Building Automation

Green Energy

Green energy integrates renewable electricity from solar, wind, and hydro into smart grids using power electronics, advanced inverters, energy storage, and grid automation to enhance reliability, power quality, and low-carbon transmission.

What Is Green Energy?

Green energy is renewable electricity from solar, wind, and hydro, using power electronics, smart grids, and storage.

✅ Power electronics and inverters convert PV DC to grid-synchronous AC.

✅ Smart grids manage variable renewables with SCADA, EMS, and demand response.

✅ Energy storage and microgrids enhance reliability, power quality, and resilience

Green energy, often synonymous with renewable energy, has gained significant attention in recent years as the world seeks to reduce its reliance on fossil fuels, minimize environmental damage, and promote a more sustainable future. This shift towards clean energy resources helps reduce greenhouse gases and air pollutants and plays a vital role in conserving non-renewable resources and promoting efficiency.

There are several green energy sources, each with unique benefits and challenges. Solar energy, one of the most popular renewable sources, harnesses the sun's energy to generate electricity. Solar panels, commonly installed on rooftops or in solar farms, convert sunlight into electricity for homes and businesses. As solar technology advances, solar system installation costs have dropped significantly, making it more accessible to individuals and communities alike. For homeowners, adopting comprehensive strategies is easier when using resources like energy management frameworks that track consumption and optimize production.

Wind energy, another widely recognized green energy source, is generated by converting the kinetic energy of wind into electricity using wind turbines. Large wind farms can produce significant energy, often enough to power entire communities or cities. However, wind power's effectiveness depends on the location and weather conditions, as wind speeds must be sufficient to generate electricity consistently. To mitigate variability, utilities often integrate energy management systems to balance wind output with demand forecasts.

Hydropower, one of the oldest renewable green energy sources, utilizes the movement of water to generate electricity. Dams and hydroelectric power stations convert the potential energy of water stored at a height into electricity, providing a stable and reliable source of energy. However, the construction of dams can lead to environmental concerns, such as habitat disruption and changes to local ecosystems. In facilities adjacent to dams, building energy management systems can tune loads to align with scheduled releases for greater efficiency.

Biomass energy is derived from organic materials, such as plants and animal waste, which can be burned directly for heat or converted into biofuels, such as ethanol and biodiesel. This form of green energy can help reduce waste and greenhouse gas emissions. However, the large-scale production of biomass crops can compete with food production and lead to deforestation. Modern plants deploy energy management controls to maintain combustion efficiency and emissions performance across feedstock variations.

Geothermal green energy taps into the Earth's natural heat by capturing steam or hot water from underground reservoirs to generate electricity. This clean energy source has a minimal environmental impact, but its availability is limited to areas with specific geological conditions. In buildings served by district geothermal, integrating building automation enables coordinated HVAC setpoints and thermal storage strategies.

Green energy offers numerous environmental benefits, such as reducing greenhouse gas emissions, air pollution, and dependence on finite energy resources like coal, oil, and natural gas. By transitioning to renewable green energy sources, we can significantly reduce our carbon footprint and mitigate the effects of climate change. Additionally, green energy technologies can create new job opportunities and stimulate economic growth.

However, there are also some drawbacks to green energy sources. For example, intermittency issues can arise with solar and wind power, depending on weather conditions. Moreover, the initial investment for installing renewable energy systems can be high, although costs have decreased recently.

Individuals can contribute to the growth of green energy by installing solar panels in their homes, using energy-efficient appliances, and supporting policies that encourage the adoption of renewable energy sources. The cost of switching to green energy varies depending on the technology, location, and government incentives available.

Emerging trends in green energy technology include advancements in energy storage solutions, such as batteries and hydrogen storage, which can help address intermittency issues. Furthermore, innovations in smart grids and microgrids allow for better integration and management of renewable sources. These improvements are complemented by advanced energy management analytics that forecast loads and orchestrate distributed assets.

Government policies play a critical role in supporting the adoption of green energy. For example, incentive programs, tax credits, and subsidies can help lower the cost of renewable power installations, making them more accessible to consumers. Additionally, regulations and targets for reducing greenhouse gas emissions and increasing the use of renewable sources can drive further investment in green energy technologies. Organizations can accelerate adoption by instituting a formal energy management program that aligns incentives, metering, and continuous commissioning efforts.

