Motors and Drives

How Does an Electric Motor Work?

An electric motor works by converting electrical energy into mechanical power through electromagnetism, producing rotation, torque, and speed control that drive equipment and machinery in industrial, commercial, and institutional power systems.

How Does an Electric Motor Work?

An electric motor converts electrical energy into mechanical energy, making our lives easier and more efficient. An electric motor:

✅ Converts electrical energy into mechanical motion

✅ Uses electromagnetism to create torque and rotation

✅ Powers appliances, vehicles, and industrial equipment

Let's explore the fundamental principles behind this device, discuss its key components, and address some common questions about its operation and applications.

Electric Motor Testing Training

Request a Free Training Quotation

Working Principle of Electric Motors

The working principle of an AC or DC electric motor relies on electromagnetic principles. When a current passes through a wire, it creates a magnetic field around it. This magnetic field interacts with other magnetic fields, producing a force that generates motion. In a motor, this force is harnessed to create rotational motion, driving the moving part of the motor, known as the rotor. To learn more about how motors function in modern facilities, see our detailed guide on electric motors and drives.

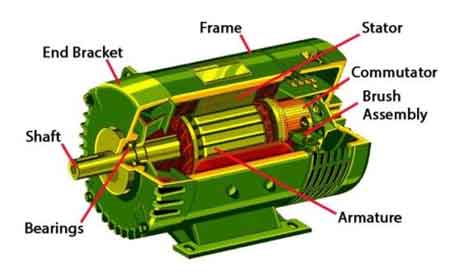

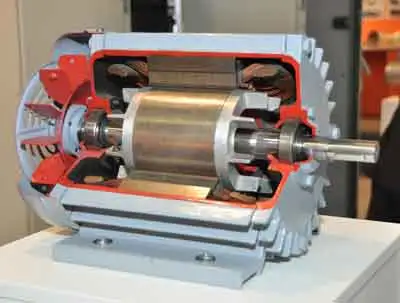

Main Components

The main components of a motor include the stator, rotor, magnetic field, current, brushes, and commutator. The stator is the stationary part of the motor, usually made of magnetic materials or wound with wire coils. It provides a stable magnetic field that interacts with the rotor's magnetic field, creating motion. The rotor is the rotating part of the motor, also made of magnetic materials or wound with wire coils. As the rotor turns, it converts the electrical energy from the power source into mechanical energy. Understanding control systems is essential for optimizing performance, and our overview of electric motor control covers the basics and advanced applications. When designing systems for industrial or commercial facilities, our article on electric motor design explains how construction choices impact performance, efficiency, and durability.

Magnetic Fields and Motion

Magnetic fields generate motion in AC motors by interacting with the current flowing through the motor's windings. When current flows through a coil, it produces a magnetic field that interacts with the stator's magnetic field. This interaction creates a force that pushes the rotor to rotate. As the rotor turns, the magnetic field changes, continuously generating a force that maintains the rotation. Facilities that rely on HVAC equipment can benefit from advanced variable frequency drive HVAC applications, which improve comfort while lowering operating costs.

Types of Electric Motors

There are various types of motors, each with distinct characteristics and specific applications:

-

AC induction motors – robust, efficient, and widely used in industry and household appliances.

-

Permanent magnet motors – compact, reliable, and highly efficient, found in EVs, robotics, and automation.

-

Brushed DC motors – simple and inexpensive, common in tools and small appliances.

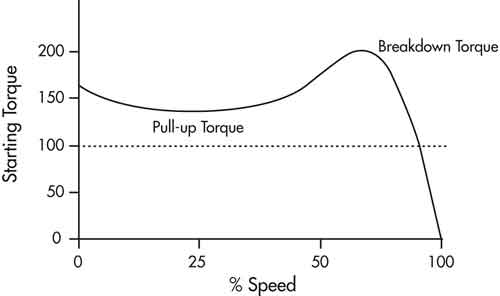

Each motor type has a unique torque–speed curve and efficiency profile, making them suitable for different industrial, commercial, and institutional needs. To understand the differences in performance between motor types, visit our resource on what is a synchronous motor, which highlights its role in precision-driven applications.

Efficiency and Losses

Motors are efficient machines, but several forms of energy loss occur during operation:

-

Copper losses – resistance heating in the windings.

-

Iron losses – eddy currents and hysteresis in the motor core.

-

Mechanical losses – bearing friction and windage.

-

Stray load losses – leakage flux and minor construction imperfections.

Typical efficiencies vary by design:

-

AC induction motors: 85–95%

-

Permanent magnet motors: 92–98%

-

Brushed DC motors: 75–85%

Even a 2–3% efficiency improvement translates into major cost savings in industrial and institutional systems. Regular inspection and servicing can reduce energy waste, as explained in our article on efficiency opportunities through motor maintenance.

Motor Control and Variable Speed Drives

Modern facilities often use variable frequency drives (VFDs) or variable speed drives (VSDs) to adjust voltage and frequency. This enables precise control of torque and speed, enhances part-load efficiency, reduces mechanical wear, and achieves energy savings of up to 30% in pumps, fans, and conveyors. Variable frequency drives are a proven way to cut energy costs, and you can explore their role in detail in our section on VFD drives.

Material Innovations

Advances in materials have boosted efficiency and reliability. High-performance steels reduce core losses, rare-earth magnets improve torque density, and ferrite composites are emerging as sustainable alternatives. Hairpin windings increase copper fill and torque output, while advanced insulation resists thermal breakdown, extending motor life.

Thermal Management

Heat is a major challenge in motor design. Cooling methods range from simple air cooling with fans to liquid cooling systems in high-power applications, to direct cooling methods where a fluid removes heat directly from the windings. Effective thermal management prevents insulation failure, ensuring reliable operation under heavy industrial loads.

Commutators and Brushes

Commutators and brushes transfer current to the rotor in DC motors. The commutator directs current through the windings, while brushes maintain continuous contact, sliding as the rotor turns to sustain motion. Though effective, this design requires regular inspection and maintenance.

