What Is a Motor Control Centre?

By R.W. Hurst, Editor

Motor Control Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

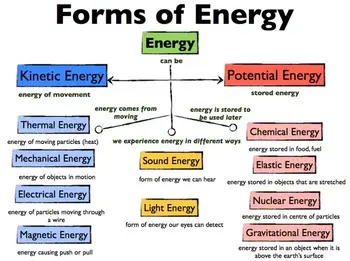

A motor control centre (MCC) is a centralized system that houses motor starters, protection devices, and control equipment. It is used to safely and efficiently manage and automate electric motors in industrial and commercial environments.

Quick Definition: What Is a Motor Control Centre?

-

✅ Definition: A Motor Control Centre (MCC) is an assembly of one or more enclosed sections containing motor control units, including starters, circuit breakers, and other control devices, used to control and protect electric motors in industrial settings.

-

✅ Components: Typically includes motor starters, circuit breakers, fuses, overload relays, and disconnect switches, all housed in a centralized enclosure.

-

✅ Applications: Commonly used in manufacturing plants, commercial buildings, and other industrial environments to manage multiple electric motors from a central location.

The MCC is an assembly of multiple enclosed sections, each containing control components used to manage and protect the electric motors in the system. MCCs are usually installed in a separate air-conditioned room, known as a controlled room, for easy access and maintenance. The MCC panels include starters, circuit breakers, fuses, circuit breaker-fuse combinations, solid-state and thermal overload relays, variable-frequency drives (VFDS), and disconnecting switches. The control panels in MCCs manage the power distribution, switching, and protection of electric motors in a central control system.

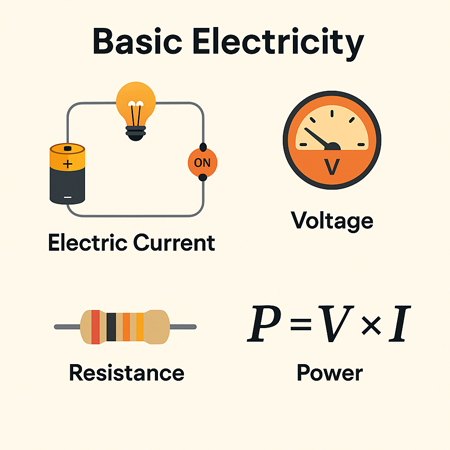

An MCC is typically composed of three sections: the vertical bus, the horizontal bus, and the control section. The vertical bus connects the main power source to the various starter units in the main control center (MCC). The horizontal bus connects the individual starters to the common power bus, which distributes the power to the motors in the system. Finally, the control section contains the control circuits and switches used to operate the starters and the other control components in the MCC.

Test Your Knowledge About Motors and Drives!

Think you know Motors and Drives? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Types of Motor Starters in Motor Control Centres

Motor starters are essential components within an MCC, responsible for initiating and regulating electric motors. Selecting the appropriate starter type is crucial for optimal performance and energy efficiency.

-

Direct-On-Line (DOL) Starters: These starters apply full voltage directly to the motor terminals, making them suitable for small motors where high inrush current does not pose issues.

-

Star-Delta Starters: Utilized to reduce starting current and torque in larger motors by initially connecting in a star configuration before transitioning to a delta setup.

-

Soft Starters: These devices gradually ramp up voltage during startup, minimizing mechanical stress and extending the lifespan of equipment.

-

Variable Frequency Drives (VFDs): VFDs offer precise control over motor speed and torque by adjusting input frequency and voltage, enhancing energy efficiency.

For a comprehensive understanding of these starter types and their applications, refer to our detailed guide on Electric Motor Control - Starters, VFDs.

MCC Safety Standards

Ensuring safety in MCC operations is paramount, necessitating adherence to established standards and regulations in both the U.S. and Canada.

-

NFPA 70 (National Electrical Code): In the U.S., this code outlines safe electrical design, installation, and inspection practices.

-

UL 845: This standard pertains to the construction and performance of MCCs, ensuring they meet specific safety requirements.

