Latest Utility Transformers Articles

Power Transformer Explosion Causes And Prevention

Power transformer explosions pose a serious risk to electrical substations, causing fires, equipment damage, and power outages. Proper maintenance, insulation monitoring, and the use of protective relays help reduce hazards and improve grid reliability.

What is a Power Transformer Explosion?

A power transformer explosion is a catastrophic failure in high-voltage equipment that can result from insulation breakdown, overheating, or internal arcing.

✅ Leads to fire, smoke, and equipment destruction

✅ Causes blackouts, downtime, and safety hazards

✅ Preventable with testing, monitoring, and protection

A power transformer explosion is a serious concern for industrial electricians, posing a significant safety hazard and the potential for widespread power outages. Understanding the causes, consequences, and preventative measures associated with these incidents is crucial for maintaining a safe working environment and ensuring the reliable operation of electrical systems. Let's examine the causes of explosions, covering key topics such as common causes of failure, the devastating effects of explosions, essential safety features, and best practices for maintenance, inspection, and prevention. By gaining a deeper understanding of these critical aspects, industrial electricians can enhance their knowledge, improve safety protocols, and contribute to preventing catastrophic transformer failures.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Causes of Transformer Explosions

A power transformer explosion can occur due to various internal and external factors. Internal faults, such as insulation breakdown, short circuits within the windings, and overheating due to excessive current flow, can trigger a catastrophic failure. External factors, including lightning strikes, power surges from the grid, and even animal intrusion, can also damage the unit and lead to an explosion. Overloading the unit beyond its designed capacity, as well as poor maintenance practices that neglect regular inspection and upkeep, can significantly increase the risk of such incidents. Many failures occur in high-voltage environments, making a substation transformer especially prone to catastrophic explosions if not properly maintained.

Effects of Transformer Explosions

The effects of a transformer explosion can be devastating. The immediate consequence is often a widespread power outage, disrupting electricity supply to homes, businesses, and critical infrastructure. The intense heat and release of flammable oil during an explosion can ignite fires, causing further damage to property and endangering lives. Additionally, transformer explosions can lead to environmental damage due to oil spills and the release of toxic gases, posing risks to both human health and ecosystems. The safety hazards associated with these events cannot be overstated, as explosions can cause serious injuries or even fatalities to people in the vicinity. Regular monitoring, such as using a hydrogen detection system, can help identify early fault conditions that often lead to explosions.

Transformer Safety Features

To mitigate the risks associated with transformer explosions, various safety features are incorporated into the design of transformers. Pressure relief valves are crucial components that release excess pressure buildup inside the unit tank, preventing it from rupturing. Buchholz relays act as sensitive detectors, sensing gas accumulation within the device, which often indicates an internal fault, and triggering a trip mechanism to isolate the faulty equipment. Overcurrent protection devices, such as fuses and circuit breakers, interrupt excessive current flow, preventing overheating and potential explosions. Preventive measures, such as condition monitoring, in an age of modernization provide operators with tools to detect insulation breakdowns and prevent failures.

Transformer Maintenance and Inspection

Regular maintenance and inspection are vital for ensuring the safe and reliable operation of power transformers. This includes visual checks for signs of damage or deterioration, oil analysis to assess its condition and identify potential issues, and electrical testing to evaluate the integrity of the unit's insulation and windings. Preventive maintenance, including cleaning, tightening connections, and replacing worn-out components, is crucial in preventing premature failures. Proper training for personnel working with transformers is crucial to ensure they understand the risks involved and follow safe operating procedures. The role of transformer insulation is crucial, as its deterioration is one of the leading causes of transformer explosions.

Transformer Types and Applications

Power transformers come in various types, each designed for specific applications. Large power transformers are used in power generation and transmission networks, while smaller distribution types step down the voltage for residential and commercial use. Instrument units serve a critical role in measurement and protection systems, ensuring the accurate monitoring and safe operation of electrical equipment. Learning about the construction of a transformer highlights how design features such as pressure relief valves and bushings affect explosion risk.

Transformer Oil

Oil plays a critical role in the operation and longevity of these devices. It serves as an insulator, preventing electrical breakdown between the windings, and as a coolant, dissipating the heat generated during operation. Different types of transformer oil are available, including mineral oil, silicone oil, and ester oil, each with its own characteristics and applications.

Transformer Explosion Case Studies

Analyzing real-world case studies of transformer explosions provides valuable insights into their causes and consequences. By examining what went wrong in previous incidents, engineers and operators can learn valuable lessons and implement preventive measures to avoid similar occurrences. These case studies also highlight the importance of proper maintenance, adherence to safety standards, and prompt response to potential issues.

Transformer Standards and Regulations

Various standards and regulations govern the design, installation, and operation of power transformers to ensure safety and reliability. IEEE standards provide comprehensive guidelines for design, testing, and maintenance, while NFPA codes focus on fire safety regulations for electrical equipment. Local regulations may also impose specific requirements for installation, ensuring compliance with regional safety codes.

Transformer Explosion Prevention

Preventing transformer explosions requires a multifaceted approach that encompasses proper installation, regular maintenance, and adherence to safety protocols. Ensuring adequate ventilation and grounding during installation is crucial for preventing overheating and electrical hazards. Following manufacturer recommendations for maintenance, including periodic inspections and oil testing, is essential to identify and address potential issues before they escalate. Implementing overload protection using appropriate fuses and circuit breakers safeguards the unit from excessive current flow.

