Arc Flash

Electrical Safety Training - NFPA 70E, CSA Z462

Electrical safety training teaches workers how to recognize, avoid, and respond to hazards. Learn proper PPE use, safe work practices, and compliance with NFPA 70E and OSHA standards to reduce risks in industrial and commercial power systems.

What is Electrical Safety Training?

Electrical safety training is essential because it equips workers with the knowledge and skills necessary to avoid potential hazards. Energized work presents numerous risks, from electric shock to arc flash, both of which can cause serious injuries or fatalities. It:

✅ Teaches hazard recognition, PPE use, and lockout/tagout procedures

✅ Helps meet NFPA 70E and OSHA compliance requirements

✅ Reduces risk of arc flash, shock, and injury on the job

Request a Free Training Quotation

Proper instruction minimizes these risks by teaching safe work practices, compliance requirements, and hazard recognition. It also ensures that anyone working with or near energized systems follows national safety standards like NFPA 70E, OSHA 1910, CSA Z462, and the NEC.

Let’s explore the importance of this kind of instruction, who needs it, what it covers, and how your organization can benefit from implementing a robust worker safety education program.

Why is Electrical Safety Training Important?

Working near energized systems exposes personnel to hazards such as arc flash, shock, electrocution, and equipment failure. OSHA mandates that workers be trained to recognize and avoid these hazards. NFPA 70E and CSA Z462 outline specific requirements for qualified and unqualified workers, retraining intervals, and safety documentation.

Arc flash incidents can reach temperatures hotter than the sun and send shrapnel flying at deadly speeds. Electric shock can stop the heart in milliseconds. Education is the first line of defence.

At The Electricity Forum, our courses use real-world scenarios to mitigate risks, reduce liability, and strengthen workplace safety.

Aligned to Current Editions

Electrical safety standards are constantly updated to reflect new technologies, research, and workplace practices. Staying aligned with the latest editions is essential for both compliance and worker protection. Our programs are fully updated for NFPA 70E 2024 and CSA Z462:24. Key updates include:

-

Enhanced risk assessment procedures and job safety planning requirements

-

Clarified PPE selection methods and arc-rated clothing categories

-

Updated approach and arc-flash boundary calculations

-

Expanded requirements for energized work permits and documentation

-

Closer harmonization with the Canadian Electrical Code (CE Code)

Who Needs Electrical Safety Training?

Not everyone working around electricity is an electrician, but many workers face the risk of exposure to energized parts. Regulatory standards make it clear that training is not optional—it’s a fundamental requirement for a safe workplace. Electrical safety training is required for:

-

Electricians, engineers, and maintenance staff

-

Anyone exposed to energized equipment

-

Non-power workers in hazardous environments

-

Supervisors and EHS managers are responsible for program compliance

Even workers whose primary job isn’t related to working on energized equipment must be trained if there’s a reasonable chance of exposure to energized parts. OSHA requires retraining whenever job duties change, new equipment is installed, or deficiencies are observed.

What’s Covered in Electrical Safety Training?

A well-designed training program goes beyond theory. It combines compliance requirements with practical instruction so workers know exactly how to apply safety principles on the job. Topics covered include:

-

Hazard Recognition: Identify exposed conductors, faulty wiring, and poor insulation.

-

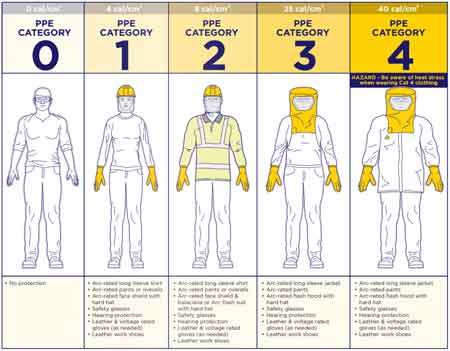

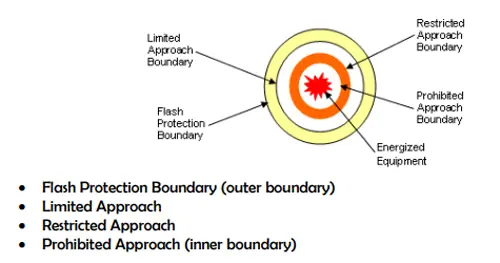

Arc Flash Awareness: Understand causes, PPE, labels, and arc flash boundaries. The arc flash boundary is the distance where incident energy equals 1.2 cal/cm², requiring PPE and safe work practices.