-

CSA C22.2 No. 254: In Canada, this standard governs the safety of MCCs, aligning with national electrical codes.

-

Arc Flash Compliance: Standards like NFPA 70E and CSA Z462 provide guidelines to protect workers from arc flash hazards through proper labeling, PPE, and safe work practices.

Safety also depends on proper motor design and usage. For deeper insight, review Electric Motor Design Engineering

Integrating MCCs with Automation Systems

Modern MCCs are integral to industrial automation, facilitating enhanced control, monitoring, and efficiency.

-

PLC and HMI Integration: MCCs often interface with Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) to enable real-time monitoring and control.

-

Communication Protocols: Utilizing protocols like Ethernet/IP, Modbus, or PROFIBUS allows seamless communication between MCCs and other automation systems.

-

Smart MCCs: Equipped with intelligent devices, these MCCs provide data analytics, predictive maintenance, and improved energy management.

Explore the intricacies of industrial automation and how MCCs play a pivotal role in our article on Industrial Automation And Communication Networks.

Efficiency and Maintenance in MCC Applications

A well-maintained MCC directly contributes to operational efficiency and reduced energy waste. Routine inspections, thermal imaging, and vibration analysis are common maintenance practices.

Read more in Electric Motor Maintenance and Diagnostics

For strategies to improve energy use, see Efficiency Opportunities Through Motor Maintenance

Choosing the Right Equipment for Your Application

Whether designing a new MCC or upgrading an existing one, component selection is vital. This includes proper motor sizing, overload protection, and circuit isolation methods.

Learn how Electric Motor Protection plays a role in MCC reliability.

Frequently Asked Questions

What components are typically included?

Components included in an MCC panel include starters, circuit breakers, fuses, or circuit breaker-fuse combinations, solid-state and thermal overload relays, variable frequency drives (VFD), and disconnecting switches.

What is the purpose of an MCC?

The purpose of an MCC is to manage and protect electric motors in an industrial or commercial setting. MCCs provide efficient power management, safety, and protection for the motors in the system.

What is the difference between MCC and PLC?

An MCC is an assembly of multiple enclosed sections containing control components to manage and protect electric motors in an industrial or commercial setting. On the other hand, a programmable logic controller (PLC) is a digital computer used to control and automate industrial processes. While MCCs and PLCs are used in industrial applications, they serve different functions.

Sign Up for Electricity Forum’s Motors and Drives Newsletter

Stay informed with our FREE Motors and Drives Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Is a VFD considered an MCC?

No, a variable frequency drive (VFD) is not considered an MCC. A VFD is an electronic device that controls an AC motor's speed by varying the electrical supply's frequency. On the other hand, an MCC is an assembly of multiple enclosed sections containing control components used to manage and protect electric motors in industrial and commercial applications.

What is an MCC in electrical?

In electrical engineering, an MCC assembles multiple enclosed sections containing control components to manage and protect electric motors in industrial and commercial applications.

How are motor control centres used in industrial applications?

MCCs are used in industrial applications to manage and protect the electric motors in the system. MCCs provide efficient power management, safety, and protection for the motors in the system and can be designed to suit specific application requirements, providing the necessary level of protection and control for each motor in the system.

What are the benefits of using an MCC?

The benefits of using an MCC include efficient power management, safety, and protection for the motors in the system. In addition, MCCs provide a safe and organized means of managing the power distribution system by housing all the required control components in a single location. The MCC panels can also be designed to suit specific application requirements, providing the necessary level of protection and control for each motor in the system.

How is a motor control centre different from a traditional control panel?

An MCC differs from a traditional control panel in that it is an assembly of multiple enclosed sections containing control components used to manage and protect electric motors in industrial and commercial applications. In contrast, a traditional control panel typically has only a few components and is used to control a single machine or process.

What are the safety considerations?

Safety considerations when working with MCCs include ensuring that the power supply to the MCC is disconnected before maintenance work is performed, wearing appropriate personal protective equipment (PPE), and following lockout/tagout procedures. It is also crucial to ensure that only qualified personnel work on MCCs, as they can pose a significant risk of electrical shock or electrocution.

Related Articles