Industry Standards and Regulations

Motors must meet international standards to ensure efficiency and safety. IEC efficiency classes range from IE1 (standard) to IE4 (super premium), and many regions now require IE3 or higher for new installations. NEMA sets similar benchmarks in North America, ensuring motors deliver reliable performance while reducing long-term energy costs. For engineers selecting equipment in industrial environments, our resource on what is an induction motor explains why this type remains one of the most widely used.

Applications

Motors are used in nearly every sector of society:

-

Industrial – pumps, compressors, conveyors, and heavy machinery.

-

Commercial – HVAC systems, elevators, escalators, and refrigeration.

-

Institutional – hospitals, schools, and critical infrastructure.

-

Transportation – EVs, trains, aircraft systems, and ships.

From small appliances to massive industrial installations, motors remain essential to modern life.

Future Trends and Challenges

The future will be shaped by sustainability, smart technologies, and regulation. Manufacturers are reducing reliance on rare-earth magnets, developing recyclable designs, and improving lifecycle efficiency. Smart motors with IoT sensors enable predictive maintenance. Growing EV adoption drives demand for compact, high-efficiency motors, while renewable energy expands their role in wind, hydro, and solar systems. Governments worldwide continue to raise minimum efficiency standards, pushing the industry toward cleaner and smarter designs.

Frequently Asked Questions

What is the working principle of an electric motor?

They convert electrical energy into mechanical energy through the interaction of magnetic fields and electric currents.

What are the main components?

The main components include the stator, rotor, magnetic field, current, brushes, and commutator.

How do magnetic fields generate motion?

Magnetic fields generate motion by interacting with the current flowing through the motor's windings, creating a force that pushes the rotor to rotate.

What are the different types?

Some common types include AC induction motors, permanent magnet motors, and brushed DC motors.

How do commutators and brushes work?

Commutators and brushes transfer current to the rotor, with the commutator directing current through the motor windings and the brushes maintaining the flow of current as the rotor turns.

How can efficiency be improved?

Efficiency can be improved by optimizing motor design, using high-quality materials, implementing advanced control techniques, and maintaining the motor properly.

What are the common applications of electric motors?

They are utilized in various applications, including household appliances, power tools, EVs, and industrial equipment.

By understanding how motors work and their importance in our lives, we can better appreciate the engineering and innovation that goes into these devices. With ongoing advancements in the field, we can look forward to even more efficient and environmentally friendly motor technologies that will continue to shape our world.

Related Articles

Download Our FREE Motors and Drives Handbook

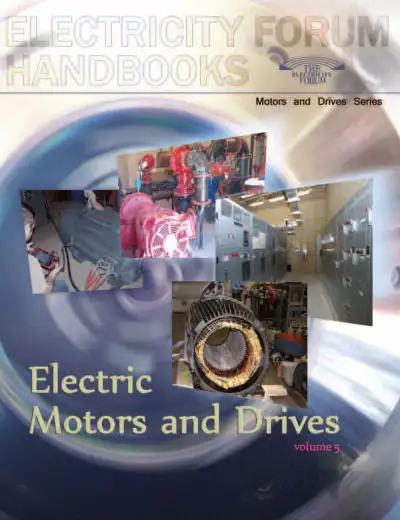

Electric Motors and Drives Handbook, Vol. 5

This highly prized and very popular handbook is now into its fifth year of publication, providing exhaustive information on electrical motors and drives.

In this edition, we explore a wide range of topics, from the fundamentals of motor design and operation to the latest innovations in drive technologies, including variable-speed drives, energy-efficient solutions, and advanced motor control techniques. This volume also addresses emerging trends, such as the integration of electric motors with smart grid systems, renewable energy applications, and the growing demand for energy-efficient solutions across all industries.

Whether you’re working in manufacturing, robotics, HVAC, or electric vehicle systems, this handbook provides practical guidance on improving motor performance, troubleshooting, and selecting the right motor and drive combination for specific applications. With a focus on both theoretical principles and real-world applications, Volume 5 is designed to support both experienced professionals and those new to the field of electric motors and drives.

We hope this volume serves as a comprehensive and indispensable reference, enabling you to enhance your understanding, optimize your systems, and achieve greater efficiency and reliability in the operation of electric motors and drives.

Latest Motors and Drives Articles

What Does VFD Stand For?

A VFD stands for Variable Frequency Drive, also known as an adjustable frequency drive or AC drive, controls motor speed and torque by varying voltage and frequency, thereby helping systems conserve energy, reduce wear, and enhance process performance across various applications.

What Does VFD Stand For?

A VFD is a vital technology in electrical engineering and industrial maintenance, and it plays a transformative role in modern motor control systems.

✅ Improves energy efficiency and reduces operating costs

✅ Extends equipment lifespan with smoother motor control

✅ Enhances process performance and system reliability

Electric Motor Testing Training

Request a Free Training Quotation

For professionals in these fields, understanding VFDs is essential due to their ability to enhance efficiency, optimize energy use, and improve the performance of electric motors. By varying the frequency and voltage of the power supply, VFDs enable precise control over speed and torque, making them indispensable for applications ranging from conveyor belts in manufacturing to HVAC systems in commercial buildings. With their impact on sustainability, cost savings, and operational reliability, motor controls are at the forefront of innovation in industrial automation. Precise electric motor control is a primary reason why VFDs are essential in industrial and commercial systems.

A modern variable speed drive relies on advanced semiconductor components such as the insulated gate bipolar transistor IGBT to regulate power efficiently. By converting incoming line voltage into controlled pulses, the system uses pulse width modulation PWM to shape the output waveform. This precise control enables the drive to dynamically adjust motor load, ensuring smoother operation, improved efficiency, and extended equipment life.

