Electrical Engineering

Understanding DC Voltage Drop Calculation

DC voltage drop calculation determines energy lost through resistance in a DC circuit. It’s critical for efficient design, proper wire sizing, and ensuring devices receive the right voltage without performance issues, especially in long wiring runs.

Power Quality Analysis Training

Request a Free Power Quality Training Quotation

What is "DC voltage drop calculation"?

DC voltage drop calculation determines the voltage loss along a DC circuit due to conductor resistance.

✅ Ensures proper voltage reaches devices

✅ Helps size conductors to minimize losses

✅ Prevents system inefficiencies and malfunctions

Learn more about voltage dropping and its impact on power quality.

DC Voltage Drop Calculation - In electrical design, calculating voltage drop is essential, particularly in direct current (DC) systems. Voltage drop refers to the loss of electrical potential as current flows through a conductor, typically caused by resistance. This energy loss can impact system performance, especially in circuits with long wiring runs or undersized conductors. Need a quick estimate? Try our voltage drop calculator for fast DC system planning.

How do you calculate voltage drop in a DC circuit?

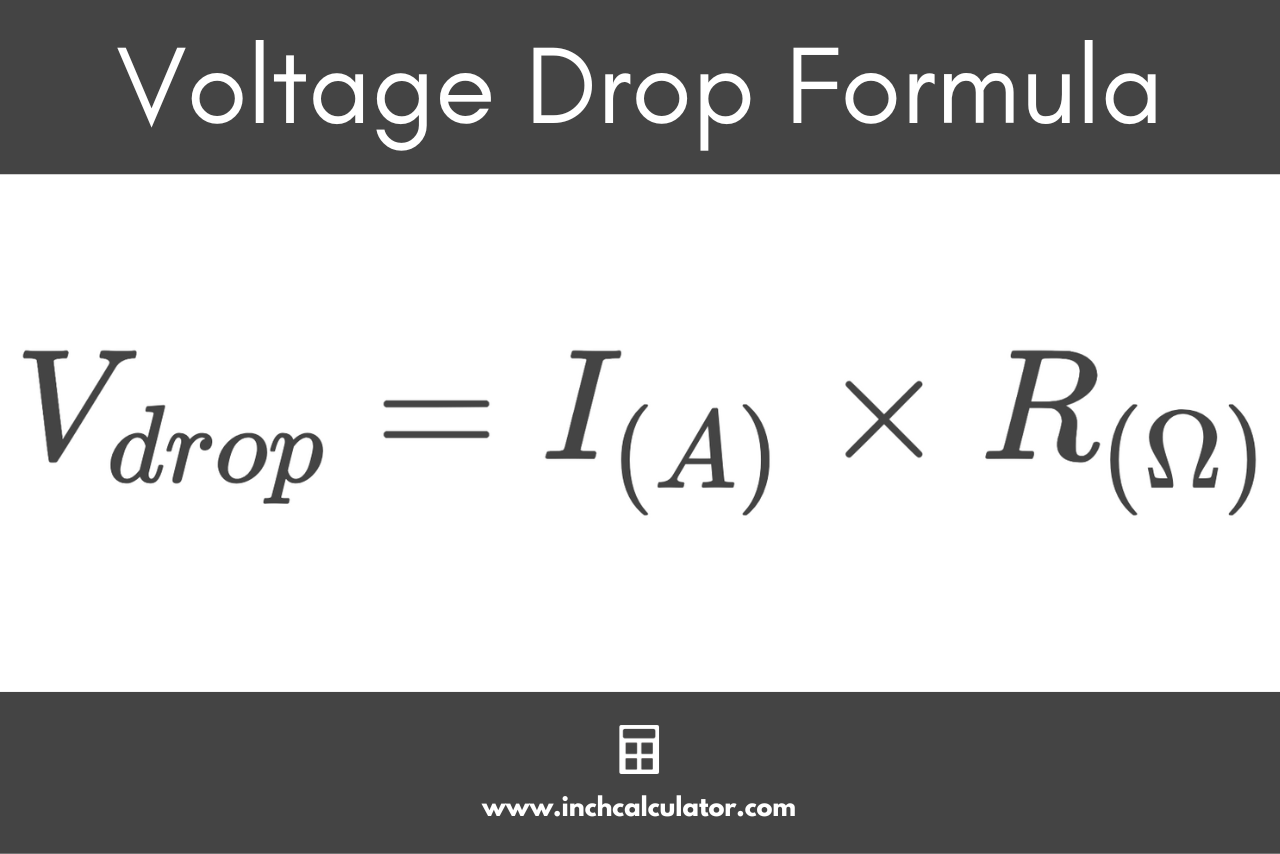

To calculate voltage drop in a DC circuit, you can use the formula:

V drop = I × R

Where V drop is the voltage drop, I is the current in amperes, and R is the conductor’s resistance in ohms. Resistance is influenced by factors such as wire length, wire size (gauge), and material. A voltage drop calculator can be used to quickly determine losses, taking into account wire length and size. For more accurate calculations, some tools also account for the effects of temperature and other variables. Want the full math? Visit our voltage drop formula guide for detailed equations and examples.

Frequently Asked Questions

What is the acceptable percentage for DC voltage drop?

The acceptable percentage of voltage drop depends on the type of circuit. Typically, for power and lighting circuits, a voltage drop of no more than 3% is ideal. According to the National Electric Code (NEC), the total system voltage drop, including branch circuits and feeders, should not exceed 5%. Maintaining low voltage drops ensures devices receive enough electrical potential to function properly without significant energy loss. For an overview of the general principles of voltage drop across AC and DC systems, read our article.

How does wire length and size affect DC voltage drop?

