Grounding Electrode Conductor - NEC Section 250 Definition

By Pablo Diaz, P.Eng, Grounding Systems Technologies (GST)

Grounding and Bonding and The NEC - Section 250

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

A grounding electrode conductor (GEC) connects the grounding system to a grounding electrode, helping stabilize voltage and ensure electrical safety. It protects people and equipment by dissipating fault current safely into the earth, following NEC and power quality standards.

What is a Grounding Electrode Conductor?

A Grounding electrode conductor is a critical component in electrical systems, serving as the backbone of effective earthing practices.

✅ Connects an electrical system to a grounding electrode (earth rod or plate)

✅ Safely carries fault current during short circuits or surges

✅ Required by NEC and other power quality standards

For those new to these concepts, our article on Understanding Electrical Grounding provides a beginner-friendly explanation of how earthing and GECs work to protect people and equipment.

Understanding its role is essential for electrical engineering and maintenance professionals to ensure system safety, reliability, and compliance with the National Electrical Code (NEC). This ground (or earthing) conductor provides a direct path for fault currents to dissipate into the earth, reducing the risk of electrical surges and protecting both equipment and personnel. Proper implementation and sizing are not just regulatory requirements; they are vital for preventing failures, minimizing downtime, and ensuring the longevity of electrical installations in residential, commercial, and industrial settings. To understand how electrical grounding systems function in fault conditions, it’s essential to examine how they interact with electrode conductors to dissipate current safely.

While both the GEC and the equipment grounding conductor play roles in electrical safety compliance, they serve distinct functions within the NEC grounding system. The GEC connects the electrical system to the earth through a grounding electrode, providing a low-impedance path for ground fault dissipation during surge events or lightning strikes. In contrast, equipment grounding conductors bond non-current-carrying metal parts of equipment to the system ground to prevent shock hazards. Understanding this distinction is essential for ensuring proper installation and code-compliant system design.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

How GECs Work in Fault Current Dissipation

Visit our Grounding and Bonding and The NEC - Section 250 Course

NEC Table 250.66: Ground Wire Sizing Rules

The size of the grounding electrode conductor is crucial, and its determination often follows the guidelines outlined in Table 250.66 of the National Electrical Code (NEC). This table establishes the required conductor size based on the largest ungrounded service entrance conductor or equivalent area of parallel conductors. For example, systems with AWG copper conductors often require specific sizes to maintain effective current dissipation. Ensuring the correct size prevents overheating and provides an adequate fault current path, a critical safety feature in any electric service installation. For NEC-specific rules on conductor sizing and compliance, refer to our detailed guide on NEC ground wire size charts, which outlines key requirements, including Section 250.66.

Grounding Electrode Conductor Sizing NEC Table 250.66

| Largest Ungrounded Conductor or Equivalent Area (Copper) | Minimum Copper GEC Size | Minimum Aluminum GEC Size |

|---|---|---|

| 2 AWG or smaller | 8 AWG | 6 AWG |

| 1 or 1/0 AWG | 6 AWG | 4 AWG |

| 2/0 or 3/0 AWG | 4 AWG | 2 AWG |

| 4/0 – 350 kcmil | 2 AWG | 1/0 AWG |

| 400 – 600 kcmil | 1/0 AWG | 3/0 AWG |

| 700 – 1,100 kcmil | 2/0 AWG | 4/0 AWG |

| Over 1,100 kcmil | 3/0 AWG | 250 kcmil |

NEC Compliance and Safety Standards

Compliance with the NEC is non-negotiable in designing and implementing these systems. The NEC mandates that a grounding electrode conductor must meet specific safety standards to protect against overvoltage conditions. By adhering to these regulations, electrical systems achieve consistency, ensuring that they function as intended and provide safety during fault conditions. The use of an overcurrent protective device adds another layer of security, safeguarding equipment and personnel from potential hazards. If you're looking to explore the broader role of earthing in electrical design, our grounding and bonding page offers insight into how different components must be interconnected for safety and compliance.

The primary purpose of the grounding electrode conductor is to ensure safety by providing a low-resistance ground fault path to the earth. This path is designed to carry fault current away from sensitive equipment, thereby mitigating the risks associated with electrical surges. It also protects the grounded conductor and ensures that the earthing conductors of connected equipment function correctly. A well-implemented system enhances the safety of an electrical installation, reducing the likelihood of catastrophic failures and ensuring a stable operation.