VFD Core Operation and Motor Speed Control

At its core, a VFD converts an AC power supply into a form that allows for precise control of a motor's speed and torque. The process begins with a rectifier, which converts AC power into DC power. A stabilized DC link then ensures smooth operation, while an inverter—powered by advanced components such as insulated gate bipolar transistors—transforms the DC power back into AC power, but with variable frequency. This sophisticated operation enables a motor to run at speeds that perfectly match the demands of a given task, offering unparalleled flexibility and efficiency. To understand how these drives function, see our guide on how does a VFD work, which explains rectifiers, inverters, and frequency conversion.

VFD Technology Overview

| Aspect | Details | Purpose / Benefit |

|---|---|---|

| Input Power | Receives standard AC supply (typically 50/60 Hz) | Provides source energy for conversion |

| Rectifier Stage | Converts AC power to DC power | Creates a stable intermediate power source |

| DC Link | Smooths and stabilizes the DC using capacitors/inductors | Ensures steady flow before inversion |

| Inverter Stage | Uses IGBT transistors and PWM to convert DC back to AC at variable frequency | Controls motor speed and torque precisely |

| Output to Motor | Variable frequency and voltage supplied to the motor | Matches motor speed to load requirements |

| Main Advantages | Energy savings, reduced wear, improved process control, extended equipment life | Efficiency, sustainability, cost reduction |

Benefits of Adjustable Frequency Drives

Industries rely on VFDs to optimize performance and energy consumption. Conveyor belts in assembly lines often require varying speeds to accommodate different production phases, which a VFD enables to be done seamlessly. Similarly, HVAC systems use motor controls to regulate airflow, ensuring comfort while minimizing energy use. By allowing motors to operate at partial rather than full speed when maximum output is unnecessary, these devices help save energy, reduce wear, and extend the lifespan of equipment. In an era of environmental consciousness, the role of motor controls in sustainability cannot be overstated.

Benefits of Motor Control

The benefits of motor controls extend beyond energy savings. These devices reduce mechanical stress on motors by allowing gradual acceleration and deceleration, which is crucial for heavy-duty applications such as operating phase AC motors or single-phase systems. For example, a variable frequency drive VFD can ensure smooth startups for high-frequency industrial machines, mitigating the risk of mechanical failure. This capability is particularly valuable in industries where reliability and longevity of equipment are critical. Because VFDs directly influence energy use, they play a significant role in improving electric motor efficiency across various industries.

VFD Types

There are several types of VFDs, each tailored to specific needs. The Volts-per-Hertz control method is a versatile option suitable for general applications, offering straightforward control of an AC motor. For more demanding tasks requiring precision, vector control and direct torque control (DTC) provide enhanced accuracy in managing speed and torque. These advancements ensure that every type of motor controller meets the exacting standards of modern industries, whether for simple or complex operations. For a comprehensive overview of applications and benefits, visit our Variable Frequency Drive Resource page.

VFDs in Industrial Automation and IoT

The integration of motor controls with advanced technologies has opened new frontiers in industrial automation. IoT-enabled systems now incorporate VFDs to provide real-time data for predictive maintenance and operational optimization. In manufacturing, VFDs paired with smart systems can control the speed of motors in conveyor belts based on dynamic production requirements. These innovations not only improve efficiency but also provide valuable insights into operational performance, creating a feedback loop that fosters continuous improvement.\\VFDs and Syust

Sustainable Motor Control Solutions

VFDs are also reshaping the sustainability narrative by reducing energy consumption and minimizing carbon footprints. Industries can significantly lower their environmental impact by utilizing motor controls to optimize motor operation. The ability to control the speed and torque of electric motors ensures energy is used only when and where it is needed, aligning with global efforts to reduce waste and conserve resources. In many operations, synchronous motors are paired with VFDs to deliver constant speed and reliable performance.

Future of AC Motor Drive Technology

The future of motor control technology is equally promising. Emerging trends such as the adoption of silicon carbide semiconductors promise greater efficiency and smaller device sizes. Wireless control capabilities are also being explored, paving the way for even more versatile applications. These innovations will further enhance the role of motor controls in industrial automation and energy management.

The question, "What does VFD stand for?" goes beyond defining the term. It encompasses an entire ecosystem of innovation, efficiency, and sustainability. From controlling the speed of an AC motor to enabling smart, energy-efficient systems, the VFD continues to revolutionize the way industries operate. As technology evolves, so too will the capabilities, cementing their place as indispensable tools in the modern industrial landscape.

Related Articles

What Is a Motor Control Centre?

A motor control centre (MCC) is a centralized system that houses motor starters, protection devices, and control equipment. It is used to safely and efficiently manage and automate electric motors in industrial and commercial environments.

Quick Definition: What Is a Motor Control Centre?

-

✅ Definition: A Motor Control Centre (MCC) is an assembly of one or more enclosed sections containing motor control units, including starters, circuit breakers, and other control devices, used to control and protect electric motors in industrial settings.

-

✅ Components: Typically includes motor starters, circuit breakers, fuses, overload relays, and disconnect switches, all housed in a centralized enclosure.

-

✅ Applications: Commonly used in manufacturing plants, commercial buildings, and other industrial environments to manage multiple electric motors from a central location.

The MCC is an assembly of multiple enclosed sections, each containing control components used to manage and protect the electric motors in the system. MCCs are usually installed in a separate air-conditioned room, known as a controlled room, for easy access and maintenance. The MCC panels include starters, circuit breakers, fuses, circuit breaker-fuse combinations, solid-state and thermal overload relays, variable-frequency drives (VFDS), and disconnecting switches. The control panels in MCCs manage the power distribution, switching, and protection of electric motors in a central control system.

An MCC is typically composed of three sections: the vertical bus, the horizontal bus, and the control section. The vertical bus connects the main power source to the various starter units in the main control center (MCC). The horizontal bus connects the individual starters to the common power bus, which distributes the power to the motors in the system. Finally, the control section contains the control circuits and switches used to operate the starters and the other control components in the MCC.