-

Shock Protection: Learn limited and restricted approach boundaries, insulated tools, and grounding.

-

PPE: Select and wear arc-rated clothing, gloves, shields, and other equipment.

-

NFPA 70E 2024 Compliance: Apply the latest procedures for energized and de-energized work.

-

Lockout/Tagout (LOTO): Follow OSHA 1910.147 practices to isolate energy and verify safe states.

-

Hazard Risk Assessment: Perform shock and arc-flash risk evaluations and apply mitigation strategies.

-

Energized Power Work Permits: Understand when permits are required and how to document them.

Measurable Outcomes

The ultimate measure of any training program is whether workers can apply what they’ve learned. Our courses emphasize hands-on skills, documentation, and compliance readiness so participants leave with practical capabilities. Graduates of our courses are able to:

-

Create a documented job safety plan

-

Perform a shock and arc-flash risk assessment

-

Select PPE using category and incident energy methods

-

Complete and apply an energized work permit

-

Verify lockout/tagout and establish a safe work condition

All participants receive a certificate of completion with CEUs/PDHs. Retraining is required at least every three years or sooner if conditions change.

Electrical Safety Training Courses

Arc Flash Training

Arc flash instruction focuses on incident energy, hazard analysis, PPE selection, and label reading. Workers learn how to assess arc flash boundaries and follow safe work protocols.

➡️ Explore Arc Flash Training - CSA Z462

➡️ Explore Arc Flash Training Certification

Arc Flash Analysis

Arc Flash Analysis course is intended for engineers and safety professionals who perform or oversee arc flash studies. This course covers calculating incident energy levels, defining arc flash boundaries, and applying IEEE 1584 methodologies to ensure compliance with NFPA 70E and OSHA requirements.

➡️ Learn more about Arc Flash Analysis Training

NFPA 70E

This course dives into the standard’s requirements, including risk assessment procedures, PPE categories, safe work practices, and documentation.

➡️ View NFPA 70E Training

Arc Flash Training Online

Our live online format delivers interactive content covering arc flash hazards, incident energy, PPE, and NFPA 70E basics — ideal for remote or distributed teams.

➡️ Take Arc Flash Training Online

Arc Flash Training Requirements

OSHA and NFPA 70E both require regular instruction and documentation of employee competency. This includes hazard recognition, use of energized work permits, and emergency response.

➡️ Understand Arc Flash Training Requirements

OSHA Electrical Safety Training

OSHA 29 CFR 1910 Subpart S, education teaches hazard recognition, PPE, and LOTO. It is essential for compliance in industrial, utility, and commercial environments.

➡️ Visit our OSHA Electrical Safety Training Page

NEC Training

Our NEC course covers updates and ensures safe design and installation practices. It is ideal for electricians, inspectors, and engineers.

➡️ View NEC Electrical Code Training

Electrical Safety Training for EHS Managers

EHS managers must understand safety programs, audit protocols, and compliance planning. This course supports safety officers and supervisors in developing compliant procedures.

➡️ See Electrical Safety Training for EHS Managers

Electrical Safety Program Development

Our Safety Program Development course is designed for supervisors, EHS managers, and safety professionals responsible for creating and maintaining compliant programs.

➡️ See Electrical Safety Program Development

Lockout/Tagout Training

LOTO procedures are critical for safe maintenance and shutdowns. This course covers OSHA 1910.147 requirements and proper isolation and verification of energy sources.

