Electrical Protection

Arc Fault Circuit Interrupter Protection

Arc Fault Circuit Interrupter Protection detects dangerous arc faults in wiring, preventing electrical fires, enhancing home safety, and meeting NEC code requirements. AFCI breakers safeguard circuits in bedrooms, living areas, and other critical spaces.

What is Arc Fault Circuit Interrupter Protection?

Arc fault circuit interrupter protection involves AFCIs devices that are vital components in modern electrical systems designed to prevent electrical fires. It:

✅ Detects hazardous arc faults in electrical wiring before they ignite fires.

✅ Improves home safety by shutting off power during arc conditions.

✅ Meets NEC requirements for protection in key residential areas.

Arc Fault Circuit Interrupter (AFCI) protection is a critical safety measure that prevents electrical fires by detecting dangerous arc faults before they can ignite surrounding materials. This technology is required in many areas of modern homes under the National Electrical Code (NEC) and offers protection beyond that of standard breakers. In this article, we explain what AFCIs do, how they work, the different types available, NEC requirements, and why investing in them is a smart safety choice. For a broader understanding of system safety, see our Electrical Protection overview, which explains the key principles behind safeguarding circuits and equipment.

Basic Protection Relay Training

Request a Free Training Quotation

Why AFCI Protection Matters

Arc faults occur when electricity jumps through the air between damaged conductors or loose connections, creating extreme heat that can ignite nearby materials. Common causes include:

-

Damaged or frayed wires

-

Loose terminal connections

-

Aging electrical systems

-

Cords pinched by furniture

According to the U.S. Consumer Product Safety Commission, arc faults are a leading cause of electrical fires in residential settings. AFCI circuit breakers detect these faults and instantly de-energize the circuit, significantly reducing fire risk in dwelling units. Learn more about specialized AFCI devices in our guide to AFCI Protection, which details their role in preventing arc fault–related fires.

How AFCIs Detect Arc Faults

Arc faults create a distinct electrical signature, different from normal current flow. AFCIs use advanced electronics and waveform recognition technology to continuously monitor branch circuits. When abnormal patterns consistent with either parallel or series arcs are detected, the breaker trips, cutting power before heat can build to dangerous levels. Our detailed article on the Arc Fault Interrupter Breaker explains how these breakers function and where they should be installed for maximum protection.

-

Parallel arcs occur between two conductors, often from damaged insulation.

-

Series arcs occur along a single conductor, often from loose or corroded connections.

How an AFCI Works

Inside an AFCI breaker, microprocessors compare live waveform data against known arc fault patterns. When a match is found, the device trips in fractions of a second, interrupting the circuit. This quick action prevents ignition and limits damage, offering protection standard breakers cannot match. If you want to understand the broader category of devices that limit damage from faults, visit our page on Circuit Protection Devices.

Types of AFCI Devices

Branch/Feeder AFCI

-

Installed at the panel to protect the entire branch circuit from parallel arcing faults.

Combination Type AFCI

-

Protects against both series and parallel arcs. Required by NEC in most applications since 2008, it offers the most complete branch-circuit protection in bedrooms, living areas, dining rooms, and more.

AFCI Receptacles

-

Installed at the outlet, ideal for retrofit situations where panel replacement isn’t practical.

AFCI vs GFCI vs Dual-Function Devices

While both AFCIs and Ground Fault Circuit Interrupters (GFCIs) improve safety, they address different hazards:

-

AFCI Protection – Prevents electrical fires caused by arc faults.

-

GFCI Protection – Prevents electrical shock by shutting off power during ground faults.

-

Dual-Function Breakers – Combine AFCI and GFCI in one device for protection against both hazards, recommended for comprehensive home safety.

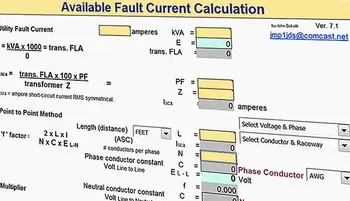

Proper fault analysis is key to safe design—read our Fault Current Calculation guide to see how engineers size and coordinate protection systems.

NEC Requirements & Code Evolution

The NEC has expanded AFCI requirements over time:

-

1999 – Required in bedrooms only.

-

2008 – Expanded to family rooms, dining rooms, living rooms, parlours, libraries, and dens.

-

2014 – Added kitchens, laundry areas, and hallways.

-

2017/2020 – Maintained broad coverage for most habitable rooms.

Always check local adoption of NEC rules, as requirements can vary by jurisdiction.

Installation Guidelines

-

Follow NEC Guidelines – Install AFCIs in branch circuits supplying outlets in required areas.

-

Hire a Licensed Electrician – Proper wiring and secure connections are essential for reliability.

-

Consider Voluntary Installation – Even if not required by local code, adding AFCI protection enhances safety.

Cost vs Safety

AFCI breakers cost about $30–$50 each—more than standard breakers—but their fire prevention capability can save property, possessions, and lives. The cost is small compared to the potential loss from an electrical fire.

Where AFCI Protection Is Required

Under NEC, branch circuits supplying outlets in the following areas require AFCI protection:

-

Family rooms

-

Dining rooms

-

Living rooms

-

Parlors

-

Libraries

-

Dens

-

Bedrooms

-

Recreation rooms

-

Closets

-

Hallways

Bathrooms – GFCI First, AFCI Optional

Bathrooms require GFCI protection due to water shock hazards. While AFCI protection is not mandated in most bathrooms, adding dual-function protection provides both fire and shock safety.

