Dual Voltage Transformer

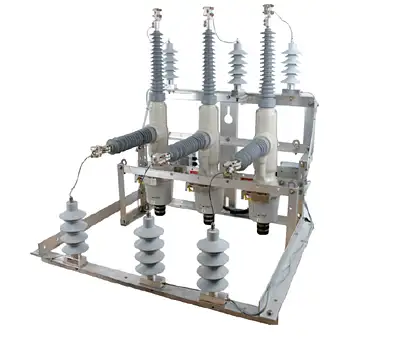

A dual voltage transformer is a versatile electrical device designed to efficiently manage and convert voltage levels for different applications. Commonly used in power distribution systems, industrial settings, and residential areas, these transformers allow for the operation of equipment across varying voltage requirements. With the ability to handle both high and low voltage configurations, dual voltage transformers ensure a stable and reliable power supply, minimizing the risk of equipment damage or power loss. Whether for stepping up or stepping down voltage, dual voltage transformers are essential in optimizing energy efficiency and maintaining system reliability.

What is a dual voltage transformer?

A dual voltage transformer is a crucial component in electrical systems, offering a versatile solution to power equipment that requires two different voltage levels. Unlike standard transformers, which typically work with a single electric specification, a multi-electrical device is designed to handle multiple electric outputs. This ability to adapt to different electricity needs makes it ideal for global applications where electrical standards vary from one region to another. For instance, while North America uses 120V, many parts of Europe rely on 230V, and this transformer helps ensure that equipment can function properly across different electrical grids.

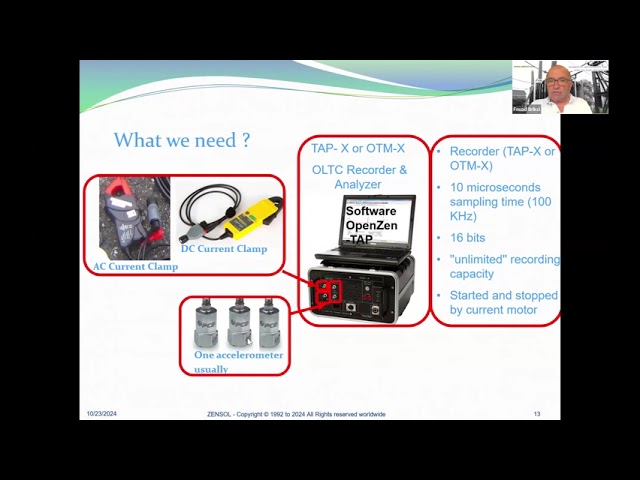

How Dual Voltage Transformers Work

The functioning of a dual voltage transformer revolves around the principle of electromagnetic induction. When an alternating current (AC) passes through the primary winding, it creates a magnetic field that induces a current in the secondary winding. By adjusting the number of turns in each winding, the equipment can step up or down the electricity. For multi-voltage devices, this flexibility means that the same device can operate at different voltages depending on the configuration of the windings.

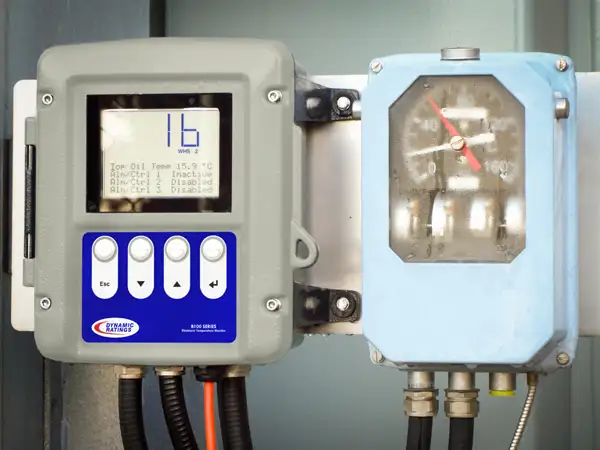

In practical terms, multi-electrical devices are often equipped with a switch or jumper that allows the user to change the voltage output. This configuration makes the equipment adaptable to a range of applications. For example, in industrial applications, where heavy machinery may require different power inputs, this equipment allow equipment to be compatible with varying voltage levels without the need for multiple transformers. This reduces costs and simplifies the installation process.

Common Applications of Dual Voltage Transformers

A dual voltage transformer is particularly useful in industries where equipment and machinery must operate across different electrical grids. One of the most prominent applications is in renewable energy systems, where dual electrical equipment can help adjust the power generated by solar panels or wind turbines to match the grid electricity. This ensures that the power generated can be efficiently fed into the grid or stored in batteries for later use.

In addition to renewable energy, these equipment are common in household appliances, HVAC systems, and industrial machinery. In global markets, where manufacturers distribute products worldwide, the ability to switch between different electrical configurations makes multi-electrical devices essential. For instance, if a piece of machinery is manufactured in the U.S. and later sold in Europe, a multi-electrical device ensures the equipment will work correctly regardless of the local electrical standard.

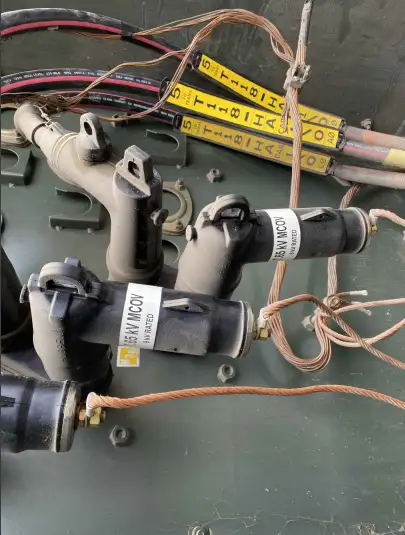

Identifying a Dual Voltage Transformer

Identifying a dual voltage transformer is relatively straightforward. Typically, manufacturers will label the equipment with the electrical options it supports, such as “110/220V” or “120/240V.” In addition, this equipment often features switch or jumper settings that allow the user to select the desired electrical output. When inspecting a multi-electrical device, it is important to look for this labelling, as it provides clear guidance on how the device can be configured.

These equipment are also distinct from single-electrical models in that they may have more intricate windings or additional wiring configurations that enable the flexibility of dual electricity. Understanding the equipment’s labelling and configuration is key to determining its suitability for specific applications.

Why Choose a Dual Voltage Transformer?

Choosing a multi-electrical device over a standard one comes with several benefits, primarily flexibility and cost-effectiveness. Instead of purchasing separate equipment for different electrical systems, dual electrical equipment allows for the same device to be used in multiple locations with varying voltage requirements. This versatility not only saves on equipment costs but also simplifies inventory and maintenance.

In regions with frequent electrical fluctuations or where equipment may need to be moved across different locations, a multi-electrical device is an excellent solution. It ensures that machinery continues to operate at optimal performance levels regardless of the local power standards. Additionally, for companies involved in international trade or operation, having dual electrical compatibility in their equipment ensures smooth and reliable functioning no matter where the machines are located.

Multi-electrical devices are indispensable tools for industrial electricians, allowing them to seamlessly integrate equipment into diverse electrical systems. By stepping up or down electrical, this equipment ensures optimal performance and safety in various operational environments. Understanding their principles, applications, and selection criteria is crucial for industrial electricians to optimize system efficiency and minimize downtime.

EF PARTNER MEDIA

Videos

Product Showcases

Shared Media