Wire length and wire gauge are key factors in determining the voltage drop in a circuit. As wire length increases, so does resistance, leading to a higher voltage drop. Similarly, smaller wire sizes (thinner wires) have more resistance than larger ones. Wire size, often measured in circular mils, plays a crucial role in minimizing voltage loss. By selecting wires with a larger cross-sectional area, you can reduce resistance and minimize energy loss, particularly in circuits designed to carry larger loads over longer distances.

What is the difference between voltage drop in AC and DC circuits?

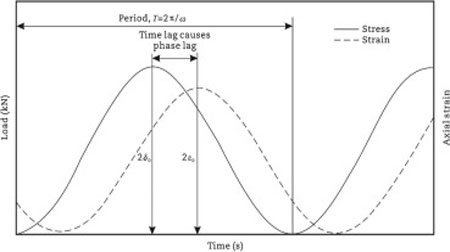

Voltage drop occurs in both AC and DC circuits, but the difference lies in the factors contributing to it. In DC systems, voltage drop is purely a function of resistance, whereas in AC systems, both resistance and reactance must be considered. Reactance occurs due to the presence of inductance and capacitance in the circuit. Therefore, calculating voltage drop in an AC system is more complex, as it involves factors such as phase angle and impedance. However, the same basic principles of wire size, material, and length apply to both AC and DC systems.

How can you minimize voltage drop in a DC system?

To minimize voltage drop in DC systems, several approaches can be used. First, reducing wire length in the design will naturally reduce resistance. Second, using the correct wire gauge based on the load and distance is critical. A voltage drop calculator helps determine the optimal wire size for a specific system. Ensuring clean, proper connections throughout the circuit also plays a role in minimizing energy loss. For circuits carrying single-phase loads or mixed AC and DC systems, maintaining balance using methods like zig-zag transformers can improve overall efficiency.

DC Voltage Drop Calculation

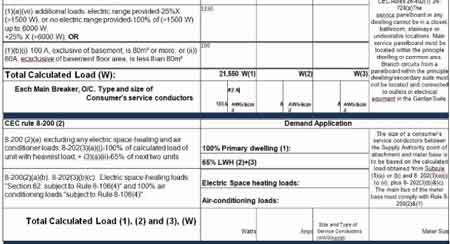

In North America, electrical systems follow guidelines established by the National Electric Code to ensure safety and performance. By using proper voltage drop formulas and selecting the appropriate wire length, gauge, and material, engineers can optimize the performance of DC circuits. Tools like voltage drop calculators facilitate the design of systems that minimize energy loss and ensure reliable operation. These methods help maintain efficient power delivery while meeting regulatory requirements.

Related Pages

Download Our FREE Arc Flash Handbook

Electrical Safety and Arc Flash Handbook, Vol. 6

Far and away our biggest seller, the Safety/Arc Flash technical handbook continues to provide a valuable resource for people and companies looking to provide the maximum protection with the minimal risk.

The Electrical Safety and Arc Flash Handbook, Vol. 6 is designed to be an indispensable resource for professionals responsible for the safety of electrical systems, equipment, and personnel. In this volume, we delve deeply into the theory and practice of arc flash safety, outlining the steps needed to assess, mitigate, and prevent the potentially devastating consequences of an arc flash event.

This handbook offers a clear and practical approach to electrical safety, with a focus on arc flash hazard analysis, risk assessments, and the latest safety standards and regulations. We cover essential topics such as the identification of electrical hazards, understanding arc flash calculations, and the implementation of protective measures like personal protective equipment (PPE), proper labeling, and warning systems.

Volume 6 also highlights the importance of proactive safety programs and training initiatives to ensure that workers are equipped with the knowledge to identify and respond to electrical hazards effectively. Real-world case studies, expert insights, and actionable guidance are provided to help organizations minimize risks and foster a safety-first culture in the workplace.

Latest Electrical Engineering Articles

How Can Mastering Electrical Training

Electrical training equips engineers and technicians with hands-on skills in power systems, circuits, NEC code compliance, PLC programming, safety procedures, instrumentation, and troubleshooting, preparing candidates for certification, apprenticeships, and advanced maintenance roles.

What Is Electrical Training?

Instruction in electrical safety and skills to design, troubleshoot, and maintain power and control systems.

✅ NEC/IEC code compliance, arc flash, and lockout/tagout safety

✅ Power systems, distribution, grounding, and fault analysis

✅ PLCs, drives, SCADA, and industrial control troubleshooting

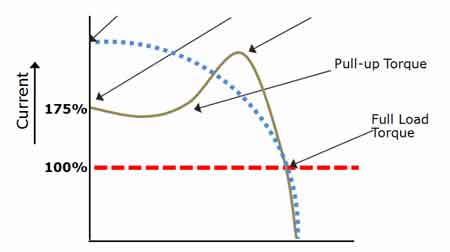

Electrical training is the foundation for a successful career in the dynamic field of engineering. Whether you're starting your journey or looking to advance your skills, continuous learning is essential to stay ahead in this ever-evolving industry. A fundamental concept that is often explored in basic training is understanding starting current, or inrush current. Starting current refers to the surge of current drawn by the device when it is first turned on. This surge is significantly higher than the device’s normal operating current, and understanding this phenomenon is essential for anyone working with systems. Training courses often explain the causes of this surge, such as the low impedance of devices like motors and transformers during startup. Knowing how to manage this surge can prevent common problems, such as tripping circuit breakers or fuses, and can help avoid unnecessary stress on the components of the system. For a structured overview of foundational topics, many professionals consult power system training curricula to align their learning with industry expectations.

Understanding Starting Current and Its Impact in Electrical Training

The causes and implications of starting current are crucial areas covered in power system course programs. For instance, many learners are introduced to the concept that devices, particularly motors, may experience a substantial inrush current due to factors like charging capacitors or the initial resistance to motion. Through hands-on exercises and simulations, training centers enable participants to understand how these surges affect the overall system. The ability to anticipate such surges is vital for preventing voltage dips and minimizing the risk of equipment damage. Knowledge gained in training helps ensure that the right strategies are in place to handle such challenges. Accurate modeling of inrush alongside short-circuit current calculation helps trainees size protective devices with greater confidence.