Arc Fault Circuit Interrupter Protection is an essential part of a safe, modern electrical system. By detecting and stopping arc faults before they cause fires, AFCIs meet and exceed electrical code requirements and offer peace of mind for homeowners. Whether required by law or installed voluntarily, these devices are one of the most effective ways to protect your home from electrical fire hazards. For more advanced applications, explore Power System Protection, which covers methods to safeguard entire electrical networks from faults and outages.

Frequently Asked Questions

Do AFCIs really prevent fires?

Yes. AFCIs detect dangerous arc faults before they can generate enough heat to ignite surrounding materials. By interrupting the circuit in milliseconds, they greatly reduce the risk of electrical fires caused by damaged wiring, loose connections, or aging systems.

Where are AFCIs not required?

AFCIs are not typically required in garages, unfinished basements, or bathrooms under the NEC. However, local codes may vary, and some homeowners choose to install them in these areas for added protection.

Can I replace a standard breaker with an AFCI?

Yes. In most modern panels, you can replace a standard breaker with an AFCI breaker of the same amperage. Always use a compatible breaker for your panel brand and have the work performed by a licensed electrician.

What is the difference between a combination AFCI and a branch/feeder AFCI?

A branch/feeder AFCI detects parallel arcs, while a combination AFCI detects both parallel and series arcs. Combination AFCIs provide broader protection and are required in most residential circuits under current NEC rules.

Are AFCI breakers worth the cost?

Yes. At $30–$50 each, AFCI breakers are inexpensive compared to the potential losses from a fire. They also bring your home closer to full code compliance and provide peace of mind for families.

Related Articles

Download Our FREE Electrical Protection Handbook

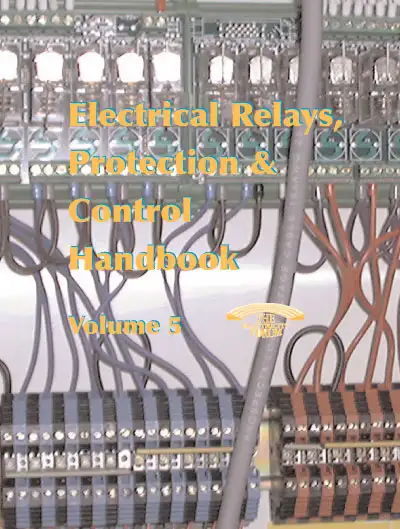

Electrical Relays, Protection & Control Handbook Vol. 5

This more than 100 page handbook is an invaluable tool for the protection and control of your electrical systems.

In this edition, we delve into the latest advancements in relay technology, covering both conventional and digital protection relays, their applications, and the principles behind their operation. With a focus on practical strategies for system coordination, fault detection, and response, this volume provides a detailed understanding of how to design and implement effective protection schemes. Additionally, we explore the growing role of automation and smart control systems in enhancing system reliability, efficiency, and fault tolerance.

Throughout this handbook, you'll find a wealth of knowledge on key topics such as overcurrent protection, differential relays, distance protection, and fault analysis, with real-world case studies and troubleshooting advice to help you navigate complex electrical challenges. Volume 5 also addresses the integration of protection systems with modern communication networks, highlighting how technologies like IEC 61850 are transforming the way protection and control systems are configured and managed.

Whether you are an electrical engineer, technician, or systems operator, Electrical Relays, Protection & Control Handbook, Volume 5 provides you with the tools, best practices, and insights needed to optimize the protection and control of electrical systems, ensuring both safety and operational continuity in today's ever-evolving electrical landscape.

Latest Electrical Protection Articles

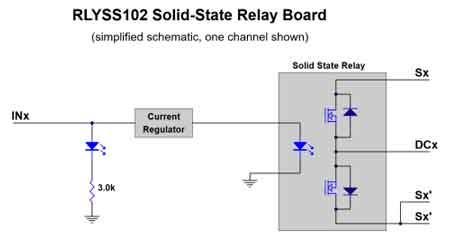

How to Test a Solid State Relay?

Use a multimeter to test a solid-state relay by checking the input voltage, output continuity, and switching function. Ensure the relay switches properly when the control voltage is applied across the input terminals.

How to Test a Solid State Relay?

Testing a solid state relay ensures proper operation and safe electrical system performance.

✅ Use a multimeter to check input and output terminals for voltage and continuity

✅ Apply control voltage to confirm switching functionality

✅ Verify load connection and output behavior under various conditions

Basic Protection Relay Training

Request a Free Training Quotation

Regular testing of solid state relays plays a vital role in ensuring the smooth operation and reliability of control systems. By implementing a combination of off-line and on-line testing procedures, users can proactively identify potential issues with SSRs and prevent costly downtime. Understanding the appropriate testing methods and safety precautions is crucial for maintaining optimal performance and ensuring the safe operation of SSRs within various applications. To ensure accurate testing of solid-state relays and other electrical components, it's essential to understand how to Use a Digital Multimeter, including its voltage, resistance, and continuity settings.

Preparing for Testing

Solid state relays (SSRs) are reliable and durable switching devices, but like all electrical components, they can degrade over time due to thermal stress, overvoltage, or excessive load conditions. Routine testing is essential to ensure these devices continue to operate within their design parameters. Whether used in industrial automation, HVAC systems, or power distribution, a malfunctioning SSR can compromise the performance and safety of the entire system. By implementing a structured testing routine, operators can identify potential issues early, verify the proper functioning of relays, and avoid costly unplanned outages. If you're new to SSRs or want to deepen your understanding of switching devices, start by reviewing the basics of What is an Electrical Relay is and how it differs from solid-state technology.