Grounding Electrode Conductor Material Requirements (Copper vs Aluminum)

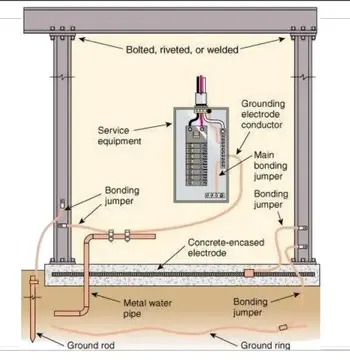

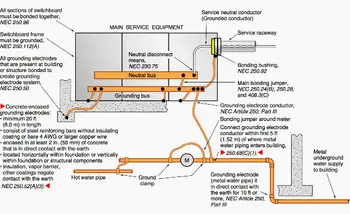

NEC requires that, where available on the premises at each building or structure served, all electrodes, including “made” electrodes, be bonded together to form the “Grounding Electrode System.” Learn how grounding systems support stable voltage conditions across service entrances, generators, and building frames in both residential and industrial installations.

Visit our Electrical Grounding Training Page

The “Grounding Electrode System” includes metal underground water pipes, metal frames of buildings, concrete-encased electrodes and ground rings. See how the grounding bonding CSA/NEC comparison highlights the similarities and differences between Canadian and U.S. earthing requirements.

Bonding and Grounding Systems

The general requirement is that a bonding jumper must be installed between the earthing conductor and the GEC installation to ensure they are bonded together.

-

Grounding electrode conductor is run from the service equipment to one of the electrodes that are bonded together.

-

NEC Section 250-24(c) is a requirement to connect the equipment conductors, the service-equipment enclosures, and, where the system is grounded, the grounded service conductor to an electrode. The conductor used to make this connection is considered the “Grounding Electrode Conductor.”

-

Grounding electrode conductor from an electrical service to a ground rod, pipe or plate electrode is never required to be larger than 6 AWG copper or 4 AWG aluminum unless the grounding electrode conductor continues on from the rod, pipe or plate to connect another electrode that may require a larger GEC such as a concrete encased electrode building steel or metal underground water pipe that qualifies as an earthing electrode.

Common Misconceptions About Grounding Electrode Conductor

NEC Section 250 Requirements

The requirements of NEC Section 250.2 states that an effective ground fault current path is an intentionally constructed, permanent, low impedance, electrically conductive path designed and intended to carry current under a ground fault conditions from the point of a ground fault (like an overcurrent device) on a wiring system to the electrical supply source and that facilitated the operation of the overcurrent protective device. This is the function of a “Bonding Conductor” and not the function of a grounding electrode conductor.

Test Your Knowledge About Power Quality!

Think you know Power Quality? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

With that assumption, and based on that incorrect interpretation, many electricians assume that in a properly functioning electrical system, currents in grounding electrode conductors are only present during faults, and only for a very short time.

NEC 250.4 and Fault Current Paths

Although further examination of 250.4(A)(5) should clarify that the earth shall not be considered an effective ground-fault current path, misconceptions still persist.

-

Grounding electrode conductors from an electrical service to a ground rod, metal water pipe, or plate must be no larger than 6 AWG copper.

-

Aluminum grounding electrode conductors can not be in contact with earth, masonry or subjected to corrosive conditions.

-

A grounding electrode conductor is permitted to “supply” or “serve” any number of electrodes, but must be sized for the largest grounding electrode conductor required.

-

You can also explore the electrical grounding code to better understand how national regulations define safe earthing conductor practices.

Frequently Asked Questions

Can a single grounding electrode conductor serve multiple buildings or systems?

Yes, a single grounding electrode conductor can serve multiple systems if properly sized and installed. However, each system must still meet bonding requirements, and local codes may require individual electrical connection to earth arrangements in some cases.

What happens if a grounding electrode conductor is too small?

An undersized grounding electrode conductor may overheat or fail to carry fault current effectively, increasing the risk of equipment damage, fire, or shock hazard. It also violates NEC requirements and could lead to code violations or failed inspections.

Does the type of soil affect grounding electrode conductor performance?

Yes. Soil resistivity impacts how effectively current dissipates into the earth. High-resistance soil (like dry sand or rock) may reduce earthing effectiveness, which is why supplemental electrodes or soil conditioning methods are sometimes used.

Is there a difference between earthing for lightning protection and a GEC system?

Yes. While both direct current to earth, lightning protection systems often use separate electrodes specifically designed to handle high-frequency surges. These must be bonded to the GEC to maintain potential equalization but follow different design principles.

When should a grounding electrode conductor be replaced or upgraded?

Replacement is recommended if the GEC shows corrosion, mechanical damage, improper sizing, or poor terminations. Upgrading may also be required if the electrical service is expanded or reconfigured.

Related Articles