What is Power Quality?

By John Houdek

Substation Grounding Training

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 12 hours Instructor-led

- Group Training Available

Download Our OSHA 3873 Fact Sheet – Minimum Approach Distance and Training Requirements

- Calculate MAD using voltage and overvoltage values

- Ensure proper communication between host and contract employers

- Meet OSHA training requirements for qualified electrical workers

Power quality describes the stability, reliability, and efficiency of electrical power. Good power quality ensures voltage, current, and frequency remain steady, allowing equipment to perform without damage or disruption.

What is Power Quality and Why It Matters

Modern electrical systems depend on clean, stable electric energy to ensure reliable performance of sensitive equipment. However, issues like voltage drops can cause disruptions, making power conditioning essential for maintaining consistent output. Many facilities rely on switching power supplies to improve efficiency, but these devices can also introduce harmonics and noise if not properly managed. To protect against outages and maintain continuous operation, critical systems often use an uninterruptible power supply (UPS), which safeguards loads during disturbances and provides backup power when needed.

Power Quality Analysis Training

Request a Free Power Quality Training Quotation

The Importance of Maintaining Good Power Quality

Power quality (PQ) has become a growing concern as electrical systems use more sensitive devices — and more devices that can create disturbances. Today’s commercial, industrial, and municipal facilities depend on clean power to protect electronic loads. Assessing voltage stability is a primary way to diagnose underlying issues before damage or inefficiency occurs.

Facilities can begin assessing PQ by focusing on voltage levels. If voltage is low or distorted, analyzing downstream linear load currents can help pinpoint the source of distortion.

Key issues to watch for include:

-

Inrush current: Motors draw high peak current during startup, causing voltage sags that may shut down equipment.

-

Distorted currents: Non-linear devices, such as motor drives and welders, produce pulsed currents, resulting in harmonic distortion.

-

Harmonics: Distorted currents increase true RMS current and peak values, leading to higher system heating and stressing of transformers and cables.

Over time, installing harmonic filtering can help resolve many of these hidden PQ issues. See Fig. 1 for ideal voltage waveform and Fig. 2 for typical distortions.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Learn more about how disturbances affect systems by visiting Understanding Inrush Surge Current.

Fig. 1 Power Quality represented by sinusoidal voltage and current

Black = Voltage; Grey = Current

Why PQ Matters

Maintaining good power quality is essential to the performance, efficiency, and lifespan of electrical and electronic equipment. Poor quality results in higher operating costs, unexpected failures, and possible safety risks. The more facilities depend on sensitive systems, the more critical it becomes to maintain clean, stable voltage and current.

Acceptable power quality benchmarks include:

-

Sinusoidal voltage held within ±5% of nominal rating

-

Voltage harmonic distortion below 2.5%

-

Current harmonic distortion below 5%

By maintaining these standards, organizations can significantly reduce downtime and extend the life expectancy of their systems. Learn more about power quality voltage flicker and how it affects stability.

Leading Causes of Power Quality Issues

Several factors can degrade power quality:

-

Motor starting and stopping (large inrush currents)

-

Nonlinear loads like variable frequency drives (VFDs)

-

Lightning strikes and weather events

-

Switching of capacitor banks in power systems

-

Harmonic distortion from electronic equipment

For more insight on this topic, see Power Quality and Harmonics Explained.

Identifying Internal vs External Power Quality Problems

Not all PQ problems originate within a facility. Some disturbances arise from the utility supply, while others are generated internally by equipment operation. Understanding both external and internal sources allows for better planning and targeted mitigation strategies.

External sources can include:

-

Equipment failure and switching events on the distribution network

-

Weather events such as lightning strikes

-

Animal interference and vehicular accidents

-

Disturbances caused by neighbouring facilities

Internal sources often include:

-

Large motor startups causing voltage sags

-

Harmonic generation from electronic devices

-

Power factor capacitor interactions creating resonance

Proper application of grounding and bonding techniques can help control internal problems and make facilities more resilient to external disturbances.

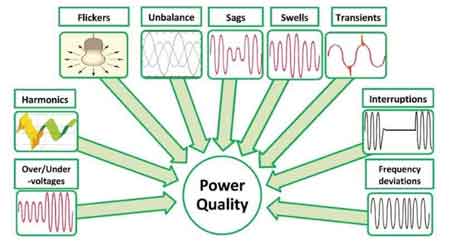

Different Types of Power Quality Disturbances Explained

PQ disturbances take many forms and can affect voltage, current, or frequency. Each disturbance type has distinct causes and effects on equipment. Recognizing these categories helps diagnose root problems and plan corrective actions to preserve system health. Examples of common PQ disturbances are illustrated in Fig. 2, showing typical waveform distortions.

Common types of disturbances include:

-

Overvoltage or undervoltage: Fluctuations that stress insulation or cause equipment misoperation

-

Harmonics: Additional frequencies that distort current and voltage

-

Transients: Sudden spikes caused by switching events or faults

-

Electrical noise: High-frequency interference that disrupts sensitive electronics

-

Voltage sags and swells: Temporary drops or rises that affect performance

-

Low power factor: Inefficient use of supplied power leading to system losses

For deeper insight, see our guide to power factor calculation and its impact on system efficiency.

Fig. 2 Power Quality Disturbances

Best Practices

Improving PQ involves a combination of monitoring, maintenance, and applying corrective technologies. Understanding the unique challenges in your facility is key to selecting the right solutions and maintaining high operational reliability.

Effective improvement methods include:

-

Installing voltage regulators to correct sags and swells

-

Applying harmonic filters to remove distortion

-

Upgrading transformers and conductors for harmonic loads

-

Using proper grounding systems to stabilize voltages

-

Monitoring load profiles with power quality analyzers

-

Protecting circuits with surge suppression devices

By implementing these strategies, companies can protect their investments, enhance safety, and increase energy efficiency.

Power quality plays a vital role in the modern electrical environment. As systems become more complex and sensitive, the risks associated with poor voltage and current characteristics also increase. By understanding sources of disturbances, recognizing their impacts, and applying appropriate solutions, facilities can ensure reliable, efficient, and safe operations well into the future.

Test Your Knowledge About Power Quality!

Think you know Power Quality? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

Frequently Asked Questions

What causes poor power quality?

Poor PQ can be caused by both internal and external factors. Internally, issues like motor starting, switching power supplies, or faulty wiring contribute to disturbances. Externally, utility switching, weather events, and neighboring facilities with heavy loads can cause voltage sags, surges, and harmonic distortion.

How does poor power quality affect equipment?

Poor PQ can lead to equipment malfunction, frequent resets, overheating, shortened lifespan, and higher maintenance costs. Sensitive electronic devices are especially vulnerable to voltage drops, harmonic currents, and transients that degrade performance and reliability over time.

What are common solutions to improve power quality?

Improving PQ often involves installing harmonic filters, surge protection devices, and voltage regulators. Facilities may also use an uninterruptible power supply (UPS) to protect critical loads. Regular PQ monitoring helps detect issues early and guide corrective action for better energy efficiency.

Related Articles