Required Tools and Equipment

To examine an SSR effectively, you will need:

-

A multimeter with continuity, diode, and resistance measurement functions

-

A controlled DC or AC power source for input signal simulation

-

A known load (e.g., resistive lamp or heater) for output switching validation

-

An oscilloscope for observing switching timing (optional but ideal)

-

A clamp meter or ammeter for current measurement

Importance of SSR Testing

Solid state relays are critical components in many industrial and commercial control systems, offering silent, fast, and reliable switching. However, their solid-state nature means internal failures may not be immediately visible or audible, making regular testing essential. Without proactive testing, a faulty SSR could remain undetected until it causes a system malfunction or downtime. Understanding why SSR testing matters—and how it contributes to system reliability, efficiency, and troubleshooting accuracy—helps maintenance teams prioritize it as part of a standard preventive maintenance routine. Protecting control systems requires proper circuit design, including the integration of an Overcurrent Protective Device to prevent equipment damage from excessive current flow.

Regular testing of SSRs is essential for several reasons:

-

Preventative Maintenance: Early detection of potential issues within an SSR can help prevent unexpected equipment failures and costly downtime.

-

Performance Verification: Testing ensures that SSRs continue to meet their specified switching speeds, load handling capabilities, and control signal requirements.

-

Troubleshooting: In case of equipment malfunctions within a control system, testing SSRs helps isolate the root cause of the issue.

There are two primary approaches to testing SSRs:

-

Off-Line: This method involves removing the SSR from the control system for a more comprehensive evaluation.

-

Online: This approach enables testing the SSR while it remains installed within the system, thereby minimizing downtime.

When troubleshooting malfunctioning circuits, it’s important to understand what is an Electrical Fault and recognize the various causes and consequences of electrical faults, which can stem from short circuits, ground faults, or overload conditions.

Off-Line Testing Methods

This offers a more controlled environment for evaluating SSR performance. Here are some common off-line testing procedures:

-

Visual Inspection: A basic yet crucial step involves visually inspecting the SSR for any signs of physical damage, such as burns, cracks, or discoloration on the housing. Additionally, checking for loose connections or corrosion on terminals is essential.

-

Input LED Diode: Using the multimeter’s diode mode, check the SSR’s input terminals. The forward voltage drop across the internal opto-isolator LED should fall within 1.0–1.5 V DC range. No reading could indicate a failed input circuit.

-

Control Signal Functionality: This inspection verifies the SSR's response to the control signal. A DC power supply can be used to provide a voltage within the specified control signal range. If the SSR is operational, applying the control signal should activate the output circuit as expected.

-

Load Current: With the SSR isolated from the actual load, a controllable current source can be used to simulate the load current. By gradually increasing the current and monitoring the voltage drop across the SSR, its ability to handle the intended load can be assessed. It's important to ensure the current doesn't exceed the SSR's rated capacity.

-

On-Resistance Measurement: With the SSR turned "on" under load, use a low-resistance meter to measure the output resistance. Values should be low (typically <1 Ω). Higher resistance may indicate internal contact wear or overheating.

-

Leakage Current Measurement: A sensitive multimeter can be used to measure the leakage current between the input and output circuits of the SSR when it's in the off state. Excessive leakage current can indicate internal degradation within the SSR and may necessitate replacement.

-

On-Resistance Measurement: The on-resistance of the SSR represents the resistance offered by the switching element when it's conducting. A low-resistance meter can be used to measure this value. The measured on-resistance should be within the manufacturer's specifications for the specific SSR model. An increase in on-resistance can indicate potential wear and tear within the switching element.

On-Line Testing Methods

This allows for a quick assessment of SSR functionality without system downtime. However, these methods may not be as comprehensive as off-line examination. Here are some common online approaches:

-

Control Signal Verification: Similar to the off-line method, a voltage meter can be used to measure the control signal voltage at the SSR's input terminals while the control system is operational. This verifies that the SSR is receiving the appropriate control signal.

-

Output Voltage Monitoring: For AC SSRs, a voltmeter can be used to measure the voltage across the load while the SSR is activated. A similar approach can be used with DC SSRs. In both cases, the measured voltage should be close to the supply voltage, indicating proper conduction through the SSR.

-

Functional Load Testing: Use a live load (e.g., incandescent lamp) to verify that the SSR properly completes the circuit when control voltage is applied. Absence of load can lead to misleading results, as some SSRs won’t switch visibly without it.

-

Pulse and Switching Delay Observation (Advanced): An oscilloscope can help measure switching response time and verify zero-cross behavior (if applicable). This is especially useful for high-speed applications and timing-sensitive circuits.

-

Temperature Monitoring: Using a non-contact temperature sensor, the SSR's housing temperature can be monitored during operation. An abnormal rise in temperature can be a sign of internal issues within the SSR and may warrant further investigation or replacement.

-

System Performance Observation: Carefully observing the overall performance of the control system can provide clues about potential SSR malfunctions. Signs like flickering lights, erratic motor behavior, or unexpected equipment shutdowns may indicate issues with the SSRs controlling those functions.

Safety Considerations During Testing

Safety is paramount when testing SSRs, especially when dealing with high voltages or currents. Ensure all equipment is properly grounded and follow standard electrical safety procedures to prevent accidents.