Embracing green energy sources is crucial for building a sustainable and cleaner future. By understanding the different types of green energy and their environmental benefits, individuals and governments can make informed decisions to promote adopting green energy solutions.

As the United States and other countries worldwide continue to invest in renewable technologies, the production landscape is rapidly changing. This transition to green energy sources is essential to reducing our reliance on fossil fuels, minimizing the environmental impacts of energy production, and ensuring a sustainable future for generations to come.

Increasing public awareness and education is one way to promote green energy further. By informing citizens of the benefits and potential drawbacks of different renewable sources, we can foster a more informed and engaged public, encouraging individuals to make greener choices in their daily lives.

Community-based green energy renewable projects can also help facilitate the widespread adoption of green energy. These projects, such as community solar gardens or small-scale wind farms, allow individuals who may need more resources or space to install their renewable systems to benefit from clean energy production. In addition, by pooling resources and sharing the benefits, communities can work together to create a more sustainable future.

Advancements in green energy technologies will also play a significant role in increasing the adoption of renewable sources. As researchers and engineers continue to develop more efficient and affordable technologies, the barriers to entry for green energy will continue to decrease. In addition, innovations in materials science, such as the development of more efficient solar cells or improvements in wind turbine design, can lead to significant gains in the performance of renewable systems.

Finally, international cooperation and collaboration will be essential in advancing green energy on a global scale. Climate change and environmental degradation do not respect national borders; thus, a united effort is necessary to combat these challenges. By sharing knowledge, resources, and technology, countries can work together to promote the adoption of green energy and build a more sustainable future for all.

Green energy is an essential component of a sustainable, environmentally responsible future. Investing in renewable technologies, supporting government policies, and engaging in individual and community-based efforts can help drive the adoption of green energy sources and ensure a cleaner, healthier world for future generations. With continued innovation, increased public awareness, and international collaboration, the promise of a green energy revolution becomes more attainable each day.

Related Articles

Download Our FREE Building Automation Handbook

Lighting Handbook, Vol. 1

Industrial Lighting Handbook presents a wide array of lighting choices and problems in the industrial, commercial and institutional sectors, from fluorescent to HID lamps, solid state lighting and office lighting scenarios. This handbook covers everything from basic lighting to advanced automation emergency lighting applications.

The Lighting Handbook, Vol. 1 is designed to serve as a comprehensive guide for professionals, designers, engineers, and anyone involved in the planning, implementation, and optimization of lighting systems. In this volume, we explore the core principles of lighting design, technology, and innovation, providing practical insights and strategies to help you harness the full potential of modern lighting solutions.

From understanding the science of light to selecting the right fixtures and technologies, this handbook covers a wide range of topics, including energy-efficient lighting, smart lighting systems, and the latest trends in LED technology. It also delves into the environmental impact of lighting and the growing importance of sustainability in the industry.

Whether you are designing a new space, upgrading an existing system, or simply looking to stay informed about the latest advancements, Lighting Handbook, Vol. 1 equips you with the knowledge and tools needed to create optimal lighting solutions that are both functional and eco-friendly.

Embark on this journey into the world of lighting and discover how thoughtful, well-executed lighting can transform spaces, enhance user experience, and contribute to a more sustainable future.

Latest Building Automation Articles

PLC Training Courses

PLC training courses build automation skills in ladder logic, SCADA, HMI, and motion control, with hands-on programming on Siemens and Allen-Bradley platforms, diagnostics, IEC 61131-3 standards, safety, and commissioning best practices.

What Are PLC Training Courses?

Programs teaching PLC programming, SCADA, HMI, and industrial automation with hands-on labs and commissioning.

✅ Ladder logic, function blocks, and IEC 61131-3 programming

✅ Siemens TIA Portal and Allen-Bradley RSLogix labs

✅ Fault finding, I/O wiring, safety, and commissioning

Our PLC training courses are designed to help students keep abreast of the latest PLC technologies and techniques available for industrial automation. These courses offer an excellent opportunity for students to ask specific questions and exchange ideas relating to their own applications. For context on modern plant connectivity, see the overview of industrial automation communication standards used in training.

