Substation SCADA

By R.W. Hurst, Editor

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

Substation SCADA provides real-time monitoring, control, and automation for substations using RTUs, HMIs, and protocols like IEC 61850 and DNP3, improving grid reliability, fault detection, and operational efficiency.

What is Substation SCADA?

Substation SCADA refers to a digital control and data acquisition system that enhances substation performance, protection, and operational visibility.

✅ Real-time monitoring, alarms, and automated control

✅ Uses IEC 61850, DNP3, RTUs, and HMIs for interoperability

✅ Improves fault detection, response time, and uptime

Substation SCADA and Intelligent Automation

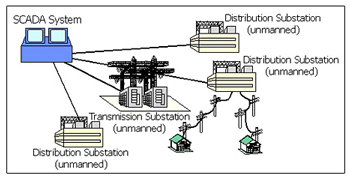

In a modern electrical grid, where reliability, speed, and remote control are essential, substation SCADA systems form the backbone of intelligent automation and control. These systems integrate advanced hardware, fibre-based networks, and standardized protocols to deliver real-time insights, enable proactive fault detection, and optimize electrical power distribution. A well-designed substation SCADA implementation is more than a control system—it is a comprehensive digital platform for grid management. For a broader overview of SCADA applications across the electrical grid, visit our article on what is SCADA and how it's used.

Why Substation SCADA Matters for Modern Power Grids

Modern electrical grids are more complex than ever, with fluctuating demand, renewable energy integration, and a growing need for remote management. Substation SCADA systems give utilities the ability to monitor and control operations in real time, ensuring that equipment failures are detected and addressed before they cause widespread outages. By enabling proactive maintenance, these systems reduce downtime, lower operating costs, and allow faster recovery from faults—critical advantages in an era where even brief service interruptions can impact thousands of customers and significant revenue.

Core Benefits of Substation SCADA Systems

-

Faster fault isolation — IEC 61850 peer-to-peer messaging coordinates protective relays in milliseconds, minimizing outage duration.

-

Reduced operational costs — Remote monitoring and control reduce the need for frequent site visits and manual inspections.

-

Improved reliability — Redundant communication paths and automated fault detection keep the grid stable under stress.

-

Enhanced security — Edge computing, VPNs, and network segmentation guard against cyber threats while maintaining operational performance.

-

Optimized asset life — Continuous condition monitoring helps schedule maintenance before failures occur, extending equipment lifespan.

Sign Up for Electricity Forum’s Smart Grid Newsletter

Stay informed with our FREE Smart Grid Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

The Evolution of Substation SCADA Technology

Early SCADA systems in substations were limited to basic telemetry and manual control, relying on analog signals and proprietary protocols. The shift to digital platforms introduced standardized communication, greater interoperability, and richer data visualization. Today’s systems are fully integrated into smart grid architectures, using IEC 61850 for high-speed data exchange, real-time analytics, and automated decision-making. Emerging trends—such as AI-driven fault prediction, distributed energy resource (DER) management, and advanced cybersecurity—are transforming SCADA into a central intelligence hub that not only monitors the grid but actively optimizes its performance in a dynamic energy landscape.

Substation SCADA System Overview

| Component | Function | Technology/Standard | Benefit |

|---|---|---|---|

| Remote Terminal Unit (RTU) | Collects data from field devices and transmits it to SCADA master | DNP3, Modbus, IEC 60870-5 | Enables remote data collection and control |

| Intelligent Electronic Device (IED) | Executes protection and automation logic at the bay level | IEC 61850, GOOSE, Sampled Values | Provides fast fault isolation and local control |

| Human-Machine Interface (HMI) | Visualizes system status, alarms, and trends for operators | SCADA Master Station | Enhances situational awareness and decision-making |

| Communication Network | Transfers real-time data and control signals | Fiber Optic Ethernet, Redundant Ring | Ensures fast and secure communication |

| SCADA Master Station | Central control hub for data processing, command execution, and logging | Supervisory Control and Data Acquisition | Enables remote operation and data integration |

| Data Historian | Stores time-stamped data for analysis and reporting | SQL, NoSQL, or proprietary DB systems | Supports trend analysis and compliance |

| Cybersecurity Layer | Protects communication and device access | VPN, Firewalls, IEC 62351, Authentication | Prevents unauthorized access and cyber threats |

| Phasor Measurement Unit (PMU) | Captures time-synchronized electrical waveforms for WAMS | IEEE C37.118, IEEE 1588 | Enables wide-area situational monitoring |

| Remote Access Gateway | Enables secure access from control centers or field locations | VPN, HTTPS, 2FA | Allows flexible and secure substation management |

Key Components and Architecture

Substation SCADA is an automated system that manages monitoring and control of substation equipment via a structured, three-tier architecture:

-

Process Level: Current and voltage transformers, merging units, and sensors gather data from field equipment. Phasor Measurement Units (PMUs) also measure time-synchronized values critical for wide area monitoring.