Transformer Explosion Investigation

When a transformer explosion occurs, a thorough investigation is necessary to determine the root cause and prevent similar incidents in the future. This involves a comprehensive scene assessment to gather evidence and document the damage, followed by data analysis to review operational data and maintenance records. The final step involves a root cause analysis to identify the underlying factors that contributed to the explosion, enabling corrective actions and improvements to safety protocols.

By understanding the various aspects of power transformer explosions, from their causes and effects to prevention and investigation, we can work towards minimizing the risks associated with these critical components of our electrical infrastructure.

Frequently Asked Questions

What causes a power transformer to explode?

Several factors can cause a power transformer to explode, including:

-

Internal faults: Insulation breakdown, short circuits, and overheating.

-

External factors: Lightning strikes, power surges, and animal intrusion.

-

Overloading: Exceeding the unit's capacity.

-

Poor maintenance: Lack of regular inspection and upkeep.

What are the potential hazards of a power transformer explosion?

A power transformer explosion poses several hazards, such as:

-

Power outages: Disruption of the electricity supply.

-

Fires: Release of flammable oil and materials.

-

Environmental damage: Oil spills and the release of toxic gases.

-

Safety hazards: Risk of injury or death to people nearby.

How can a power transformer explosion be prevented or mitigated?

They can be prevented or mitigated through:

-

Regular maintenance and inspection: Including visual checks, oil analysis, and electrical testing.

-

Proper installation: Ensuring adequate ventilation and grounding.

-

Overload protection: Using appropriate fuses and circuit breakers.

-

Safety features: Utilizing pressure relief valves, Buchholz relays, and other protective devices.

-

Adherence to standards and regulations: Following IEEE standards, NFPA codes, and local regulations.

-

Thorough investigation of incidents: Conducting root cause analysis to identify and address contributing factors.

To minimize downtime and hazards following an incident, utilities often rely on power transformer health checks to inform repairs and replacement planning.

Related Articles

Sign Up for Electricity Forum’s Utility Transformers Newsletter

Stay informed with our FREE Utility Transformers Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Padmount Transformer Explained

A padmount transformer is a ground-mounted electric power distribution device enclosed in a secure, weatherproof cabinet. Commonly used in residential and commercial areas, it steps down high-voltage electricity to lower levels for safe local use.

What is a Padmount Transformer?

A padmount transformer is a ground-mounted utility distribution transformer, typically housed in a locked metal cabinet and situated on a small concrete pad.

✅ Used to step down high-voltage electricity to usable levels

✅ Housed in locked, weather-resistant metal enclosures on concrete pads

✅ Common in residential neighbourhoods, commercial buildings, and industrial sites

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Because all live components are fully enclosed in grounded metal boxes, padmount transformers can be installed in accessible residential areas without fencing, unlike large substation transformers. They are usually connected to underground distribution lines at a service drop, reducing primary voltage to secondary levels supplied to utility customers. Depending on the application, one unit may serve a single large building or dozens of homes. Many operate as distribution transformers, stepping down high voltages to levels suitable for everyday use.

Types of Padmount Transformers

They are available in single-phase and three-phase designs. Single-phase units are commonly found in residential subdivisions, while three-phase models are typically used in commercial and industrial facilities. Configurations include delta and wye connections, with common primary voltages ranging from 4 kV to 34.5 kV, which are stepped down to secondary levels such as 120/240 V or 480 V. The choice of type depends on the load profile, service requirements, and local utility standards.

Internal Components, Cooling, and Insulation

Inside the enclosure, the transformer tank holds the core and windings, which are immersed in insulating fluid, typically mineral oil, less-flammable fluids, or biodegradable ester-based alternatives. These media cool and insulate the windings, extending service life. The wiring cabinet contains high- and low-voltage bushings, with compartments separated for safety. Protective devices, such as bayonet fuses, current-limiting fuses, and load-break switches, are often built in, providing fault isolation and ensuring reliable service continuity. In larger facilities, a three-phase transformers configuration may be chosen instead of a single-phase padmount to handle heavier loads.

Standards and Regulatory Codes

They must comply with strict international and regional standards to ensure safety, performance, and interoperability. IEEE C57.12.34 outlines design and performance requirements for pad-mounted distribution transformers, while ANSI C57.12 provides specifications for enclosures, clearances, and operational reliability. In Canada, CSA C227.4 defines similar benchmarks for construction and testing. These standards govern everything from insulation levels and thermal performance to short-circuit strength and sound levels. Compliance ensures equipment can withstand environmental stresses, meet fire resistance requirements, and operate safely under fault conditions. Utilities and building owners rely on certified products to meet the requirements of inspection authorities and maintain insurance eligibility.

Installation and Siting Guidelines

Proper siting is critical for safety, accessibility, and long-term reliability. The National Electrical Code (NEC) Article 450 requires specific clearances between the transformer enclosure and nearby structures, with distances varying depending on the wall construction and the presence of door or window openings. For example, clearances may range from 3 to 10 feet to minimize fire risk and allow emergency access. Transformers should be installed on reinforced concrete pads that elevate the enclosure above ground level to prevent flooding. Adequate working space around all sides is required for safe maintenance, and conduit entry points must be properly sealed against moisture and pests. Local fire codes and insurance carrier requirements often impose additional siting rules, making early coordination with inspectors essential.

Operation and Electrical Function

The operating principle is straightforward: primary high-voltage power enters the unit through underground cables, passes through the core and windings, and exits at a lower, usable voltage for end-users. For example, a 13.8 kV feeder may be stepped down to 120/240 V for homes or 480 V for industrial equipment. Proper siting and safety measures are crucial, and some designs overlap with those of electrical substation transformers in terms of installation guidelines.

