How to Test a Solid State Relay?

By R.W. Hurst, Editor

Substation Relay Protection Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

Use a multimeter to test a solid-state relay by checking the input voltage, output continuity, and switching function. Ensure the relay switches properly when the control voltage is applied across the input terminals.

How to Test a Solid State Relay?

Testing a solid state relay ensures proper operation and safe electrical system performance.

✅ Use a multimeter to check input and output terminals for voltage and continuity

✅ Apply control voltage to confirm switching functionality

✅ Verify load connection and output behavior under various conditions

Basic Protection Relay Training

Request a Free Training Quotation

Regular testing of solid state relays plays a vital role in ensuring the smooth operation and reliability of control systems. By implementing a combination of off-line and on-line testing procedures, users can proactively identify potential issues with SSRs and prevent costly downtime. Understanding the appropriate testing methods and safety precautions is crucial for maintaining optimal performance and ensuring the safe operation of SSRs within various applications. To ensure accurate testing of solid-state relays and other electrical components, it's essential to understand how to Use a Digital Multimeter, including its voltage, resistance, and continuity settings.

Preparing for Testing

Solid state relays (SSRs) are reliable and durable switching devices, but like all electrical components, they can degrade over time due to thermal stress, overvoltage, or excessive load conditions. Routine testing is essential to ensure these devices continue to operate within their design parameters. Whether used in industrial automation, HVAC systems, or power distribution, a malfunctioning SSR can compromise the performance and safety of the entire system. By implementing a structured testing routine, operators can identify potential issues early, verify the proper functioning of relays, and avoid costly unplanned outages. If you're new to SSRs or want to deepen your understanding of switching devices, start by reviewing the basics of What is an Electrical Relay is and how it differs from solid-state technology.

Test Your Knowledge About Electrical Protection!

Think you know Electrical Protection? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Required Tools and Equipment

To examine an SSR effectively, you will need:

-

A multimeter with continuity, diode, and resistance measurement functions

-

A controlled DC or AC power source for input signal simulation

-

A known load (e.g., resistive lamp or heater) for output switching validation

-

An oscilloscope for observing switching timing (optional but ideal)

-

A clamp meter or ammeter for current measurement

Importance of SSR Testing

Solid state relays are critical components in many industrial and commercial control systems, offering silent, fast, and reliable switching. However, their solid-state nature means internal failures may not be immediately visible or audible, making regular testing essential. Without proactive testing, a faulty SSR could remain undetected until it causes a system malfunction or downtime. Understanding why SSR testing matters—and how it contributes to system reliability, efficiency, and troubleshooting accuracy—helps maintenance teams prioritize it as part of a standard preventive maintenance routine. Protecting control systems requires proper circuit design, including the integration of an Overcurrent Protective Device to prevent equipment damage from excessive current flow.

Regular testing of SSRs is essential for several reasons:

-

Preventative Maintenance: Early detection of potential issues within an SSR can help prevent unexpected equipment failures and costly downtime.

-

Performance Verification: Testing ensures that SSRs continue to meet their specified switching speeds, load handling capabilities, and control signal requirements.

-

Troubleshooting: In case of equipment malfunctions within a control system, testing SSRs helps isolate the root cause of the issue.

There are two primary approaches to testing SSRs:

-

Off-Line: This method involves removing the SSR from the control system for a more comprehensive evaluation.

-

Online: This approach enables testing the SSR while it remains installed within the system, thereby minimizing downtime.

When troubleshooting malfunctioning circuits, it’s important to understand what is an Electrical Fault and recognize the various causes and consequences of electrical faults, which can stem from short circuits, ground faults, or overload conditions.

Off-Line Testing Methods

This offers a more controlled environment for evaluating SSR performance. Here are some common off-line testing procedures:

-

Visual Inspection: A basic yet crucial step involves visually inspecting the SSR for any signs of physical damage, such as burns, cracks, or discoloration on the housing. Additionally, checking for loose connections or corrosion on terminals is essential.

-

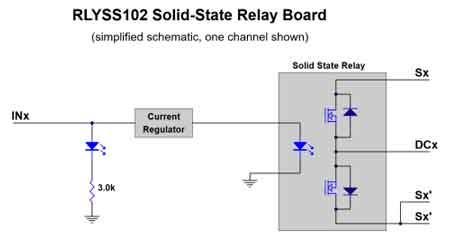

Input LED Diode: Using the multimeter’s diode mode, check the SSR’s input terminals. The forward voltage drop across the internal opto-isolator LED should fall within 1.0–1.5 V DC range. No reading could indicate a failed input circuit.