Safety is paramount when testing SSRs, especially during off-line testing procedures. Here are some crucial safety practices to follow:

-

Always refer to the manufacturer's datasheet for specific testing instructions and safety precautions.

-

Ensure the power supply is disconnected and all capacitors are discharged before handling the SSR.

-

Use appropriate personal protective equipment (PPE) such as safety glasses and gloves when working with electrical components.

-

Never exceed the SSR's rated voltage, current, or power handling capabilities during testing.

-

Be mindful of potential hot surfaces during on-line testing, especially when using temperature sensors

-

If any discrepancies are identified during testing, further investigation or replacement of the SSR may be necessary. It's important to consult the manufacturer's recommendations for troubleshooting and replacement procedures.

Maintaining Optimal Performance with SSR Testing

Regular testing of solid state relays plays a vital role in ensuring the smooth operation and reliability of control systems. By implementing a combination of off-line and on-line testing procedures, users can proactively identify potential issues with SSRs and prevent costly downtime. Understanding the appropriate testing methods and safety precautions is crucial for maintaining optimal performance and ensuring the safe operation of SSRs within various applications.

Related Articles

Overcurrent Protection Device Explained

An overcurrent protection device (OCPD) is designed to automatically interrupt electrical flow when excessive current occurs, preventing equipment damage and fire hazards. Common OCPDs include fuses and circuit breakers used in industrial electrical systems.

What is an Overcurrent Protection Device?

An overcurrent protection device (OCPD) is a crucial component of modern electrical systems, ensuring the safety of circuits and equipment by interrupting the flow of electricity in the event of an overcurrent situation. It:

✅ Prevents electrical fires and equipment damage by limiting current flow

✅ Includes fuses, circuit breakers, and protective relays

✅ Essential for safe residential, commercial, and industrial systems

Basic Protection Relay Training

Request a Free Training Quotation

Overcurrent occurs when the current flowing through a circuit exceeds its safe limit, which can result from a short circuit, ground fault, or overload. OCPDs detect these dangerous conditions and either open the circuit or interrupt current flow to protect conductors and equipment. By doing so, they reduce the risk of electrical fires, arc flash hazards, and costly downtime. Understanding the types of overcurrent protection devices is essential for designing systems that comply with OCPD standards, NEC, NFPA, and UL requirements.

Device Types

Overcurrent protection devices provide defence against electrical faults, short circuits, or overloads. Whether safeguarding residential wiring, industrial panels, or utility substations, these devices maintain safe operation by detecting abnormal current levels and triggering interruption before damage occurs.

-

Fuses react instantly to high current and are cost-effective for sensitive equipment.

-

Circuit breakers offer resettable protection, with advanced designs featuring trip curves tailored to various applications.

-

Protective relays coordinate large-scale systems, including switchgear and substations.

-

GFCIs and AFCIs protect residential systems against ground faults and arc faults.

Choosing the right device often means comparing fuse vs circuit breaker coordination. While fuses offer speed and precision, breakers provide reset capability and are easier to maintain in industrial or utility-scale systems. Proper protective relay coordination also ensures safe operation in complex power systems.

Selectivity and Coordination

Selectivity, or protective coordination, ensures that only the device closest to a fault trips, preserving continuity of service. Poor coordination can result in nuisance tripping, causing the shutdown of entire feeders unnecessarily. By matching time-current curves of upstream and downstream devices, engineers ensure selective isolation of faults. Devices such as circuit protection devices are designed to detect faults and isolate affected sections, ensuring safety and reliability.

Poor selectivity can lead to nuisance tripping, where a small downstream fault disables an entire feeder or facility. By properly coordinating the time-current characteristics between devices (such as fuses and circuit breakers), engineers can ensure that only the affected portion of a circuit is de-energized.

Key Concepts:

-

Upstream vs. downstream devices: The upstream device (e.g., main breaker) should have a delayed response compared to downstream breakers.

-

Zone Selective Interlocking (ZSI): Some systems utilize digital communication between breakers to dynamically adjust trip times, thereby improving selectivity.

-

NEC 240.12 recommends documented coordination studies for essential systems.

Simplified OCPD Comparison Table

| Device Type | Function | Response Time | Typical Use |

|---|---|---|---|

| Fuse | Melts to open circuit | Instant to fast | Residential panels, small electronics |

| Circuit Breaker | Trips to stop current flow | Fast (resettable) | Homes, offices, distribution boards |

| Thermal Breaker | Detects overload via heat | Slower (delayed trip) | Motors, lighting, HVAC systems |

| Protective Relay | Sends a trip signal when a fault is detected | Programmable | Substations, industrial switchgear |

| GFCI | Trips on ground faults | <1 second | Bathrooms, kitchens, outdoor outlets |

| AFCI | Detects dangerous arc faults | <1 second | Bedrooms, wall wiring, new construction |

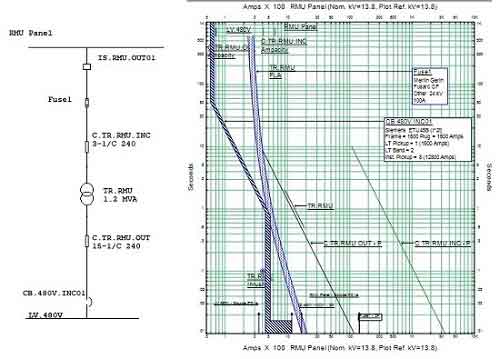

Time-Current Curves

A time-current curve (TCC) graphically represents the relationship between the magnitude of current and the trip time for an overcurrent protection device. It allows engineers to compare the performance of various devices to ensure selective operation.