Maintenance and Reliability

Like all distribution equipment, these transformers require regular maintenance to ensure safe operation. Utilities may perform oil sampling, thermal scanning, and inspections for leaks, corrosion, or insulation breakdown. Record-keeping helps track load history and predict potential failures, reducing unplanned outages. To ensure long-term performance, utilities employ transformer maintenance practices, including inspections, oil testing, and condition monitoring, for padmount installations.

Applications and Sizing

Ratings typically range from 75 kVA to 5000 kVA, making padmounts versatile across residential subdivisions, schools, hospitals, shopping centers, and renewable energy systems. Selection depends on the anticipated load, with engineers sizing units to strike a balance between efficiency, reliability, and cost. Engineers often compare padmount units to medium-voltage transformers when selecting equipment for commercial or industrial applications.

Safety and Environmental Considerations

Beyond electrical safety, padmount transformers must address environmental and public hazards. Cabinets are designed with tamper-resistant locks to prevent unauthorized access, especially in residential areas where children may be nearby. Grounding practices protect both the equipment and the public from fault currents. Environmental safety is also a growing concern: insulating fluids must meet spill containment requirements, and less flammable or biodegradable ester-based oils are increasingly specified to reduce fire and environmental risks. Noise levels are another factor, with modern designs incorporating sound-dampening measures to reduce humming in urban and suburban settings. By combining physical security, fluid containment, and noise control, they minimize risks to people and the environment.

Padmount vs Pole-Mounted Transformers

While both padmount and pole-mounted transformers step down distribution voltage for end-users, their applications differ. Pole-mounted transformers are typically installed on overhead distribution systems, common in rural areas where space and visibility are less of a concern. In contrast, padmount transformers connect to underground distribution lines and are preferred in residential subdivisions, commercial complexes, and urban environments where aesthetics, accessibility, and safety are priorities. Padmount units are more secure, since all live components are enclosed, and they often include built-in protective devices. Pole-mounted units are less costly to install but require more visible infrastructure and can be vulnerable to weather-related damage. Utilities choose between them based on terrain, population density, cost, and safety considerations. Unlike pole-mounted transformers, padmount units are designed for underground distribution networks, offering improved aesthetics and security.

Emerging Trends and Innovations

Modern designs are evolving with eco-friendly insulating fluids, quieter operation, and integrated smart sensors that provide real-time monitoring of load, temperature, and oil condition. These innovations improve efficiency, reliability, and sustainability.

Padmount transformers are essential to modern electrical distribution systems, as they combine safety, reliability, and adaptability. By stepping down voltage at the point of use, they support the needs of residential, commercial, and industrial users while aligning with evolving standards, safety practices, and innovative technologies.

Related Articles

Do All The Transformers Use Power With No Load

Do all the transformers use power with no load? Practical units draw magnetizing current and incur core (iron) losses from hysteresis and eddy currents, causing reactive power and standby consumption even without secondary load.

Do All the Transformers Use Power With No Load?

Yes. Practical transformers draw magnetizing current with iron core losses at no load; an ideal transformer would not.

✅ No-load losses from hysteresis and eddy currents are nearly constant.

✅ Magnetizing current supplies reactive power; real power equals iron loss.

✅ Better core steel and laminated design minimize standby watts and heating.

Do all the transformers use power with no load? This question holds significant importance for electrical engineering and maintenance professionals because understanding transformer energy consumption during no-load conditions can impact operational efficiency, energy costs, and system reliability. Transformers play a vital role in electrical power distribution, but even when they aren't actively supplying power to a load, they can still draw energy from the grid. This no-load loss, primarily caused by core magnetization, directly affects energy efficiency and long-term operating costs. For engineers and facility managers, knowing how and why they consume power without a load can inform smarter decisions on equipment selection, energy audits, and system optimization, ultimately supporting more sustainable and cost-effective power management strategies. In practical networks, assets like electrical power distribution transformers must be evaluated for standby losses to align reliability with lifecycle cost goals.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

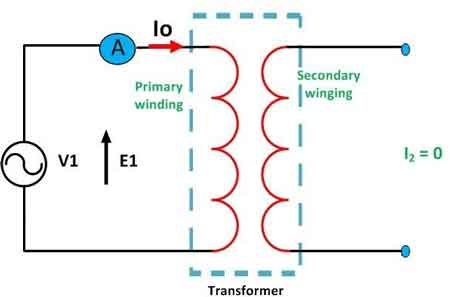

The operation of transformers is often associated with the efficient transfer of electrical energy from one circuit to another. However, a lesser-known aspect of their operation is that they consume power even when there is no load connected to the secondary winding. This power consumption is not a design flaw but an inherent characteristic of how they work. Understanding the underlying principles can offer insight into why this happens and what it means for energy efficiency. For a deeper primer on flux, turns ratio, and energy transfer, see how transformers work in AC systems to contextualize no-load behavior.

One of the key reasons for this phenomenon lies in the concept of core losses. When a transformer is connected to a power supply, its core must be continuously magnetized and demagnetized to maintain the alternating magnetic flux. This continuous process results in power consumption due to resistance within the core material. The primary contributors to core losses are hysteresis loss and eddy current loss. Hysteresis loss occurs because the magnetic domains within the core must realign with each change in the AC current—a process that releases heat and consumes energy. Eddy current loss happens when small, swirling currents are induced within the core material itself, creating resistive heating. These two components together are responsible for a significant portion of the power consumed by transformers during no-load operation.

