SCADA Architecture

By R.W. Hurst, Editor

Download Our NFPA 70E Fact Sheet – 2024 Electrical Safety Edition

- Understand how NFPA 70E works with NEC and NFPA 70B standards

- Clarify the shared responsibility between employers and employees

- Learn how NFPA 70E supports OSHA compliance

SCADA architecture defines how supervisory control and data acquisition systems are structured across field devices, control servers, and operator interfaces to ensure efficient monitoring, automation, and communication across electrical and industrial utility networks.

What is SCADA Architecture?

SCADA Architecture refers to the layered structure of hardware and software that enables data collection, control, and monitoring in real-time utility operations.

✅ Clearly separates field, control, and user interface layers

✅ Supports scalable and distributed system integration

✅ Enhances real-time visibility, reliability, and fault response

SCADA Architecture – System Design

Supervisory control and data acquisition (SCADA) architecture forms the structural backbone of modern industrial automation. It connects field-level devices with centralized software systems to control and monitor processes across wide geographic areas. A robust SCADA design framework ensures reliable data acquisitions, timely system responses, and actionable visibility into remote operations.

SCADA architecture refers to the design and layout of components that enable real-time supervisory control and data acquisition. It includes the physical devices, software platforms, communication networks, and user interfaces that work together to collect data and execute control actions.

This architecture is critical to electrical utilities, water systems, oil and gas pipelines, and other sectors where infrastructure must be controlled from a central location.

-

Organizes sensors, controllers, and software into defined system layers

-

Enables automation and human oversight across remote sites

-

Integrates field data into centralized SCADA software for decision-making

If you want more information about What is SCADA, read the full article.

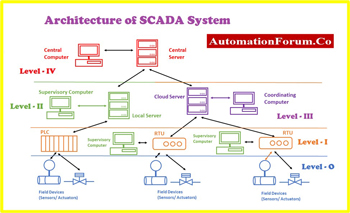

Core Layers of SCADA Architecture

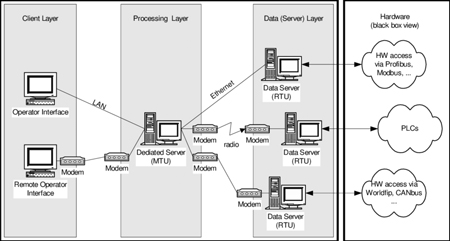

A typical supervisory control design includes four primary functional layers: field instrumentation, control equipment, communication networks, and supervisory software. Each plays a role in the seamless operation of the entire system.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

At the field level, sensors measure process variables like voltage, temperature, or flow. These readings are transmitted to remote terminal units (RTUs) or programmable logic controllers (PLCs) for processing. These control devices perform localized automation and send data upstream.

-

Sensors: Capture physical values (e.g., voltage, pressure, flow)

-

PLCs and RTUs: Execute control logic and transmit data

-

Control equipment: Responds to automated or manual operator commands

This structure ensures that real-world operations are constantly observed, interpreted, and acted upon as needed. Read How Does SCADA Work, for a complete description of how this technology is used.

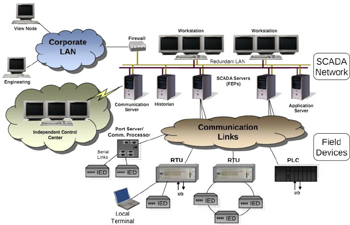

Communication and Data Flow

The effectiveness of SCADA design framework relies heavily on the communication network that links all devices. This network carries data from remote sites to central control rooms using secure, often redundant communication protocols.

Common standards such as Modbus, DNP3, and IEC 60870 ensure data integrity and compatibility across systems. Both wired (Ethernet, fiber) and wireless (radio, cellular) technologies may be used.

-

Protocols: Enable interoperability between diverse equipment

-

Networks: Ensure real-time connectivity across long distances

-

Cybersecurity: Protects control and data acquisition pathways from intrusion

Reliable communication is essential not only for remote control but also for storing and retrieving historical data, which supports trend analysis and maintenance planning.

SCADA Software and User Interfaces

Once data reaches the central system, SCADA software processes it. This software layer applies logic, triggers alarms, and archives operational records. Operators interact with the system through human machine interface (HMI) screens that provide real-time visualizations of process conditions.

A well-designed user interface enhances safety and decision-making. It displays alarms, trending data, equipment status, and control options in an intuitive layout.

-

SCADA software: Executes automation logic, stores data, manages alarms

-

HMI: Allows operators to monitor and control systems through graphic displays

-

User interfaces: Provide access to live and historical data

Operators can manually adjust setpoints, acknowledge alerts, or trigger system overrides as needed.

Types of SCADA System Architecture

Over the years, several architectural models have evolved to meet growing industrial needs. Each model represents a step toward greater connectivity, reliability, and scalability.

-

Monolithic SCADA systems – Early centralized systems with limited external communication. Rarely used today.

-

Distributed systems – Introduced modularity by spreading tasks across separate computers. Increased reliability.

-

Networked SCADA systems – Today’s standard, connecting all components through integrated networks.

-

Modern SCADA systems – Incorporate cloud platforms, mobile access, and advanced analytics for greater flexibility.

These types of SCADA system architectures reflect the increasing demand for system integration, remote access, and real-time automation.

Applications in Electrical Automation

In electrical engineering, SCADA system layout plays a central role in industrial automation and grid management. It enables power utilities to control transmission lines, substations, and switchgear from a distance.

Control equipment, such as circuit breakers and transformers, is operated via PLCs and monitored through HMI terminals. Data is logged for performance evaluation, fault detection, and preventive maintenance.

-

Coordinates voltage regulation and load balancing

-

Reduces manual intervention and improves response time

-

Ensures safe, reliable operation across high-voltage infrastructure

As smart grid initiatives grow, SCADA serves as the command center for distributed energy resources and grid-wide optimization.

The Role of System Integrators

Designing and deploying a modern SCADA framework requires the expertise of system integrators. These professionals configure communication links, program PLCs, set up RTUs, and develop custom HMI layouts tailored to the application.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

They also ensure that all components—from field sensors to control software—function together as a cohesive system.

-

Build and program automation systems

-

Configure user interfaces and alarm management

-

Optimize system architecture for reliability and scalability

Their work is essential in creating solutions that meet industry-specific standards for safety and performance.

SCADA system layout is more than just a technical blueprint—it’s the operational foundation for critical infrastructure. By combining programmable logic controllers and remote terminal units, reliable networks, powerful SCADA software, and intuitive HMIs, this architecture enables seamless control and data acquisition across diverse applications.

It supports real-time decisions, minimizes downtime, and offers centralized visibility for complex systems. As demands grow and technologies evolve, supervisory system design remains a cornerstone of connected, intelligent, and automated operations.

Related Articles