Electric Motor Maintenance

By Richard Borge, President, Performance Evaluation

VFD Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

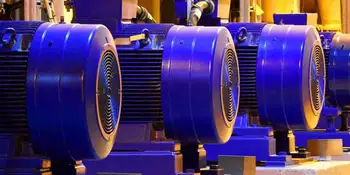

Electric motor maintenance improves efficiency, extends lifespan, and prevents costly failures. Regular inspections, predictive maintenance, and motor protection help reduce downtime and ensure reliable operation in industrial systems.

What is Electric Motor Maintenance?

Electric motor maintenance is the process of inspecting, servicing, and protecting motors to ensure reliable performance, energy efficiency, and long-term operation.

✅ Extends motor lifespan and reduces unexpected failures

✅ Improves efficiency and lowers operating costs

✅ Enhances reliability with predictive maintenance practices

Electric Motor Testing Training

Request a Free Training Quotation

Why Electric Motor Maintenance Matters

The application of motor systems maintenance and management programs has the potential to save the industry an initial $26.5 billion in electrical energy costs while reducing greenhouse gas emissions by over 3,000 megatons per year. Production availability also improves, with troubleshooting time reduced by over 50%, motor repair by over 30%, and general motor-related labor by up to 50%. These benefits demonstrate how preventive and predictive maintenance programs improve both profitability and sustainability. The principles of electric motor design play a major role in determining how maintenance practices should be applied to maximize service life.

Opportunity 1: Application of Motor Diagnostics for Periodic Testing

In a recent study, 1,054 motors were evaluated with Motor Circuit Analysis (MCA) in a marine environment. The motor system owner’s previous program involved only insulation-to-ground testing with a pass/fail limit of 1 MegOhm. Using an ALL-TEST IV PRO 2000 motor circuit analyzer, which measures resistance, impedance, inductance, phase angle, current/frequency response, and insulation-to-ground testing, revealed deeper issues.

During testing, 35 machines showed insulation resistance values of ‘0’ MegOhms, and 398 had developing winding shorts, contamination, poor connections, or combinations of faults. While only one of the 35 low-resistance machines failed in the next eight months, over 20% of the others identified did fail, proving the predictive value of diagnostics. Many motors were critical fire pumps, yet were allowed to run to failure—highlighting how diagnostics can prevent costly downtime and safety risks.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Opportunity 2: Application of Motor Diagnostics for Predictive Maintenance

A field service company initiated a predictive maintenance program using MCA devices. Within a year, annual motor repairs dropped by 33% while production output remained stable. Emergency work orders were reduced by 66%, which cut overtime and allowed planned maintenance to take priority.

Although repairs weren’t eliminated, their severity was reduced. However, when management discontinued the program, downtime, costs, and failures quickly returned to pre-program levels. This underscores the importance of maintaining ongoing diagnostic programs rather than viewing them as short-term fixes.

Opportunity 3: Application of Motor Diagnostics for Condition Monitoring

A Midwestern transmission manufacturer integrated Motor Circuit Analysis with infrared, ultrasonics, and vibration monitoring. Within the first quarter:

-

Troubleshooting time dropped by 50%

-

“No problem found,” shop reports dropped by 80%

-

Proactive repairs cut costs by 50%

-

Motor life-cycle costs dropped by 35%

For example, addressing winding contamination early allowed for clean-dip-and-bake maintenance instead of catastrophic rewinds. Over three-quarters, maintenance labour savings exceeded $30,000 per quarter; after full program adoption, savings jumped to $300,000 per month. These results highlight the long-term ROI of condition monitoring.