Curve Characteristics:

-

X-axis: Multiple of rated current (e.g., 1x to 100x)

-

Y-axis: Time to trip (milliseconds to seconds)

-

Steep slopes: Fast-acting fuses

-

Flat slopes: Inverse-time breakers with delays

Using these curves, designers can overlay devices to ensure that downstream protection activates before upstream protection, vital for selectivity and compliance.

Example:

-

A 20A branch breaker may trip in 0.1s at 100A, while a 100A main breaker delays for 1s at the same current level.

Applicable Standards and Codes

Overcurrent protection devices are governed by multiple electrical safety codes and international standards, ensuring devices operate safely and reliably:

Key Standards:

-

NEC Article 240: Overcurrent protection for conductors and short-circuit ratings.

-

NFPA 70E: Reduces arc flash hazards through properly rated OCPDs.

-

UL 489: Testing for molded case circuit breakers.

-

IEC 60269 / IEC 60947: Global fuse and breaker standards.

-

ANSI C37: Protective relay and breaker operation.

Compliance with these standards ensures that the selected devices:

-

Are appropriately rated for interrupt capacity

-

Match the load characteristics

-

Conform to local safety regulations

Real-World Scenarios: How OCPDs Respond

-

Industrial motor overload: A thermal breaker protects conveyors, HVAC systems, and pumps from overheating.

-

Residential short circuit: A fuse blows instantly in a lighting circuit, preventing the insulation from melting.

-

Arc fault in outlet: AFCI disconnects sparking outlets to prevent fire.

-

Utility feeder fault: The relay detects a ground fault and trips only the affected feeder breaker, thereby preserving system reliability.

Modern systems benefit from protective relays and multifunction relays, which offer fast and intelligent responses to electrical faults.

Frequently Asked Questions

What is the interrupting capacity of an OCPD?

Interrupting rating defines the maximum short-circuit current the device can safely withstand. Selecting a device with an insufficient rating can result in catastrophic failure. Understanding the role of current-limiting fuses can help reduce the energy loss during a short-circuit event.

How do OCPDs reduce arc flash risk?

By clearing faults quickly and using current-limiting designs, OCPDs minimize incident energy. Proper relay coordination and arc-flash studies further reduce hazards. Learning about different types of short circuit faults in power systems helps ensure that your protective strategy matches your application’s fault characteristics.

What is selective coordination, and why is it required by NEC?

Selective coordination ensures only the affected device trips. NEC 240.12 mandates coordination studies for critical systems, such as hospitals and data centers, to guarantee service continuity. Selecting the correct circuit breaker type is crucial for effective short-circuit fault mitigation, particularly in industrial and high-load environments.

What are the different types of overcurrent protection devices?

Fuses, breakers, relays, AFCIs, and GFCIs provide tailored protection across residential, industrial, and utility systems.

How do you select the appropriate OCPD?

Selection depends on load type, interrupting rating, short-circuit withstand requirements, and compliance with NEC guidelines. Current-limiting fuses and relays are essential for high-energy fault environments.

What is the key difference between fuses and circuit breakers

Fuses must be replaced after operation, but they offer speed and precision. Breakers, on the other hand, are resettable and more practical for large installations. Fuse vs circuit breaker coordination is a critical design step.

A thorough short circuit analysis, combined with regular system testing and review of fault current ratings, is essential. Consulting with an electrical engineer ensures your protective devices are correctly rated and coordinated for your specific load and environment.

Related Articles

Fuse Types Explained

Fuse types cover blade, cartridge, glass, and resettable PTC options for circuit protection, with fast-acting or time-delay ratings, AC/DC compatibility, voltage and amperage classes, and standards like IEC, UL, and DIN for safety.

What Are Fuse Types?

Fuse types classify overcurrent protection by form, speed, and ratings to safely interrupt faults.

✅ Common forms: blade, cartridge, glass tube, resettable PTC.

✅ Operating traits: fast-acting vs time-delay (slow-blow).

✅ Key specs: voltage, amperage, interrupt rating, approvals (UL, IEC).

Fuses are crucial in protecting electrical systems from damage caused by overcurrents or short circuits. By understanding the various fuse types, you can ensure the safety and efficiency of your electrical circuits. For a concise overview of what a fuse does and how it behaves under fault conditions, see this guide to what a fuse is for foundational context.

There are several fuse types, each designed for specific applications and purposes. The most common types include AC fuses and DC fuses, automotive cartridge, high rupturing capacity (HRC), and high voltage. Other less common fuse types include Type S, Type T, Type D, and Type P. These categories sit within the broader family of circuit protection devices that safeguard conductors and loads.

AC and DC

AC fuses and DC fuses differ primarily in their voltage ratings and the nature of the electrical arcs they extinguish. AC ones can interrupt alternating current, while DC ones are designed to handle the direct current. Voltage ratings determine the maximum voltage the fuse can safely handle without breaking down. Understanding these distinctions supports proper overcurrent protection coordination practices across systems.

Automotive

Automotive kinds are specifically designed to protect the electrical circuits within vehicles. These are typically smaller and have lower voltage ratings than those used in residential or commercial applications. Blade ones, a subtype of automotive fuse, are widely used due to their compact design and ease of installation. They differ from other types in that they have a thin, flat metal strip rather than a cylindrical body. In automotive and low-voltage panels, it can be helpful to compare options alongside different circuit breaker types to choose serviceable solutions.

