Prohibited Approach Boundary

By R.W. Hurst, Editor

CSA Z462 Arc Flash Training - Electrical Safety Essentials

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

Prohibited approach boundary defines the closest clearance distance to energized equipment under NFPA 70E, indicating extreme shock hazard, arc flash risk, required PPE, and access limited to qualified persons with proper training and permits.

What Is the Prohibited Approach Boundary?

The minimum approach distance to energized parts where only qualified personnel may enter due to severe shock risk.

✅ Defined by NFPA 70E for shock protection boundaries

✅ Requires PPE, permits, and a qualified person

✅ Distance varies with system voltage and equipment

Note: The Prohibited Approach Boundary no longer appears in the most recent edition of NFPA 70E, but it is still found in legacy documentation and training. It represented the closest distance to live parts where direct contact was considered imminent.

The Prohibited Approach Boundary, was once part of NFPA 70E, defined the closest distance to energized parts where shock was imminent. Though now removed from the standard, it’s still relevant in legacy training, emphasizing high-risk zones requiring maximum protection. For context, see the NFPA 70E approach boundaries to understand how proximity zones are structured.

Understanding its role remains valuable for those reviewing older power system studies, facility labels, or historical safety procedures. This zone reinforced the highest level of precaution, requiring the same level of protection as direct contact with live parts.

Historical Context and Training Relevance

The Prohibited Approach Boundary was established to protect workers from the highest level of electrical risk associated with working near conductors or circuit parts. It represented the closest distance from an exposed energized component where accidental contact could be equivalent to a direct electrical shock. Although no longer part of the current NFPA 70E standard, the boundary is still referenced in some electrical safety training programs to emphasize historical safety practices and situational awareness. Developed under the guidance of the National Fire Protection Association (NFPA), commonly known as the Fire Protection Association NFPA, this concept underscored the critical need for proper PPE, risk assessment, and worker qualification in high-voltage environments. A concise primer on the three limits of approach boundaries can help differentiate legacy concepts from current practice.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

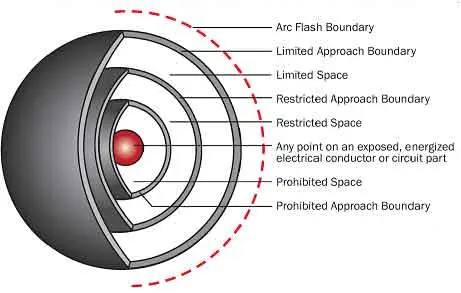

Legacy NFPA 70E Approach Boundaries (Including the Prohibited Boundary)

NFPA 70E defines three distinct approach boundaries for electrical work:

- Limited Approach Boundary: This is the outermost boundary beyond which a shock hazard exists. Unqualified personnel must not cross this boundary unless escorted by a qualified person.

- Restricted Approach Boundary: This boundary lies within the limited approach boundary and signifies an increased risk of shock due to potential arc-over and inadvertent movement. Only qualified workers may enter this zone, and they must be adequately insulated or guarded from live parts.

- Prohibited Approach Boundary: The innermost boundary, where work is equivalent to making direct contact with the live part. Only qualified personnel with specific training, an approved energized electrical work permit, and appropriate Arc Flash PPE can cross this boundary.

For deeper insight into qualifications and distances within this zone, review the Restricted Approach Boundary requirements to align procedures and training.

What are the Requirements for Working in the PAB?

Working within the PAB requires strict adherence to safety protocols to prevent electrical shock and incidents. The requirements include:

-

Qualified Person: Only qualified persons with specific training in avoiding electrical hazards can work within this boundary.

-

Personal Protective Equipment (PPE): Workers must wear appropriate PPE and shock protection equipment. This includes insulated tools, rubber gloves, and flame-resistant clothing to protect against potential incident energy and boundary hazards.

-

Work Permit: Before commencing any work, a detailed work permit outlining the scope of the work, the hazards involved, and the protective measures required must be issued.

-

De-energization: The electrical system should be de-energized before work begins. If de-energization is not feasible, other protective measures, such as insulating barriers or guards, must be implemented.

How to Determine the PAB?

The PAB is determined based on the voltage of the exposed energized parts. NFPA 70E provides tables that specify the distance from an exposed piece of electrical equipment for various voltage levels. For example, for systems operating at 750V to 15kV, the PAB is typically calculated to ensure that any inadvertent movement does not result in contact with live parts. For a broader methodology, see how arc-flash and electric shock protection boundaries are determined across various system conditions.

The calculation considers the potential for electrical arcing and the need to prevent any degree burn or other injuries. Incident energy analysis is often conducted to determine the appropriate boundaries and necessary PPE for workers. Many practitioners consult the Arc Flash Boundary Chart when validating study results and communicating PPE levels.

Barricades and the limited and restricted approach boundaries

Barricades can be placed to demarcate the limited approach boundary and prevent unauthorized personnel from entering the hazardous zone. However, they should not be placed closer than the limited approach protection boundary, as this would restrict the movement of qualified workers who need to access the equipment. The barricades should be clearly marked and visible to ensure everyone understands the safety restrictions. To ensure barricades are set appropriately, reference the Limited Approach Boundary guidance for minimum distances and escort provisions.

Additional Considerations

Beyond the PAB, other safety measures are essential for electrical work. These include using insulated tools, maintaining proper clearances, and de-energizing equipment whenever possible. Regular training and refresher courses on electrical safety and NFPA 70E standards are crucial for both qualified and unqualified personnel. These practices work in concert with the Arc Flash Boundary to manage thermal and shock exposures holistically.

Understanding and respecting the PAB is vital for ensuring the safety of workers in electrical environments. Adhering to NFPA 70E guidelines, conducting thorough risk assessments, and using appropriate PPE can minimize the risk of electrical shock and injuries. Electrical safety is a shared responsibility, and every worker plays a role in preventing accidents and promoting a safe work environment.

Related Pages

Arc Flash Boundary Table By Incident Energy

What's the Arc Flash Boundary for 8 cal/cm²?