SCADA HMI

By R.W. Hurst, Editor

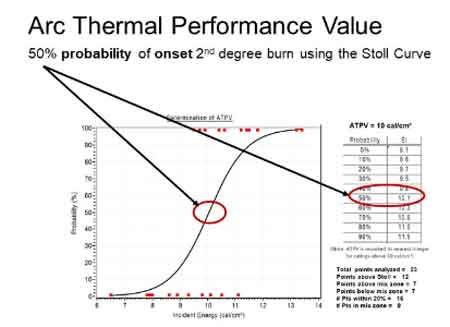

Download Our OSHA 4475 Fact Sheet – Being Aware of Arc Flash Hazards

- Identify root causes of arc flash incidents and contributing conditions

- Apply prevention strategies including LOTO, PPE, and testing protocols

- Understand OSHA requirements for training and equipment maintenance

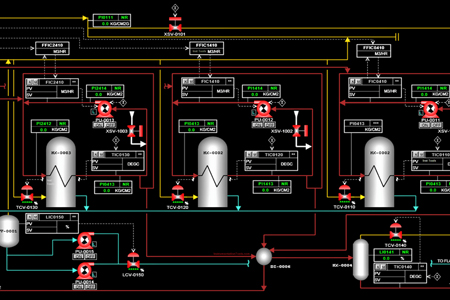

SCADA HMI integrates Supervisory Control and Data Acquisition (SCADA) with Human-Machine Interface (HMI), providing operators with real-time system visibility, data visualization, and equipment control to enhance monitoring, decision-making, and performance.

What is SCADA HMI?

SCADA HMI refers to the interface that enables operators to visually monitor and control SCADA systems. It plays a key role in real-time control, efficiency, and safety.

✅ Enables real-time system control for remote and local operations

✅ Visualizes equipment and process data through intuitive dashboards

✅ Improves operator decision-making with alerts, trends, and diagnostics

Supervisory control and data acquisition (SCADA) is essential to modern industrial automation. Its Human Machine Interface (HMI) empowers operators to monitor and control complex systems, integrating control and data acquisition into a unified supervisory framework. This article examines control system architecture, hardware components, software layers, and operational benefits while limiting the term “SCADA” to 14 uses. For a deeper understanding of how data flows through a control system, see our guide on how does SCADA work.

SCADA HMI System Components and Functions

| Component | Function | Location in System Architecture |

|---|---|---|

| Field Devices | Measure and transmit process variables (e.g., pressure, temperature, flow) | On-site at the equipment/process level |

| Programmable Logic Controllers (PLCs) | Execute control logic, manage I/O, and interface with sensors and actuators | Local panels or near-field equipment |

| Remote Terminal Units (RTUs) | Collect remote data, perform basic control, relay info to SCADA master | Remote or distributed field locations |

| SCADA Software | Perform supervisory control, log data, generate alarms and trends | Centralized server or control center |

| HMI Software | Provide a graphical user interface for operator interaction | Control room displays, local or remote |

| Human Machine Interface (HMI) | Visualize process data, alarms, and system status in real time | Operator terminals or mobile access points |

| Communication Network | Transmit data between devices, controllers, and servers | Throughout the facility and remote sites |

| Data Historian | Archive process data for trend analysis and reporting | SCADA server or cloud environment |

| Cybersecurity Layer | Protect the system from unauthorized access and cyber threats | Across the entire control system |

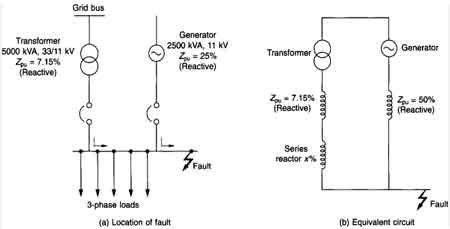

Control System Architecture and Field Devices

A reliable control system architecture integrates multiple hardware layers. Field devices such as sensors, actuators, and meters collect real-time data from operational environments. These signals are sent to programmable logic controllers (PLCs) and remote terminal units (RTUs), which perform local control and transmit data upstream. If you're new to the subject or need a refresher, start with this overview on what is SCADA, including its role in industrial automation and remote system control.

At the supervisory level, SCADA software running on host computers executes control logic, stores historical data, and manages alarms. The HMI SCADA system offers a graphical user interface that enables operators to visualize process conditions, receive alerts, and interact with the system through HMI software.

Electricity Today T&D Magazine Subscribe for FREE

- Timely insights from industry experts

- Practical solutions T&D engineers

- Free access to every issue

Key architectural elements include:

-

Field devices for sensing and actuation

-

PLCs for high-speed local logic

-

RTUs for wide-area communication

-

Central servers for supervisory functions

-

HMI for user interaction and process feedback

Data Acquisition and Visualization

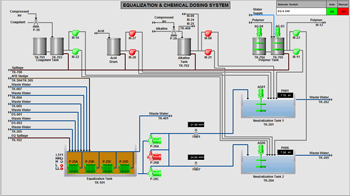

Data acquisition SCADA systems gather real-time analog and digital inputs from multiple sources. These inputs are processed and displayed through the human machine interface HMI, which converts raw values into visual formats such as graphs, status indicators, and alarm panels. To explore the core layers and logic behind supervisory control systems, visit our detailed explanation of SCADA architecture.