Our PLC training courses are intended for experienced users and will give them greater knowledge of enhanced PLC functionality. Participants also review the benefits of industry networks to understand how network design impacts reliability.

We have three PLC training courses:

Before selecting a pathway, it helps to understand the hierarchical levels of industrial networks that underpin PLC architectures.

PLC Training Basic - Our 12-Hour (2-Day) live online instructor-led industrial automation course is designed to instruct electrical control professionals on how to successfully integrate a PLCs into actual day-to-day industrial electrical processes. The course not only deals with the hardware and software, but all the surrounding systems that must be compatible to achieve a safe and reliable control system. This PLC Training Basic course is generic in nature and applies to all PLC types and manufacturers. We also examine key industrial network components so attendees can better integrate field devices.

PLC Training - Intermediate - Our 12-Hour (2-Day) live online instructor-led industrial automation course is designed to instruct electrical control professionals on how to successfully integrate a PLC into actual day-to-day industrial electrical processes. It not only deals with the hardware and software, but all the surrounding systems that must be compatible to achieve a safe and reliable control system. The curriculum compares common transmission methods in industrial networks to guide protocol selection.

PLC Training Course - Advanced

In the advanced module, we connect control strategies to advanced energy management concepts for measurable performance gains.

Our 12-Hour (2-Day )Advanced PLC Training Course is designed to give students a basic understanding of Programmable Logic Controllers and how PLCs function. This Advanced PLC training course will not make students PLC experts but rather give them a basic understanding of the PLC, the PLC’s functionality and limitations. The PLC training seminar is generic in nature and applies to all types and manufacturers. Case studies include applications like smart city automated level crossings where safety and uptime are critical.

Related Articles

Advanced Energy Management

Advanced energy management integrates smart grid analytics, demand response, and SCADA/IoT sensors to optimize loads, enable peak shaving, enhance power quality, and coordinate renewables, storage, and microgrids for efficient, resilient electrical systems.

What Is Advanced Energy Management?

A control-and-analytics approach to optimize electrical loads, integrate renewables and storage, and improve reliability.

✅ Load forecasting and demand response reduce peaks and costs.

✅ SCADA, IoT, and EMS enable real-time monitoring and control.

✅ Optimizes power quality, peak shaving, and asset utilization.

Advanced energy management systems involve control systems and processes. Control systems can be as simple as a residential thermostat, to very complex computer controlled systems for multiple buildings, to industrial process control. Their diligence and repeatability can also serve to maintain the savings of project improvements for years, further justifying their existence by providing economic return to the customer. Advanced energy management systems include control technology and control mode categories, basic input and output instrumentation, and the practical need to temper “things possible” with the skill level of the operators who will inherit it. The importance of advanced energy management system controllability and user-friendliness as primary design parameters will be stressed. Industry overviews of energy management systems highlight common architectures and integration paths useful during early design.

The following is a very important first statement before any discussion about control hardware: “The type of advanced energy management systems hardware used in optimization is less important than the understanding of the process and of the control concepts that are to be implemented.” The main goal should be to become clear about the process fundamentals and what should happen—then the parts and pieces are just details. This discussion of different available hardware types is a familiar but sometimes laborious and dull part of any controls text. Remember that automatic controls are really nothing more than machines that do for us what we would do ourselves if we had nothing better to do; they do work for us like any other tool, and they are only as clever as the people who craft them. As a complement, primers on energy management controls summarize control modes and device families that support these concepts.

The field of automatic control in advanced energy management systems is similar in that we continually adjust some device to cause a particular measured variable to remain at a desired state. In facilities practice, deploying a building automation system provides the supervisory layer that implements such setpoint maintenance and scheduling.

Examples:

• The need to throttle heating and cooling equipment sized for maximum load that is effectively over-sized at part load conditions. Within building energy management systems these strategies are automated through reset logic and variable speed control for stable part-load operation.

• Varying occupancy, and systems attendant to the occupants (lighting, ventilation). Guides on energy management emphasize occupancy-based control sequences that tie lighting and ventilation to real-time demand.