Cartridge fuses are cylindrical ones enclosed in a tube made of either glass or ceramic. Glass kinds allow for easy visual inspection. In contrast, ceramic types offer better protection against high temperatures and are more durable. In addition, the fuse elements within cartridge fuses are designed to melt and break the circuit when an overcurrent occurs.

HRC

High rupturing capacity (HRC) fuses are designed to handle high current loads and interrupt large fault currents. They contain a wire enclosed in a ceramic body filled with an arc-quenching material. HRC kinds are commonly used in power transformers and other high-power applications. Where high fault energy must be limited quickly, engineers often specify a current-limiting fuse to reduce let-through energy.

High Voltage

High voltage ones are used in electrical systems with voltage ratings above 1,000 volts. They are designed to protect electrical equipment, such as transformers, from damage caused by overcurrents and short circuits. High voltage fuses can also be found in power distribution networks and industrial applications. Distribution networks that protect overhead transformers may use a transformer cutout fuse for coordinated isolation.

Type S and T

Type S and Type T types are time-delay, designed to tolerate brief overcurrents without tripping. They are used in circuits with motors, transformers, or other inductive loads that can cause temporary current surges. Type S is typically used in residential applications, while Type T is more common in industrial settings.

Type D or P

Type D or P are also known as semiconductor fuses. They are specifically designed to protect sensitive electronic devices, such as integrated circuits and power transistors, from damage caused by overcurrents. They have a very fast-acting response time and a low voltage drop, ensuring minimal disruption to the electrical system.

When choosing the right fuse for your application, it's essential to consider the type of electrical system, voltage ratings, and the specific devices being protected. It's also crucial to understand the difference, such as cartridge and glass or rewirable fuse, which can be reset by replacing the fuse wire after a fault has been cleared.

Various kinds are essential protective devices in electrical systems, designed to prevent damage and ensure safety. By understanding the different ones and their applications; you can select the most appropriate one for your needs and maintain a safe and efficient electrical system. Comprehensive planning should also address short-circuit protection so that devices operate safely under worst-case faults.

Related Articles

Maximum Fault Current Calculation Explained

Maximum fault current calculation quantifies short-circuit current using source impedance, transformer data, and conductor reactance for protective device coordination, equipment rating, arc flash studies, and IEC 60909 compliant fault level assessments.

What Is Maximum Fault Current Calculation?

Maximum fault current calculation estimates short-circuit current to size protective devices and verify ratings.

✅ Apply IEC 60909 or ANSI C37 short-circuit methods

✅ Include source, transformer, and line impedances

✅ Validate breaker kAIC, bus bracing, and arc-flash labels

Maximum Fault Current Calculation

In order to determine maximum fault current in either a single-phase circuit or a three-phase circuit, you need to perform a calculation involving impedance. Total impedance is the sum of the impedances of the conductors from the origin of the installation to the circuit under consideration. For single phase circuits, the maximum fault current is between the phase and the neutral and in three-phase circuits the maximum fault current is when all phases are shorted (symmetrical current). The total impedance is that with operating temperature 20 degrees C (lower temperature means lower resistance).

For a concise refresher on definitions, see what is fault current to align terminology used here.

Power System Protection Courses

For broader context on relaying, coordination, and device schemes, consult power system protection as you plan your studies.

Short Circuit Study & Protective Device Coordination

Arc Flash Analysis/Study - IEEE 1584 Update

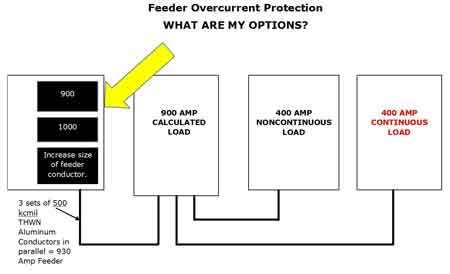

Maximum fault current calculations should be performed at all critical points in the system including:

- Service entrance equipment

- Transfer switches

- Panelboards

- Load centers

- Motor control centers

- Disconnects

- Motor starters

Normally, fault current studies involve calculating a bolted three-phase fault condition. This can be characterized as all three phases “bolted” together to create a zero impedance connection. This establishes a “worst case” (highest current) condition that results in maximum three- phase thermal and mechanical stress in the system.

To compare bolted faults with unsymmetrical events, review types of short-circuit faults to understand characteristic currents.

From this calculation, other fault condition types can be approximated. This “worst case” condition should be used for interrupting rating, component protection, “Table” method for determining PPE per NFPA 70E and selective coordination. In practice, quantifying available fault current at equipment line terminals informs PPE selection and device ratings.

Arc flash hazard analysis calculations should consider both maximum and minimum fault current calculations. Incident energy depends upon current and time. For lower arcing current values, clearing times could be longer than those for higher arcing current values, which could result in higher incident energy values. Therefore, an arc flash analysis must consider both spectrum of available fault current for calculating arcing currents, which are then compared with OCPD TCC curves to determine clearing times. Effective selection of TCCs starts with grasping overcurrent protection concepts that shape device behavior.

There are several variables in a distribution system affecting calculated bolted three-phase fault currents. Variable values applicable for the specific application analysis must be selected. The point-to-point method presented in this section includes several adjustment factors given in notes and footnotes that can be applied, and that will affect results. Some of the parameters that must be considered include utility source fault current, motor contribution, transformer percent impedance tolerance and voltage variance.