➡️ Learn About Lockout Tagout Training

High Voltage Training

This course is tailored for workers dealing with systems above 600v. Topics include approach distances, rubber goods, switching procedures, and equipment grounding.

➡️ Explore High Voltage Safety Training

Frequently Asked Questions

What does OSHA-compliance mean?

It’s aligned with OSHA standards, such as 1910.269 and 1910.333, which cover hazard identification, PPE, and safe practices.

Who needs certification?

Electricians, engineers, and anyone working near energized equipment should be certified to prove competence.

What is covered in arc flash training?

Causes, incident energy, arc flash boundaries, risk assessment, and PPE selection.

Why is lockout/tagout training important?

It prevents unexpected energization by teaching proper energy isolation during servicing.

How does training support an ES program?

It ensures workers understand procedures, comply with NFPA 70E/OSHA, and reduce risk company-wide.

Summary

Electrical safety training is the backbone of any industrial safety program. Whether you're a frontline worker, a supervisor, or a safety manager, staying current with hazards, PPE practices, and compliance standards is essential.

At The Electricity Forum, our courses are designed to support compliance, reduce liability, and, most importantly, protect lives.

➡️ Contact us to learn more about our courses or request a free quotation.

Related Articles:

Download Our FREE Arc Flash Handbook

This edition continues our commitment to providing essential knowledge and best practices for safeguarding electrical professionals and maintaining safety standards in high-risk environments. As electrical systems become increasingly complex and the demand for higher power capacities grows, the importance of addressing electrical hazards—particularly arc flash risks—has never been more critical.

In this volume, we explore the latest advancements in electrical safety, focusing on strategies to mitigate the dangers of arc flash incidents and ensure the protection of workers in the field. From updated standards and regulations to innovative protective equipment and advanced risk assessment techniques, this handbook is designed to help professionals stay informed and equipped to prevent electrical accidents.

Through expert insights, case studies, and practical safety solutions, Volume 10 provides a comprehensive guide to minimizing risks, enhancing safety protocols, and fostering a culture of safety in electrical environments. Whether you're an electrical engineer, safety officer, or technician, this handbook serves as an invaluable resource for creating safer workplaces and improving the overall safety of electrical operations. Join us as we continue to advance the standards for electrical safety and arc flash prevention in this ever-evolving field.

Collections of the articles on electrical safety and arc flash in particular including a review of OSHA’s new electric power generation, transmission, and distribution and electrical protective equipment standards.

Latest Arc Flash Articles

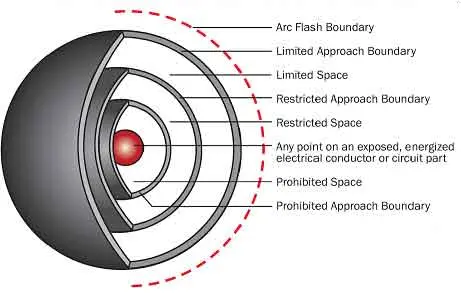

NFPA 70E Approach Boundaries Explained

NFPA 70E approach boundaries define specific distances from energized parts to reduce electrical shock and arc flash risks. These include limited, restricted, and prohibited boundaries, each requiring proper training, PPE, and authorization to enter safely.

NFPA 70E Approach Boundaries

-

✅ Limited Boundary: Outer zone where unqualified persons must be escorted.

-

✅ Restricted Boundary: Only qualified workers with PPE may enter.

-

✅ Prohibited Boundary: Closest distance; treated like direct contact with live parts.

Understanding NFPA 70E Approach Boundaries for Electrical Safety. Electrical work demands constant vigilance. Electrical explosions, incidents of sudden bursts of intense heat and light caused by electrical short circuits, pose a significant threat. The National Fire Protection Association (NFPA 70E) , Standard for Electrical Safety in the Workplace®, establishes a framework for mitigating these hazards. A cornerstone of this standard is the concept of approach boundaries, which define safe working distances around energized electrical conductors or circuit parts. It is crucial to understand the arc flash boundary as defined by NFPA 70E, which outlines the minimum safe distance from exposed energized conductors to avoid second-degree burns in case of an arc flash incident.