• Varying product throughput rate through manufacturing facilities. Establishing an enterprise energy management program helps align throughput-driven process controls with measurable performance targets.

• Varying demands, and the need to maintain level or full state for water or fuel reservoirs, feed or coal bins, etc.

• Coordination: Organizing or sequencing multiple processes in a logical and efficient manner is an important aspect of automatic control applications.

• Automation: Human beings can make very good manual controllers because we can think on our feet and consider many variables together, but most control tasks are repetitive and suitable for mechanization. Introductory references explaining what building automation is clarify how routine tasks are delegated to algorithms while operators focus on exceptions.

Automatic operation allows people to provide oversight of advanced energy management system operations and more effectively utilize their time.

• Consistency: Manual control by people can be effective, although we are not all that repeatable and are sometimes forgetful. Using machinery for automatic control adds the improvement of consistent, repeatable operations. The repeatability and consistency feature of automatic control is very important in manufacturing.

• Conservation: Supplemental enhancement control routines can be incorporated to reduce energy use while still maintaining good control. It is important to note that control systems do not necessarily reduce energy consumption unless specifically applied and designed for that purpose.

Advanced energy management automatic controls are useful for basic regulation and quality control of processes and environments. They can also be leveraged for energy savings through optimization. Properly applied, these energy management systems are reliable and cost effective.

From: Energy Management Handbook, 7th Edition, The Fairmont Press

Related Articles

Benefits of Industry-Standard Networks Explained

Benefits of industry networks include collaboration, knowledge sharing, standards alignment, and vendor partnerships that accelerate innovation in electrical engineering, grid modernization, smart manufacturing, and safety compliance across power systems and automation ecosystems.

What Are the Benefits of Industry Networks?

They enable faster innovation, standards compliance, risk mitigation, and scalable solutions through shared expertise.

✅ Accelerates compliance with IEEE, IEC, UL standards and codes

✅ Improves interoperability across SCADA, PLC, and smart grid systems

✅ Enables supplier benchmarking, risk sharing, and joint R&D

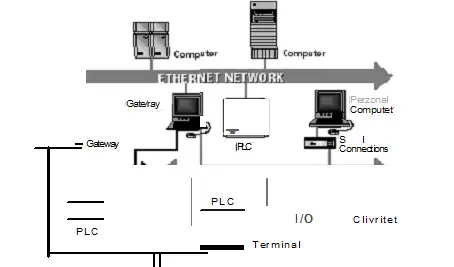

Modern control and business systems require open, digital communications. Industrial networks replace conventional point-to-point RS-232, RS-485, and 4-20 mA wiring between existing measurement devices and automation systems with an all-digital, 2-way communication network. Industrial networking technology offers several major improvements over existing systems. With industry-standard networks, we can select the right instrument and system for the job regardless of the control system manufacturer. Other benefits include:

To understand how device-level buses, controllers, and enterprise systems coordinate, resources like industrial automation communication outline protocol choices, latency tradeoffs, and integration patterns. Selecting between Ethernet, fieldbus, and wireless options benefits from comparing transmission methods for industrial networks with respect to determinism, noise immunity, and distance.

- Reduced wiring -- resulting in lower overall installation and maintenance costs

- Intelligent devices -- leading to higher performance and increased functionality such as advanced diagnostics

- Distributed control -- with intelligent devices providing the flexibility to apply control either centrally or distributed for improved performance and reliability

- Simplified wiring of a new installation, resulting in fewer, simpler drawings and overall reduced control system engineering costs

- Lower installation costs for wiring, marshalling, and junction boxes

Delivering these benefits also depends on choosing switches, gateways, and physical media from a well-architected set of industrial network components that match environmental and reliability requirements. Designers often map sensors, controllers, and supervisory systems across the hierarchical levels of industrial networks to balance real-time control with plantwide visibility.

Standard industrial networks offer the capability to meet the expanding needs of manufacturing operations of all sizes. As our measurement and automation system needs grow, industrial networks provide an industry-standard, open infrastructure to add new capabilities to meet increasing manufacturing and production needs. For relatively low initial investments, we can install small computer-based measurement and automation systems that are compatible with large-scale and long-term plant control and business systems. This standards-based approach aligns closely with how a building automation system aggregates HVAC, power, and security data for unified operations. For teams expanding beyond production into facilities integration, understanding what building automation entails helps frame networking requirements and data governance.

