VFD Programming: Crucial For Motor Control

By Paul Wright, P.Eng.

Motor Control Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

VFD programming configures variable frequency drives for motor control, optimizing torque, acceleration, and energy efficiency. Proper setup ensures reliable performance, reduced downtime, and tailored operation in industrial and HVAC systems.

What is VFD Programming?

VFD Programming is the process of setting parameters in variable frequency drives to regulate motor performance, efficiency, and safety.

✅ Adjusts speed, torque, and acceleration profiles

✅ Enhances motor efficiency and reduces energy use

✅ Improves reliability, safety, and process control

Electric Motor Testing Training

Request a Free Training Quotation

In industrial applications, Variable Frequency Drive (VFD) programming plays a crucial role in motor control and energy efficiency. VFD programming involves configuring and optimizing the settings of a VFD to achieve desired motor performance and reduce energy consumption. With the right programming techniques, users can remotely control motor speed, improve energy efficiency, and leverage common VFD communication protocols for seamless operation.

The VFD service industry has long faced a safety dilemma. Traditionally, VFDs with a high arc flash risk potential were housed within the same cabinet as live 600-volt power. This dangerous combination required technicians to wear protective clothing when programming the VFD, increasing the risk of accidents due to limited dexterity and poor visibility. Fortunately, innovations like the JZB1000 MCC by Higrid Power Corp. have mitigated these risks by isolating the VFD from high-energy power sources. Effective VFD programming depends on understanding the fundamentals of electric motor control and how drives regulate torque, speed, and efficiency.

When programming a VFD, careful adjustment of acceleration and deceleration times is essential for smooth operation in applications that require precise control, such as fans and pumps. Proper use of digital and analog input signals enables operators to fine-tune speed settings according to the motor's rated values, ensuring both efficiency and protection. These parameters directly influence how the drive manages the motor's starting and stopping, minimizing stress on the equipment while extending its service life.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

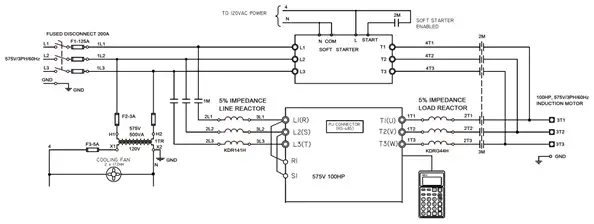

Figure 1. Typical VFD with 30 to 60kA short circuit capability

Key VFD Parameters and Settings

To understand the intricacies, it is essential to become familiar with specific VFD parameters and concepts. These include motor nameplate data, motor overload protection, full-load amperage, and analog inputs. Additionally, technicians should know how to reset the drive to factory or default settings when necessary and be able to navigate parameter numbers to configure the VFD for optimal performance.

Beyond the basics, modern programming requires deeper knowledge of:

-

Control modes: V/Hz scalar control, sensorless vector control, and closed-loop vector control.

-

Carrier frequency and PWM control: Determines switching noise, torque ripple, and harmonic distortion.

-

Acceleration and deceleration ramps: Control how quickly the motor reaches or slows from set speed.

-

Start/stop methods: Coast to stop, soft stop, or controlled braking, including regenerative braking options.

-

Direction control and minimum speed limits: Ensure safe and application-specific operation.

Motor nameplate data is crucial for ensuring proper VFD configuration. The motor's nameplate provides essential information, such as voltage, current, and speed ratings, to determine suitable VFD settings. Motor overload protection is also crucial to prevent damage to the motor due to excessive current or overheating. Full load amperage refers to the current a motor draws when operating at its rated horsepower. At the same time, analog inputs enable remote motor speed control via a proportional signal from an external device. Technicians can optimize energy use by combining VFD programming with efficiency opportunities through motor maintenance for long-term cost savings.

Figure 2. Typical VFD with 30 to 60kA short circuit capability with Draw out isolation

Wiring, Installation, and Environmental Considerations

Proper installation has a direct impact on performance and longevity. Key factors include:

-

Mounting and enclosures: NEMA or IP-rated enclosures protect against dust, moisture, and contaminants.

-

Cooling and ventilation: Adequate airflow prevents overheating.

-

Cable routing: Long motor leads can create voltage spikes, requiring dV/dt filters or output reactors.

-

Grounding and shielding: Essential to minimize electromagnetic interference.

-

Control wiring: Proper connections for digital inputs, analog signals, or communication protocols like Modbus, Profibus, or Ethernet/IP.

Programming a VFD requires accurate motor data, which is why knowledge of electric motor design and electric motor efficiency is essential.

Safety Enhancements

The JZB1000 MCC features two design versions that eliminate arc flash incidents during coding. In the first version, the complete VFD and necessary options are mounted in a draw-out unit that can be disconnected from the vertical bus. A low-energy control power supply, typically 24VDC or AC, powers up the microprocessor and keypad while the unit is physically disconnected from the 600-volt bus. This setup allows technicians to program the VFD safely without needing face shields or gloves. For safe and reliable operation, VFD parameters should always be set with proper motor overload protection in mind.

The second version also features a draw-out cell but utilizes a separate cell for the fused switch or circuit breaker. Once this feeder cell is padlocked in the disconnected position, the arc flash risk is reduced.

Additional safety functions include Safe Torque Off (STO), ground fault protection, thermal protection, and interlocks that ensure safer maintenance and operation.

Advanced Applications

Different loads demand different programming approaches:

-

Pumps and fans: Utilize PID loops and variable speed control for enhanced energy efficiency.

-

Conveyors: Require precise torque and acceleration control to avoid product damage.

-

Compressors: Benefit from soft start/stop to minimize mechanical stress.

-

Flying start: Enables the VFD to catch a motor that is already spinning.

By optimizing these advanced settings, technicians can tailor drive performance to specific industrial applications.

If you’re new to drives, learning how a VFD works provides the foundation for understanding more advanced VFD drives programming techniques.

Troubleshooting, Fault Codes, and Maintenance

Common VFD faults include overvoltage, undervoltage, overcurrent, ground faults, and motor overheating. Proper programming and monitoring help minimize these issues.

Maintenance practices should include:

Test Your Knowledge About Motors and Drives!

Think you know Motors and Drives? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

-

Regular inspection and cleaning to prevent dust buildup.

-

Checking cooling fans and filters.

-

Monitoring diagnostic data (motor vibration, current, and temperature).

-

Updating firmware and reviewing fault logs.

In building systems, variable frequency drive HVAC programming shows how tailored drive settings can maximize comfort while lowering energy use.

Real-World Benefits and Energy Savings

The numerous benefits include energy savings, remote motor speed control, and improved motor performance. By optimizing the VFD parameters, technicians can ensure the motor operates at the most efficient point on its torque-speed curve, resulting in substantial energy savings and lower operating costs. Payback periods are often achieved within two to three years due to reduced power bills and extended equipment life.

Moreover, with modern VFD communication protocols, users can remotely monitor and control motor speed, adding flexibility to industrial operations. Comparative studies show that while soft starters provide reduced inrush current, VFDs deliver continuous energy efficiency, torque control, and diagnostic feedback.

It is an essential skill in the industrial sector. With innovations like the JZB1000 MCC, technicians can program VFDs more safely while understanding key parameters and concepts that will ensure optimal motor performance and energy efficiency. Whether you're an experienced engineer or new to VFDs, mastering these skills will undoubtedly prove invaluable in today's demanding industrial landscape. To apply this knowledge in real projects, variable frequency drive training courses expand skills in commissioning, VFD sizing, and practical programming.

Related Articles