Understanding Electrical Grounding

By Pablo Diaz, P.Eng, Grounding Systems Technologies (GST)

Substation Grounding Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our NFPA 70E Fact Sheet – 2024 Electrical Safety Edition

- Understand how NFPA 70E works with NEC and NFPA 70B standards

- Clarify the shared responsibility between employers and employees

- Learn how NFPA 70E supports OSHA compliance

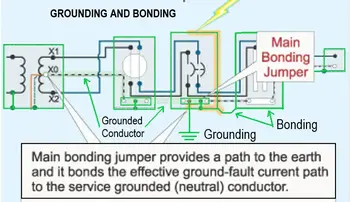

Understanding electrical grounding ensures safe earthing, bonding, and low-impedance fault paths per NEC. It covers grounding electrodes, equipotential bonding, surge protection, and lightning mitigation for reliable power systems and equipment safety compliance.

What Is Understanding Electrical Grounding?

Connecting systems to earth to manage fault current via bonding and electrodes, ensuring safety and code compliance.

✅ Provides low-impedance paths for ground faults to clear breakers

✅ Bonds conductive parts to maintain equipotential and reduce touch voltage

✅ Requires grounding electrodes sized per NEC Article 250

Electrical Grounding is a general term that is often used loosely to refer to “Bonding” (Safety Grounding) and “Earth Grounding”. Personnel of major industries have often misinterpreted grounding to mean that anything in contact with the earth is considered to be grounded. For clarity, see the electrical grounding definition for distinctions used in industry today.

Electrical Grounding is the reference zero for the electrical system. When we talk about 120 Volts RMS, it represents 120 units above the zero electrical reference. To understand this reference point further, review the concepts in what is electrical grounding to see how zero reference is established.

Electrical Grounding is the reference zero for the electrical system and all the equipment should be at this same equipment potential plane.

A well-designed grounding system helps keep all enclosures at an equal potential to mitigate touch voltage.

According to accident reports, most electrical accidents occur when the earth is used as the safety grounding system (Bonding). Understanding the difference is covered in this overview of grounding and bonding principles that reduce shock risk.

Accident reports details the hazards of using earth as a safety grounding and the practice of electrical grounding the equipment through local grounds. (grounding each individual piece of equipment with a separate ground rod, driven into the earth).

Test Your Knowledge About Power Quality!

Think you know Power Quality? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Regulatory frameworks like the CSA and NEC grounding and bonding requirements provide guidance on avoiding isolated rods and ensuring effective fault clearing.

The best method for ensuring the safety of personnel is to use a “Bonding Conductor”. This conductor should be continuous, with sufficient ampacity and the lowest impedance path back to the circuit interrupting devices, which insures positive operation of the protective devices.

Once a system that connects all the metallic frames of electrical equipment together has been established, then the grounding system must be placed at “Zero Reference Potential”. The earth grounding electrode should have the lowest resistance value possible, preferably 5 ohms or less. The role of the grounding electrode conductor is to connect the system to the earth electrode with adequate capacity.

This low resistance to earth ground will limits the potential of the electrical system to earth (limiting the stresses placed on components such as switches, insulators and transformers).

Broader reliability outcomes are discussed in this primer on electrical grounding and how it affects equipment insulation and surge withstand.

It will also reduce the effects of static charges on the electrical system and will protect against lightning strokes, lightning induced voltages, and minimizes the effects of transient over-voltages.

Visit Our Electrical Grounding and Bonding Course