Another essential concept to understand is magnetizing current. Even in the absence of load power, they draw a small amount of current from the input power source. This magnetizing current is used to generate and maintain the magnetic flux within the core. While this current is relatively small, it is a continuous drain on the system's power supply. Since the magnetizing current is required to sustain the core’s magnetic field, it results in ongoing power consumption, even when no electricity is being delivered to an end device. This is one of the fundamental reasons why they consume power even when idle. The magnetizing branch is driven by induced emf, and understanding what causes voltage to be induced in a transformer clarifies why this current never truly falls to zero.

No-load power consumption is a broader concept that includes all the power used by the transformer when the secondary winding is open. This consumption is often referred to as standby power consumption. When a transformer’s load power demand is zero, the power required to overcome core losses and maintain the magnetic field is still present. This consumption is generally measured in watts or as a percentage of the transformer's total capacity. The no-load power consumption can vary depending on the size and design of the transformer. Larger units, such as those used in substations, tend to have higher no-load losses due to the larger magnetic cores required to handle high voltages and currents. For perspective, analyses of how much electricity a high-voltage transformer uses can help benchmark acceptable standby losses in large installations.

The impact of no-load consumption on energy efficiency cannot be overlooked. While they are designed to be highly efficient, the power used during no-load conditions still represents an energy loss that contributes to overall system inefficiency. This is particularly relevant in large power systems where multiple transformers may remain connected to the grid without serving active loads. Reducing these losses is a priority for utilities and industries aiming to improve energy efficiency. Some transformer designs use advanced core materials that have lower hysteresis and eddy current losses, thereby minimizing power consumption during idle periods. Addressing these issues can lead to significant cost savings, especially in facilities where multiple transformers are in operation 24/7. In many plants, specifying a modern power transformer with optimized core steel reduces no-load watts while maintaining fault withstand margins.

The role of the primary winding is another critical aspect to consider. When a transformer is connected to a power supply, the primary winding draws power to establish and maintain the magnetic flux within the core. This process happens even when the secondary winding has no connected load. As a result, power consumption occurs due to resistance within the primary winding, further adding to no-load power consumption. The induced flux in the core is necessary for the operation of the transformer, but it also means that the primary winding’s current draw cannot be eliminated. Consequently, the input power used by the primary winding is not zero, even when the output load is nonexistent. This interplay of input and output is governed by electromagnetic laws, and reviewing why power is conserved in transformers helps separate ideal behavior from real losses.

One aspect of transformer operation that often goes unnoticed is the role of voltage drop. Although voltage drop is more commonly discussed in the context of loaded conditions, it is also present during no-load operation. When current flows through the primary winding, the resistance of the winding causes a slight voltage drop. While this drop is relatively small under no-load conditions, it becomes a part of the total power loss associated with the transformer's operation. This subtle but important aspect underscores the complexities of energy efficiency in transformer design and usage.

In summary, the answer to "do all the transformers use power with no load" is a clear yes. The reasons behind this consumption are rooted in core losses, magnetizing current, and the power required to maintain magnetic flux in the core. These processes are all driven by fundamental principles of electromagnetism and the physical properties of the materials used in transformer construction. Although modern designs strive to reduce these losses, they cannot be entirely eliminated. This ongoing power consumption, which occurs due to resistance, no-load losses, and the draw of magnetizing current, affects energy efficiency and operating costs. Recognizing the factors that contribute to no-load power consumption is crucial for engineers, utilities, and facility managers who aim to optimize energy use in electrical systems. Finally, it is worth noting that a power supply is not the same device as a transformer, and this distinction is outlined in a guide comparing power supplies and transformers for common engineering contexts.

Related Articles

How Many Volts Go Into a Distributor Bucket Transformer

How many volts go into a distributor bucket transformer? Typically, a pole-mounted distribution transformer takes 7.2-13.8 kV primary and steps down to 120/240 V service; values vary by utility feeder, region, and system design.

How Many Volts Go Into a Distributor Bucket Transformer?

Typically 7.2-13.8 kV primary, stepped down to 120/240 V; exact values depend on utility standards.

✅ Common primary: 7.2, 7.62, 12.47, 13.2, 13.8 kV (utility-dependent)

✅ Typical secondary: 120/240 V split-phase for residential service

✅ Verify nameplate for primary kV, kVA, phase, and tap settings

How many volts go into a distributor bucket transformer? is a critical question for electrical engineering and maintenance professionals. Understanding the primary voltage levels applied to these transformers is essential for several reasons. Firstly, it ensures the safe and efficient operation of the electrical grid, minimizing the risk of equipment failure and power outages. Secondly, it allows for proper selection and sizing, ensuring that the equipment can handle the expected loads. Finally, knowledge of primary voltages is crucial for adhering to electrical safety codes and regulations, protecting both workers and the public from potential hazards.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

The voltage that goes into a distributor bucket transformer plays a crucial role in determining its performance, safety, and efficiency. Understanding the electrical specifications and operational requirements of these units is essential for electrical engineers, contractors, and utility workers. Distributor bucket transformers are a vital part of electrical distribution systems, especially when stepping down high-voltage electricity to levels suitable for residential, commercial, and industrial applications. These units are a subset of distribution transformers commonly deployed on feeders and service drops.