Types of Motor Starters in Motor Control Centres

Motor starters are essential components within an MCC, responsible for initiating and regulating electric motors. Selecting the appropriate starter type is crucial for optimal performance and energy efficiency.

-

Direct-On-Line (DOL) Starters: These starters apply full voltage directly to the motor terminals, making them suitable for small motors where high inrush current does not pose issues.

-

Star-Delta Starters: Utilized to reduce starting current and torque in larger motors by initially connecting in a star configuration before transitioning to a delta setup.

-

Soft Starters: These devices gradually ramp up voltage during startup, minimizing mechanical stress and extending the lifespan of equipment.

-

Variable Frequency Drives (VFDs): VFDs offer precise control over motor speed and torque by adjusting input frequency and voltage, enhancing energy efficiency.

For a comprehensive understanding of these starter types and their applications, refer to our detailed guide on Electric Motor Control - Starters, VFDs.

MCC Safety Standards

Ensuring safety in MCC operations is paramount, necessitating adherence to established standards and regulations in both the U.S. and Canada.

-

NFPA 70 (National Electrical Code): In the U.S., this code outlines safe electrical design, installation, and inspection practices.

-

UL 845: This standard pertains to the construction and performance of MCCs, ensuring they meet specific safety requirements.

-

CSA C22.2 No. 254: In Canada, this standard governs the safety of MCCs, aligning with national electrical codes.

-

Arc Flash Compliance: Standards like NFPA 70E and CSA Z462 provide guidelines to protect workers from arc flash hazards through proper labeling, PPE, and safe work practices.

Safety also depends on proper motor design and usage. For deeper insight, review Electric Motor Design Engineering

Integrating MCCs with Automation Systems

Modern MCCs are integral to industrial automation, facilitating enhanced control, monitoring, and efficiency.

-

PLC and HMI Integration: MCCs often interface with Programmable Logic Controllers (PLCs) and Human-Machine Interfaces (HMIs) to enable real-time monitoring and control.

-

Communication Protocols: Utilizing protocols like Ethernet/IP, Modbus, or PROFIBUS allows seamless communication between MCCs and other automation systems.

-

Smart MCCs: Equipped with intelligent devices, these MCCs provide data analytics, predictive maintenance, and improved energy management.

Explore the intricacies of industrial automation and how MCCs play a pivotal role in our article on Industrial Automation And Communication Networks.

Efficiency and Maintenance in MCC Applications

A well-maintained MCC directly contributes to operational efficiency and reduced energy waste. Routine inspections, thermal imaging, and vibration analysis are common maintenance practices.

Read more in Electric Motor Maintenance and Diagnostics

For strategies to improve energy use, see Efficiency Opportunities Through Motor Maintenance

Choosing the Right Equipment for Your Application

Whether designing a new MCC or upgrading an existing one, component selection is vital. This includes proper motor sizing, overload protection, and circuit isolation methods.

Learn how Electric Motor Protection plays a role in MCC reliability.

Frequently Asked Questions

What components are typically included?

Components included in an MCC panel include starters, circuit breakers, fuses, or circuit breaker-fuse combinations, solid-state and thermal overload relays, variable frequency drives (VFD), and disconnecting switches.

What is the purpose of an MCC?

The purpose of an MCC is to manage and protect electric motors in an industrial or commercial setting. MCCs provide efficient power management, safety, and protection for the motors in the system.

What is the difference between MCC and PLC?

An MCC is an assembly of multiple enclosed sections containing control components to manage and protect electric motors in an industrial or commercial setting. On the other hand, a programmable logic controller (PLC) is a digital computer used to control and automate industrial processes. While MCCs and PLCs are used in industrial applications, they serve different functions.

Is a VFD considered an MCC?

No, a variable frequency drive (VFD) is not considered an MCC. A VFD is an electronic device that controls an AC motor's speed by varying the electrical supply's frequency. On the other hand, an MCC is an assembly of multiple enclosed sections containing control components used to manage and protect electric motors in industrial and commercial applications.

What is an MCC in electrical?

In electrical engineering, an MCC assembles multiple enclosed sections containing control components to manage and protect electric motors in industrial and commercial applications.

How are motor control centres used in industrial applications?

MCCs are used in industrial applications to manage and protect the electric motors in the system. MCCs provide efficient power management, safety, and protection for the motors in the system and can be designed to suit specific application requirements, providing the necessary level of protection and control for each motor in the system.

What are the benefits of using an MCC?

The benefits of using an MCC include efficient power management, safety, and protection for the motors in the system. In addition, MCCs provide a safe and organized means of managing the power distribution system by housing all the required control components in a single location. The MCC panels can also be designed to suit specific application requirements, providing the necessary level of protection and control for each motor in the system.

How is a motor control centre different from a traditional control panel?

An MCC differs from a traditional control panel in that it is an assembly of multiple enclosed sections containing control components used to manage and protect electric motors in industrial and commercial applications. In contrast, a traditional control panel typically has only a few components and is used to control a single machine or process.

What are the safety considerations?

Safety considerations when working with MCCs include ensuring that the power supply to the MCC is disconnected before maintenance work is performed, wearing appropriate personal protective equipment (PPE), and following lockout/tagout procedures. It is also crucial to ensure that only qualified personnel work on MCCs, as they can pose a significant risk of electrical shock or electrocution.

Related Articles

What is an Induction Motor?

An induction motor is a widely used AC machine that converts electrical energy into mechanical motion. Known for efficiency, durability, and low maintenance, it powers fans, pumps, compressors, and industrial drives across modern power systems.

What is an Induction Motor?

An induction motor is an alternating current (AC) machine where electromagnetic induction generates torque to drive mechanical loads in residential, commercial, and industrial applications.