Operators use the HMI to oversee system status, detect anomalies, and initiate process control adjustments. In addition to live data, most systems offer historical trend analysis, allowing teams to track performance and investigate past events.

HMI visualization typically includes:

-

Real-time data meters and digital indicators

-

Process flow diagrams and mimic panels

-

Historical trend charts for performance evaluation

-

Alarm dashboards and status logs

Supervisory Control and Remote Monitoring

One of the greatest strengths of SCADA HMI systems is their ability to facilitate remote monitoring. RTUs and PLCs located across extensive infrastructure transmit data to central servers, enabling the supervision and control of industrial processes from a control room or even a mobile device. Substations are a critical part of many SCADA deployments; learn more about how SCADA is used in electric utilities through our article on substation SCADA.

Benefits of remote monitoring:

-

Reduced need for on-site personnel

-

Faster response to system faults

-

Centralized oversight of geographically dispersed assets

-

Enhanced worker safety and operational efficiency

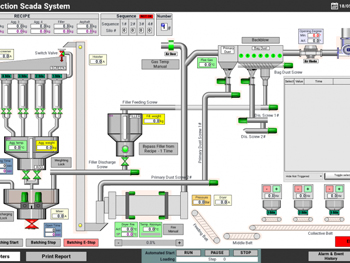

HMI Software and Operator Interaction

The role of HMI software is to present complex process data in an intuitive and manageable format. It allows operators to adjust setpoints, acknowledge alarms, and issue manual commands using touchscreen displays, keypads, or workstations. A key benefit of SCADA HMI is continuous oversight of operations—see how SCADA monitoring supports real-time visibility and incident response.

By simplifying the interaction between people and machines, the human machine interface HMI improves situational awareness and reduces the risk of operator error. It also allows multiple operators to manage different parts of the system simultaneously, supporting greater operational scale and flexibility.

Typical operator functions include:

-

Start/stop of motors and pumps

-

Adjustment of process setpoints

-

Acknowledgment of system alarms

-

Review of operational logs and reports

Integration and Interoperability

Modern systems must operate in heterogeneous environments with diverse devices and protocols. Standards such as Modbus, OPC UA, and IEC 61850 ensure that SCADA HMI platforms can communicate with third-party controllers, sensors, and enterprise systems. Effective systems must integrate hardware, software, and protocols seamlessly—our article on SCADA integration explains how this is achieved across platforms.

This interoperability allows organizations to:

-

Upgrade legacy systems with minimal disruption

-

Combine multi-vendor equipment into a unified platform

-

Support digital transformation and enterprise integration

-

Scale operations without redesigning core systems

Real-Time Data, Alarms, and Process Control

Real-time visibility is a core function of any SCADA HMI platform. By accessing real-time data through the HMI, operators can detect out-of-range conditions, act on alarms, and engage in immediate troubleshooting.

The graphical user interface not only displays alarms but also records them in chronological logs for post-event analysis. These features form the backbone of effective process control, providing insight into every stage of operation and enabling predictive maintenance and continuous improvement.

Effective alarm systems should include:

-

Prioritized alert levels (critical, warning, info)

-

Time-stamped event logs

-

Audible/visual signals for attention

-

Escalation rules for safety compliance

Applications Across Industry Sectors

SCADA HMI systems are used in virtually every sector of the industrial economy. In power utilities, they manage substation control and distribution grids. In the oil and gas industry, they control pipeline pressure and operate remote pumping stations. In water and wastewater, they oversee filtration systems, chemical dosing, and reservoir levels.

Test Your Knowledge About Smart Grid!

Think you know Smart Grid? Take our quick, interactive quiz and test your knowledge in minutes.

- Instantly see your results and score

- Identify strengths and areas for improvement

- Challenge yourself on real-world electrical topics

In manufacturing, these systems track assembly lines, batch processes, and machine utilization. Across all these applications, the integration of SCADA software and HMI enables high-efficiency, scalable, and safe control of complex operations.

Controllers, RTUs, and Field-Level Integration

Programmable logic controllers PLCs and remote terminal units RTUs are essential components of data acquisition SCADA systems. PLCs are optimized for high-speed local control, whereas RTUs are often used in remote or harsh environments.

Both devices serve as bridges between field devices and higher-level supervisory control. The HMI visualizes their activity, translating electrical signals into user-friendly graphics and alarms.

Advanced Features and Cybersecurity

New-generation SCADA HMI platforms support edge computing, cloud connectivity, and AI-enhanced analytics. These features enable predictive maintenance, reduce manual effort, and support continuous optimization.

Security is also critical. As part of the broader industrial control system, HMI platforms must be able to resist cyber threats. Encryption, role-based access, firewalls, and network segmentation are now standard to protect systems from intrusion and maintain operational integrity.

SCADA HMI systems provide the foundation for modern control and data acquisition. They empower operators to visualize conditions, monitor and control processes, and respond to events in real time. By integrating HMI software, graphical user interfaces, and a robust control system architecture, organizations can achieve operational efficiency, enhanced safety, and long-term reliability.

This tightly integrated solution supports dynamic operations across energy, manufacturing, water, and infrastructure sectors, where visibility, control, and action must align at all times. As connectivity expands, protecting control systems is more critical than ever. Read how SCADA cybersecurity strategies help defend industrial infrastructure from modern threats.