Request a Free Training Quotation

In accordance with NFPA 70E, arc flash boundaries are crucial for ensuring the safety of workers around energized electrical systems. Workers must not cross the restricted approach boundary unless they are authorized and wearing the appropriate personal protective equipment (PPE). For any work involving exposed, energized electrical conductors or circuit parts, an energized electrical work permit must be obtained. Workers should be escorted by a qualified person when entering areas with high potential hazards. Additionally, risk assessments should be conducted before any work begins to identify potential dangers. It is essential that unqualified individuals are not permitted to enter areas where these boundaries exist unless they are closely supervised to prevent accidents and injuries. These protocols are essential to minimizing exposure to electrical hazards and ensuring safe work practices in the workplace.

Three Lines of Defense: Understanding Approach Boundaries

NFPA 70E establishes three distinct approach boundaries, each serving as a critical zone for electrical safety:

-

Limited Approach Boundary: This outermost boundary marks the farthest point at which a shock hazard exists. Unqualified workers must always remain outside this limit. Only qualified personnel (individuals with electrical safety training and certifications) are permitted to cross the limited approach boundary. However, doing so requires a work permit and adherence to strict safety protocols.

-

Restricted Approach Boundary: This boundary defines the closest distance a qualified person can approach exposed energized conductors without wearing arc-rated PPE. Working within this zone necessitates a work permit, a thorough hazard assessment, and strict adherence to safety protocols.

-

Prohibited Approach Boundary: (No Longer Used) This zone carries the highest risk of severe injury from an electrical explosion. No one is permitted to enter this zone while electrical components are energized.

To ensure electrical safety, it's important to follow the shock protection boundaries specified in NFPA 70E, which help to mitigate the risks of electrical shock based on voltage levels and the type of equipment in use.

Voltage, Equipment, and Safe Distances

NFPA 70E tables provide reference values for these approach boundaries based on factors like nominal system voltage and the type of conductor (exposed or fixed). These tables offer a starting point, but a comprehensive hazard assessment is crucial for each specific situation. Factors like short-circuit current, grounding practices, and equipment clearances can all influence the actual boundaries.

Crossing the Limited Approach Boundary: Safety First

Even when remaining outside the limited approach boundary, prioritizing safety is paramount:

-

Work Permit: Obtaining a work permit ensures a documented hazard assessment is conducted, outlining necessary safety protocols.

-

De-Energize if Possible: Whenever feasible, de-energizing equipment before working on it is the safest approach.

-

Visual Inspection: Before approaching energized components, a qualified person should conduct a visual inspection to identify any potential hazards.

-

Testing and Verification: Depending on the situation, electrical testing and verification procedures may be necessary to confirm safe working conditions.

The AF Boundary: Quantifying the Danger Zone

The AF boundary represents the distance at which a worker could experience a specific level of incident energy (measured in calories/cm²) from an electrical explosion. NFPA 70E doesn't mandate a specific incident energy level for the AF boundary, but 1.2 calories/cm² is a commonly used threshold associated with a 50% chance of sustaining second-degree burns.

Calculating the AFboundary involves specialized software and expertise. Electrical engineers or qualified specialists often perform this task, considering factors like:

-

Short-circuit current: The higher the short-circuit current available, the more severe an electrical explosion can be.

-

Equipment layout and clearances: The physical configuration of equipment and the surrounding workspace influence the potential for electrical explosion propagation.

-

Bolted fault current: This value represents the amount of current that would flow in a bolted fault situation, providing insight into the potential severity of an electrical explosion.