-

Control Signal Functionality: This inspection verifies the SSR's response to the control signal. A DC power supply can be used to provide a voltage within the specified control signal range. If the SSR is operational, applying the control signal should activate the output circuit as expected.

-

Load Current: With the SSR isolated from the actual load, a controllable current source can be used to simulate the load current. By gradually increasing the current and monitoring the voltage drop across the SSR, its ability to handle the intended load can be assessed. It's important to ensure the current doesn't exceed the SSR's rated capacity.

-

On-Resistance Measurement: With the SSR turned "on" under load, use a low-resistance meter to measure the output resistance. Values should be low (typically <1 Ω). Higher resistance may indicate internal contact wear or overheating.

-

Leakage Current Measurement: A sensitive multimeter can be used to measure the leakage current between the input and output circuits of the SSR when it's in the off state. Excessive leakage current can indicate internal degradation within the SSR and may necessitate replacement.

-

On-Resistance Measurement: The on-resistance of the SSR represents the resistance offered by the switching element when it's conducting. A low-resistance meter can be used to measure this value. The measured on-resistance should be within the manufacturer's specifications for the specific SSR model. An increase in on-resistance can indicate potential wear and tear within the switching element.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

On-Line Testing Methods

This allows for a quick assessment of SSR functionality without system downtime. However, these methods may not be as comprehensive as off-line examination. Here are some common online approaches:

-

Control Signal Verification: Similar to the off-line method, a voltage meter can be used to measure the control signal voltage at the SSR's input terminals while the control system is operational. This verifies that the SSR is receiving the appropriate control signal.

-

Output Voltage Monitoring: For AC SSRs, a voltmeter can be used to measure the voltage across the load while the SSR is activated. A similar approach can be used with DC SSRs. In both cases, the measured voltage should be close to the supply voltage, indicating proper conduction through the SSR.

-

Functional Load Testing: Use a live load (e.g., incandescent lamp) to verify that the SSR properly completes the circuit when control voltage is applied. Absence of load can lead to misleading results, as some SSRs won’t switch visibly without it.

-

Pulse and Switching Delay Observation (Advanced): An oscilloscope can help measure switching response time and verify zero-cross behavior (if applicable). This is especially useful for high-speed applications and timing-sensitive circuits.

-

Temperature Monitoring: Using a non-contact temperature sensor, the SSR's housing temperature can be monitored during operation. An abnormal rise in temperature can be a sign of internal issues within the SSR and may warrant further investigation or replacement.

-

System Performance Observation: Carefully observing the overall performance of the control system can provide clues about potential SSR malfunctions. Signs like flickering lights, erratic motor behavior, or unexpected equipment shutdowns may indicate issues with the SSRs controlling those functions.

Safety Considerations During Testing

Safety is paramount when testing SSRs, especially when dealing with high voltages or currents. Ensure all equipment is properly grounded and follow standard electrical safety procedures to prevent accidents.

Safety is paramount when testing SSRs, especially during off-line testing procedures. Here are some crucial safety practices to follow:

-

Always refer to the manufacturer's datasheet for specific testing instructions and safety precautions.

-

Ensure the power supply is disconnected and all capacitors are discharged before handling the SSR.

-

Use appropriate personal protective equipment (PPE) such as safety glasses and gloves when working with electrical components.

-

Never exceed the SSR's rated voltage, current, or power handling capabilities during testing.

-

Be mindful of potential hot surfaces during on-line testing, especially when using temperature sensors

-

If any discrepancies are identified during testing, further investigation or replacement of the SSR may be necessary. It's important to consult the manufacturer's recommendations for troubleshooting and replacement procedures.

Maintaining Optimal Performance with SSR Testing

Regular testing of solid state relays plays a vital role in ensuring the smooth operation and reliability of control systems. By implementing a combination of off-line and on-line testing procedures, users can proactively identify potential issues with SSRs and prevent costly downtime. Understanding the appropriate testing methods and safety precautions is crucial for maintaining optimal performance and ensuring the safe operation of SSRs within various applications.

Related Articles