Pad Mounted Transformer

Substation Maintenance Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

A pad mounted transformer is a ground-level electrical transformer enclosed in a tamper-proof cabinet, safely distributing medium-voltage power to residential, commercial, and industrial areas. It is commonly used in underground utility systems.

What is a pad mounted transformer?

A pad mounted transformer is a vital component in modern transmission and distribution (T&D) electrical networks, designed to step down high-voltage electricity to usable levels for residential, commercial, and industrial applications. It:

✅ Safely steps down medium-voltage electricity for local distribution.

✅ Enclosed in a weatherproof, tamper-resistant cabinet for public safety.

✅ Ideal for underground utility networks in residential and commercial settings.

Electrical Transformer Maintenance Training

Substation Maintenance Training

Request a Free Training Quotation

A pad mounted transformer is a type of distribution transformer installed at ground level to provide safe, reliable, and efficient medium-voltage power to residential, commercial, and industrial facilities. Commonly used in underground utility systems, these transformers step down high-voltage electricity to usable levels while ensuring minimal visual impact and enhanced public safety. Their tamper-proof enclosures and weather-resistant designs make them a preferred choice for electrical substation extensions, urban infrastructure projects, and power distribution systems where aesthetics and security are important.

Unlike traditional pole-mounted equipment, a pad mounted transformer offers superior protection against environmental hazards and unauthorized access. It is widely deployed in areas requiring consistent utility transformer performance, such as data centers, manufacturing plants, and residential developments. Designed for medium-voltage distribution networks, these transformers support modern grid reliability by integrating seamlessly with electrical substation equipment and advanced monitoring systems. Their ability to handle varying loads, combined with low maintenance requirements, makes them essential for efficient power distribution. A pad mounted transformer is commonly compared with a pole-mounted transformer for distribution efficiency in urban and suburban areas.

Sign Up for Electricity Forum’s Utility Transformers Newsletter

Stay informed with our FREE Utility Transformers Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Installed on a concrete pad and fully enclosed for safety, these transformers are ideal for outdoor use, providing reliable power distribution while minimizing exposure to environmental and security risks. Their compact design, weather-resistant construction, and low-maintenance operation make them essential for ensuring efficient and seamless power delivery in urban and rural settings. A pad-mounted transformer plays a key role in supporting the resilience and efficiency of electrical distribution networks. When learning the basics, it's helpful to know that a transformer is a device that increases or decreases voltage in electrical power systems.

Types of Pad Mounted Transformers for Power Distribution

A pad mounted transformer comes in various configurations to suit diverse needs. Single-phase transformers are suitable for residential and small commercial uses where single-phase power is adequate. Three-phase transformers are commonly employed in industrial and commercial settings that necessitate a three-phase power supply. While pole-mounted transformers are typically seen in residential areas, mounted on utility poles, substation equipment is larger units found in substations, responsible for stepping down high-voltage power from transmission lines to lower distribution voltages.

Pad Mounted vs Pole Mounted Transformers

| Feature | Pad Mounted Transformer | Pole Mounted Transformer | Best Use Case |

|---|---|---|---|

| Installation Location | Ground level on a concrete pad in underground utility systems | Elevated on utility poles with overhead lines | Urban and suburban vs rural settings |

| Voltage Capacity | Medium-voltage, typically up to 35 kV | Low-to-medium voltage, usually below 25 kV | Higher demand vs lighter loads |

| Safety Features | Tamper-proof cabinet with weatherproof enclosure | Exposed components, requires pole access | Public areas needing high safety |

| Maintenance | Easy access with minimal climbing requirements | Requires linemen to climb poles for repairs | Fast service vs low-cost installations |

| Visual Impact | Hidden behind landscaping or fencing | Highly visible on poles | Preferred in areas where aesthetics matter |

Safety and Security Features of Utility Transformers

One of the key advantages of a pad mounted transformer is its safety features. This equipment is designed with tamper-proof enclosures, making it ideal for installation in public areas or sensitive environments, such as near schools or data centers. The enclosure securely houses all energized components, preventing unauthorized access and reducing the risk of electrical accidents. Additionally, the grounded metal housing of the equipment provides an extra layer of protection, ensuring that any electrical faults do not pose a risk to the public or nearby property. The security features of this equipment contribute to its widespread use in areas where safety cannot be compromised. For certain applications, a buck boost transformer can be used to fine-tune voltage levels for better system performance.