PPE Selection: A Matter of Boundaries

The type of PPE required for a specific task is directly linked to the approach boundaries. Workers outside the limited approach boundary may only require basic PPE like safety glasses and hearing protection. However, qualified persons entering the restricted approach boundary must wear PPE specifically designed to withstand the anticipated incident energy level at that distance. The AF boundary serves as a critical threshold for determining the appropriate level of PPE for a given task.

By understanding and respecting approach boundaries as outlined in NFPA 70E, workers can significantly reduce the risk of electrical hazards. Remember, electrical safety is paramount. Always prioritize de-energizing equipment if possible. If working near energized components, ensure a thorough hazard assessment is conducted, work permits are obtained, and appropriate safety measures, including proper personal protective equipment (PPE), are in place.

To comply with NFPA 70E standards, electrical workers must adopt proper safety practices, including appropriate training and PPE use, to minimize the dangers of electrical hazards in the workplace.

Related Articles:

Arc Flash Gear Explained

Arc flash gear provides PPE compliant with NFPA 70E and CAT ratings, including arc-rated clothing, face shields, FR gloves, and balaclavas, to safeguard electrical workers during switchgear operations and high incident energy tasks.

What Is Arc Flash Gear?

Arc flash gear is arc-rated PPE meeting NFPA 70E to reduce burn risk from high incident energy exposures.

✅ Includes arc-rated clothing, face shields, gloves, balaclavas

✅ Meets NFPA 70E, OSHA, and CAT rating requirements

✅ Sized by hazard analysis to match incident energy levels

Arc flash gear is specialized personal protective equipment (PPE) designed to safeguard workers against the devastating effects of arc flash (AF) incidents. These incidents can generate intense heat, light, and pressure, leading to severe burns and other injuries. Understanding the intricacies of PPE is crucial for ensuring the safety of electrical workers. For a concise overview of key terms and selection basics, consult this arc flash PPE resource to align training with best practices.

Understanding AF Ratings and PPE Categories

The National Fire Protection Association (NFPA) 70E standard provides guidelines for selecting appropriate PPE based on the anticipated incident energy level. If you need help interpreting cal/cm² and hazard categories, see an explanation of arc flash ratings for real-world examples.

The incident energy is measured in calories per square centimeter (cal/cm²) and indicates the amount of heat energy released during an AF.

Arc flash gear is categorized into different PPE categories, ranging from 1 to 4, with each category corresponding to a specific arc rating. For instance, Category 2 PPE is suitable for tasks with an incident energy level of 8 cal/cm², while Category 4 PPE is designed for higher incident energy levels exceeding 40 cal/cm².

Selecting the Right Arc Flash Gear: The Most Important Criterion

The most critical factor in choosing PPE is ensuring its arc rating matches or exceeds the anticipated incident energy level of the task. This requires conducting an AF hazard analysis to determine the potential energy levels at various points in the electrical system. A practical purchasing checklist is outlined in this safety gear guide to help match tasks and environments.

Components of Arc Flash Gear

PPE typically includes a combination of flame-resistant clothing, such as bib overalls, jackets, and coveralls. It may also include additional protective items like hoods, gloves, and face shields. These components work together to provide comprehensive protection against the thermal hazards of an electrical explosion. For garment selection, laundering tips, and layering strategies, reference this guide to arc-rated clothing to optimize protection and comfort.

It may also include additional protective items like hoods, gloves, and face shields. These components work together to provide comprehensive protection against the thermal hazards of an electrical explosion. For a broader view of tools, barriers, and supporting devices, consult this arc flash safety equipment overview to round out your protection strategy.

The Lifespan of Arc Flash Gear

The lifespan of PPE depends on various factors, including the frequency of use, exposure to contaminants, and proper care and maintenance. Regular inspections are essential to identify any signs of wear and tear, such as holes, tears, or discoloration. Damaged gear should be replaced immediately to ensure continued protection.