✅ Converts electrical energy into mechanical power efficiently

✅ Reliable, durable, and requires minimal maintenance

✅ Powers fans, pumps, compressors, and industrial equipment

An induction motor is critical in numerous applications thanks to its robustness, efficiency, and low maintenance requirements. A solid understanding of its principles, types, and methods for optimizing performance can help businesses and individuals select the right device for their needs and ensure long-lasting, efficient operation. To better understand electric motors and drives, it is helpful to study induction motors as they form the backbone of many industrial and residential applications.

Induction motors, also known as AC motors, are a crucial component in operating various machinery and appliances. Due to their efficiency, robustness, and relatively simple construction have become a staple in many industrial, commercial, and domestic applications. But what is an induction motor, and how does it work? Regular electric motor maintenance is essential to preserve the durability and efficiency that make induction motors so widely used in power systems.

An induction motor operates based on the principles of electromagnetic induction and the generation of rotating magnetic fields. A rotating magnetic field is generated when an alternating current (AC) is passed through the stator winding. This field induces an electric current in the rotor, which in turn creates its own magnetic field. The interaction between these fields generates torque, causing the rotor to turn and drive the device. Learning how electric motor control works provides insight into the way an induction motor achieves precise performance in industrial environments.

Types of Induction Motors

There are two primary types of induction motors: squirrel-cage and wound-rotor device. Squirrel cage induction motors have a simple rotor construction with bars short-circuited at both ends by conducting rings, resembling a squirrel cage. These are common due to their low cost and minimal maintenance requirements. In contrast, wound rotor devices have rotor windings connected to external slip rings, which can be adjusted to control the device's performance.

Three-phase induction motors are the most widely used, offering superior power and torque characteristics compared to single-phase devices. Single-phase induction motors, however, are commonly found in smaller applications, such as household appliances. Additionally, induction motors typically require a starting mechanism to initiate rotation, as they are not self-starting. This is typically achieved by using split-phase or capacitor-start designs. A comparison of synchronous motors helps illustrate key differences in construction, operating principles, and performance.

Comparison of Induction, Synchronous, and DC Motors

| Feature | Induction | Synchronous | DC |

|---|---|---|---|

| Power Supply | AC (single-phase or three-phase) | AC (requires additional excitation for rotor) | DC (direct current supply) |

| Starting Mechanism | Self-starting (three-phase); capacitor/split-phase needed (single-phase) | Requires external starting method | Typically self-starting |

| Rotor Construction | Squirrel-cage or wound rotor | Rotor excited with DC or permanent magnets | Wound rotor with commutator and brushes |

| Speed | Runs below synchronous speed (slip present) | Runs exactly at synchronous speed | Variable with applied voltage and load |

| Efficiency & Maintenance | High efficiency, low maintenance (no brushes/commutators) | High efficiency but complex construction | Moderate efficiency; frequent brush/commutator wear |

| Applications | Fans, pumps, compressors, industrial drives | Power factor correction, high-precision machinery | Traction, cranes, elevators, variable speed equipment |

| Cost | Generally low, economical for most uses | Higher cost due to complexity | Moderate to high, depending on size and design |

What is an induction motor - Disadvantages

One of the main advantages of induction motors is their efficiency. The absence of brushes and commutators in the construction reduces friction and energy loss, increasing efficiency. Additionally, their robust construction makes induction motors highly reliable and capable of withstanding harsh environments.

Induction motors differ from other electric ones, such as DC units and synchronous devices, in several ways. For example, DC motors require a direct current supply and have brushes and commutators to enable current flow in the rotor windings. This creates friction and wear, reducing efficiency and lifespan. On the other hand, synchronous devices operate at a fixed speed, which is synchronized with the supply frequency. A review of electric motor efficiency highlights why induction motors are valued for their ability to convert electrical energy into mechanical power with minimal losses.

Primary Components

The primary components of an induction motor include the stator, rotor, and frame to support these elements. The stator consists of laminated iron cores with windings, while the rotor has either a squirrel cage or a wound rotor construction. The frame provides mechanical support and helps dissipate heat generated during operation.

Starting an induction motor typically involves creating a rotating magnetic field in the stator winding, which induces an electric current in the rotor. As the rotor starts to turn, its speed increases until it reaches a point slightly below the synchronous speed. This difference in speed, known as "slip," enables it to generate torque and maintain rotation. Many applications rely on variable frequency drives, which optimize the speed and torque while reducing energy consumption.

Efficiency and Performance

The efficiency and performance of induction motors can be improved through several methods. Optimizing the design, such as enhancing the quality of materials and reducing energy loss in the magnetic core, can contribute to increased efficiency. Proper maintenance, like ensuring the bearings are lubricated and the device is clean, also maximizes performance. Finally, using variable frequency drives (VFDs) enables better control over speed and torque, thereby further optimizing energy consumption. Exploring motor overload protection shows how safety devices safeguard them from excessive currents and overheating.

Thanks to their efficiency, durability, and straightforward design, induction motors are vital to many industrial and domestic applications. Understanding the working principles, types, and components can help individuals and businesses decide which one is best suited for their needs. With proper design, maintenance, and control, induction motors can offer reliable and efficient performance for various applications.

Frequently Asked Questions

What is an Induction Motor and what is its working principle?

The working principle relies on the interaction between the rotating magnetic field generated by the stator winding and the electric current induced in the rotor. This interaction produces torque, which causes the rotor to rotate.

How does an induction motor differ from other types?

They differ from other ones, such as DC and synchronous devices, in their construction, operating principles, and performance characteristics. For instance, induction motors do not require brushes or commutators, which reduces friction and increases efficiency.

What is an Induction Motor, and what are the main components?

The main components include the stator, rotor, and frame. The stator contains windings that generate the rotating magnetic field, while the rotor has either a squirrel cage or wound rotor construction that interacts with the magnetic field. Finally, the frame provides mechanical support and facilitates heat dissipation.

What are the advantages?

Some advantages of induction motors include their efficiency, reliability, low maintenance requirements, and ability to operate under harsh conditions. Their simple construction also makes them cost-effective for many applications.