The effects of starting current are far-reaching, and this is why engineers must be well-trained to mitigate these issues. If left unaddressed, starting current can result in equipment malfunction, damage to sensitive components, or even the failure of an entire system. In an industrial setting, the consequences of a power surge can be severe, leading to costly repairs or downtime. A good power system course program teaches professionals how to properly size protection devices, such as fuses and circuit breakers, and also how to use techniques like star-delta to manage these effects. This training ensures that engineers are capable of mitigating risks while maintaining operational efficiency. Coursework often uses power system analysis and design case studies to show how starting methods influence voltage dips and coordination.

What are the essential skills and knowledge required for a successful career in electrical engineering?

Understanding starting current and its effects, training also equips professionals with various mitigation strategies. For example, soft starters and variable frequency drives (VFDs) are common solutions used to reduce the inrush current and manage the surge more effectively. These strategies, along with inrush current limiters, are often explored in-depth during training. Participants learn how these tools can be used to reduce the stress on the system and improve its overall stability. By being exposed to these strategies, workers are better prepared to implement solutions that align with the unique needs of the systems they work with. When configuring motor starters, practitioners frequently reference 480 V power and current formulas to verify conductor sizing and torque requirements.

Practical Applications and Industry Standards in Electrical Training

Real-world applications of systems are another critical aspect of the power system course. For example, transformers, industrial machinery, and HVAC systems are often featured as examples of systems that experience starting current. Trainees get hands-on experience with these systems, learning how to apply their knowledge in real-world environments. Understanding how starting current affects everything from small household appliances to large industrial equipment is essential for engineers who work across various sectors of the industry. Exposure to medium- and high-voltage equipment underscores why high-voltage electrician training emphasizes safe commissioning practices during energization.

Furthermore, power system course programs help professionals stay up-to-date with the latest industry practices, including understanding the code. The National Electrical Code (NEC) governs the safety and installation of systems, and it is a crucial component of any comprehensive training course. Whether it's understanding how to comply with safety standards or learning new advancements in technology, continuing education is key to staying compliant and ahead in the field. Training programs are specifically designed to cover these codes, ensuring professionals remain knowledgeable and prepared for changes in legislation. Compliance efforts are strengthened by using tools like an electrical load calculator to validate panel schedules and feeder capacities.

How does the power system course help ensure workplace safety?

In terms of career advancement, engineers often pursue certifications to gain specialized knowledge. These certifications are a clear indicator of expertise and are highly valued in the industry. Power system course courses provide the necessary preparation for certification exams, ensuring that professionals are well-equipped to pass and perform effectively in their roles. Specialized certifications allow engineers to branch into areas such as renewable energy systems or advanced automation, expanding their career options. The power system course also addresses safety concerns. Power system work can be hazardous, and having the right training reduces the risk of accidents. Courses often focus on safety protocols, from the correct use of personal protective equipment (PPE) to understanding the best practices for working with live circuits. This focus on safety ensures that all workers are aware of the potential dangers they face and are prepared to act safely and effectively in any given situation. Many roles also benefit from a broader power system engineering perspective that integrates protection, controls, and asset management.

Power system course programs cover a range of essential topics, including codes, safety practices, and the workings of various components. Beyond preparing individuals for industry-recognized certifications, the power system course also focuses on addressing real-world challenges such as managing starting currents and ensuring system protection. Ongoing education in this field helps professionals stay up-to-date with new standards and technological advances, ensuring they are equipped to maintain and improve the safety and functionality of systems.

Related Articles

Phase Rotation Meter

A phase rotation meter determines the sequence of three-phase electrical systems, ensuring correct motor connections and preventing damage to the system. It verifies phase sequence, detects wiring errors, and improves safety in industrial, commercial, and utility power applications.

What is a Phase Rotation Meter?

A phase rotation meter is an indispensable tool for industrial electricians. It ensures the correct sequence in three-phase power systems, preventing potential damage to motors, transformers, and other critical equipment.

✅ Identifies the correct sequence of three-phase power systems.

✅ Prevents motor damage by ensuring proper rotation direction.

✅ Detects wiring faults and improves system reliability.

Power System Fundamentals Training

Short Circuit Study & Protective Device Coordination Training

Arc Flash Analysis/Study Training

By understanding how to use this device, you can guarantee the safety and efficiency of your electrical installations. These systems are widely used in industrial applications because they provide a stable and efficient power supply. The term phase rotation refers to the order in which the phases of an electrical system reach their peak values. This sequence is critical for devices like motors, as it determines the direction in which they rotate. Incorrect phase rotation can result in reverse motor operation, potentially damaging equipment and halting production. A rotational phase tester is specifically designed to detect and indicate the phase sequence, ensuring that systems are installed correctly and function safely. It is a vital tool in electrical engineering, ensuring the proper phase sequence and safe operation of motors and transformers.

Functionality

The role of this meter is straightforward yet vital. By connecting its test leads to the three conductors of a system, the device measures the sequence of the electrical phases. Many modern meters display results through intuitive interfaces, making them user-friendly even for those less experienced. The ability to verify a sequence quickly and accurately minimizes downtime during installations and troubleshooting. Understanding phase rotation is closely related to load flow analysis, which evaluates power distribution and system performance.