A step-by-step point-to-point example is summarized in fault current calculation to streamline hand calculations.

In most situations, the utility source(s) or on-site energy sources (such as generators) are the major fault current contributors. The point-to- point method includes steps and examples that assume an infinite available fault current from the utility source. Generally, this is a good assumption for highest, worst case conditions since the property owner has no control over the utility’s system and future utility changes. In many cases, a large increase in the utility available fault current does not increase the building system’s fault current a great deal on the secondary of the service transformer. However, there are cases where the actual utility medium voltage available fault current provides a more accurate fault current assessment (minimum bolted fault current conditions) that may be needed to assess arc flash hazards.

Coordinating primary and secondary devices should consider transformer protection practices to balance sensitivity and security.

When motors are in the system, motor fault current contribution is also a very important factor to include in any fault current analysis. When a fault occurs, motor contribution adds to the fault current magnitude, with running motors contributing four to six times their normal full load current. Series rated combinations can’t be used in specific situations due to motor fault current contributions.

For short time duration capacitor discharge currents, certain IEEE (Institute of Electrical and Electronic Engineers) publications detail how to calculate these currents if they are substantial.

Read Other Electrical System Protection Articles

Transformer Protection Explained

Related Articles

Metal Clad Switchgear Protection Explained

Metal clad switchgear offers medium-voltage power distribution with arc flash protection. Its compartmentalized design enhances safety, supports reliable operation, and simplifies maintenance in industrial, commercial, and utility electrical systems.

What is Metal Clad Switchgear?

Metal clad switchgear is a type of medium-voltage electrical switchgear with separately enclosed compartments for added protection and serviceability.

✅ Enhances safety by isolating live components in metal-enclosed compartments

✅ Simplifies maintenance with draw-out circuit breakers

✅ Ideal for industrial, utility, and commercial applications

Basic Protection Relay Training

Request a Free Training Quotation

It is a critical component in modern electrical infrastructure, providing safe and reliable power distribution across various sectors. From bustling industrial plants and commercial complexes to essential institutions like hospitals and universities, this technology ensures the seamless operation of critical equipment and processes. Let's explore the key aspects that make it indispensable for today's power requirements.

To understand how metal clad switchgear fits into broader system safety, see our full guide on electrical protection, covering technologies that reduce risk across medium-voltage environments.

Safety Features

When dealing with electricity, safety is non-negotiable. metal clad switchgear is engineered with a multitude of safety features to protect both personnel and equipment. Constructed according to the stringent IEEE C37.20.2 standard, these units boast a robust metal enclosure that shields live parts from accidental contact. Effective insulation plays a vital role in preventing short circuits and ensuring safe operation. Furthermore, many modern units incorporate advanced arc flash protection, minimizing the risk of dangerous arc flash incidents that can lead to serious injuries. Thorough training for personnel interacting with this equipment is crucial to ensure safe operation and that maintenance procedures are diligently followed. Proper arc fault circuit interrupter protection is essential in switchgear design to mitigate hazards caused by arc flash incidents.

Reliable Power Distribution with Circuit Breaker Switchgear

Uninterrupted power distribution is the lifeblood of industrial, commercial, and institutional facilities. metal clad switchgear contributes significantly to this reliability by housing vital components like circuit breakers. These circuit breakers act as protective sentinels, swiftly interrupting the flow of electricity in the event of a fault or overload. This rapid response prevents damage to downstream equipment and minimizes costly downtime. Utilizing high-quality components and implementing a rigorous maintenance program ensures the long-term reliability of the power circuit and the overall stability of the electrical system. Circuit breakers play a key role in system reliability—learn more about different circuit breaker types used in medium-voltage switchgear.

Industrial and Commercial Applications

Metal clad switchgear finds its place in a diverse array of applications across various sectors. In industrial settings, it powers heavy machinery, intricate production lines, and essential processes. Commercial buildings rely on it for lighting, HVAC systems, and other vital services. Institutions, including hospitals and data centers, depend on it for an uninterrupted power supply to life-saving equipment and sensitive data systems. Whether it's within an electrical substation or at the heart of a manufacturing plant, metal clad switchgear provides a safe and dependable solution for controlling and distributing power. If you're analyzing system capacity, explore how available fault current impacts the performance and safety of metal clad installations.

Maintenance Best Practices

Maintaining the safe and reliable operation of metal clad switchgear demands a comprehensive maintenance program. Regular inspections are crucial for identifying signs of wear and tear, loose connections, or potential insulation failures. Testing procedures, including insulation resistance tests and circuit breaker operation checks, should be carried out periodically to verify the integrity of the system's components. A proactive maintenance strategy helps prevent unexpected failures, extends the equipment's lifespan, and minimizes disruptive downtime. Coordination between relays and breakers is vital in protection schemes—read about relay and circuit breaker coordination to optimize your setup.

Comparing Switchgear Types: Metal Clad vs Metal Enclosed

While metal clad switchgear offers a high level of protection and performance, other types cater to specific applications and budget considerations. For instance, metal-enclosed switchgear offers a cost-effective alternative for medium-voltage applications with lower fault current requirements. When unique needs arise, a custom solution can be engineered to meet the specific demands of a particular installation. Understanding the nuances of different types, including high voltage and indoor options, empowers engineers to select the most suitable solution for their electrical system.

Metal clad switchgear must be supported by effective overcurrent protection devices to detect and isolate faults quickly.