Key Focus Areas for Reliable Motor Performance

| Maintenance Focus Area | Key Activities | Benefits | Common Risks if Ignored |

|---|---|---|---|

| Bearings & Lubrication | Greasing, alignment checks, seal inspection | Reduced friction, longer bearing life | Overheating, bearing seizure, motor failure |

| Insulation Health | Resistance testing, polarization index, Hi-Pot testing | Prevents breakdown, ensures dielectric strength | Short circuits, insulation breakdown, fire hazards |

| Cooling & Ventilation | Clean filters, inspect fans, verify airflow | Controls temperature, prevents overheating | Thermal damage, winding degradation, reduced efficiency |

| Power Quality | Monitor voltage balance, harmonics, grounding | Protects windings, stable operation | Shaft currents, overheating, nuisance tripping |

| Vibration & Alignment | Use sensors, balancing, alignment checks | Early detection of imbalance and wear | Excessive vibration, shaft damage, catastrophic failure |

| Control Systems (VFDs/MCCs) | Inspect drive parameters, grounding, surge protection | Smooth starts/stops, energy savings, extended motor life | Bearing currents, parameter drift, unexpected shutdowns |

Checklist for Long-Term Motor Reliability

A structured schedule ensures that issues are addressed before they lead to costly failures. By breaking tasks into daily, monthly, quarterly, and annual routines, maintenance teams can detect problems early and keep motors operating at peak performance.

-

Daily/Weekly: Visual inspections, check for noise, vibration, overheating, leaks, and unusual smells.

-

Monthly: Clean filters and vents, inspect lubrication, verify electrical connections, measure voltage and current balance.

-

Quarterly: Perform vibration analysis, thermal imaging, ultrasonic checks, and insulation resistance tests.

-

Annually: Conduct full MCA testing, surge and Hi-Pot testing, shaft alignment, rotor balance, polarization index (PI) tests, and review motor control center (MCC) records.

Recognizing Early Warning Signs

Motors rarely fail without giving some warning signs first. Identifying these early symptoms enables the application of targeted diagnostics and the prevention of unplanned downtime. Operators should remain vigilant for the following indicators of potential problems.

-

Vibration – shaft misalignment, bearing wear, or imbalance

-

Excessive heat – poor ventilation, overloading, insulation failure

-

Unusual noise – bearing failure, loose mounts, rotor bar damage

-

Voltage/current imbalance – power quality issues or winding degradation

-

Corrosion/contamination – harsh environments, dust, or moisture ingress

Recognizing these signs allows targeted diagnostic testing and timely corrective action.

Mechanical and Electrical Aspects

Effective motor maintenance requires attention to both the mechanical and electrical systems. Each plays a critical role in performance, and neglecting either side can shorten motor life or trigger costly repairs. Maintenance programs should address both mechanical and electrical components:

-

Mechanical: Bearings lubrication, shaft alignment, rotor balancing, seals, cooling fans, housings, and enclosures.

-

Electrical: Stator windings, insulation resistance, rotor bar condition, grounding systems, current/voltage imbalance, and overload protection.

Tailoring Maintenance to Environment

No two operating environments are the same. Motors in marine conditions, dusty facilities, or those operating in continuous-duty cycles require different approaches. Adjusting maintenance programs to fit environmental stressors ensures reliability and safety. Maintenance requirements vary by environment:

-

Marine/High Humidity: Extra attention to insulation resistance, corrosion control.

-

Dusty/Harsh Industrial: Frequent ventilation cleaning, sealed bearings, enhanced lubrication.

-

Explosive Atmospheres: Compliance with IEC and NEMA standards for enclosures.

-

Continuous Duty Motors: More frequent vibration and thermal checks.

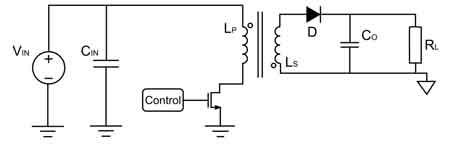

Understanding how a VFD works is also critical, since variable frequency drives can reduce stress on motors when properly programmed and maintained.