Comparison of Phase Rotation Meters and Other Testing Devices

| Device Type | Primary Function | Advantages | Limitations |

|---|---|---|---|

| Phase Rotation Meter | Determines the three-phase sequence | Quick, accurate phase sequence detection | Limited to phase rotation checks |

| Digital Multimeter | Measures voltage, current, and resistance | Versatile, widely available | Cannot directly detect phase rotation |

| Oscilloscope | Visualizes waveforms and signal timing | Detailed phase and signal analysis | Expensive and requires technical skill |

| Clamp Meter | Measures current flow without breaking the circuit | Easy to use for current measurements | Does not indicate phase sequence |

Addressing Starting Current Challenges

A critical aspect of using equipment is managing the starting current or inrush current. This surge of electricity occurs when devices like motors or transformers are first activated, and it can trip circuit breakers if not properly managed. Understanding the relationship between phase sequence and starting current is essential for maintaining system stability. Properly using tools like devices helps mitigate issues caused by these initial electrical surges. Industrial electricians often use this device in conjunction with power system analysis and design to ensure optimal motor connections.

Frequently Asked Questions

What does it do?

It is a specialized electrical testing device used to determine the direction of the rotating magnetic field in a three-phase electrical system. It identifies the sequence in which the three phases (L1, L2, L3) are arranged, which is crucial for ensuring proper motor rotation and the safe operation of equipment. Proper rotation is crucial for motors, generators, and other rotating equipment, as incorrect rotation can lead to malfunction or mechanical damage. Proper sequence verification is a key concept in power system engineering, helping prevent costly equipment failures.

What are the common applications?

From manufacturing plants to HVAC systems, the applications of testers are vast. These devices are particularly crucial when installing or maintaining machinery reliant on three-phase power, such as industrial compressors and large-scale motors. These machines could operate inefficiently or sustain permanent damage without first confirming the rotation. Additionally, they are widely used in power distribution to verify proper connections between transformers and load equipment.

How do you calculate phase rotation?

It is not "calculated" in a mathematical sense but is rather "measured" or "determined" using a rotation meter or an oscilloscope. Here’s how you determine phase rotation:

Use a Meter:

-

Connect the three test probes of the meter to the conductors (L1, L2, L3) of the system.

-

Turn on the device.

-

The meter will display the sequence as either "ABC" (positive rotation) or "CBA" (negative rotation).

Using an Oscilloscope (Manual Method):

-

Connect the oscilloscope probes to the three phases.

-

Observe the waveform

-

The order in which the waveforms cross zero from negative to positive indicates the rotation.

-

Label the order as ABC or CBA, depending on the sequence.

How to test phase rotation with a multimeter?

A standard digital multimeter (DMM) cannot directly measure rotation, as it lacks the capability to detect the sequence. However, you can indirectly check rotation using the following method:

Identify the Phases:

- Identify the three-phase wires L1, L2, and L3.

Voltage Measurements:

- Measure the voltage between L1 and L2, L2 and L3, and L3 and L1 using the multimeter.

- Note the values. In a balanced system, the voltages should be equal.

Compare Relative Voltages:

- If you have access to two separate points (like motor terminals), turn on the motor and observe its direction of rotation.

- If the motor rotates in the opposite direction of what is intended, the rotation is incorrect, and you should swap two of the three-phase connections (like L1 and L2).

Since a multimeter cannot detect the order of the voltages, it is recommended to use a meter for this task.

How to Check the Phase Sequence with a Meter?

To check the sequence, follow these steps:

Turn Off Power: Ensure the system is de-energized before connecting the meter.

Connect the Meter Probes:

- Attach the meter's probes to the three phases (L1, L2, and L3).

- Ensure the probes are properly connected to avoid false readings.

Turn On Power:

- Energize the system.

Check the Display:

- The meter will display the sequence as either ABC (positive sequence) or CBA (negative sequence).

- Some meters have indicator lights or arrows to show the direction.

Interpret the Results:

- If the sequence is incorrect, it can be corrected by swapping two conductors (such as L1 and L2) to change the rotation.

These steps ensure the proper functioning of motors and other equipment that rely on specific rotation for normal operation.

Electricians can enhance their skills with specialized power system training, which often includes hands-on use of rotation meters and testing tools.

Related Articles

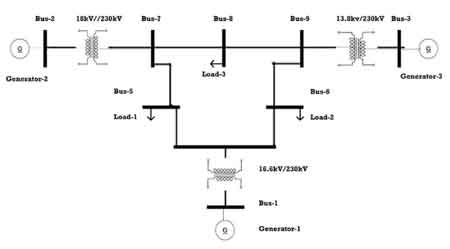

Three-Phase Bus Line Diagram Explained

Three Phase Bus Line Diagram illustrates busbars, feeders, and switchgear in a three-phase system, using single-line schematics for substations, distribution networks, protection coordination, load flow, and fault analysis; wiring, equipment ratings, interlocks.

What Is a Three Phase Bus Line Diagram?

A single-line schematic of three-phase busbars, feeders, and switchgear for power distribution, control, and protection.

✅ Shows busbar arrangements: single, double, ring, and one-and-a-half.

✅ Indicates breakers, isolators, CTs, PTs, relays, and metering.

✅ Supports load flow, fault studies, and protection coordination.

A three-phase bus line diagram is a critical tool for representing the flow of electrical power in large-scale systems such as industrial plants and power distribution grids. This type of diagram illustrates how electricity moves through a phase power system, providing a visual guide to the connections and components involved. It plays a key role in ensuring that power is distributed efficiently and safely across multiple circuits. Understanding the elements of this diagram is essential for engineers, technicians, and anyone involved in electrical design and maintenance.

What is a Three-Phase Bus Line Diagram, and How is it Used in Electrical Systems?

A three-phase bus line diagram provides a graphical representation of how electrical energy is transmitted through a multi-phase power system. Unlike a single-phase system, where electricity flows along one conductor, a three-phase system involves three conductors carrying current. This type of diagram is commonly used in industrial settings and high-power electrical grids to show how electricity is distributed across various parts of the system, including transformers, circuit breakers, and other equipment. It helps operators visualize the configuration of the system and troubleshoot any issues that may arise. For context, engineers often compare three-phase performance to single-phase power fundamentals when explaining differences in conductor use and load balance.

