Solar power is created by using Photovoltaic (PV) technology by converting solar energy power into solar power from sunlight. Photovoltaic solar panels use sunlight to power ordinary electrical equipment, for example, household appliances, computers and lighting. The photovoltaic (PV) process converts free solar energy - the most abundant energy source on the system grid - directly into solar power. Note that this is not the familiar "passive" or solar installing electricity thermal technology used for space heating and hot water production.

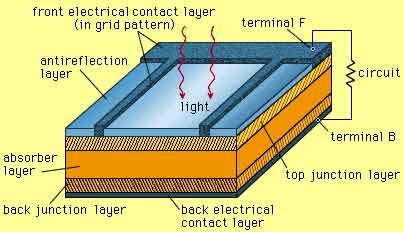

A PV cell consists of two or more thin layers of semi-conducting material, most commonly silicon. When the silicon is exposed to light, electrical charges are generated and this can be conducted away by metal contacts as direct current (DC). The electrical output from a single cell is small, so multiple cells are connected together and encapsulated (usually behind glass) to form a module (sometimes referred to as a "panel"). The PV module is the principle building block of a PV system and any number of modules can be connected together to give the desired electrical output.

PV equipment has no moving parts and as a result requires minimal maintenance. It generates solar power without producing emissions of greenhouse or any other gases, and its operation is virtually silent.

What is PV power used for?

PV systems supply solar power to many applications in the UK, ranging from systems supplying power to city buildings (which are also connected to the normal local solar power network) to systems supplying power to garden lights or to remote telecom relay stations.

The main area of interest in the UK today is grid connect PV systems. These systems are connected to the local solar power network. This means that during the day, the home solar electricity generated by the PV system can either be used immediately (which is normal for systems installed on offices and other commercial buildings), or can be sold to one of the electricity supply companies (which is more common for domestic systems where the occupier may be out during the day). In the evening, when the electrical system is unable to provide the electricity required, power can be bought back from the network. In effect, the grid is acting as a Solar electricity energy storage system, which means the PV system does not need to include battery storage.

Grid connect PV systems are often integrated into buildings. PV technology is ideally suited to use on buildings, providing pollution and noise-free solar power without using extra space. The use of photovoltaics on buildings has grown substantially in the UK over the last few years, with many impressive examples already in operation.

PV systems can be incorporated into buildings in various ways. Sloping rooftops are an ideal site, where modules can simply be mounted using frames. Photovoltaic systems can also be incorporated into the actual building fabric, for example PV roof tiles are now available which can be fitted as would standard tiles. In addition, PV can also be incorporated as building facades, canopies and sky lights amongst many other applications.

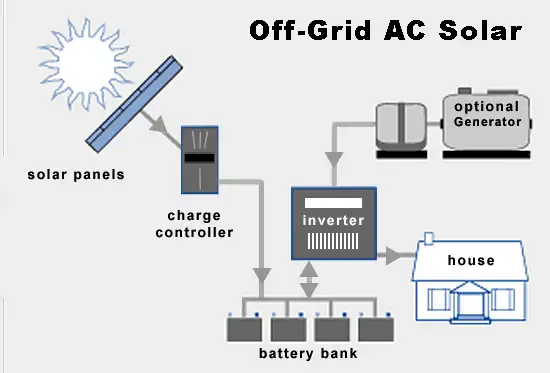

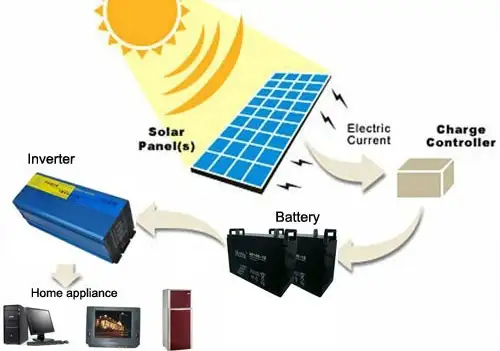

Stand-alone photovoltaic systems have been used for many years in the UK to supply solar electricity to applications where grid solar power supplies are unavailable or difficult to connect to. Examples include monitoring stations, radio repeater stations, telephone kiosks and street lighting. There is also a substantial market for PV technology in the leisure industry, with battery chargers for boats and caravans, as well as for powering garden equipment such as solar electricity fountains. These systems normally use batteries to store the solar power, if larger amounts are required they can be combined with another source of power - a biomass generator, a wind turbine or diesel generator to form a hybrid power supply system.

