Electrical Grounding Explained

By Pablo Diaz, P.Eng.

Power Factor Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

Electrical grounding protects people and equipment by providing a safe path for fault current to flow into the earth. It stabilizes voltage levels, reduces shock hazards, and prevents equipment damage in electrical systems. Grounding is essential for safety, compliance, and system reliability.

What is Electrical Grounding?

Electrical grounding is the practice of connecting electrical systems to the earth to ensure safe operation and fault protection:

✅ Safely directs fault current to the ground to prevent shock

✅ Stabilizes system voltage to protect connected equipment

✅ Ensures compliance with safety codes and standards

Grounding and Bonding and the CE Code

Grounding and Bonding and NEC Section 250

Electrical Grounding – Definition, Types, Components

Electrical grounding is the intentional connection of electrical systems or equipment to the earth, ensuring safety, stability, and compliance with relevant codes. It provides a low-resistance path for excess current — such as from lightning, short circuits, or faults — to safely flow into the ground, reducing the risk of shock, fire, and equipment damage.

Also known as earthing, grounding refers to the process of connecting the non-current-carrying parts of equipment or the neutral point of a supply system to the earth using a conductive wire. This provides a reference voltage (zero potential) and a discharge path for faults.

In a properly grounded system, any excess or stray current is redirected away from people and equipment, toward the earth, through a grounding conductor. It is required by both the National Electrical Code (NEC) and Canadian Electrical Code (CEC) for all installations. Properly sizing a grounding electrode conductor is crucial for safely directing fault current to earth and ensuring compliance.

A ground fault circuit interrupter (GFCI) is a safety device designed to shut off power when it detects a difference in current between the hot and neutral conductors in a circuit, indicating a potential shock hazard. Typically installed in areas exposed to moisture, such as bathrooms and kitchens, GFCIs play a critical role in modern service panel configurations. Within these panels, power is distributed through individual circuit breakers or, occasionally, a single circuit breaker or fuse, both of which protect specific branch circuits from overload or short circuits. Each protected circuit is wired using copper wire, which offers low resistance and high conductivity, ensuring safe and efficient current flow throughout the system. Proper integration of GFCIs and circuit breakers enhances safety and compliance with national safety codes.

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

Why Is it Important?

Grounding performs several critical safety and operational functions in power systems:

-

Redirects fault current safely into the earth

-

Prevents electric shock and electrical fires

-

Stabilizes voltage during normal and abnormal conditions

-

Ensures the operation of overcurrent protection devices

-

Reduces the risk of damage to sensitive equipment

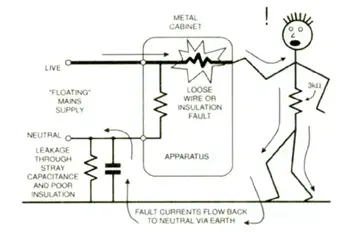

In the absence of grounding, stray current may travel through human bodies, building structures, or devices, leading to serious injury, property damage, or system failure.

Types of Grounding Systems

Types vary depending on the design and installation requirements. The most common include:

1. Solidly Grounded Systems

The neutral is directly connected to ground with no impedance. Common in residential and commercial buildings.

2. Impedance Grounded Systems

A resistor or reactor is placed between the system neutral and ground to limit fault current. Used in some industrial applications.

3. Ungrounded Systems

No intentional connection to ground. Used in specific scenarios, such as legacy systems or certain control circuits, but they pose increased shock and detection risks.

Each system type has its advantages and is chosen based on application needs, safety requirements, and maintenance considerations.

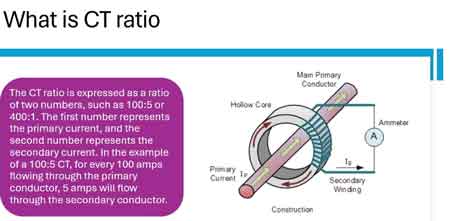

How Electrical Grounding Works: Charge Transfer and Safety

Electricity flows along the path of least resistance. In grounding, a conductive wire — typically made of copper — creates a safe path to earth, where excess charge is neutralized.

-

For negatively charged objects: (excess electrons), grounding allows electrons to flow into the earth.

For positively charged objects: (electron deficit), grounding allows electrons to flow from the earth into the object.

In either case, protective earthing balances the charge, restoring a neutral state.

In modern power systems:

-

The hot wire delivers current,

-

The neutral wire returns current during normal operation,

-

The ground wire carries fault current safely to earth when needed.