As energy costs and sustainability goals rise, leveraging advanced energy management over the same industrial network can drive measurable efficiency gains and carbon reporting accuracy.

Related Articles

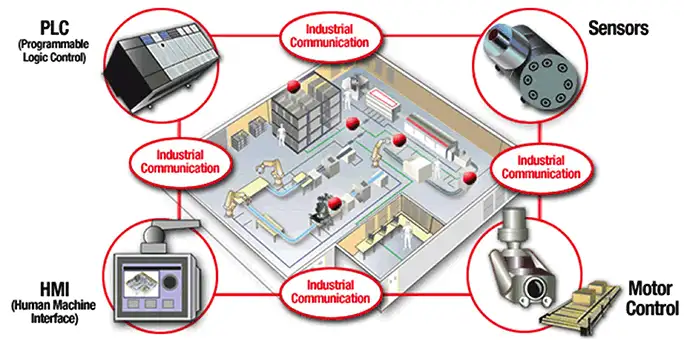

Industrial Automation and Communication Networks

Industrial automation communication connects PLCs, sensors, drives, and SCADA via protocols like PROFINET, Modbus, OPC UA, and Ethernet/IP, enabling deterministic control, interoperability, diagnostics, safety, and IIoT data across electrical systems and networks.

What Is Industrial Automation Communication?

Networked real-time data exchange between PLCs, sensors, HMIs, and SCADA using standardized industrial protocols.

✅ Supports deterministic Ethernet (TSN) and legacy fieldbus integration

✅ Enables real-time control, diagnostics, and predictive maintenance

✅ Interoperates via PROFINET, Modbus, EtherNet/IP, and OPC UA

In the early 20th century, process control systems and the manufacturing systems were designed based primarily on the mechanical technology and with analog devices. After the period, the pneumatic control technology and the hydraulic power were introduced. The pneumatic control technology made it possible to control remote systems by a centralized control system. These technologies are still very common.

At the beginning of 1960, a digital computer was for the first time really applied as a digital controller. The term direct digital control (DDC) was used to emphasize that the computer directly controls the process. In the 1960s, the application of a minicomputer was still a fairly expensive solution for many control problems. In the meantime, programmable logic controller (PLC) was developed and it replaced the conventional, relay-based controller, having relatively limited control functions. In addition, many technologies were developed for machine tools and discrete production processes. The numerically controlled (NC) machine tool became to be controlled by computers and the robot was developed in this period.

With the more widespread use of digital computers and the associated technologies, industrial communication networks became to be developed with or converted to digital transmission. Proprietary digital communication networks for industrial use started in the 1960s as computers for automation systems were first linked together.

In mid 70s, the first distributed computer control system (DCCS) was announced by Honeywell as a hierarchical control system with a large number of microprocessors. Since its introduction in mid 1970s, the concept of the DCCS spread widely in many industrial automation systems such as power plant control systems, manufacturing systems, etc. The installation of distributed control systems in the newly planned plants or replacement of existing analogue or centralized control systems is presently a common decision of enterprise management. In sectors like power generation, advanced energy management strategies leverage DCS data to optimize load balancing and maintenance planning across units.

The use of local area networks to interconnect computers and automation devices within an industrial automation system has become popular since 1980. The high capacity low cost communication offered by local area networks has made distributed computing a reality, and many automation services. The

As deployments expanded, many organizations realized that the benefits of industrial networks include lower downtime, scalable integration, and improved data visibility across operations.

industrial automation systems are often implemented as an open distributed architecture with communication over digital communication networks. Achieving high availability requires the right mix of industrial network components such as managed switches, protocol gateways, and ruggedized edge controllers.

It is now common for users connected to a local area network to communicate with computers or automation devices on other local area networks via gateways linked by a wide area network. Similar architectures now extend into transportation, where smart city automated level crossings depend on resilient networking to coordinate sensors, barriers, and central oversight.