-

Bay Level: Intelligent Electronic Devices (IEDs) execute local control logic and protection relays to isolate faults within milliseconds.

-

Station Level: Remote terminal units (RTUs) or embedded gateway devices collect data and send it via secure communication protocols to the SCADA master station for centralized management.

Each layer contributes to low-latency operation and ensures that the system can withstand equipment failure through redundancy, including backup RTUs, IEDs, and dual-fibre optic communication rings. To better understand the fundamentals behind substation control, see our article on how does SCADA work.

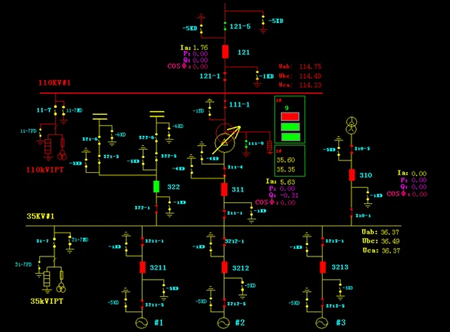

Human-Machine Interface and Real-Time Operations

The human machine interface (HMI) serves as the operator’s window into the substation. It displays a dynamic single-line diagram with live status of switches, breakers, voltages, and currents. Operators can view historical data through a data historian, manage alarms, and analyze event sequences through replay tools.

Advanced HMIs support custom dashboards, drill-down views of assets, and secure remote access, allowing utilities to operate substations across wide territories with minimal on-site presence.

Communication Protocols and Interoperability

Reliable communication is the foundation of substation automation. Modern systems implement a suite of communication protocols such as DNP3, Modbus/TCP, and IEC 60870-5-104, but increasingly rely on the IEC 61850 standard, which supports vendor interoperability, high-speed messaging, and data modelling.

IEC 61850 enables peer-to-peer GOOSE messaging for fast relay coordination, sampled values (SV) for accurate analog data over Ethernet, and MMS for secure station-level communication. These protocols run over industrial fibre optic networks designed with ring or star topologies for fault-tolerant performance.

To ensure deterministic performance, substation devices rely on network time synchronization technologies like IEEE 1588 Precision Time Protocol, which ensures aligned data timestamps across IEDs, PMUs, and historian logs.

Cybersecurity and Edge Protection

As remote access and cloud integration become increasingly common, cybersecurity becomes critical. Modern SCADA architectures utilize encrypted communication channels, firewalls, intrusion detection systems, and OT network segmentation. Virtual Private Networks (VPNs), two-factor authentication (2FA), and firmware hardening further protect substations from unauthorized access.

Edge computing also plays a growing role in securing and streamlining substation functions. By processing data locally, edge devices reduce bandwidth needs, improve response time, and isolate critical operations from cyber threats.

Intelligent Devices and Substation Automation

Substation automation depends on the distributed intelligence of IEDs and merging units. These devices not only respond to protection logic but also automate routine switching, collect asset health data, and manage bay-level operations without constant supervision from the SCADA master.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

IEDs communicate using IEC 61850 and interact seamlessly with HMIs, alarm managers, historians, and remote control centers. Integration with Wide Area Measurement Systems (WAMS) using PMUs adds another layer of situational awareness, especially valuable during grid disturbances.

Integration with Smart Grid and DERs

Substation SCADA plays a key role in smart grid evolution. As utilities incorporate distributed energy resources (DERs) like solar, wind, and battery storage, SCADA systems provide real-time data, coordination, and automation and control logic to manage fluctuating inputs and load balancing.

Smart substations are also equipped to support demand response, VRE forecasting, and grid-forming inverter coordination. This flexibility ensures resilience in the face of grid decentralization and enhances long-term asset management capabilities. Learn how communication layers and network design impact performance in our detailed explanation of SCADA architecture.

Event Management, Alarms, and Historian Functions

Real-time and historical visibility is essential for diagnosing faults and optimizing performance. Substation SCADA includes a robust alarm management system that prioritizes events and enables detailed event replay. The data historian captures time-series values for analysis, regulatory reporting, and predictive maintenance.

By analyzing trends, correlating alarms, and reviewing switching sequences, engineers gain deep insights into substation performance and can proactively manage equipment health.

Substation SCADA systems are far more than basic supervisory control and data acquisition platforms—they are critical enablers of modern power system functionality. Built on fibre optic networks, secured with advanced cyber protections, and powered by IEDs and PMUs, these systems offer scalable, real-time monitoring and control solutions for today’s dynamic grid. As substation automation advances, SCADA’s role will continue to evolve, integrating edge analytics, smart grid orchestration, and secure remote operations to support the growing complexity of electrical power infrastructure.