Typical Primary Voltages

Typically, distributor bucket transformers receive a primary voltage ranging from 7,200V to 13,800V, depending on the specific design of the local grid infrastructure. This primary voltage is crucial for ensuring the effective distribution of electricity. The primary and secondary windings within these they facilitate the process of voltage conversion. Primary voltage is introduced through the primary windings, while secondary voltage is produced through the secondary windings to provide usable electricity for end-users. The supply voltage must align with local utility standards to ensure proper operation and safety. In protection and metering, the term voltage transformer often denotes instrument-class PTs used to step down signals safely for relays and meters.

Distributor bucket transformers are categorized into single-phase transformer and three-phase transformer. Single-phase transformers are commonly used in residential areas, while three-phase ones support larger commercial and industrial applications. These phase units are specifically designed to meet the energy demands of their respective loads. The phase system, whether single or three-phase, affects the efficiency and power output. The way they connect to the electrical grid depends on the type of phase system in use. Open delta configurations are sometimes used as a cost-saving measure for certain three-phase systems. These configurations offer a balance between operational efficiency and cost, especially in areas with fluctuating power demands.

Safety precautions are paramount when working with distributor bucket transformers, as the high voltages involved pose significant hazards. Workers must follow strict lockout/tagout procedures, ensure proper grounding, and wear personal protective equipment (PPE) to prevent accidental contact with live electrical components. Electrical safety standards, such as those set by the National Electrical Code (NEC), dictate how they are designed and operated to minimize risks. Compliance with these codes is essential for the safe installation, maintenance, and operation of distribution systems.

Transformer Types

Different types are used in power distribution systems, including isolation, dry type transformers, and auto transformer. Isolation ones provide electrical isolation between the primary and secondary windings, reducing the risk of shock and ensuring greater safety. Dry-type, on the other hand, use air rather than liquid for cooling, making them suitable for indoor environments where fire hazards must be minimized. Autotransformers differ from other designs by using a single winding to serve both primary and secondary functions, offering a more compact and cost-effective solution for voltage conversion. Each type serves specific purposes, depending on the application's voltage requirements and environmental conditions. For bulk transfer between transmission and subtransmission levels, utilities rely on power transformers that operate at higher MVA ratings than bucket-style units.

The load capacity of a distributor bucket transformer is another key factor influencing the required voltage. They are designed to handle a full load of electricity without overheating or experiencing voltage drops. The load that the unit must support is calculated using kilovolt-ampere (kVA) ratings, which represent the maximum amount of power it can safely handle. kVA ratings dictate the capacity to serve residential and commercial loads effectively. When operating at full load, these transformers must maintain maximum efficiency to minimize energy losses and ensure consistent power delivery. If the load exceeds the capacity, the voltage output may drop, leading to potential service interruptions or equipment damage. Selecting the correct kVA aligns the unit with the broader electrical power distribution transformer architecture of the circuit for reliability.

Another essential consideration is the role of buck-boost transformers in power systems. Buck-boost transformers are commonly used to make minor adjustments to the supply voltage. When supply voltage is slightly higher or lower than required, a buck-boost transformer can increase (boost) or decrease (buck) the voltage to the desired level. These transformers are often used to correct slight deviations in supply voltage, ensuring that downstream equipment receives a stable and reliable power supply. This type of adjustment prevents under-voltage or over-voltage conditions, protecting electrical devices from damage.

Electrical Codes and Standards

Electrical codes and standards, such as those set by the NEC, play a significant role in how distributor bucket transformers are specified and installed. Compliance ensures the safe and effective operation of the electrical distribution system. These standards address the acceptable range of primary voltage, the grounding, and how they connect to distribution systems. Adhering to these guidelines ensures they operate safely and efficiently while minimizing risks to personnel and equipment.

Applications

The applications of distributor bucket transformers are widespread, supporting residential, commercial, and industrial power needs. These step down high-voltage distribution lines to lower voltages suitable for powering homes, businesses, and industrial facilities. This process enables the safe delivery of 120 volts and other usable voltages to homes and buildings. By converting the high primary voltage to a lower secondary voltage, distribution units provide the essential electrical energy required for lighting, appliances, and industrial machinery. These transformers must be designed to accommodate the specific voltage needs of the area they serve, ensuring stable and consistent power delivery. In overhead systems, many bucket configurations are implemented as pole-mounted transformers to reach dispersed loads efficiently.

Frequently Asked Questions

What is the input voltage of a distribution transformer?

The input voltage typically ranges from 2.4 kV to 34.5 kV, depending on the system's design and the utility's distribution network. This high voltage allows for efficient transmission of electrical energy over long distances with minimal power loss. The input voltage is referred to as the "primary voltage". Upstream on the grid, high-voltage transformers handle transmission-level steps before energy reaches distribution circuits.

How many volts come into a transformer?

The voltage that comes into a transformer varies depending on its application. For distribution types, the incoming voltage is usually between 2.4 kV and 34.5 kV. For smaller residential transformers, the voltage may be 7.2 kV, 13.8 kV, or 25 kV. Industrial types can have even higher incoming voltages, especially for large facilities connected directly to high-voltage transmission lines.

What voltage do pole-mounted transformers step down to?

Pole-mounted transformers step down high distribution voltages (typically 7.2 kV, 13.8 kV, or 25 kV) to lower, usable secondary voltages for residential and commercial use. The most common secondary voltages are 120/240 V for residential applications. This allows homes and small businesses to safely power electrical devices and appliances. These devices are often referred to as an electric pole transformer in utility vernacular, especially in residential neighborhoods.