How does an induction motor start and run?

It starts and runs by creating a rotating magnetic field in the stator winding, which induces an electric current in the rotor. As the rotor starts to rotate, it reaches a speed slightly below the synchronous speed, allowing for torque generation and maintaining rotation.

What are the different types of induction motors, and how do they vary?

The two primary types of induction motors are squirrel-cage and wound-rotor devices. Squirrel cage types have a simple rotor construction with short-circuited bars, while wound rotor devices have rotor windings connected to external slip rings. Additionally, there are single-phase and three-phase induction motors, with the latter being more widely used due to their improved power and torque characteristics.

How can the efficiency and performance of an induction motor be improved?

The efficiency and performance of an induction motor can be enhanced through optimized design, proper maintenance, and the use of variable frequency drives (VFDs), which enable better control over speed and torque.

To properly answer the question: What is an Induction Motor? It is essential to understand that induction motors are the most widely used AC machines in modern industry and daily life due to their efficiency, durability, and simple design. They operate on electromagnetic induction, using a rotating magnetic field in the stator to generate torque in the rotor. Found in everything from fans and pumps to large industrial drives, induction motors require little maintenance yet deliver reliable performance under demanding conditions. Understanding their principles, types, and efficiency optimization methods allows businesses and individuals to select the right type for their needs and ensure long-term, cost-effective operation.

Related Articles

VFD Sizing: The main onsiderations

VFD sizing matches a drive’s current rating to motor amperage. Consider load type, torque demands, and conditions to choose a drive that prevents overheating and ensures long-term motor performance.

Quick Definition: VFD Sizing

-

✅ Definition: The process of selecting a Variable Frequency Drive (VFD) that matches the motor's electrical and operational requirements.

-

✅ Key Considerations: Motor full-load amperage, application type (constant or variable torque), overload capacity, and environmental conditions.

-

✅ Importance: Proper VFD sizing prevents equipment damage, ensures energy efficiency, and extends the lifespan of both the motor and the drive.

Proper VFD sizing is critical to ensure optimal motor performance, energy efficiency, and equipment protection. When sizing a Variable Frequency Drive (VFD), it is essential to consider the motor's full-load amperage, the application type, overload requirements, and environmental factors. Selecting a correctly sized Variable Frequency Drive prevents overheating, improves system reliability, and maximizes the lifespan of both the drive and the motor. When considering Variable Frequency Drive sizing, it's important also to understand how different VFD drives operate and the impact they have on motor control performance.

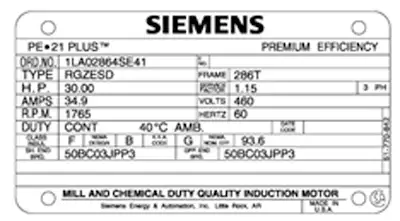

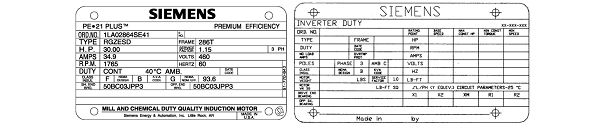

When selecting a Variable Frequency Drive, it’s essential to match the drive’s current rating to the motor’s full load amps (FLA) as listed on the motor nameplate. The horsepower (hp) rating alone is not enough, because different motors with the same hp can have varying current requirements based on efficiency, design, and application. Always use the motor nameplate data for accurate sizing to ensure the Variable Frequency Drive can handle the full operational load without overheating or tripping during normal operation.

In VFD Sizing, the main considerations are:

1. The Variable Frequency Drive continuous current shall be higher than the motor’s current at maximum load. It is not necessary to size the Variable Frequency Drive to the motor Full Load Amps (FLA) rating if the motor application is oversized. A motor that operates under worst-case conditions at 80% FLA current flowing only requires a Variable Frequency Drive that can continuously supply this 80% current value.

2. For Variable Torque Applications, the intermittent current shall be 115% greater than the motor current rating for the worst case starting scenario. If the motor rated current is 65 amperes, then the intermittent current rating should be greater than 74.8 amperes (65A x 115%).

For Constant Torque Application, the intermittent current shall be 150 to 200% of the motor rated current. The equipment OEM can provide the actual worst-case starting torque that they would normally expect for the application. By ensuring that the intermittent current capability of the Variable Frequency Drive is higher than this value, the ac drive will produce sufficient torque to start the HP motor under abnormal situations. Accurate VFD programming ensures that a properly sized drive operates within the correct voltage and current limits, protecting connected equipment.

3. The single-phase input voltage tolerance rating for the Variable Frequency Drive shall be higher than the highest line voltage and lower than the lowest line voltage that lasts longer than two seconds in the facility. Variable Frequency Drives have a 100% voltage rating of 200, 230, 460 or 575 Volts. Each site has different high and low line levels that the Variable Frequency Drive must be able to safely operate at without being damaged. If the measured low line voltage is 550 volts and the high line voltage is 625 volts, then we need a 575-volt-rated Variable Frequency Drive with a voltage tolerance of 575 volts plus 10.9% (625 volts), minus 4.6% (550 volts), or greater. Actual common tolerance values for Variable Frequency Drives are as follows: -5 %, 10%, 12%, 15%, and 20%. Some 575v commercial-rated Variable Frequency Drives are 575v +5%, -10% (518v to 603v), whereas an industrial-rated Variable Frequency Drive may be rated 575v +/- 15% (489v to 660v). If the tolerance rating of the Variable Frequency Drive does not meet the high-line actual site voltage condition, then the Variable Frequency Drive is subject to potential catastrophic failure. In some cases, a frequency converter may be necessary in conjunction with a Variable Frequency Drive to manage input or output frequencies that affect proper sizing.