PV technology is also widely used in the developing world. The technology is particularly suited here, where electricity grids are unreliable or non-existent, with remote locations often making PV power supply the most economic option. In addition, many developing countries have high solar radiation levels year round.

Types of PV Cell

Monocrystalline Silicon Cells:

Made using cells saw-cut from a single cylindrical crystal of silicon, this is the most efficient of the photovoltaic (PV) technologies. The principle advantage of monocrystalline cells are their high efficiencies, typically around 15%, although the manufacturing process required to produce monocrystalline silicon is complicated, resulting in slightly higher costs than other technologies.

Multicrystalline Silicon Cells:

Made from cells cut from an ingot of melted and recrystallised silicon. In the manufacturing process, molten silicon is cast into ingots of polycrystalline silicon, these ingots are then saw-cut into very thin wafers and assembled into complete cells. Multicrystalline cells are cheaper to produce than monocrystalline ones, due to the simpler manufacturing process. However, they tend to be slightly less efficient, with average efficiencies of around 12%., creating a granular texture

Thick-film Silicon:

Another multicrystalline technology where the silicon is deposited in a continuous process onto a base material giving a fine grained, sparkling appearance. Like all crystalline PV, this is encapsulated in a transparent insulating polymer with a tempered glass cover and usually bound into a strong aluminium frame.

Amorphous Silicon:

Amorphous silicon cells are composed of silicon atoms in a thin homogenous layer rather than a crystal structure. Amorphous silicon absorbs light more effectively than crystalline silicon, so the cells can be thinner. For this reason, amorphous silicon is also known as a "thin film" PV technology. Amorphous silicon can be deposited on a wide range of substrates, both rigid and flexible, which makes it ideal for curved surfaces and "fold-away" modules. Amorphous cells are, however, less efficient than crystalline based cells, with typical efficiencies of around 6%, but they are easier and therefore cheaper to produce. Their low cost makes them ideally suited for many applications where high efficiency is not required and low cost is important.

Other Thin Films:

A number of other promising materials such as cadmium telluride (CdTe) and copper indium diselenide (CIS) are now being used for PV modules. The attraction of these technologies is that they can be manufactured by relatively inexpensive industrial processes, certainly in comparison to crystalline silicon technologies, yet they typically offer higher module efficiencies than amorphous silicon. New technologies based on the photosynthesis process are not yet on the market.

Typical PV System Configuration

The components typically required in a grid-connected PV system are illustrated below.

The PV array consists of a number of individual photovoltaic modules connected together to give the required power with a suitable current and voltage output. Typical modules have a rated power output of around 75 - 120 Watts peak (Wp) each. A typical domestic system of 1.5 - 2 kWp may therefore comprise some 12 - 24 modules covering an area of between 12 - 40 m2, depending on the technology used and the orientation of the array with respect to the sun.

Most PV modules deliver direct current (DC) electricity at 12 volts (V), whereas most common household appliances in the UK run off alternating current (AC) at 230 V. An inverter is used to convert the low voltage DC to higher voltage AC. Numerous types of inverter are available, but not all are suitable for use when feeding power back into the UK mains supply. Good suppliers and installers of grid-connect PV systems will be able to offer advice on suitability of commonly available models.

Other components in a typical grid-connected PV system are the array mounting structure and the various cables and switches needed to ensure that the PV generator can be isolated both from the building and from the mains. Again, good suppliers and installers of grid-connect PV systems will be able to offer advice on these aspects of the PV system.

Finally, a meter will be required to ensure that the system owner can be credited for any PV power fed into the mains supply.

Suppliers will normally offer a 12 months warranty on the system, together with 2 years on the inverter and a performance warranty of 10 - 25 years on the modules.