What is the standard voltage of a transformer?

The standard voltage depends on its application. For residential types, the output (secondary) voltage is typically 120/240 V in North America. For commercial and industrial ones, the standard output voltage can be 208 V, 480 V, or 600 V, depending on the system's needs. On the primary side, the standard voltages are commonly 2.4 kV, 7.2 kV, 13.8 kV, 25 kV, or 34.5 kV for distribution networks.

The voltage that goes into a distributor bucket transformer typically ranges from 7,200V to 13,800V. The primary and secondary voltages are managed through windings, which is influenced by the type, load capacity, and phase system. Compliance with electrical codes and adherence to safety precautions are essential to ensure safe and efficient operation. Various transformer types, including autotransformers, isolation transformers, and buck-boost transformers, play key roles in meeting the diverse voltage demands of modern power distribution systems. With proper design, maintenance, and safety protocols, distributor bucket transformers continue to serve as a vital component in electrical power distribution.

Related Articles

How Much Electricity Does a High-Voltage Transformer Use?

A high-voltage transformer does not directly use electricity in the same way as devices plugged into the wall. Instead, it facilitates the transfer of electrical power while experiencing power losses. These losses, primarily core and copper losses, are caused by electromagnetic induction and the flow of current through the windings. Although transformers are highly efficient, typically ranging from 95% to 99%, some energy is still wasted. In large-scale power distribution systems across North America, these losses add up, impacting overall energy consumption.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

How Much Power Does a High-Voltage Transformer Use During Normal Operation?

Transformers in power distribution networks, including distribution transformers and power transformers, handle the conversion of voltage ranges and power supplies. They do not consume electricity like household devices but experience losses during operation. Core losses occur continuously as long as the transformer is energized, while copper losses vary depending on the load. Power consumption is a result of these energy losses, which occur during the process of transforming voltage levels for electrical power transmission.

What Factors Determine the Energy Consumption of a High-Voltage Transformer?

Several factors influence a transformer's power consumption. The design of the transformer plays a critical role—transformer design, including materials and construction, affects how efficiently it operates. The load placed on a transformer also impacts its consumption. Transformers operating closer to full load tend to be more efficient, while those running with lighter loads waste more energy. Additionally, the type of transformer—whether phase transformers or voltage transformers—along with the voltage range and winding types, contributes to the overall efficiency. Lastly, short circuits or faults in the distribution system can significantly increase energy losses.

How Does a Transformer’s Load Affect Its Power Usage?

The load on a transformer is a key factor in determining power losses. When a transformer is running at full or near-full capacity, its efficiency is at its highest. In contrast, light loads result in higher proportional energy losses, with core losses making up a larger percentage of the total power consumption. The efficiency of power distribution transformers in distribution systems is affected by fluctuations in load, which can cause transformers to operate less efficiently at off-peak times.

What is the Typical Efficiency of High-Voltage Transformers, and How Does It Impact Energy Consumption?

Transformers are generally very efficient, with typical efficiency rates between 95% and 99%. However, even small percentages of waste energy can add up in large-scale electrical power distribution networks. The efficiency depends on factors such as load, design, and materials used in construction. Higher efficiency means lower power consumption, but the inevitable losses, such as copper and core losses, still affect overall energy use. The more efficient the transformer, the less energy is lost in the process of electromagnetic induction and power transmission.

How Can Energy Losses in Transformers Be Minimized?

Minimizing energy losses in transformers can be achieved through better transformer design and materials. Using advanced core materials, such as grain-oriented steel, helps reduce core losses, while optimizing the voltage windings and cooling systems can lower copper losses. Proper load management in distribution systems can also minimize waste energy by ensuring transformers operate at optimal loads. Voltage windings should be designed to handle the appropriate voltage range, while primary and secondary windings should be engineered to reduce energy loss during transformation. Additionally, maintaining transformers in good condition and preventing short circuits is essential for reducing unnecessary energy consumption.

While transformers in power distribution systems across North America are highly efficient, they still experience energy losses in the form of core and copper losses. By improving transformer design, optimizing load management, and maintaining high efficiency in distribution transformers and power supplies, the overall energy losses can be reduced, contributing to more efficient power distribution across the grid.

Powerline Transformer Explained

A powerline transformer reduces high voltage from distribution lines to usable service levels. Installed on poles or ground units, they ensure safe electricity delivery, stable voltage regulation, and reliable power flow for residential, commercial, and rural networks across the electric grid.

What is a powerline transformer?

A powerline transformer is a distribution device that converts high-voltage electricity into lower, usable levels for safe and reliable delivery. It:

✅ Reduces high-voltage electricity from distribution lines to safe, usable levels.

✅ Ensures reliable voltage regulation and efficient power delivery to end users.

✅ They are mounted on poles or ground units in residential and rural networks.

The primary function of a powerline transformer is to step down the high voltage transmitted through power lines to a lower voltage suitable for distribution to end-users. This voltage transformation is essential for maintaining the efficiency and safety of the electrical grid. For a broader overview of grid equipment, see our detailed utility transformers guide, which explains their role in large-scale power distribution.

