Power Factor Correction

By R.W. Hurst, Editor

Power Factor Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 3875 Fact Sheet – Electrical PPE for Power Industry Workers

- Follow rules for rubber gloves, arc-rated PPE, and inspection procedures

- Learn employer obligations for testing, certification, and training

- Protect workers from arc flash and electrical shock injuries

Power factor correction reduces energy waste by minimizing reactive power in electrical systems. It aligns voltage and current, improving system efficiency, lowering electricity bills, preventing penalties, and enhancing equipment performance.

What is Power Factor Correction?

Power factor correction is the process of improving the power factor in electrical systems, reducing wasted energy from reactive loads and optimizing efficiency.

✅ Enhances energy efficiency and reduces utility costs

✅ Improves voltage stability and electrical reliability

✅ Meets compliance with utility and regulatory standards

Power Quality Analysis Training

Request a Free Power Quality Training Quotation

Understanding Power Factor

In many industrial and commercial electrical systems, a poor power factor (PF) can result in higher utility bills, system inefficiencies, and even penalties from the utility. Power factor correction (PFC) helps optimize the relationship between real power (useful work) and apparent power (S) (total power supplied), thereby reducing unnecessary energy losses. Improving efficiency saves costs and supports better electrical performance across your entire operation.

If you’re not familiar with the basics, you might want to review our what is power factor page for a simple overview.

How Power Factor Correction Works

|<-----S----->|

| |

| __φ__|____ P (Watts)

| | |

| | |

| | |

| | |

| |_____|

| Q (VAR)

|<--PF--->|

FREE EF Electrical Training Catalog

Download our FREE Electrical Training Catalog and explore a full range of expert-led electrical training courses.

- Live online and in-person courses available

- Real-time instruction with Q&A from industry experts

- Flexible scheduling for your convenience

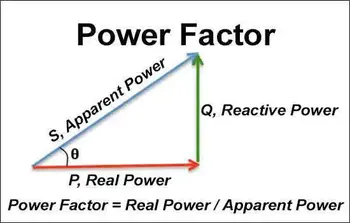

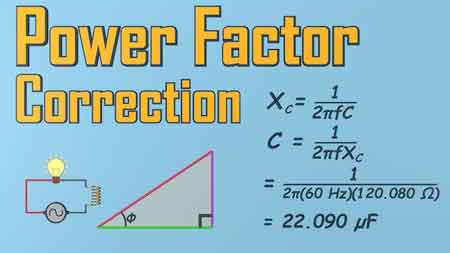

The PF is the cosine of the phase angle (φ) between the voltage and current waveforms, or:

PF = cos(φ)

A PF of 1 (or 100%) means that the real power equals the S, and the circuit has no Q. Conversely, a PF of less than 1 means that some of the S is consumed by Q, leading to inefficiencies in transmission and reduced capacity of electrical systems.

Managing Q compensation is essential for optimizing electrical load management across industrial and commercial systems. When facilities implement dynamic PFC strategies, they achieve kvar reduction and enhance system efficiency. Businesses can better control their reactive loads and maintain stable voltage conditions across their network by carefully analyzing equipment needs and applying capacitor installation projects.

Effective load balancing techniques further support peak demand reduction, helping companies achieve measurable industrial energy savings. Facilities that proactively address power quality issues can avoid costly utility surcharge avoidance penalties while also protecting sensitive equipment. Dynamic solutions, such as automatic capacitor banks, enable real-time adjustments, ensuring that Q is minimized during changing load conditions, thereby delivering both long-term savings and enhanced operational reliability.

How Correction Methods Work

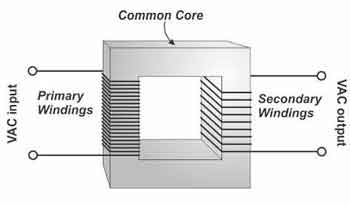

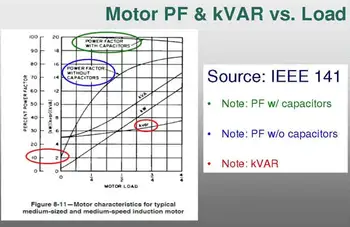

At its core, PF correction involves installing equipment, such as capacitors or capacitor banks, to offset the inductive effects of motors, transformers, and other heavy loads. These inductive devices generate Q, which increases the current flow without doing useful work. By adding capacitors, which produce leading Q, the system’s PF approaches unity (1.0), meaning that almost all the supplied energy is converted into useful work.

For a deeper dive into how these calculations work, visit our power factor correction formula page.

In an AC electrical system, the amount of real power—energy that actually performs useful work is directly impacted by the relationship between voltage and current. A system with a significant phase shift between the two experiences reduced efficiency, as more energy is wasted as Q. When corrective measures are taken, such as adding capacitor banks, it increases the PF by minimizing this phase displacement. In some cases, overcorrection can result in a leading PF, where the current leads the voltage, which may cause other operational issues if not properly managed.

Benefits of Power Factor Correction

Correcting your system’s power factor provides several important advantages:

-

Lower utility bills by reducing demand charges

-

Increased available capacity from transformers and generators

-

Improved voltage regulation

-

Reduced losses in cables and transformers

-

Less overheating of equipment and extended service life

Learn more about practical techniques on our how to calculate power factor page.