The Highest Rated PPE for Arc Flash Gear

The highest rated PPE is typically Category 4, designed to withstand incident energy levels exceeding 40 cal/cm². This category includes specialized suits that provide head-to-toe protection, including hoods, gloves, and face shields.

The Primary Goal of Arc Flash Gear

The primary goal of PPE is to minimize the risk of injury or death from an incident. By creating a barrier between the wearer and the intense heat and flames, ppe can significantly reduce the severity of burns and other injuries.

What is the Most Important Criteria for Choosing PPE for Arc Flash Gear?

The most important criteria for choosing PPE is the arc rating. The arc rating measures the protective performance of the clothing and indicates the level of incident energy that the gear can withstand. It is typically measured in calories per square centimeter (cal/cm²). For example, PPE with a 12 cal/cm² rating can protect against lower energy exposures, while gear with a 40 cal/cm² rating provides higher protection for more intense incidents.

Additionally, selecting PPE that complies with NFPA 70E standards is crucial. NFPA 70E outlines the requirements for electrical safety in the workplace, including the specifications for protection. Ensuring that PPE meets these standards guarantees that the gear is designed and tested to protect against hazards effectively. For specific employer obligations, selection steps, and labeling rules, review the arc flash PPE requirements to verify compliance efforts.

How Long is Arc Flash Gear Good For?

The longevity of ppe depends on several factors, including the frequency of use, the conditions under which it is used, and how well it is maintained. Generally, ppe should be inspected regularly for signs of wear and tear. Flame resistant (FR) clothing, for instance, may need to be replaced after about 1 to 2 years of regular use, but this can vary based on the manufacturer's recommendations and the intensity of the work environment.

Storage bags play a crucial role in extending the life of ppe. Proper storage can prevent damage from environmental factors such as moisture, dust, and UV light, which can degrade the protective properties of the gear over time.

What is the Highest Rated PPE for Arc Flash Gear?

The highest rated PPE for ppe is typically found in the PPE Category 4 as defined by NFPA 70E. This category includes gear with an arc rating of at least 40 cal/cm². An arc flash suit in this category often comprises multiple layers, including a flame-resistant outer layer, arc-rated bib overalls, and a hood with a face shield.

PPE in this category is designed to provide maximum protection for workers exposed to high incident energy levels, ensuring they remain safe during even the most severe incidents.

What is the Primary Goal of Arc Flash Gear?

The primary goal of ppe is to protect workers from the thermal and physical hazards. This includes protecting against burns from intense heat, injuries from molten metals, and impacts from the pressure wave generated by an electrical explosion. Properly designed arc flash gear minimizes the risk of severe injury or death, allowing workers to perform their duties safely in hazardous environments.

PPE aims to:

- Prevent Burns: The heat from an electrical explosion can cause severe burns. Flame resistant clothing helps to prevent these burns by providing a barrier between the worker and the heat source.

- Protect Against Molten Metals: During an arc blast, metals can melt and splatter. PPE is designed to withstand and repel these molten materials.

- Shield from Pressure Waves: The pressure wave can cause physical injuries. Sturdy, well-fitted gear helps to protect against the force of these blasts.

Additional Considerations

When selecting PPE, consider factors such as comfort, fit, and ease of movement. Ill-fitting gear can hinder the wearer's ability to perform tasks safely. Additionally, ensure the gear is compatible with other PPE, such as hard hats and safety glasses.

Proper storage of PPE is also important to maintain its integrity. Consider using storage bags or containers to protect the gear from dust, moisture, and other contaminants.

PPE is a critical component of electrical safety. By understanding the importance of arc ratings, PPE categories, and proper selection criteria, workers and employers can make informed decisions to protect themselves from the devastating effects of incidents. Remember, investing in high-quality PPE is an investment in the safety and well-being of electrical workers. For selection, care, and training considerations in one place, see this PPE for arc flash summary as you develop or update your program.