Understanding safe phase-to-phase connections helps technicians apply the diagram to real equipment layouts and avoid inadvertent faults.

How Does a Three-Phase Bus Line Diagram Represent Power Distribution in an Electrical Grid?

In electrical grids, a line diagram serves as a map of how power flows from one point to another. A three-phase bus line diagram typically displays the three phases—referred to as A, B, and C phases—alongside key components like transformers, circuit breakers, and the busbar that connects different parts of the system. Each phase operates in sequence, providing continuous power with less voltage fluctuation, which is especially important in systems that rely on stable, high-power transmission. Verification of that sequence is routinely done with a phase rotation meter to prevent motor miswiring and process disruptions.

The diagram will show the points at which each phase interacts with the components, helping engineers and technicians ensure that the entire system functions efficiently. For example, it can reveal potential issues with phase imbalances, which could lead to equipment damage or inefficiencies.

What are the Key Components Typically Shown in a Three-Phase Bus Line Diagram?

A typical bus line diagram in a three-phase system includes several key components that ensure efficient operation:

- Busbar: This metal bar conducts electricity and connects different sections of the electrical system, allowing for the distribution of power across multiple circuits.

- Transformers: Step up or step down the voltage levels as required.

- Circuit breakers: Protect the system by interrupting the current flow in case of overloads or faults.

- Lines and conductors: Represent the pathways through which the electrical current travels between components.

These components are strategically placed in the diagram to show how electricity flows from one part of the system to another.

How Do You Interpret Voltage and Current Flow in a Three-Phase Bus Line Diagram?

Interpreting voltage and current flow in a three-phase bus line diagram requires understanding how the three phases interact. In a typical three-phase system, the voltage and current are out of phase with each other by 120 degrees, creating a constant flow of power that is more stable than what is found in a single-phase system. This means that at any given moment, one of the three phases is reaching its peak voltage while the others are either rising or falling. When analyzing unbalanced conditions, a phase angle calculator aids in quantifying displacement and its impact on real power.

The line diagram will show the voltage levels for each phase, typically at points where the phases connect with equipment like transformers or circuit breakers. It’s essential to understand these flows to ensure that the system operates without issues like phase imbalances or voltage drops, which can affect the performance of the entire system. For facility studies at common service levels, applying a 480 V power and current formula clarifies expected currents for protective device coordination.

What is the Role of the Busbar in a Three-Phase Bus Line System, and How is it Represented in the Diagram?

The busbar is one of the most crucial components in a three-phase bus line system, as it serves as the central hub for distributing electrical power. It is a conductive material, usually made of copper or aluminum, that carries large amounts of current from one part of the system to another. The busbar helps to distribute power to various circuits without the need for multiple connections, simplifying the system and increasing efficiency. During design, an electrical load calculator helps estimate diversity factors and peak currents for busbar selection.

In a bus line diagram, the busbar is represented as a solid bar connecting different sections of the system, such as transformers or circuit breakers. It plays a vital role in ensuring that the electrical system remains balanced and can handle high loads efficiently. Properly designed busbars prevent overloading and ensure that power is delivered evenly across all phases.

A three-phase bus line diagram is an essential tool in the management of complex electrical power systems, particularly in industrial and high-voltage environments. It illustrates how electricity flows through different phases and components, allowing for efficient power distribution and easier troubleshooting. By understanding the diagram and the role of key components like the busbar, engineers and technicians can ensure that electrical systems operate smoothly and safely, minimizing the risk of faults or inefficiencies. This knowledge is crucial for maintaining and optimizing modern electrical grids and power distribution networks. These diagrams also underpin power system analysis and design workflows used for planning, protection, and reliability studies.

Related Articles

Short Circuit Current Calculation Explained

Short circuit current calculation determines the maximum electric current that can flow during a fault. It’s essential for sizing protective devices, ensuring system safety, and preventing equipment damage. Factors include voltage, impedance, transformer rating, and conductor length.

What is a Short Circuit Current Calculation?

Short circuit current calculation (SCCC) is essential for ensuring the safety and reliability of electrical systems. It:

✅ Ensures proper selection of circuit breakers and fuses

✅ Prevents equipment failure during electrical faults

✅ Complies with NFPA 70E and IEEE standards for system protection

This critical process enables electrical professionals to determine the magnitude of currents that can occur during fault conditions, which in turn helps them design protective measures to prevent system failures. Knowing how to perform a SCCC enables engineers and electricians to select the appropriate protective devices, minimize potential damage, and reduce downtime in both industrial and commercial environments. This vital skill not only safeguards equipment but also improves overall system performance and efficiency. Understanding how to read nominal voltage is essential for anyone working with electrical systems, especially when evaluating safe operating levels.

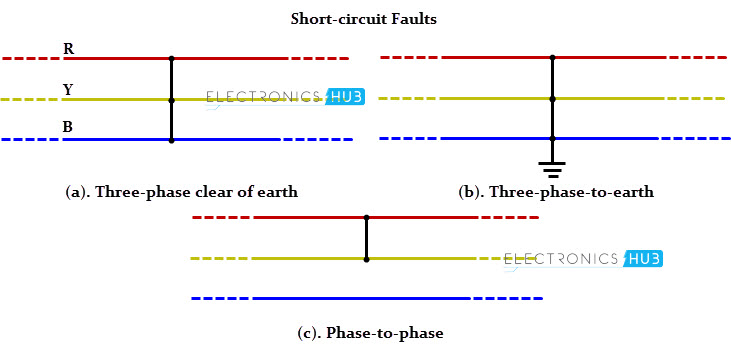

Understanding Short Circuits

A short circuit (S/C) occurs when an unintended path with very low resistance is created in an electrical circuit. This can be caused by various factors, such as insulation failure, loose connections, or accidental contact between conductors. The sudden drop in impedance leads to a dramatic increase in current flow, potentially causing significant damage to equipment and posing serious safety hazards, including fires and electric shock. In industrial and commercial environments, S/Cs can result in costly downtime, equipment failure, and even risks to human safety. As such, understanding how to predict and mitigate the effects of S/Cs through accurate measurements is fundamental to electrical engineering. Our electrical training programs help professionals master key concepts like single-phase power, voltage drop, and system design.