EF Partner Media

Photocontrol Failsafe Technology for Outdoor LED Lighting

Article

Photocontrol Failsafe Technology for Outdoor LED Lighting

Article

Power Transformer Market Research Report 2019 Predicts Global Power Transformer Market of $34 Billion by 2023

Brochure

Power Transformer Market Research Report 2019 Predicts Global Power Transformer Market of $34 Billion by 2023

Brochure

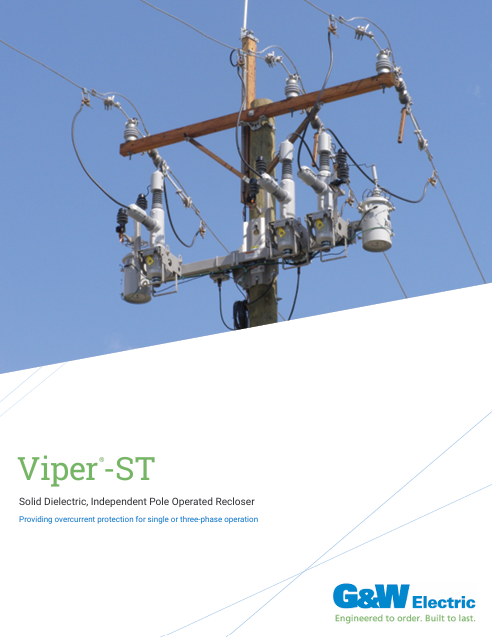

Viper®-ST Solid Dielectric, Independent Pole Operated Recloser

Product

Viper®-ST Solid Dielectric, Independent Pole Operated Recloser

Product

Line Work Bucket Products Socket Pocket w/ 3" Hook

Line Work Bucket Products Socket Pocket w/ 3" Hook

Environmental and Design Standards for Distribution Transformers

Another essential feature of a pad mounted transformer is environmental safety. This equipment is often liquid-filled, with the core and coils enclosed in a steel tank to prevent leakage or contamination. The liquid, typically mineral oil, is an insulating and cooling medium, ensuring the equipment operates efficiently without overheating. Because they are often mounted outdoors, the construction of PMT is designed to withstand various environmental conditions. The outdoor installation also facilitates easier maintenance and repairs, which are often performed through a lockable wiring cabinet adjacent to the tank. This design helps maintain environmental safety, minimizing the risk of oil spills or leaks, particularly in sensitive areas.

Flexible Design and Medium-Voltage Applications

The design and construction of the pad mounted transformer is flexible, allowing it to operate on medium-voltage distribution systems up to approximately 35 kV. They come in various electrical and mechanical configurations, with different capacities to meet the specific needs of the area in which they are installed. For example, the low-voltage winding can be tailored to customer requirements, providing either single-phase or three-phase power distribution. This versatility ensures that this equipment can be used for a wide range of applications, from powering small residential homes to large commercial or industrial facilities. Their ability to operate efficiently in diverse settings is one of the reasons why they are so commonly found in public spaces. Professionals can benefit from exploring different types of transformers to choose the right equipment for specific power distribution needs.

ANSI and NEMA Compliance for Pad Mounted Transformers

A pad mounted transformer is designed to meet strict safety and performance standards. Manufacturers follow guidelines set by organizations such as the American National Standards Institute (ANSI) and the National Electrical Manufacturers Association (NEMA). These standards ensure that equipment performs reliably and safely throughout its service life. Compliance with these standards is crucial not only for operational efficiency but also for meeting regulatory requirements in many regions. The adherence to these standards helps ensure that equipment is built to withstand the demands of modern power distribution systems and is capable of delivering power with minimal risk of failure. Industrial sites often rely on a distribution transformer to deliver medium-voltage power safely and efficiently.

Test Your Knowledge About Utility Transformers!

