Power Factor Meter Explained

Power Quality Analysis Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our NFPA 70E Fact Sheet – 2024 Electrical Safety Edition

- Understand how NFPA 70E works with NEC and NFPA 70B standards

- Clarify the shared responsibility between employers and employees

- Learn how NFPA 70E supports OSHA compliance

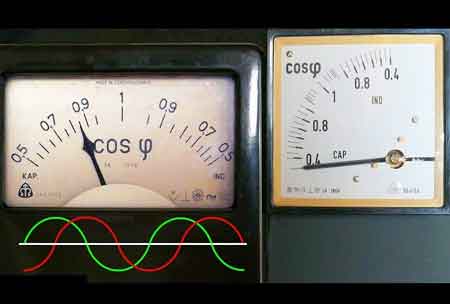

A power factor meter measures the efficiency of electrical energy usage by calculating the ratio of real power to apparent power. It helps identify energy loss, improve system performance, and ensure optimal power quality in industrial, commercial, and utility settings.

What is a Power Factor Meter?

It is an electrical measuring device that indicates the phase difference between voltage and current, helping assess energy efficiency and optimize load usage.

✅ Measures the ratio of real power to apparent power

✅ Helps improve power quality and reduce energy loss

✅ Used in industrial, commercial, and utility electrical systems

A power factor meter measures the efficiency of electrical usage by comparing the real power (P) and the apparent power (S, measured in kVA). Commonly used in energy audits and industrial systems, it helps identify poor power factor (PF) conditions and supports improvements in quality and cost savings.

It is an essential instrument used to measure the PF of an electrical system. The PF is the ratio of P to kVA and represents the efficiency with which electricity is used. It is expressed as a number between 0 and 1, with a higher PF indicating greater efficiency. Understanding and monitoring PF is crucial for optimizing energy consumption and reducing electricity costs. Our Power Factor Explained resource provides foundational knowledge ideal for those new to the concept or seeking a quick refresher. If you're looking to improve your system’s efficiency, our article on Power Factor Correction explores effective solutions using capacitors and controllers.

Power Quality Analysis Training

Request a Free Power Quality Training Quotation

How to Use a Power Factor Meter for Energy Optimization

Improving PF is a crucial step towards achieving energy efficiency. A low PF indicates that a significant portion of the electrical current is not being used to perform useful work. This wasted energy translates into higher electricity bills and increased carbon emissions. By using a PF meter to identify and correct low PF, businesses and individuals can reduce their energy consumption and contribute to a more sustainable future.

Test Your Knowledge About Power Quality!

Think you know Power Quality? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

PF correction equipment plays a vital role in improving electrical efficiency monitoring by optimizing the balance between real and reactive power (Q). Through real-time monitoring, facilities can identify inefficiencies and implement solutions, such as installing capacitor banks, to support kVAR compensation. These measures contribute significantly to energy cost reduction by minimizing waste and enhancing overall system performance.

Installation Tips

Proper installation of a power factor meter is crucial for obtaining accurate measurements and ensuring long-term reliability. Begin by identifying the appropriate location—typically at the main electrical panel or near the load where Q is highest. Ensure the meter is installed downstream of any PF correction equipment to avoid false readings. Wiring should follow the manufacturer's guidelines, and the use of shielded cables can help minimize signal interference. Grounding and secure mounting are critical to prevent vibration or electrical noise. For three-phase systems, verify correct phase alignment during setup to maintain data integrity.

Best Practices for Maintaining Accurate Readings

Maintaining accurate readings from your power factor meter involves both environmental control and routine calibration. Meters should be kept in areas with stable temperature and humidity to avoid sensor drift. Avoid placing meters near heavy machinery or transformers that could emit electromagnetic interference. Regular calibration—ideally every 12 to 24 months - ensures the reliability of the data. Most digital meters offer software-based calibration tools, while analog models may require manual adjustment. Always document each calibration session and track long-term performance trends to catch potential issues early.

Comparing Power Factor Meters: Analog vs. Digital

An analog or digital power factor meter offers distinct advantages depending on your application. Analog models are often more cost-effective and easier to operate, making them ideal for basic monitoring in smaller setups. However, digital meters offer greater precision, data logging capabilities, and real-time display features. They often include software integration for advanced electrical efficiency monitoring and remote diagnostics. For industrial or utility-scale systems, digital meters are the preferred choice due to their compatibility with SCADA and energy management systems. Consider your budget, technical requirements, and need for data integration when choosing between the two.