Short Circuit Current Calculation Reference Table

| Parameter | Low Voltage System | Medium/High Voltage System | Notes |

|---|---|---|---|

| Voltage Level | Less than 1,000 volts | Greater than 1,000 volts | Defines equipment class and calculation complexity |

| Primary Components | Transformers, panelboards, circuit breakers | Generators, transformers, switchgear, relays | Equipment affects fault current magnitude and duration |

| Impedance Source | Transformer impedance primarily | System-wide impedance (including lines and sources) | Total impedance determines fault current |

| Transformer Data Required | kVA rating, impedance percentage, voltage | Same, plus X/R ratio for accuracy | Manufacturer data needed |

| Conductor Impedance | Often neglected or simplified | Must be included for accuracy | Affects overall fault current level |

| X/R Ratio Impact | Minimal impact | Significant impact | Influences peak fault current and breaker selection |

| Calculation Tools | Manual, spreadsheet, lookup tables | Advanced software (ETAP, SKM, EasyPower) | High voltage systems require modelling tools |

| Typical Applications | Commercial buildings, light industrial facilities | Substations, utilities, large industrial sites | Affects safety and design standards |

| Protective Device Sizing | Circuit breakers, fuses | Relays, reclosers, current transformers (CTs) | Devices must be rated for worst-case fault conditions |

The Importance of SCCC

Accurately calculating the short circuit current is crucial for several reasons:

Protective devices, such as fuses and circuit breakers, must be capable of safely interrupting faults. Their interrupting rating must exceed the maximum possible short-circuit (S/C) current at their installation point to prevent equipment damage and ensure operator safety. Electrical equipment, including cables, transformers, and switchgear, must be designed to withstand the thermal and mechanical stresses generated by a short-circuit (S/C). Precise measurements ensure that equipment is rated properly to avoid catastrophic failure. Accurate analysis of system load and balance can be aided by tools such as the electrical load calculator and phase angle calculator.

High S/C currents can affect the stability of the entire electrical system, causing voltage dips, equipment malfunctions, or damage. Accurate calcs help identify areas of potential vulnerability, allowing for the implementation of corrective measures, such as adjusting protection settings or upgrading equipment. Short-circuit current calculations are also necessary for compliance with electrical codes and standards, such as the National Electrical Code (NEC) and IEEE standards. Engineers designing protection schemes should understand the implications of short-circuit current calculations and the risks associated with using 8A and 10A fuses in parallel.

Factors Influencing Short Circuit Current

Several factors influence the magnitude of the S/C current. Understanding these variables is essential to performing accurate measurements:

The impedance of the power source, whether it’s a utility grid or a generator, significantly impacts the fault. A lower source impedance results in a higher S/C current, making it essential to evaluate this parameter during system design. Transformers play a crucial role in limiting S/C currents. The transformer impedance is typically expressed as a percentage, and a higher percentage impedance results in a lower fault current on the secondary side. Accurate modelling of transformer parameters is key to determining short circuits on both the primary and secondary sides of the transformer.

The impedance of cables and busbars connecting various components in the circuit also contributes to the overall system impedance. Longer cables or those with higher resistance will lower the S/C current, while shorter, thicker cables with lower resistance allow for higher currents during faults. Motors, especially large induction motors, can contribute significantly to S/C currents during the initial moments of a fault. This motor contribution is often transient but must be included in the estimation, as neglecting it can lead to underestimating faults and improperly sizing protective devices.

The location of the fault within the system plays a significant role in determining the magnitude of the short-circuit (S/C) current. Faults closer to the power source generally produce higher S/C currents due to the reduced impedance between the fault and the source. From power system engineering to interpreting a three-phase bus line diagram, our resources support both design and troubleshooting tasks.

Calculation Methods

Various methods are employed to calculate the short-circuit current, ranging from simplified approaches to more complex analysis techniques. One common method involves using Ohm’s Law:

Isc = V / Z

Where:

Isc is the short circuit current, V is the system voltage, and Z is the total impedance of the circuit from the source to the fault location.

The total impedance (Z) includes the impedance of the source, transformer, cables, and any other components in the current path. However, in modern electrical systems, more sophisticated software tools are often used to automate SCCCs, particularly in complex systems where manual figuring may be cumbersome or prone to error.

Calculating Short Circuit Current on the Secondary Side

When calculating the short-circuit current on the secondary side of a transformer, it's essential to consider the transformer's impedance. The formula can be modified as follows:

Isc (secondary) = (V (secondary) / Z (transformer)) * 100 / %Z

Where:

Isc (secondary) is the short circuit current on the secondary side of the transformer, V (secondary) is the secondary voltage of the transformer, Z (transformer) is the transformer impedance in ohms, and %Z is the transformer impedance expressed as a percentage.

This calculation is crucial in determining the fault that protective devices on the secondary side of a transformer must be able to handle. It ensures that circuit breakers, fuses, and other protective elements are correctly sized and rated.

The Role of Advanced Simulation Tools

In addition to manual determinations, electrical engineers increasingly rely on advanced simulation tools to model S/C scenarios. These tools can account for complex system configurations, varying load conditions, and different types of faults, providing a more accurate and comprehensive analysis. By utilizing software, professionals can simulate fault conditions under various operational scenarios, enabling better contingency planning and more informed decision-making during system design.