High voltage is used for long-distance transmission to minimize energy losses due to resistance in the wires. However, this high voltage is far too dangerous for direct use in homes and businesses. Power line transformers act as intermediaries, converting the high transmission voltage to lower distribution voltages, typically 120/240 volts for residential customers and higher voltages for commercial and industrial applications. Discover how 3 phase transformers supply commercial and industrial loads with efficient, balanced power.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Power Line Transformer Technical Overview

| Feature | Description |

|---|---|

| Function | Steps down high-voltage electricity from distribution lines to safe service levels |

| Installation | Commonly pole-mounted in residential areas or ground-mounted in rural networks |

| Typical Primary Voltage | 2.4 kV – 34.5 kV (distribution line input) |

| Typical Secondary Voltage | 120/240 V single-phase or 208/120 V three-phase for end users |

| Capacity (kVA Range) | 10 kVA – 500 kVA depending on load requirements |

| Voltage Regulation | Provides stable and efficient voltage for continuous electricity supply |

| Applications | Power homes, small businesses, farms, and light commercial loads |

| Safety Role | Prevents dangerous high voltage from reaching consumer systems |

Frequently Asked Questions

How Does a Powerline Transformer Work?

A powerline transformer operates on the principle of electromagnetic induction. It consists of two or more coils of wire (windings) wrapped around a common magnetic core. The high-voltage electricity from the power lines flows through the primary winding, creating a magnetic field in the core. This changing magnetic field induces a lower voltage in the secondary winding, which is then distributed to consumers.

The ratio of turns in the primary and secondary windings determines the voltage transformation ratio. For instance, a distribution device like this with 1000 turns in the primary winding and 100 turns in the secondary winding will step down the voltage by a factor of 10. Our article on high-voltage transformers explains how bulk power is transmitted across transmission networks before being stepped down.

What are the Different Types?

There are several types of powerline transformers, each designed for specific applications:

-

Distribution: These are used to step down high voltage from power lines to the voltage levels required for residential and commercial use. They are typically mounted on poles or placed on pads. Learn how a distribution transformer steps voltage down for everyday use, similar to how electrical grid transformers serve local networks.

-

Substation: These are used in electrical substations to step down the voltage from transmission levels to distribution levels. They handle very high voltage and are critical for the intermediate stages of power distribution.

-

Pole-Mounted: Installed on utility poles, these transformers serve residential neighborhoods by converting high voltage from distribution lines to lower voltages. Compare the differences between pole mounted transformers and pad-mounted units to understand installation options available in both rural and urban areas.

-

Pad-Mounted: These are enclosed in secure, ground-level cabinets and used in residential, commercial, and industrial areas where underground power lines are preferred. For a deeper look at design fundamentals, see our resource on transformer components, covering cores, windings, and insulation.

What Safety Features are Incorporated?

Power line transformers include several safety features to ensure reliable operation and protect against potential hazards:

-

Surge Protectors: These devices protect the step-down unit from voltage spikes caused by lightning or other transient events.

-

Pressure Relief Devices: These safety valves release excess pressure within the step-down unit, preventing explosions and ensuring safe operation.

-

Fuses and Circuit Breakers: These components protect the distribution device and connected circuits from overcurrent conditions, isolating faults to prevent damage.

-

Grounding: Proper grounding ensures that any fault currents are safely directed to the ground, reducing the risk of electric shock and equipment damage.

What Maintenance is Required?

Regular maintenance is crucial to ensure the longevity and reliability of power line transformers. This includes visual inspections to check for leaks, corrosion, or physical damage, as well as periodic oil analysis for liquid-filled units. To understand performance and reliability, review condition monitoring in transformers, which details modern diagnostic tools. Additionally, infrared thermography can be used to detect hot spots that may indicate potential problems.

-

Inspection: Routine visual inspections to check for physical damage, oil leaks, and other visible signs of wear.

-

Oil Testing: Insulating oil should be regularly tested for moisture, acidity, and other contaminants to ensure proper insulation and cooling.

-

Electrical Testing: Periodic testing of the windings and insulation resistance to detect potential faults before they lead to failures.

-

Cleaning: Keeping the distribution device and its surroundings free from dust, dirt, and debris ensures proper cooling and prevents overheating.

A power line transformer is vital to the electrical grid, enabling the safe and efficient distribution of electricity from high-voltage power lines to end-users. By understanding its function, type, safety features, and maintenance requirements, we can ensure the reliable operation of this essential device. Regular maintenance and adherence to safety protocols are crucial for maximizing the lifespan and performance of pole-mounted transformers.

Related Articles

Transformer vs Autotransformer in Power Systems

Transformer vs Autotransformer compares isolation, winding design, voltage regulation, efficiency, cost, and safety for power distribution, step-up/step-down applications, helping engineers select the right device for load matching and reliable electrical performance.

What Is the Difference Between a Transformer and an Autotransformer?

A transformer provides isolation; an autotransformer shares windings, trading isolation for efficiency and lower cost.

✅ Full isolation with separate windings; safer but heavier

✅ Autotransformer shares a winding; lighter and cheaper

✅ Choose by isolation need, voltage ratio, fault tolerance

Transformers and autotransformers are essential components in the world of electrical engineering, playing a pivotal role in power distribution and voltage regulation. While both serve similar functions in transferring electrical energy efficiently, they differ significantly in design, operation, and application. Understanding the differences between transformers and autotransformers is crucial for selecting the right equipment in utility applications, where efficiency, cost, and performance are key considerations. This article dives deep into the technical distinctions, explores their advantages and limitations, and highlights their importance in modern utility transformers to ensure reliable and optimized power delivery. For context on large utility applications, our guide to power transformers outlines typical ratings and insulation classes used today.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

Structural Differences: Two Designs, Two Purposes

At their core, traditional transformers and autotransformers share the purpose of managing voltage levels, but their structural distinctions set them apart. A conventional transformer is built with separate primary and secondary windings, ensuring complete electrical isolation between the input and output. This separation enhances safety, especially in applications requiring high levels of isolation. In contrast, an autotransformer features a single continuous winding that functions as both the primary and secondary, depending on the tapped points. This design makes the autotransformer compact and lightweight, saving material and reducing costs. To explore winding connections and tap arrangements in more depth, see the overview of what an autotransformer is for practical design insights.

