Group Lockout Tagout Energy Control

By R.W. Hurst, Editor

Arc Flash Training CSA Z462 - Electrical Safety Essentials

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

Group Lockout Tagout ensures safe maintenance when multiple workers service equipment. This OSHA- and NFPA 70E-compliant system uses locks, tags, and coordination to control hazardous energy and protect every authorized employee.

What is Group Lockout Tagout?

Group Lockout Tagout is a safety method used when more than one employee works on the same machine or energy source. It:

✅ Allows each worker to apply their personal lock or tag for protection

✅ Uses group lock boxes or hasps to secure hazardous energy sources

✅ Ensures OSHA and NFPA 70E compliance with clear coordination and verification

To understand the fundamentals, start with What is Lockout Tagout and how it applies across industries.

Request a Free Training Quotation

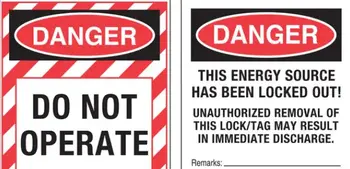

Group Lockout Tagout (LOTO) is a federally regulated safety protocol that ensures protection for multiple workers performing maintenance on the same machine. OSHA 29 CFR 1910.147(f)(3) requires each authorized employee to apply a personal lock, preventing the accidental startup of hazardous equipment. This procedure ensures that no equipment can be re-energized until every individual has safely completed their work.

When multiple workers are involved in servicing machinery, group lockout tagout procedures are essential to ensure everyone's safety. Under Standard 1910.147, the Occupational Safety and Health Administration outlines specific requirements for managing group activities within a lockout tagout program. OSHA regulations provide the foundation for compliance, as outlined in the OSHA Lockout Tagout Standard. A central component of this process is the use of a group lockbox or group lockout boxes, which securely hold the keys to the energy isolating device once it has been locked out. Each authorized worker then applies their personal lock to the group box, ensuring that the system cannot be re-energized until all locks have been removed. This method reinforces accountability and guarantees that no individual is exposed to hazardous energy during maintenance operations. OSHA Lockout Tagout Requirements

Sign Up for Electricity Forum’s Arc Flash Newsletter

Stay informed with our FREE Arc Flash Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Why Group Lockout Tagout Matters

Group Lockout Tagout is essential when multiple employees work on the same equipment. It ensures every worker is protected by requiring personal locks and tags, preventing accidental machine startup. This method also reinforces OSHA and NFPA 70E compliance while reducing downtime and improving overall workplace safety.

In many industrial and utility environments, equipment maintenance involves teams rather than individuals. Group lockout procedures are designed to:

-

Ensure personal control and accountability

-

Prevent equipment start-up until every worker has removed their lock

-

Comply with OSHA's requirements for hazardous energy control during multi-person tasks

This approach ensures no one can restart the machine until everyone is clear and protected.

OSHA Requirements for Group Lockout Tagout

According to 29 CFR 1910.147(f)(3), OSHA mandates that when multiple employees are involved:

-

A primary authorized employee is designated to oversee the lockout procedure.

-

Each employee working on the equipment must apply their own personal lock or tag to the group lockout device (usually a group lock box or hasp).

-

Each lock remains in place until the worker has completed their task.

-

If responsibility is transferred, outgoing and incoming personnel must coordinate the change.

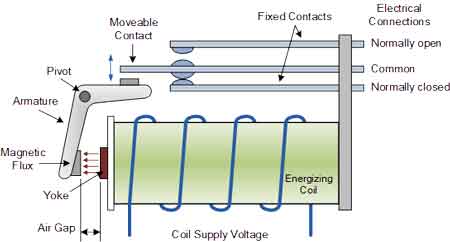

Devices Used in Group Lockout

A group lock box is the most commonly used tool. It allows all keys from locked-out energy sources to be secured inside the box. Each authorized worker places their personal padlock on the outside of the box, ensuring the equipment can't be re-energized until every worker removes their lock. Practical applications can be explored in our Lockout/Tagout Devices section, which covers padlocks, hasps, and group lock boxes.

Other common devices include:

-

Lockout hasps allow multiple padlocks on a single isolation point

-

Group tagout tags to indicate who is involved and why the equipment is isolated

How Many Locks Are Needed?

Each authorized employee must apply one personal lock to the group device or lockbox. If five employees are servicing a piece of machinery, five individual locks are required. This ensures that no single employee can restore energy until all others have confirmed it is safe.

Best Practices for Implementing Group LOTO

To maintain compliance and safety:

-

Conduct comprehensive training for all authorized employees

-

Document group LOTO procedures specific to each piece of equipment

-

Use standardized devices and labeling systems

-

Audit regularly to confirm correct execution and understanding

-

Encourage team communication during all lockout processes

If you need a clear, step-by-step breakdown, review our detailed Lockout/Tagout Procedure and best practices.

The Benefits of Group Lockout Tagout

-

Reduces risk of accidental energization

-

Ensures individual accountability

-

Complies with OSHA and CSA standards

-

Fosters a culture of safety, teamwork, and shared responsibility

By adopting well-documented and compliant group lockout procedures, employers can significantly improve safety for workers performing maintenance or servicing operations involving hazardous energy.

Frequently Asked Questions

What is the OSHA requirement for a group lockout tagout procedure?

OSHA 29 CFR 1910.147(f)(3) requires that each authorized employee apply their own lock to a group lockout device. A primary authorized employee must oversee the procedure, and all locks must remain in place until each worker finishes their task.

What is the purpose of a group lock box?

A group lock box holds the keys to locked-out equipment. After isolation, each employee attaches a personal padlock to the box, ensuring the system stays shut down until every lock is removed.

Who is the primary authorized employee in a group lockout?

The primary authorized employee is responsible for coordinating group lockout procedures, verifying lock application, ensuring communication among workers, and overseeing the orderly removal of locks once work is safely completed.

Related Articles

-

To clear up common issues, explore Lockout Tagout Questions, where frequently asked topics are explained in detail.

To ensure compliance and worker protection, The Electricity Forum offers specialized Construction Electrical Safety Training, including NFPA 70E Training and CSA Z462 Arc Flash Training courses. Request a free training quotation today to equip your team with the knowledge and skills they need to stay safe on the job.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience