What is an Autotransformer Explained

By R.W. Hurst, Editor

Substation Maintenance Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

What is an autotransformer? A single-winding transformer for AC power distribution, providing efficient step-up/step-down voltage regulation via taps, reduced copper losses, compact design, and adjustable output for motor starting and grid voltage stabilization.

What Is an Autotransformer?

An autotransformer uses a single winding with taps to regulate AC voltage for step-up or step-down control.

✅ Single-winding with taps; no galvanic isolation between circuits.

✅ Efficient step-up/step-down voltage regulation for AC power.

✅ Compact, cost-effective; used for motor starting and grid control.

What is an Autotransformer?

An autotransformer is an electrical transformer with only one winding that acts as both the primary and secondary winding. Unlike traditional transformers with separate windings, an autotransformer uses a single coil acting as both the input and output, depending on the tapped point. This single winding structure allows for significant material savings, notably the savings of copper in an autotransformer, which can lead to cost reductions and improved efficiency. For a broader overview of design variants, see this guide to autotransformers and their common use cases.

Basic Principle and Construction

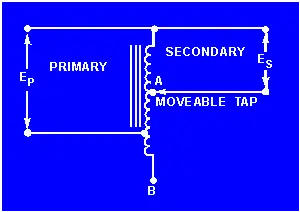

The basic principle relies on a single winding with a tap that divides the coil into two parts: the primary winding and the secondary winding. The primary and secondary circuits are common to both the primary and secondary windings, meaning they share a portion of the winding. This construction enables it to adjust the voltage level by varying the position of the tap. This tap-dependent behavior relies on the geometry and insulation of the transformer coil to control voltage sharing.

In a typical autotransformer, the primary winding is connected to the supply voltage, while the secondary voltage is taken from the tap point. The output voltage is proportional to the turns ratio between the tapped sections of the winding. This arrangement allows it to efficiently step up or step down the voltage as required. For foundational context on electromagnetic induction, review how transformers work in typical AC systems.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Advantages and Disadvantages

In many AC distribution settings, their performance is compared with that of a standard AC transformer to quantify efficiency gains.

Autotransformers offer several advantages:

- Efficiency: Due to the shared winding, autotransformers exhibit lower losses and higher efficiency compared to conventional transformers with separate windings.

- Cost-Effectiveness: The reduced use of materials, especially copper, results in lower manufacturing costs.

- Compact Size: The single winding design makes it more compact and lighter.

However, there are also disadvantages:

- Lack of Isolation: Since the primary and secondary sides are electrically connected, there is no isolation between them, which can be a safety concern.

- Short Circuit Risk: If the common winding gets short circuited, it can lead to severe damage.

- Limited Voltage Range: Autotransformers are less suitable for applications requiring significant voltage differences between the primary and secondary sides.

Applications

They are used in a variety of applications where the voltage adjustment does not require electrical isolation: In such roles they are often categorized alongside the broader class of voltage transformers used in measurement and control.

- Voltage Regulation: They serve as voltage regulators in power distribution systems to maintain a stable voltage level.

- Motor Starting: They provide reduced voltage to start motors, reducing inrush current and preventing electrical stress.

- Variable Voltage Supply: In laboratory settings, they provide adjustable output voltage for testing purposes.

- Power Transmission: They are used in power transmission to step up or step down voltages efficiently.

Differences Between Them and Two-Winding Transformers

The primary difference lies in their construction and operation. In an autotransformer, the primary and secondary windings are a single coil acting as both, whereas a two-winding transformer has separate windings for each. This fundamental difference impacts several aspects: For a structured comparison of topology and use cases, consult this overview of transformer vs autotransformer distinctions.

- Material Usage: Autotransformers use less copper and iron, leading to lower costs.

- Efficiency: With fewer windings and less resistance, they are more efficient.

- Isolation: Two-winding transformers provide electrical isolation between the primary and secondary circuits, which is not possible in autotransformers.

Safety Considerations

When using an autotransformer, safety is paramount due to the lack of isolation between the primary and secondary sides. Here are key considerations: These risks can be more pronounced near high-voltage transformers where fault energy levels are significant.

- Proper Grounding: Ensure the transformer is correctly grounded to prevent electrical shock hazards.

- Overload Protection: Implement protective devices to guard against overloads and short circuits, which can cause severe damage due to the shared winding.

- Voltage Drop Monitoring: Regularly monitor the voltage drop across the autotransformer to detect potential faults or inefficiencies.

- Inspection and Maintenance: Regular inspections and maintenance are crucial to ensure the device operates safely and efficiently.

What Is An Autotransformer? It is valuable in applications requiring efficient voltage regulation and transformation without the need for electrical isolation. Understanding their construction, benefits, limitations, and safety considerations is essential for their effective and safe use.