Advantages and Disadvantages: Efficiency vs Safety

When evaluating transformer vs autotransformer, understanding their respective advantages and disadvantages is crucial. Autotransformers stand out for their efficiency, as the shared winding reduces energy losses and improves performance. Their compact size also translates to a more economical choice for applications where isolation isn't a priority. However, this very design compromises electrical isolation, which can be a safety concern in certain scenarios. Traditional transformers, while bulkier and less efficient, offer the benefit of isolation, making them a safer choice for environments where separating circuits is essential. For a refresher on core purposes and isolation roles, this primer on the function of a transformer connects features to real-world safety requirements.

Applications: Different Roles in Power Systems

The applications of these devices further highlight their unique roles in power systems. Autotransformers excel in voltage regulation tasks, such as adjusting voltage levels in transmission lines or serving as voltage stabilizers in industrial settings. Their ability to provide variable voltage makes them ideal for tasks requiring precise voltage control. Traditional transformers, on the other hand, are indispensable in stepping voltage levels up or down, particularly in distribution networks where safety and reliability are paramount. The use of traditional transformers ensures robust performance in isolating systems and managing significant voltage transformations. In distribution and industrial plants, the behavior of an AC transformer under load guides equipment selection and protection settings.

Voltage Regulation: Stability Where It Matters

Voltage regulation is another area where the performance of these devices diverges. Autotransformers are celebrated for their superior voltage regulation due to their reduced impedance. This quality makes them particularly suitable for applications where maintaining voltage stability is critical, such as in motor start-up operations or in sensitive electronic systems. Traditional transformers, while reliable, may exhibit slightly higher impedance, which can affect voltage stability under heavy load conditions. For high-performance regulation with minimal impedance, engineers often reference autotransformer applications when sizing feeders and starting large motors.

Efficiency and Cost: Balancing Performance and Budget

Finally, the debate about transformer vs autotransformer often centers on efficiency and cost. Autotransformers are inherently more efficient in scenarios where the voltage difference between the input and output is minimal. Their design reduces the amount of copper and iron required, making them cost-effective for applications with lower transformation ratios. However, when larger voltage differences or isolation requirements are involved, the traditional transformer’s design justifies its higher material and operational costs.

Frequently Asked Questions

What is the fundamental difference between a transformer and an autotransformer?

The key difference lies in their construction and functionality. A traditional transformer consists of two separate windings, a primary and a secondary, which are electrically isolated from each other. Energy is transferred between these windings solely through electromagnetic induction. On the other hand, an autotransformer uses a single winding with a portion of it serving as both the primary and secondary. In this design, the input and output are electrically connected, and energy is transferred through a combination of conduction and induction.

Because new practitioners often conflate sources with conversion equipment, this explainer on power supplies versus transformers clarifies roles and safe integration.

When should an autotransformer be used instead of a traditional transformer?

An autotransformer is most suitable when the voltage difference between the input and output is relatively small. It is ideal for applications where cost efficiency, compact size, and high efficiency are important. Examples include voltage regulation, motor starting, and situations where equipment must operate at a different but closely related voltage level. However, it is not appropriate in scenarios requiring electrical isolation between input and output, such as safety-critical environments or noise-sensitive circuits.

How do the efficiency and losses compare between a transformer and an autotransformer?

Autotransformers are generally more efficient than traditional transformers due to their design. They use less winding material, which reduces copper losses, and their smaller core size minimizes core losses. Traditional transformers, while less efficient for small voltage ratios, are more versatile because they offer electrical isolation and are suitable for a wider range of applications.

What are the advantages and disadvantages of an autotransformer compared to a transformer?

Autotransformers have several advantages, including lower cost, smaller size, lighter weight, and higher efficiency due to reduced material use and energy losses. They also offer smoother voltage regulation in some cases. However, they come with notable disadvantages. The lack of electrical isolation between the primary and secondary circuits can pose safety risks and limit their use in sensitive applications. Additionally, autotransformers are unsuitable for large voltage differences and are more vulnerable to faults, as a failure in the winding can affect both the input and output circuits.

Can an autotransformer provide electrical isolation like a standard transformer? Why or why not?

An autotransformer cannot provide electrical isolation because its primary and secondary circuits share the same winding, resulting in a direct electrical connection between the input and output. In contrast, a standard transformer has separate windings for the primary and secondary, ensuring that no direct electrical connection exists. This separation is crucial for applications requiring isolation for safety, noise suppression, or fault protection.

The primary distinction between a transformer and an autotransformer lies in their construction and functionality. A traditional transformer uses two separate windings, ensuring electrical isolation between the input and output, while an autotransformer has a single, shared winding that provides a direct electrical connection. Autotransformers are more efficient, compact, and cost-effective, making them ideal for applications with small voltage differences where isolation is not critical. However, they lack the isolation provided by transformers, limiting their use in safety-sensitive or noise-prone environments. While transformers offer versatility and fault protection, autotransformers excel in efficiency and simplicity for specific use cases. Where rectified systems or DC links are present, guidance on DC power transformers helps align conversion stages with protection and efficiency targets.