Power Factor Explained

Electrical systems depend on efficiency to operate safely and cost-effectively. One key indicator of that efficiency is power factor, which measures how effectively electrical energy is converted into useful work.

Power Quality Analysis Training

Request a Free Power Quality Training Quotation

Poor performance in this area leads to wasted energy, increased utility costs, and potential system stress. Managing it correctly can significantly improve overall reliability and lower expenses. To understand the foundation, see our detailed overview on what is power factor.

What is Power Factor?

In an AC circuit, managing efficiency often involves addressing issues caused by poor power factor. One common solution is to install capacitor banks, which help counteract the effects of inductive loads and improve the electrical system's power factor. However, when too much capacitance is introduced, it can result in a leading power factor, which may also create complications. Equipment that generates strong magnetic fields, such as motors and transformers, often disrupts the balance between real and apparent energy, reducing the ratio of power to apparent. Modern switched-mode supplies complicate matters further by introducing harmonic distortion into the energy supply, making it even more essential to monitor and correct the system regularly.

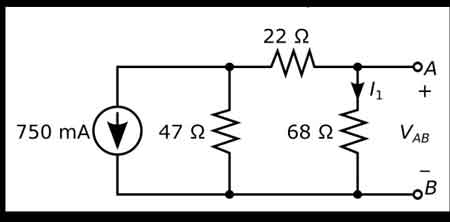

The Power Triangle visually represents the relationship between real power (kW), reactive power (kVAR), and apparent power (kVA) in an AC system. It highlights how a lower reactive component improves the overall system efficiency. In an AC circuit, real power (kW) performs useful work, reactive power (kVAR) supports magnetic fields, and apparent power (kVA) is the vector sum of the two.

How to Measure and Calculate Power Factor

Determining your system's performance begins with accurate measurement. Professionals use methods that involve real and apparent energy values, based on voltage and current readings.

To learn step-by-step techniques, visit our guide on how to calculate power factor. For the precise mathematical method, review the power factor formula.

You can also explore practical methods for finding power factor, which include using wattmeters, ammeters, and other field instruments.

Essential Tools for Performance Analysis

Accurately monitoring load conditions requires specialized equipment. Depending on the system's complexity, technicians may use portable meters, online analyzers, or built-in monitoring tools.

If you need a quick starting point, our power factor calculator simplifies the process.

For more detailed measurements, explore the capabilities of a power factor meter, designed for professional-grade accuracy.

Common Challenges in Electrical Systems

System inefficiencies often result from loads that are inductive or capacitive, creating phase shifts between voltage and current.

Inductive loads typically cause a lagging power factor, a frequent issue in industrial environments.

If you're dealing with capacitive loads or comparing system behaviors, you’ll find insights in leading vs lagging power factor.

Addressing these challenges early improves operational stability and reduces financial penalties from utilities.

Practical Methods to Improve Efficiency

Once a system's weaknesses are identified, targeted improvements can restore optimal conditions. Correction involves devices that realign the energy usage balance.

For an overview of different strategies, see power factor correction.

Installing a power factor correction capacitor is often the most straightforward method for load balancing.

For more dynamic systems, using an automatic power factor controller ensures continuous adjustments based on varying demands.

Why Unity Is the Ideal Goal

Achieving a unity rating, or a value of 1.0, means that all supplied energy is used effectively without waste.

Maintaining this condition ensures maximum cost savings, better equipment lifespan, and compliance with utility standards.

Discover the benefits and techniques by visiting unity power factor.

Measure, Monitor, and Manage for Long-Term Benefits

Improving the performance of your electrical system starts with regular monitoring, accurate measurement, and appropriate corrective action.

Whether you are troubleshooting existing problems or designing new systems, using the right tools and knowledge will keep operations running at peak power factor.

FAQ: Power Factor Questions

What causes a poor power factor?

Poor load balancing is typically caused by inductive loads like motors, transformers, and fluorescent lighting. These devices create magnetic fields that delay current flow, leading to a lagging power factor and wasted energy.

How much can a facility save by improving its power factor?

Improving system performance can reduce utility demand charges by 20% to 50% in some cases. It also decreases line losses, enhances system capacity, and extends equipment life, leading to significant operational savings.

What penalties apply for poor power factor?

Many utilities impose financial penalties if a facility’s reactive energy drops below a set threshold, often around 0.90. These charges can add thousands of dollars per year to an electric bill, making correction measures highly cost-effective.

What is a good power factor rating?

A good rating is typically above 0.95. The closer it is to 1.0, the more efficiently the system operates.

How often should I check my system's power factor?

It’s best to monitor it monthly, especially if your facility has changing load profiles throughout the year.

Can low power factor damage equipment?

While it may not cause direct damage, poor performance increases heating and losses, leading to premature wear and higher energy bills.

Are capacitors the only way to improve power factor?

No. Besides capacitors, active filters and automated correction devices like automatic power factor controllers offer flexible solutions.

What industries are most affected by poor load performance?

Industrial manufacturing, commercial buildings with heavy HVAC systems, and water treatment facilities are commonly impacted.

Related Articles