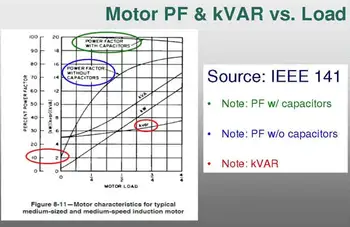

Compare high-resistance grounding systems to solidly grounded types to reduce arc flash hazards in industrial applications.

Grounding vs Bonding

Though often used together, grounding and bonding serve different purposes:

-

Grounding connects systems to the earth.

-

Bonding connects conductive parts together to ensure continuity and reduce voltage differences between equipment.

Proper bonding ensures that enclosures, conduits, and metallic components remain at the same potential, preventing dangerous touch voltages during a fault.

Key bonding components include:

-

Bonding jumpers

-

Grounding electrode conductors

-

Equipment ground conductors (EGC)

Both grounding and bonding are required for safety compliance.

Code Requirements (NEC Section 250 / CEC)

The NEC (Section 250) and CEC (Rule 10) outline the requirements for installing and maintaining grounding and bonding systems. These standards address:

-

Grounding electrode system requirements

-

Use of ground rods, plates, or metal water pipes

-

Grounding conductor sizing and routing

-

Bonding jumpers and connections

-

Main panel ground and neutral-to-ground bonding

-

Protection against ground loops and open grounds

- Inspections and system testing help confirm compliance and ensure ongoing safety.

Discover how electrical grounding code standards, as outlined in the NEC and CEC, help ensure proper safety and system grounding in all installations.

Grounding Components and Pathways

Effective grounding systems rely on several key components:

-

Grounding Electrode – Metal rod, plate, or water pipe driven or buried in the earth.

-

Grounding Electrode Conductor (GEC) – Wire connecting the electrode to the system’s neutral or bonding point.

-

Equipment Grounding Conductor (EGC) – Connects equipment enclosures to the system ground.

-

Bonding Jumpers – Create low-impedance connections between conductive parts.

-

Ground Rod Clamps – Secure conductors to rods or plates.

Pathways must be continuous, secure, and sized appropriately based on system amperage and conductor length. Learn how a ground grid can protect substations and industrial sites by dispersing high fault current through multiple paths.

Sign Up for Electricity Forum’s Power Quality Newsletter

Stay informed with our FREE Power Quality Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Common Grounding Applications

Residential: Earthing protects outlets, panels, and appliances. Plastic boxes don't need bonding, but metal boxes must be bonded.

Industrial: Systems include ground rings, grid electrodes, or ground plates for transformers, switchgear, and motors. Impedance earthing is sometimes used to limit fault current. Specialized applications like grounding a generator require unique configurations to manage transient loads and maintain continuity.

Commercial: Earthing ensures sensitive electronics are shielded from surges and interference, especially in offices, data centers, and hospitals.

Agricultural: Electric fences require multiple ground rods and proper spacing for livestock safety and energizer function.

Utilities: Substations and pole-mounted transformers rely on extensive ground systems for lightning and fault protection.

Training and Best Practices

Understanding proper grounding techniques is essential for electricians, engineers, and facility operators. Best practices include:

-

Always bond metal enclosures to the system ground

-

Use corrosion-resistant ground rods and clamps

-

Ensure continuity between bonding points and the electrode

-

Avoid creating multiple ground paths that could form loops

-

Follow NEC/CEC grounding conductor sizing charts

-

Test ground resistance — ideally under 25 ohms, often <5 ohms for critical systems

Frequently Asked Questions

What is a ground loop?

Occurs when multiple ground paths exist, causing unwanted current flow and interference. Avoid by using a single ground reference.

What is an open ground?

When a receptacle has no ground connection. Common in older homes and requires repair or GFCI installation.

What happens if an outlet isn’t grounded?

Risk of electric shock, fire, and damage to connected devices increases significantly.

What is a common ground?

A shared reference point for voltage measurement. Neutral wires may serve as common grounds in multiwire systems, but this differs from the equipment ground.

How do you ground an electric motor?

Attach a conductor to the frame or use a brazed ground pad. Prevents energized frames due to insulation failure.

How do you ground an electrical panel?

Bond all metal parts to the service neutral. Connect to a ground rod system using proper fittings and jumpers.

How do I ground an electric fence?

Install at least three 6–8 foot ground rods, spaced 10 feet apart, and connected to the energizer’s ground terminal using 20kV insulated wire.

For additional clarity on technical terms such as bonding and earthing, please refer to our page on understanding electrical grounding.

Related Articles