available Fault Current: The maximum short-circuit current supplied to the arc.

-

Clearing Time: How quickly protective devices interrupt the fault.

-

Working Distance: The distance between the arc and the worker, typically 18 inches.

These calculations are essential components of a full arc flash risk assessment and are often conducted using specialized software and data from the facility’s arc flash study (short circuit and coordination studies).

Real-World Example: How Incident Energy Affects PPE

Consider a 480V system with a potential fault current of 30,000 amps. Using IEEE 1584, the resulting incident energy may reach 9.6 cal/cm² at 18 inches.

At this level:

-

Workers require arc-rated clothing with an ATPV rating greater than or equal to the calculated exposure (≥12 cal/cm²).

-

If clearing time is reduced, incident energy may drop below 8 cal/cm², lowering PPE requirements and improving mobility.

For a deeper understanding of how these figures are determined, please refer to our main Arc Flash Study page.

Techniques to Reduce Incident Energy

Modern facilities use design and operational strategies to lower exposure:

-

Current-Limiting Fuses: Interrupt arcs within milliseconds.

-

Arc-Resistant Equipment: Redirects blast energy away from personnel.

-

Maintenance Mode Switches: Shorten trip times during energized work.

-

Zone-Selective Interlocking (ZSI): Improves protective coordination.

NEC requirements (such as Sections 240.67 and 240.87) mandate the reduction of incident energy in certain equipment, reinforcing the importance of proactive design.

These techniques are covered in more depth in our guide to arc flash study requirements, which outlines everything employers must include in a safety study.

Compliance With NFPA 70E and CSA Z462

Both standards require incident energy evaluations as part of a complete electrical safety program. Compliance includes:

-

Labeling equipment with incident energy values or PPE categories.

-

Providing PPE based on calculated exposure.

-

Training workers to recognize and mitigate arc flash hazards.

Skipping these steps exposes companies to citations, liability, and preventable accidents.

For further guidance, see our Arc Flash Study, Arc Flash PPE, OSHA Electrical Safety, and Lockout Tagout (LOTO) resources.

Arc Flash Analysis Training

Companies that skip these steps risk citations, legal liability, and preventable injuries. Discover how to develop a compliant program with our arc flash analysis training courses designed for qualified personnel. A comprehensive electrical safety program should include regular arc flash assessments, incident energy calculations, PPE training, and strict adherence to NFPA 70E compliance standards.

Benefits of Accurate Incident Energy Evaluation

Accurate evaluation delivers:

-

Reduced risk of life-threatening burns.

-

Improved compliance and lower liability.

-

Safer, more efficient work practices.

-

Reduced downtime and insurance costs.

Incident energy isn’t just a number—it is a benchmark that shapes every aspect of electrical safety. To protect your team and comply with regulations, a full arc flash study that includes incident energy evaluation is essential.

If you're looking to build or update your safety program, start with a full arc flash study and make incident energy output a central part of your risk management strategy.

Test Your Knowledge About Arc Flash!

Think you know Arc Flash? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Explore More Arc Flash Topics

Explore our Arc Flash Training Programs or contact us to Request a Free Training Quotation for group safety sessions and PPE consultation.