Integrating PF Meters with Smart Grids

A Power factor meter plays a key role in smart grid environments by enabling real-time monitoring and automated decision-making. When integrated with smart grid infrastructure, these meters can communicate with distributed energy resources (DERs), demand response systems, and advanced metering infrastructure (AMI). This integration enables utilities and large facilities to enhance grid stability, optimize kVAR compensation, and manage load profiles more effectively. Compatibility with communication protocols like Modbus, BACnet, or Ethernet/IP ensures seamless data flow across systems. As the smart grid evolves, they are becoming an indispensable tool for intelligent energy management.

PF Correction

PF correction is the process of improving PF by reducing the amount of Q in an electrical system. This is typically achieved by adding PF correction equipment, such as capacitor banks, to the circuit. These devices counteract the effect of inductive loads by supplying Q locally, reducing the burden on the electrical system and improving the overall PF. For more information, refer to Power Factor Correction.

Choosing the Right PF Meter for Your Application

A power factor meter is critical in industrial settings, where large motors and other inductive loads are prevalent. Maintaining a high PF is crucial for ensuring efficient operation and minimizing energy costs. In industrial applications, meters are used to monitor PF in real time, identify potential problems, and optimize the performance of electrical equipment. A digital power factor meter is ideal for tracking real-time efficiency metrics in three-phase systems.

Three-Phase

Three-phase electricity is a common type of electrical energy used in industrial and commercial settings. In three-phase systems, electricity is delivered through three conductors, each carrying an alternating current that is 120 degrees out of phase with the others. Measuring PF in three-phase systems is more complex than in single-phase systems, as it involves considering the PF of each individual phase as well as the overall system PF.

Sign Up for Electricity Forum’s Power Quality Newsletter

Stay informed with our FREE Power Quality Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

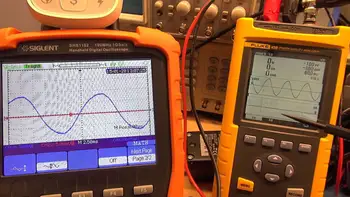

Analyzers

A power factor meter is often integrated into more comprehensive analyzers. Analyzers are sophisticated instruments that provide detailed information about various electrical parameters, including voltage, current, energy, and harmonics. These devices are used for troubleshooting PQ problems, optimizing energy consumption, and ensuring the reliable operation of electrical equipment.

Cost Savings

Improving PF can lead to significant cost savings, especially for businesses with high energy consumption. By reducing Q and improving efficiency, businesses can lower their electricity bills and avoid penalties imposed by utility companies for low PF. Additionally, PF correction can reduce the load on electrical infrastructure, potentially extending the lifespan of equipment and reducing maintenance costs.

Frequently Asked Questions

Why is monitoring PF important in industrial and commercial settings?

Monitoring PF is crucial because a low PF indicates inefficiency, which can lead to higher energy bills and potentially increased equipment maintenance costs. Many utility companies charge penalties for low PF, so keeping it close to 1.0 can save money. A high PF also reduces strain on the electrical infrastructure, allowing for more efficient operation and potentially extending the lifespan of equipment. To better understand how PF is calculated, visit our detailed guide on the Power Factor Formula, which breaks down the relationship between real, reactive, and apparent energy.

How does a power factor meter differ from other electrical meters?

Unlike voltmeters or ammeters, which measure voltage and current, respectively, a PF meter specifically measures the efficiency of electrical usage by indicating the PF. While voltmeters and ammeters provide valuable information on system performance, they don’t reveal if Q (non-working energy) is present. The PF meter fills this gap by indicating whether adjustments are needed to improve electrical efficiency.

Which power factor meter is best suited for my application?

There are analog and digital PF meters, as well as single-phase and three-phase versions. Analog meters are simple but less precise, while digital meters offer more accurate readings and often additional features, such as data logging and remote monitoring. For industrial applications with large three-phase systems, a three-phase digital PF meter is usually preferred. For smaller or simpler systems, a single-phase analog or digital meter may suffice. Learn how

Motor Power Factor impacts industrial operations, and understanding how to measure and correct it effectively is crucial.

How can a facility improve its PF after measuring it with a power factor meter?

If the power factor meter indicates a low PF, you can improve it by adding PF correction capacitors, which offset the Q in the system. Alternatively, using synchronous condensers or automatic PF correction equipment can help. Improving the PF leads to energy savings, reduced wear on equipment, and avoidance of utility company penalties for poor electrical efficiency. A Power Quality Analyzer can complement a PF meter by identifying disturbances that affect equipment performance and reliability. Using a PF meter in conjunction with an analyzer provides deeper insight into system performance.

Related Pages