As the industrial automation systems becomes large and the number of automation devices increases, it has become very important for industrial automation to provide standards which make it possible to interconnect many different automation devices in a standard way. Considerable international standardization efforts have been made in the area of local area networks. The Open Systems Interconnection (OSI) standards permit any pair of automation devices to communicate reliably regardless of the manufacturer. To plan these interoperable systems, designers often reference hierarchical levels in industrial networks to align plant-floor operations with supervisory and enterprise layers.

Industrial networks span many manufacturing applications. Standard industrial networks using digital communication technologies cover a wide range of manufacturing applications. In many applications, the types of devices and performance determine the type of network. Contrast the needs of two devices -- a proximity sensor used on a conveyor belt compared to a control valve used in a petroleum refinery. The proximity sensor has a single function - to transmit a Boolean on/off signal indicating the proximity of an object. We can accommodate this signal in a few bits of data. Diagnostic information from the sensor is probably limited to a single "health" indicator, which again requires very little data. However, we can expect the control valve to provide very sophisticated control functions and diagnostics, such as number of cycles since last servicing, packing friction, and ambient operating temperature. These parameters can be extremely critical in an environment such as a refinery -- failures can result in dangerous situations and costly downtime. Clearly, the proximity sensor and the control valve have different network requirements. Therefore, different types of industrial networks must address a variety of different needs. We must select the right network to address our specific application requirements.

What is an Industrial Network? By definition, an industrial network requires geographical distribution of the physical measurement I/O and sensors or functional distribution of applications. Most industrial networks transfer bits of information serially. Serial data transfer has the advantage of requiring only a limited number of wires to exchange data between devices. With fewer wires, we can send information over greater distances. Because industrial networks work with several devices on the same line, it is easier to add a new device to existing systems. Comparing fieldbus, Ethernet, and wireless backbones, understanding transmission methods in industrial networks helps engineers match latency, bandwidth, and environmental constraints.

To make all this work, our network must define a set of rules -- a communication protocol -- to determine how information flows on the network of devices, controllers, PCs, and so on. With improved communication protocols, it is now possible to reduce the time needed for the transfer, ensure better data protection, and guarantee time synchronization, and real-time deterministic response in some applications. Industrial networks also ensure that the system sends information reliably without errors and securely between nodes on the network.

For the lower level communication network for industrial automation, the industrial local area network solutions such as MAP are too expensive and/or do not reach the required short response times, depending on the application. The fieldbuses have been, therefore, developed to meet these requirements, and many efforts are now being made to make fieldbus standards for industrial automation applications. The same field-level connectivity principles underpin a modern building automation system where HVAC, lighting, and security integrate reliably across facilities.

Read More: Hierarchical Levels in Industrial Communication Networks

Related Articles

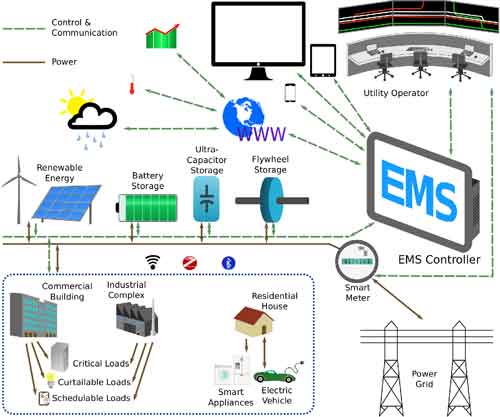

Energy Management Systems & Smart Buildings

Energy Management Systems (EMS) enhance energy efficiency, reduce costs, and promote sustainability by monitoring, controlling, and analyzing energy use in buildings, enabling smarter resource allocation and a reduction in carbon footprint.

What are Energy Management Systems?

Energy Management Systems (EMS) are integrated platforms that monitor, control, and optimize energy consumption in facilities to enhance efficiency, promote sustainability, and achieve cost savings.

✅ Monitor and control energy use in real time

✅ Enhance efficiency, sustainability, and cost reduction

✅ Support compliance, reporting, and renewable integration

Energy management systems transform how we manage and consume electricity in industrial, commercial, and institutional power systems. By incorporating energy efficiency, building automation, smart grid technology, demand response, power monitoring, conservation, HVAC control, power optimization, renewable energy integration, and analytics, EMS offer a comprehensive EM for a more sustainable future.