Tools and Testing Methods

Modern maintenance goes beyond visual inspections. Advanced diagnostic tools enable technicians to detect faults before they become severe, reduce troubleshooting time, and extend the lifespan of motors. These methods complement traditional practices, providing deeper insights into motor health. Modern diagnostics extend beyond MCA:

-

Vibration analysis – detects imbalance, misalignment, and bearing wear

-

Thermal imaging – identifies hotspots in windings, bearings, and connections

-

Ultrasonic testing – detects electrical arcing, corona, or lubrication issues

-

Hi-Pot & surge testing – validates insulation and winding integrity

-

Partial discharge testing – identifies dielectric breakdown in high-voltage motors

Power Quality and Motor Control

Power quality directly impacts motor health. Voltage imbalance, harmonics, transient spikes, and grounding issues can all reduce the lifespan of equipment. Motors controlled by VFDs (variable frequency drives) are subject to additional stress from pulse-width modulation, which can lead to shaft currents and bearing failures. Proper grounding, shaft grounding rings, and filters mitigate these risks. Effective electric motor control is directly tied to maintenance, since poor control settings often accelerate wear and reduce reliability.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Best Practices and Common Mistakes

Best practices include: establishing baseline tests, documenting all results, using CMMS systems for trending, and training staff on diagnostics.

Common mistakes include: over-lubricating bearings, ignoring minor vibration, neglecting power quality, delaying inspections, or using improper lubricants. Avoiding these pitfalls ensures program success. Businesses can realize significant efficiency opportunities through motor maintenance, lowering energy costs while reducing repair frequency and downtime.

Safety and Standards

Electric motor maintenance must follow lockout/tagout protocols, proper PPE, and compliance with standards such as IEEE, NEMA, IEC, and NFPA 70E. Insulation resistance and vibration limits should meet or exceed published guidelines to ensure both worker safety and asset reliability.

ROI, Lifecycle Cost, and Future Trends

The ROI of motor maintenance is clear: reduced downtime, extended lifespan, and lower lifecycle costs. Ignoring preventive maintenance often results in emergency repairs costing multiples more than planned interventions. Improving electric motor efficiency not only saves energy but also reduces the strain on components, extending the intervals between maintenance tasks.

Looking ahead, IIoT, smart sensors, predictive analytics, and machine learning are transforming motor maintenance. Remote monitoring, wireless vibration sensors, and cloud-based diagnostics allow continuous oversight, minimizing human error and maximizing uptime.

Frequently Asked Questions

How often should electric motors be replaced instead of repaired?

Motors should typically be replaced when repair costs exceed 60% of the price of a new motor, or when efficiency upgrades available in newer models make replacement a viable option.

What is the difference between preventive and predictive maintenance for motors?

Preventive maintenance follows a time-based schedule of tasks, while predictive maintenance utilizes real-time data (such as vibration, temperature, and current) to predict when a failure is likely to occur.

How does motor size affect maintenance requirements?

Large, high-horsepower motors require more frequent vibration analysis, lubrication checks, and alignment testing than small fractional-horsepower motors, which may need only basic visual inspections.

Are there industry standards for motor maintenance intervals?

Yes, organizations like IEEE and NEMA publish guidelines, but actual schedules depend on operating environment, motor duty cycle, and criticality to production.

Can modern sensors and IIoT reduce maintenance costs?

Yes. Smart sensors provide continuous data on temperature, vibration, and energy use. This real-time monitoring allows maintenance teams to intervene earlier, avoiding costly failures and extending the lifecycle.

The implementation of a program of Scheduled Care for Optimal Motor Performance, supported by diagnostics, preventive scheduling, and modern condition monitoring, has an immediate and lasting impact. From lowering energy consumption and reducing emissions to cutting downtime and extending motor life, the value is both economic and environmental. Organizations that adopt structured, environment-specific, and technology-driven maintenance practices not only protect their assets but also secure long-term operational excellence.

From: Electric Motors and VFDs Handbook, Vol 3, The Electricity Forum

Related Articles