For engineers selecting between switchgear options, our article on what is switchgear offers a helpful overview of types, functions, and design considerations.

Frequently Asked Questions

What is the purpose of metal clad switchgear?

Metal clad gear serves to safely and reliably control and distribute electrical power in demanding environments, protecting personnel and equipment from electrical hazards while ensuring the continuous operation of critical systems.

Is metal clad switchgear safe?

Yes, metal clad gear is meticulously designed with numerous safety features, including a robust metal enclosure, insulation, and arc flash protection, to minimize risks to both personnel and equipment.

What are some key characteristics of metal clad gear?

Key characteristics include a grounded metal enclosure, compliance with IEEE C37.20.2 standards, and the inclusion of various components like circuit breakers, disconnector switches, and busbars for efficient power distribution.

What is the main feature of arc-resistant metal clad gear?

The main feature of arc-resistant metal clad gear is its ability to withstand and contain the destructive effects of an internal arc fault, minimizing damage and protecting personnel from harm.

Related Articles

Power System Protection

Power system protection ensures the reliable operation of electrical grids by detecting faults, isolating failures, and safeguarding equipment and personnel. It maintains stability, improves safety, and supports compliance with industry standards.

What is Power System Protection?

Power system protection is a coordinated set of devices and methods designed to detect, isolate, and minimize the impact of electrical faults in electrical networks.

✅ Detects and clears faults to maintain grid stability

✅ Protects transformers, lines, and switchgear from damage

✅ Enhances safety, reliability, and compliance with standards

Power System Protection Courses

Short Circuit Study & Protective Device Coordination

Arc Flash Analysis/Study - IEEE 1584 Update

An important consideration in electrical system design is power system protection. Without system protection, the power system itself, which is intended to be of benefit to the facility in question, would itself become a hazard. Training in basic protective relay equips professionals with the knowledge to design, test, and maintain critical protection systems.

The major concern for power system protection is protection against the effects of destructive, abnormally high currents. These abnormal currents, if left unchecked, could cause fires or explosions, posing a risk to personnel and damaging equipment. Other concerns, such as transient overvoltages, are also considered when designing power system protection, although they are typically addressed only after protection against abnormal currents has been established. Understanding overcurrent protection is essential, since abnormal fault currents can cause fires, explosions, and equipment damage if not properly managed.

Characterization of power system protection faults

Any current in excess of the rated current of equipment or the ampacity of a conductor may be considered an overcurrent. Overcurrents can generally be categorized as overloads or faults. An overload is a condition where load equipment draws more current than the system can safely supply. The main hazard with overload conditions is the thermal heating effects of overloaded equipment and conductors. Faults are unintentional connections in the electrical system that result in overcurrents of a magnitude much larger than overloads. Protective relay technology forms the backbone of fault detection, ensuring fast and accurate isolation of dangerous conditions within the grid.

Electrical Faults

Faults can be categorized in several different ways. A fault with very little impedance in the unintended connection is referred to as a short circuit or bolted fault (the latter term is used due to the fact that a short circuit can be thought of as a bus bar inadvertently bolted across two phase conductors or from phase to ground). A fault to ground is referred to as a ground fault. A fault between all three phases is referred to as a 3-phase fault. A fault between two phases is referred to as a phase-to-phase fault. A fault that contains enough impedance in the unintentional connection to significantly affect the fault current compared to a true short circuit is known as an impedance fault. An arcing fault occurs when an unintentional connection is made via an electrical arc through an ionized gas, such as air. All of these terms are used in practice to characterize the nature of a fault.

In order to quantitatively characterize a fault, it is necessary to calculate how much fault current could be produced at a given location in the system. In most cases, this will be the three-phase short-circuit current, which is the current produced if all three phases were shorted to each other and/or to ground. The simplest method for illustrating this is to reduce the power system at the point in question to its Thevenin equivalent. The Thevenin equivalent is the equivalent single voltage source and impedance that produces the same short-circuit results as the electrical system itself. The Thevenin equivalent voltage Vth is the open-circuit voltage at the point in question, and the Thevenin equivalent impedance Zth is the impedance of the electrical system at the point in question with the source voltage equal to zero. If a further simplification is made such that the system can be reduced to its single-phase equivalent, then a simple 3-phase fault current calculation for the three-phase fault current If3ø can be performed as shown in Figure 1:

Fig. 1 - Simplified 3-phase fault calculation

The Thevenin impedance for a electrical system at a given point is referred to as the short-circuit impedance. In the vast majority of power systems, the short-circuit impedance is predominantly inductive; therefore, a simplification often made is to treat the impedance purely as inductance. This has the effect of causing the fault current to lag the system line-to-neutral voltage by 90°. If the system is an ungrounded delta system, the equivalent line-to-neutral voltage can be obtained by performing a delta-wye conversion of the source voltage. Engineers often apply relay and circuit breaker coordination to ensure that faults are cleared in the correct sequence, thereby minimizing disruptions to the electrical system.

The phase-to-phase fault value can be calculated from the three-phase fault value if it is remembered that the line-to-line voltage magnitude is equal to the line-to-neutral voltage magnitude multiplied by √3, and that there will be twice the impedance in the circuit since the return path must be considered. These two facts, taken together, allow computation of the line-to-line fault current magnitude. Advanced short circuit protection strategies help utilities and industries maintain safe operating conditions even during severe fault events.

A key part of system defense is transformer protection, which safeguards critical assets against overloads, faults, and insulation failures.

Related Articles