SCCC is an essential practice in electrical engineering that ensures the safe and reliable operation of electrical systems. By understanding the factors that influence faults and employing accurate determination methods, electrical professionals can ensure the proper selection of protective devices, protect equipment from damage, and maintain the stability of the electrical system. Moreover, the use of advanced tools and techniques enhances the precision of these estimations, ultimately contributing to the overall safety, efficiency, and reliability of modern electrical infrastructure.

Related Articles

Electrical Load Calculator Explained

Electrical load calculator estimates power demand, ampacity, and panel capacity, guiding circuit sizing, load balancing, voltage drop checks, and NEC-compliant design for residential, commercial, and industrial electrical projects, planning safely.

What Is an Electrical Load Calculator?

Software that estimates electrical demand to size circuits, feeders, and panels per NEC for balanced, efficient systems.

✅ Computes diversified loads for single- and three-phase systems

✅ Supports voltage drop, ampacity, and feeder/panel sizing

✅ Aids NEC compliance and equipment selection

An electrical load calculator is an essential tool for industrial and commercial power professionals. These calculators help determine the total electricity consumption of a facility, playing a crucial role in ensuring safe and efficient system operations. By using one, engineers and technicians can accurately assess the total load to properly size critical equipment like transformers, conductors, and circuit protection devices. This process prevents overloads, minimizes downtime, and supports compliance with safety standards and regulations. Seasoned teams often pair these estimates with insights from the power system engineering discipline to validate planning assumptions.

Residential ones are essential tools for homeowners. They help determine the total amount of electricity your appliances and devices will use, which is crucial for safety and efficiency. By understanding your load, you can ensure your wiring, circuits, and panel are adequately sized to handle the demand. This prevents overloads, which can lead to tripped breakers, damaged appliances, and even fires. Online calculators make this process more accessible, providing a user-friendly way to estimate your home's power needs. Homeowners curious about power factor can explore a phase angle calculator to see how reactive loads influence real power draw.

Appliance-Based Calculation

Every load calculator relies on users inputting the wattage of their appliances to determine the overall load, given the square footage of a home. Think about your kitchen: a refrigerator might use 100-200 watts, a microwave 1000 watts, and a coffee maker 1500 watts. These individual wattages add up! Heating and cooling systems, especially air conditioners, contribute significantly to the load, particularly in warmer climates. Accurately accounting for all appliances, big and small, is key to a reliable calculation.

For broader planning beyond appliance lists, engineers often run a load-flow analysis to evaluate feeder loading and voltage drop across distribution circuits.

In industrial and commercial settings, "appliances" refer to a range of equipment, from heavy machinery and HVAC systems to lighting and computer setups. Each piece of equipment has a specific power requirement, often measured in kilowatts (kW). It allows professionals to input the power consumption of each device and factor in aspects like duty cycle and simultaneous operation. This precise calculation helps determine the accurate total load, ensuring the facility’s power system can accommodate all operational needs without risk of overload. These device inputs ultimately roll into the power system analysis and design process for coherent, code-compliant layouts.

Circuit Breaker Sizing

Properly sized circuit breakers are vital for protecting power systems in industrial and commercial facilities. An electrical load calculator can assist in determining the appropriate amperage rating for each breaker, ensuring that it can handle the circuit’s demand without risk of tripping due to overload. By selecting breakers based on load calculations, facilities can prevent unnecessary disruptions and maintain the safe operation of critical equipment. Complementary short-circuit studies using a short-circuit current calculation confirm interrupting ratings and coordination.

NEC Compliance

The NEC outlines comprehensive guidelines for installations in all types of buildings, including industrial and commercial properties. Electrical load calculators are instrumental in meeting NEC standards, as accurate load calculations ensure that selected equipment and wiring meet code requirements. This compliance is essential for both safety and regulatory adherence, preventing hazards and ensuring that systems are designed and installed according to established standards. In many commercial systems, familiarity with the 480V power and current formula streamlines conductor sizing and overcurrent device selection.

The Importance of Professional Expertise

While electrical load calculators offer a helpful estimation of facility needs, they should not replace the experience of a licensed engineer or technician. Online tools provide general estimates, but only a qualified professional can consider site-specific factors, safety regulations, and industry best practices. By combining the output of a calculator with expert judgment, professionals ensure that the design and operation of systems meet the unique demands of industrial and commercial facilities safely and efficiently. Ongoing competency is supported by structured electrical training that keeps practitioners current with codes and analysis techniques.

An electrical load calculator is an invaluable tool for those managing power systems in industrial and commercial environments. By accurately assessing the power requirements, professionals can size equipment properly, prevent overloads, and ensure compliance with codes like the NEC. This contributes to a safer, more reliable infrastructure, ultimately supporting the facility's operational goals and reducing the risk of power disruptions.

Related Articles

Phase Angle Calculator

A Phase Angle Calculator helps analyze AC circuits by determining the angular difference between voltage and current. It supports electrical engineering, power factor correction, impedance analysis, and efficient system design in industrial, utility, and academic applications.

What is a Phase Angle Calculator?

A Phase Angle Calculator is a tool used in electrical engineering to compute the angular displacement between voltage and current in AC circuits, essential for analyzing impedance, power factor, and system performance.

✅ Determines phase difference in AC circuits

✅ Supports impedance, power factor, and system studies

✅ Aids in efficient design and fault analysis

It's is an essential tool for industrial electricians to accurately measure and analyze the relationship between voltage and current in AC electrical systems. Understanding angles is crucial for ensuring optimal power factor, minimizing energy waste, and enhancing the efficiency of electrical equipment. Let's examine how a phase angle calculator works, its practical applications, and why mastering this concept is crucial for troubleshooting electrical issues, optimizing system performance, and supporting energy-saving initiatives in industrial environments. Electricians will gain valuable insights into calculating angles, interpreting results, and applying this knowledge to real-world electrical systems. To fully understand how it works, electricians often review the basics of what is single-phase power to see how phase relationships develop in AC systems.