Other Variable Frequency Drive equipment to be upgraded or changed:

Many factors need to be considered when conducting Variable Frequency Drive Sizing in an existing application:

-

Is the existing motor suitable for the speed range, and is the insulation designed to withstand the dv/dt stress caused by the fast switching of the voltage pulses to the motor? If not, use a NEMA MG1 Part 31 designed motor.

-

All VFD manufacturers recommend replacing the motor feeder cable with a shielded, symmetrical cable for the Variable Frequency Drive.

Motor specifications:

In North America, NEMA MG1 standards are used to specify motors. In 1992, a new section (Part 31) was added to specifically address the motor design requirements to work on a Variable Frequency Drive application without installing motor feeder filtering. The original Part 30 design motor nameplate specification allowed for Variable Frequency Drive (VFD) operation if properly sized motor filters were installed in the VFD package.

Figure 1: NEMA Part 30 & 31 Nameplates

Since each application required a custom-engineered solution for the proper selection of motor filters, most users and Variable Frequency Drive distributors were not qualified to select the filters properly, thereby increasing the risk of a successful filter selection. By installing the NEMA MG1 Part 31 designed motor, there is no requirement to install a motor filter. The deletion of the requirement for a motor filter typically offsets the slight cost increase associated with the Part 31 motor. The Part 31 motor has an enhanced nameplate that provides motor performance data when the motor is operated at the lowest operating speed, the base 60Hz speed, and the highest speed above 60Hz.

System component used with Variable Frequency Drives:

Many factors are required when the decision for installing a Variable Frequency Drive is made: The Variable Frequency Drive solution should be supplied with all the necessary equipment to provide for a long life and reliable Variable Frequency Drive solution:

-

Circuit Breaker,

-

Transient Surge Protection,

-

Line Filtering, Harmonics and Power Factor

-

Standard or High-Performance Variable Frequency Drive chassis, as needed for the application.

-

VFD cable

-

NEMA MG1 Part 31 motor should always be used

-

Ambient Temperature

-

Derating the VFD

Figure 2: Circuit breaker, MOVs, Reactor, Harmonic Filter, and Variable Frequency Drive Cable

For Variable Frequency Drives used in building systems, review the special considerations outlined in Variable Frequency Drive HVAC applications.

Related Variable Frequency Drives Articles:

What is a Synchronous Motor? Explained

A synchronous motor is an AC motor that rotates at a constant speed, matching the frequency of the AC power supply. Its rotor locks in step with the stator’s rotating magnetic field, delivering constant speed, high efficiency, and power factor correction.

What is a Synchronous Motor?

A synchronous motor is a type of AC device that operates at a constant speed, which is directly proportional to the frequency of the AC phase supply and the number of poles in the device. Unlike induction motors, which run with slip, synchronous motors maintain perfect synchronism between the rotor and stator fields. To fully understand the role of synchronous motors, it is helpful to explore the basics of electric motors and drives, as well as their function in modern electrical systems.

A synchronous machine is more than just a fixed-speed device. In industrial environments where precision is crucial, this fixed-speed device ensures equipment operates reliably without the slip often seen in induction types. Because it locks exactly with the rotating magnetic field, it is especially valuable in applications requiring accurate timing and consistency, such as compressors, pumps, and high-precision tools.

Another important feature is its ability to act as a power factor correction unit within an electrical system. By operating at either unity power factor or leading power factor, it offsets lagging loads and improves overall system efficiency. Proper rotor and stator alignment is essential in achieving these benefits, since any misalignment can compromise performance. This balance of efficiency, stability, and system support explains why synchronous machines remain a vital choice for engineers seeking both energy savings and grid reliability.

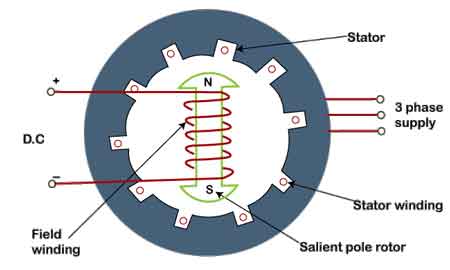

How Does a Synchronous Motor Work?

To understand the principle of operation, one must know the roles of the stator and rotor.

-

Stator: The stationary part of the device, consisting of windings that produce a rotating magnetic field when connected to an AC supply.

-

Rotor: The rotating part, which may contain wound field windings or permanent magnets.

When the rotor poles align with the stator’s magnetic field, torque is produced, driving the mechanical load at constant speed. The fundamentals of electric motor design directly influence the construction of synchronous motors and their ability to maintain constant speed.

Advantages of Synchronous Motors

Synchronous motors are widely chosen for their performance benefits:

-

Constant speed operation, regardless of load changes

-

High efficiency and lower energy losses

-

Ability to operate at unity or leading power factor, correcting system lag

Improving electric motor efficiency is often a key reason why engineers choose synchronous motors in industrial applications.

Disadvantages of Synchronous Motors

Despite their advantages, they have some drawbacks:

-

Not self-starting; requires an external starter or VFD

-

More complex construction compared to induction machines

-

Higher initial cost and additional components are needed for starting

How Do Synchronous Motors Differ from Induction Motors?

While both are AC machines, key differences exist:

-

Rotor construction: Synchronous motors utilize wound fields or permanent magnets, while induction motors typically employ squirrel-cage rotors.

-

Starting: Synchronous motors are not self-starting, while induction fixed-speed devices start on their own.

-

Power factor: Synchronous motors can operate at unity or leading power factor, thereby improving efficiency; in contrast, induction devices typically run at a lagging power factor. Comparing synchronous motors with other types, such as the induction motor, highlights their unique ability to maintain exact synchronism with the power supply.

Since many synchronous motors are started or controlled with variable-frequency drives (VFDs), it is essential to understand how a VFD works and its impact on performance.

Applications of Synchronous Motors

Synchronous motors are used wherever constant speed, precision, and efficiency are required:

-

Compressors, pumps, and fans for constant-speed drives

-

Machine tools and robotics for high precision

-

Power plants, where they operate as synchronous motors

-

Industrial settings that benefit from power factor correction

Speed Control of Synchronous Motors

Synchronous Motor speed control can be achieved in two primary ways:

-

Frequency adjustment: Changing the supply frequency alters the constant speed.