Common Methods of Power Factor Correction

Several methods can be used to correct poor PF depending on your system size, complexity, and load characteristics. These include:

-

Static capacitors: Installed across inductive loads like motors

-

Automatic capacitor banks: Adjust Q compensation as load conditions change

-

Synchronous condensers: Overexcited synchronous motors that supply Q

-

Active PFC equipment: Electronics that dynamically correct for poor factor conditions in real-time

If you're interested in equipment, you can also see how an automatic power factor controller fits into more advanced systems.

Active Power Factor Correction

Active PFC utilizes electronic circuits to dynamically adjust current and voltage alignment in real-time. Unlike passive systems that rely on fixed capacitors, active systems detect changes in the electrical load and respond instantly to maintain optimal PQ.

Common applications include:

-

Variable Frequency Drives (VFDs) for motors

-

Switch-Mode Supplies (SMPS) in industrial controls

-

High-efficiency lighting systems and automation equipment

Active PFC is ideal for facilities with highly variable or non-linear loads, where traditional capacitor banks alone cannot achieve sufficient Q compensation. By actively managing kVAR reduction and improving system efficiency, active correction also supports peak demand reduction, load balancing techniques, and utility surcharge avoidance. For more details on improving your system’s performance, see our guide to capacitor bank applications

Sign Up for Electricity Forum’s Power Quality Newsletter

Stay informed with our FREE Power Quality Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

While more expensive to install than passive systems, active correction offers long-term industrial energy savings and dynamic PFC tailored to modern electrical demands.

Active vs Passive PF Correction Explained

There are two main approaches to improving system efficiency: active and passive efficiency improvements.

Passive power factor correction uses capacitor banks or inductors installed at key points within an AC circuit. These devices provide Q compensation, improving the PF by offsetting lagging currents caused by inductive loads like motors. Passive correction is ideal for systems with a relatively steady electrical load.

Active power factor correction, on the other hand, utilizes electronic circuits to dynamically adjust and optimize the current waveforms. Active systems are more expensive but perform better in environments with fluctuating loads, such as facilities using switched-mode supplies or other nonlinear equipment. They are highly effective for dynamic correction systems where load-balancing techniques are critical.

Choosing between active and passive correction depends on system design, load variability, and budget considerations.

How a Manufacturing Facility Saved 15% on Energy Costs

One large manufacturing facility faced increasing utility surcharges due to poor PF levels below 0.85. After an assessment, engineers recommended installing a combination of fixed and automatic capacitor banks tailored to their operational schedule.

By targeting peak demand periods and using a dynamic reactive compensation system, the facility achieved:

-

Q compensation during heavy machine cycles

-

kVAR reduction by over 200 kVAR

-

Peak demand charges lowered by 12%

-

Overall industrial savings of approximately 15%

This real-world example illustrates how investing in power factor correction equipment enhances supply quality and yields measurable bottom-line benefits.

Maintaining Your Correction Equipment for Peak Efficiency

Proper power factor correction equipment maintenance is crucial to ensuring long-term system efficiency improvement and avoiding unexpected penalties.

Recommended practices include:

-

Regular inspections of capacitor banks for swelling, overheating, or leaking components.

-

Monitoring system performance with PQ meters to detect shifts in correction effectiveness.

-

Testing contactors and relays in automatic switching systems to prevent failure during high-load events.

-

Upgrading components when expanding your facility to match the increased electrical load management needs.

-

Checking settings in dynamic correction systems to ensure optimal performance with new or evolving loads.

Following these maintenance tips ensures consistent Q compensation, protects your investment, and supports continued utility surcharge avoidance.

Choosing the Right Power Factor Correction Equipment

Selecting the right equipment requires analyzing your existing load profile and operating conditions. Capacitor ratings must match the size and type of load they are designed to support. Overcompensation can lead to a leading PF, causing overvoltage issues.

A power factor meter can help monitor real-time changes and adjust correction equipment accordingly for systems with large motor loads.

If you're unsure where to start, our calculator for power factor provides a helpful estimation tool.

When Poor Power Factor Becomes a Problem

If your facility operates numerous inductive devices, such as motors, welders, or fluorescent lighting, you are at risk for poor efficiency. A lagging power factor often results in higher demand charges on your utility bill and strains your electrical distribution system.

Understanding the difference between leading vs lagging power factor is critical to applying the right correction strategy.

Real-World Example of Power Factor Correction

Consider a manufacturing plant with an installed load that has a measured power factor (PF) of 0.72. By installing a properly sized power factor correction capacitor bank, the PF improved to 0.96. This adjustment reduced utility demand charges by over 15%, resulting in a significant decrease in operational costs.

To learn more about how systems can achieve a perfect unity factor, visit our page on unity power factor.

Frequently Asked Questions

What causes poor PF in electrical systems?

Poor PF usually results from inductive loads like motors, transformers, and lighting ballasts, which consume Q without producing useful work. This inefficiency can strain your entire electrical system and drive up energy costs.

How does a capacitor improve PF?

Capacitors generate Q that cancels out the inductive effects of equipment, moving the PF closer to unity. By reducing the amount of reactive current, capacitors lower the overall current flow in the system, improving efficiency.

Can a system have too much power factor correction?

Yes, overcorrection can push the PF into a leading condition, potentially causing overvoltages and problems with sensitive electronic equipment. Automatic control systems or staged capacitor banks help prevent overcompensation.

Related Articles