By adopting Energy Management Systems, organizations can effectively manage consumption across their facilities, tracking energy usage in real-time to uncover opportunities for energy savings. This not only lowers operational costs but also reduces carbon emissions, supporting both financial performance and environmental responsibility.

Key Components of EMS

At the core of EMS systems are key components that work together to improve efficiency. These components include sensors, controllers, actuators, and communication networks that gather real-time data from various energy-consuming devices. This data is then analyzed to optimize the system's performance, ensuring cost-effective electricity use and minimal waste.

Energy Management Systems Overview

| Aspect | Description | Examples/Applications | Benefits |

|---|---|---|---|

| Core Components | Sensors, controllers, actuators, communication networks | Building systems, industrial plants | Real-time data, automation, optimized performance |

| Building Automation | Integrated control of lighting, HVAC, and equipment | Smart buildings, commercial facilities | Lower electricity use, cost savings, comfort, productivity |

| Smart Grid Integration | Linking EMS with utilities and renewable energy | Solar, wind, microgrids | Balanced supply-demand, grid reliability |

| Demand Response | Adjusting consumption in response to grid conditions | Industrial load shifting, peak demand control | Reduced costs, grid stability, incentives |

| Analytics & AI | Data analysis, predictive maintenance, optimization algorithms | Dashboards, machine learning models | Efficiency, reduced downtime, proactive management |

| Sustainability Focus | Incorporation of renewable energy and conservation strategies | Solar panels, wind turbines, green buildings | Reduced emissions, compliance, and carbon footprint cuts |

Building Automation and Efficiency

One of the primary ways energy management systems improve efficiency is through building automation. Building managers can monitor and control various aspects of their facility's electricity usage by integrating different systems such as lighting, heating, ventilation, and air conditioning (HVAC) control. This level of control enables them to make informed decisions, reducing power consumption while maintaining a comfortable and productive environment.

Smart Grids and Renewable Integration

Energy management systems also play a significant role in developing and implementing smart grids. These grids use advanced communication technologies and IoT devices to connect renewable energy sources, such as solar panels and wind turbines, with the electric utility. As a result, power supply and demand can be better balanced, leading to more efficient and reliable electricity distribution.

Demand Response and Conservation

Demand response is another crucial aspect of Energy Management Systems, allowing consumers to adjust their consumption based on real-time information from the electric grid. By participating in demand response programs, consumers can reduce their energy consumption during peak hours and benefit from lower costs.

Power conservation is a primary goal of energy management systems, which achieve this through various strategies, including efficient HVAC control, lighting optimization, and equipment scheduling. In addition, businesses and homeowners can significantly reduce their overall power usage by ensuring that power-consuming devices are used only when necessary.

Power optimization is a crucial aspect of EMS, achieved through the ongoing analysis of consumption patterns and equipment performance. Advanced power analytics tools can identify inefficiencies and recommend actions to maximize savings. These insights can help building managers create power-saving strategies, such as adjusting temperature set points, optimizing lighting controls, and scheduling equipment use.

One of the most exciting aspects of energy management systems is their seamless integration of renewable energy sources. By incorporating solar panels, wind turbines, and other clean power technologies, EMS can help businesses and homeowners reduce their reliance on fossil fuels and lower their carbon footprint.

The Role of IoT and AI

The role of IoT and AI in energy management systems is crucial, as they enable remote monitoring, real-time data analysis, and predictive maintenance. By utilizing IoT devices to collect data and AI algorithms to analyze it, EMS can identify inefficiencies and predict equipment failures, thereby ensuring optimal system performance.

By adopting EMS, businesses and homeowners can save money on their power bills and reduce their environmental impact. In addition, by optimizing power use, reducing waste, and integrating renewable energy sources, EMS leads to cost savings and contributes to the global effort to combat climate change.

Future Trends in EMS

The field of energy management systems is constantly evolving, with new trends and innovations emerging regularly. These innovations include integrating energy storage solutions, microgrids, and machine learning algorithms for even more precise power optimization.