-

Pole variation: Adjusting the number of poles in the stator.

Modern systems typically utilize variable frequency drives (VFDs), which provide smooth and efficient speed control by varying the input frequency. Learning how electric motor control works provides context for how synchronous motors achieve precise operation compared to other types.

Contribution to Power Factor Correction

Synchronous motors are valuable in power systems because they can operate at unity or leading power factor. This allows them to offset lagging power factors caused by other loads, lowering energy costs and improving system efficiency.

Frequently Asked Questions

Can a synchronous motor operate without a VFD?

Yes, but they require other starting methods, such as pony devices or damper windings, since they are not self-starting.

Why are they important in robotics?

Their precise, constant-speed operation and ability to maintain synchronism make them ideal for robotics and automation applications requiring accuracy.

Can a synchronous machine generate electricity?

Yes, when driven mechanically, synchronous motors can function as constant-speed generators, converting mechanical energy into electrical energy.

What limits the starting of synchronous motors?

They cannot develop starting torque on their own, which limits direct-on-line starting. This is why auxiliary devices, VFDs, or other methods are used.

Are synchronous machines used in renewable energy?

Yes, constant-speed generators are widely used in hydroelectric and wind power plants, where stable frequency and power factor control are critical.

For a more detailed guide covering design, performance curves, standards, and industrial applications, see our in-depth resource on synchronous motors.

Variable Frequency Drive

Variable frequency drive optimizes AC motor control using an inverter and PWM for variable speed, torque management, soft start, and energy savings in HVAC, pumps, conveyors, compressors, and industrial automation.

What Is a Variable Frequency Drive (VFD)?

An inverter that varies frequency and voltage to control AC motor speed and torque, boosting efficiency and stability.

✅ Variable speed control with PWM and vector control

✅ Soft start, ramps, braking, and torque limits

✅ Energy savings in HVAC fans, pumps, conveyors

In industrial automation, motor control has always been a critical aspect of system design. However, one device that has revolutionized the way we approach this is the variable frequency drive (VFD). By understanding how adjustable frequency drives work, how they improve energy efficiency, and the right way to choose, install, and configure them, you can harness their full potential to optimize your industrial processes. If you're new to the terminology, explanations of what VFD stands for help align teams on documentation practices.

VFDs, sometimes called adjustable frequency drives (ac drives) or variable speed drives, (or adjustable speed drive) are electronic devices that modulate the power supplied to an electric motor to control its speed and torque. At its core, the variable frequency drive takes incoming AC power, converts it to DC using an inverter, and then reconverts it to a desired AC frequency and voltage using pulse width modulation. This process allows the VFD to adjust the motor speed by varying the frequency and voltage supplied. For a step-by-step primer on the AC-DC-AC conversion and PWM, see how a VFD works to connect these concepts with real-world drive topologies.

The primary advantage of using a variable frequency drive lies in its energy efficiency through torque control. Most traditional motor systems operate at a constant speed, even when the application doesn't require it. This results in significant energy waste, especially when running motors at full speed when lower speeds suffice. By implementing VFDs, you can regulate motor speed according to the actual demand, significantly reducing energy consumption. This leads to energy savings and extends the life of the motor. To understand why variable torque loads yield the largest savings, this overview of what a VFD is ties efficiency principles to practical applications.

Choosing the right variable frequency drive for your fan pump and compressor application can be daunting, but considering a few key factors can simplify the process. First, determine the type of motor you're using, its power rating, and the voltage and frequency requirements. Next, consider the desired level of control over motor speed, torque, and acceleration, as well as any environmental factors that may affect the VFD's performance, such as temperature or dust. Proper VFD sizing considers duty cycle, overload requirements, and harmonic constraints to ensure reliable operation.

VFDs offer numerous benefits beyond energy efficiency. They can improve process control, reduce mechanical stress on equipment, and lower maintenance costs by extending the life of motors, gearboxes, and other components. Additionally, they can help eliminate the need for costly mechanical parts, such as gearboxes, often used to vary motor speed. Because many industries use the term frequency converter interchangeably with VFD, clarifying specifications avoids mismatched expectations.

Installing and configuring a single phase variable frequency drive for optimal performance requires careful planning and execution. Please ensure the VFD is compatible with your motor and correctly sized for your application. In addition, proper wiring and grounding are essential to avoid electrical interference and ensure safety. Programming the VFD to suit your specific needs involves setting parameters such as acceleration and deceleration times, motor speed limits, and protection features. To avoid potential issues, it's best for you to consult the VFD manufacturer's guidelines and, if necessary, seek professional assistance. Advanced parameter sets and macros are covered in this guide to VFD programming, which can accelerate commissioning and standardize setups.

Despite their numerous benefits, VFDs can sometimes present challenges that require troubleshooting. Common issues include overheating, erratic motor behaviour, and communication problems. Check for loose connections, incorrect parameter settings, or inadequate ventilation when troubleshooting. If the issue continues, please consult the manufacturer's documentation or seek help from a qualified technician.

One question that often arises is whether VFDs can be used with any electric motor. While VFDs are most commonly used with AC induction motors, they can also be utilized with other motor types, such as permanent magnet synchronous motors or brushed DC motors, with the appropriate configuration. However, consulting the motor and VFD manufacturers is crucial to ensure compatibility and avoid potential damage to either component.

Implementing VFDs in industrial automation has brought about significant motor control and energy efficiency advancements. By understanding their underlying principles and harnessing their benefits, industries can optimize their processes, reduce energy consumption, and save on operating costs. With proper selection, installation, and maintenance, VFDs can be a valuable addition to any motor-driven application. For application case studies and selection tips, explore these resources on VFD drives to inform future modernization plans.