How a Phase Angle Calculator Works?

A phase shift analyzer operates by analyzing the circuit's impedance components, including resistance, inductance, and capacitance. The calculator determines the shift using the arctangent function by inputting relevant values, such as the resistive load and reactance. This calculation not only aids in understanding circuit behaviour but also helps identify mismatches in system design that could lead to inefficiencies or malfunctions. Modern calculators often feature user-friendly interfaces, making them accessible to both seasoned engineers and students. Accurate phase angle calculations are crucial in power system analysis and design, where engineers evaluate system stability, load flow, and efficiency.

Types and Applications of Phase Shift Analyzer

There are various types of analyzers available, each tailored for specific applications. Some are standalone devices designed for field use, while others are integrated into advanced testing equipment. Engineers use these tools in diverse settings, from evaluating power systems in industrial plants to troubleshooting electrical issues in residential setups. For instance, when aligning generators or synchronizing multiple power sources, accurate angle calculations ensure seamless operation and prevent costly disruptions.

Troubleshooting

When electrical problems arise, a shift analyzer becomes a diagnostic asset. It enables engineers to pinpoint issues such as imbalanced loads, faulty connections, or deviations in power factor. By identifying anomalies in the shift, the tool facilitates targeted interventions, reducing downtime and improving system reliability. This functionality is particularly valuable in industries where an uninterrupted power supply is critical, such as data centers and manufacturing facilities. When working with multi-phase systems, understanding phase-to-phase connection and phase rotation meter principles ensures accurate angle measurements and prevents costly errors.

Safety Precautions When Using a Phase Angle Calculator

Working with AC systems involves inherent risks, particularly when dealing with high voltages. Proper safety protocols must be followed to ensure the safe use of a shift analyzer. Always verify that the Phase Angle Calculator and its accessories are rated for the voltage level of the system being analyzed. Use insulated tools and wear appropriate personal protective equipment (PPE). Additionally, ensure the calculator is calibrated regularly to maintain accuracy and reliability.

Real-World Applications and Benefits

In practical scenarios, a phase shift analyzer is used to enhance the performance of various electrical systems. For example, it plays a pivotal role in designing HVAC systems, optimizing motor operations, and balancing transformer loads. By ensuring accurate alignment, these calculators prevent equipment damage and extend the lifespan of critical components. Their versatility and ease of use make them an essential tool for professionals in the electrical and engineering fields.

From diagnosing electrical issues to optimizing power efficiency, the Phase Angle Calculator enables engineers to make informed decisions and ensure system integrity. By adhering to safety guidelines and leveraging the calculator’s capabilities, professionals can ensure the reliability and efficiency of electrical systems in diverse applications. This equipment is invaluable for troubleshooting and ensuring that electrical systems are operating optimally. By using a shift analyzer, electricians can improve the accuracy of their diagnostics, enhance the reliability of electrical installations, and prevent costly operational disruptions. Ultimately, it contributes to the overall safety and performance of electrical systems. For in-depth studies, combining a phase angle calculator with related tools, such as the electrical load calculator or DC voltage drop calculation, helps professionals achieve precise system performance and energy efficiency.

Frequently Asked Questions

How do I calculate phase angle?

To calculate the phase angle in an AC electrical system, you need to understand the relationship between the voltage and current waveforms. The angle (θ) represents the shift in degrees between these two waveforms. It is typically measured using an angle calculator or by applying trigonometric functions. The calculation requires knowing the values of the resistive (R) and reactive (X) components in the circuit. The angle can be calculated using the arctangent (tan⁻¹) of the ratio of the reactance (X) to the resistance (R), as shown in the formula:

θ = tan⁻¹(X / R)

What is the formula for the phasor angle?

The formula for the phasor angle, often referred to as the angle, is derived from the components of impedance (Z) in an AC circuit. The impedance has two components: the resistive component (R) and the reactive component (X), which can be either inductive (XL) or capacitive (XC). The phasor angle (θ) is calculated using the following trigonometric formula:

θ = tan⁻¹(X / R)

Where:

θ is the phasor or phase angle in degrees.

X is the total reactance of the circuit (inductive reactance XL or capacitive reactance XC).

R is the resistance of the circuit.

The angle tells you whether the current is leading or lagging the voltage. A positive phase angle indicates lagging (typical for inductors), while a negative angle indicates leading (typical for capacitors).

How do I calculate the phase angle of an inductor?

The phase angle of an inductor is calculated based on the relationship between the inductive reactance (XL) and the resistance (R) in the circuit. Since an inductor causes the current to lag behind the voltage by 90 degrees in a purely inductive circuit, the shift can be calculated if the circuit also has resistive components. The angle (θ) is calculated using the formula:

θ = tan⁻¹(XL / R)

Where:

θ is the phase angle in degrees.

XL is the inductive reactance, calculated as XL = 2πfL, where f is the frequency and L is the inductance in henries.

R is the resistance of the circuit.

If the circuit is purely inductive (no resistance), the angle will be 90 degrees, indicating maximum lag. However, in real-world applications, circuits usually have both resistance and inductance, so the angle will be less than 90 degrees.

How to Calculate Phase Angle Using Power Factor?

The phase angle can also be calculated using the power factor (PF) of the circuit. Power factor represents the cosine of the angle between the current and voltage waveforms. The power factor is a dimensionless value between 0 and 1, where 1 represents a perfectly in-phase system. To calculate the angle (θ) from the power factor, use the following formula:

θ = cos⁻¹(PF)

Where:

θ is the phase angle in degrees.

PF is the power factor (a decimal value between 0 and 1).

For example, if the power factor is 0.8, the angle is calculated as:

θ = cos⁻¹(0.8) ≈ 36.87°

This method is widely used in power quality analysis and system optimization, as power factor correction is often necessary to reduce phase angle and improve energy efficiency.

Related Articles

Electrical Engineering Channel