Related Articles

Building Automation System - HVAC Control

Building automation system integrates electrical controls for HVAC, lighting, and power distribution, using BMS platforms, PLCs, BACnet/Modbus protocols, IoT sensors, and SCADA to optimize energy management, demand response, safety, and predictive maintenance.

What Is a Building Automation System?

An electrical control system automating HVAC, lighting, and power to improve efficiency, safety, reliability, and uptime.

✅ Integrates PLCs, sensors, VFDs, and switchgear controls

✅ Uses BACnet/Modbus for HVAC, lighting, and metering

✅ Enables energy analytics, demand response, fault diagnostics

In an era of rapidly evolving technology, smart buildings have become crucial to modern infrastructure. With the advent of the Internet of Things (IoT), facility managers are increasingly adopting advanced systems to monitor and control various parts of a building's performance. One such solution is the Building Automation System (BAS), which focuses on improving energy efficiency and occupant comfort and reducing maintenance costs. For an overview of foundational concepts, resources like what is building automation can help contextualize these systems for stakeholders.

The primary purpose of a building automation system is to streamline the operation and management of a building's critical subsystems, such as Heating, Ventilation, Air Conditioning (HVAC), lighting, security, and energy management. In addition, a centralized control platform enables facility managers to optimize resource utilization and respond to changing conditions more effectively. To understand device-level orchestration, guidance on energy management controls clarifies how setpoints and schedules are coordinated across platforms.

A typical BAS comprises three main components: input, controller, and output. Input devices like sensors to measure environmental parameters like temperature, humidity, and light levels. Controllers process this information and use pre-defined algorithms to determine the best action. Output devices, including actuators and relays, then implement these decisions by adjusting various systems, such as modifying the temperature in an HVAC system.

In practice, the data path often feeds into building energy management systems that aggregate trends for analytics and reporting.

There are numerous benefits to implementing a building automation system. First and foremost, it can significantly improve energy efficiency. By monitoring and controlling various systems, including HVAC, lighting, and energy management, a building automation system can ensure that resources are only used when necessary, leading to substantial cost savings. Moreover, intelligent building control system algorithms can identify inefficiencies and take corrective action, enhancing overall performance. When paired with disciplined energy management practices, these optimizations translate directly into measurable Key Performance Indicators.

In addition to improving energy efficiency, a BAS also enhances occupant comfort. By monitoring environmental factors like temperature, humidity, and air quality, the system can always maintain optimal conditions for occupants. Furthermore, many systems allow users to customize their preferences via a user interface, empowering them to create a comfortable environment suited to their needs. Organizations that formalize a energy management program often align comfort objectives with operational targets more consistently.

Another significant advantage of a BAS is its ability to integrate with IoT devices. As the IoT ecosystem expands, more devices and sensors are being developed, providing valuable data for building management. By incorporating this information into the building automation system, facility managers can gain deeper insights into building performance and make more informed decisions. This increasingly connected architecture enables advanced energy management workflows that leverage predictive models and fault detection for continuous improvement.

A wide range of building automation control systems is available on the market, catering to different needs and budgets. These include Energy Management Systems (EMS), which focus specifically on monitoring and controlling energy usage, and Building Management Systems (BMS), which offer a more comprehensive integration of various subsystems. In addition, some solutions provide systems integration capabilities, enabling facility managers to combine multiple systems under a user interface. Choosing among various energy management systems requires assessing scalability, interoperability, and cybersecurity posture for long-term success.

As technology continues to evolve, so will the capabilities of building automation systems. From advanced HVAC control to robust security systems and energy management solutions, a building automation system can potentially transform how buildings are managed and maintained. By implementing these systems, facility managers can achieve significant cost savings, improve occupant comfort, and contribute to a more sustainable future.

A building automation system is essential for modern facility management. They provide centralized control over various subsystems, improving energy savings and efficiency, occupant comfort, and reducing maintenance costs. Furthermore, as the IoT ecosystem expands, these systems are set to become even more powerful, offering deeper insights and more advanced control over building performance. So whether you are a facility manager looking to optimize your existing infrastructure or an architect designing the next generation of smart buildings, embracing the potential of building automation systems will undoubtedly lead to a more efficient and sustainable future.