Think you know Utility Transformers? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Maintenance and Lifespan of Pad Mounted Transformers

A significant benefit of the dead front pad mounted transformer is its ease of maintenance. This equipment is equipped with features such as elbow connectors, which allow maintenance personnel to operate it while it is energized, using a hot stick. This design feature enhances safety and reduces downtime, as repairs and maintenance can be carried out quickly without interrupting the system's operation. The accessibility of the equipment’s components is another factor that contributes to the efficiency of the maintenance process. By reducing the time spent on repairs and ensuring that systems stay operational, this equipment helps minimize service disruptions.

Frequently Asked Questions – Installation, Ratings, and Use

How is a pad mounted transformer installed and maintained?

When installing a PMT, the first step is to choose a location that is both accessible and complies with safety regulations. It is typically placed on a concrete pad in a well-ventilated area, free from obstructions. The equipment is then connected to high-voltage primary distribution lines, which supply power, and to low-voltage secondary distribution lines that deliver electricity to homes or businesses. Proper grounding is essential to ensure safety, and the equipment is usually housed in a metal enclosure for protection against environmental factors and unauthorized access.

Regarding maintenance, it involves regular inspections to check for signs of wear or damage, especially to the enclosure and electrical connections. If the equipment uses oil for insulation and cooling, the oil levels must be monitored to prevent leaks. Regular cleaning of the area around the equipment is important to maintain proper airflow for cooling. Electrical tests, such as measuring voltage and checking insulation resistance, are performed to ensure the equipment operates efficiently. Additionally, the filters and vents should be checked periodically for cleanliness and proper functioning. The performance and protection of electrical systems are enhanced by using specialized devices like a current transformer for accurate metering and monitoring.

What is the typical capacity of a pad mounted transformer?

The typical capacity of a pad mounted transformer ranges from 50 kVA to 5000 kVA, although larger capacities can be customized depending on the specific application. Smaller equipment, ranging from 50 kVA to 500 kVA, are often used in residential neighbourhoods, while those with higher capacities (1000 kVA or more) are common in commercial or industrial settings. The equipment’s capacity is selected based on the electrical demand of the area it serves.

Where do you locate a pad mounted transformer?

A pad mounted equipment is usually placed in residential, commercial, or industrial areas where underground electrical distribution is preferred. In residential neighbourhoods, it is often installed in easements or within fenced enclosures, typically located in yards or green spaces to minimize visibility and disruption. In commercial or industrial areas, the equipment may be placed on-site, near the equipment or building it serves. Additionally, in some public areas, the pad mounted transformer is installed along streets, often behind landscaping or fencing to reduce its visual impact. The location of the equipment must comply with local regulations and safety standards, ensuring it is not placed too close to structures, roads, or other potential hazards. Understanding 3-phase to single-phase transformers is crucial when adapting power distribution for residential or smaller loads.

What is the difference between pad mounted and pole mounted transformer?

The main difference between pad-mounted and pole-mounted transformers lies in their installation and the areas where they are commonly used. A pad mounted transformer is installed at ground level on a concrete pad and is typically used in urban or suburban areas with underground distribution systems. It is often preferred in places where aesthetics and safety are important, as it is easier to maintain and keep out of sight. This equipment is usually used for higher capacities, such as in densely populated areas or commercial zones.

In contrast, a pole-mounted transformer is installed on utility poles and is more common in rural or suburban areas with overhead power lines. While pole-mounted transformers are easier to install in such areas, they are more visible and can be harder to maintain, as technicians may need to climb the poles for repairs or inspections. This equipment is typically used for lower to medium electrical loads, making it more suitable for areas with less demand compared to urban centers.

A pad mounted transformer is a key component in modern electrical distribution systems. Their ability to operate safely, efficiently, and flexibly makes them ideal for use in both residential and commercial applications. Whether used in busy urban centers or quiet suburban neighbourhoods, this equipment provides reliable service while ensuring safety, environmental protection, and ease of maintenance. The role of a pad mounted transformer in stepping down primary voltage to levels suitable for everyday use cannot be overstated, as it continues to play an essential part in keeping power flowing to homes, businesses, and critical infrastructure.

Related Articles