Related Articles

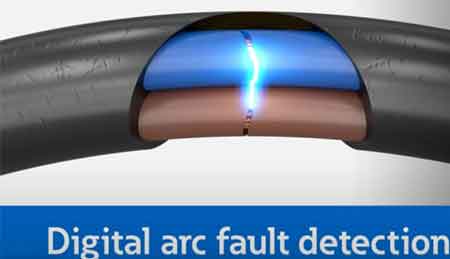

Arc Flash Breaker: The Ultimate Electrical Safety Solution

Arc flash breaker, also known as an arc fault circuit interrupter (AFCI), detects dangerous electrical arcs and de-energizes the circuit to prevent fires. Unlike a standard breaker, it provides enhanced protection against arc faults in residential and commercial systems.

Quick Definition: Arc Flash Breaker

-

✅ Arc flash breaker: A specialized circuit breaker designed to detect high-energy electrical arcs and rapidly isolate faulted equipment.

-

✅ Enhanced protection: Interrupts arc faults faster than standard breakers, reducing incident energy and protecting workers.

-

✅ Industrial use: Deployed in switchgear, MCCs, and panelboards to meet NFPA 70E and IEEE 1584 safety standards.

An arc flash breaker is a specially designed arc fault circuit breaker that helps reduce the risk of arc flash(AF) incidents by quickly detecting faults and interrupting current flow before dangerous energy levels are reached. These breakers are critical in enhancing electrical safety by limiting incident energy and protecting both personnel and equipment in high-risk environments. The electric discharge flash breaker is one innovative technology that has significantly improved safety measures in the realm of industrial power systems. This advanced device helps protect personnel and property from the hazards of AF incidents. Understanding arc flash protection is essential for maintaining electrical safety and minimizing risks.

Request a Free Training Quotation

How Does an AF Breaker Help Prevent AF Incidents in Electrical Systems?

AF breakers, particularly AF circuit breakers, are designed to detect electrical discharges that could result in hazardous incidents. When an AF is detected, these breakers immediately de-energize the circuit, preventing further damage. An AF breaker is particularly effective in monitoring branch circuits supplying outlets in areas such as family rooms, dining rooms, living rooms, parlours, libraries, dens, recreation rooms, closets, and hallways. Quickly addressing conditions prevents short circuits and the potential for electrical fires. For general electrical safety tips and guidelines, be sure to check out our comprehensive resources.

What Is the Difference Between a Regular Circuit Breaker and an AF Breaker?

A standard circuit breaker is primarily designed to protect against overloads and short circuits by tripping when the current exceeds a certain threshold. However, it does not detect the small electric discharges that can occur in damaged wiring, which may ultimately lead to electrical fires.

In contrast, an AF circuit breaker is designed to detect these smaller electric discharges that would otherwise go unnoticed by a standard circuit breaker. These devices monitor both series and parallel conditions, providing enhanced protection by interrupting the arc fault circuit interrupters before the fault can escalate. This makes AF circuit interrupters, AFCIS, essential for residential electrical systems, especially in areas where electrical fires are a common risk. Electrical breakers play a vital role in protecting systems from faults. Learn more in our article on circuit breaker types.

Do You Select the Right AF Breaker for Your Electrical System?

Selecting the right AF breaker depends on the type of electrical system you are working with and the level of protection required. In residential installations, combination-type AFCIS are typically used. These breakers offer protection from both series and parallel electric discharge faults, which can occur in aging or damaged wiring. The National Electrical Code (NEC) requires AFCIS to be installed in various dwelling unit areas, including family rooms, living rooms, dining rooms, and more.

In addition to AFCIS, a GFCI (ground fault circuit interrupter) may also be installed in locations such as bathrooms to protect against electric shock. A GFCI works by detecting current leakage to the ground and cutting off the power, providing a different form of protection than an AFCI circuit breaker.

What Role Does An AF Breaker Play in Enhancing Workplace Safety?

AF breakers, including AF circuit interrupters, enhance workplace safety by preventing electrical fires and other incidents. In industrial settings, they help protect workers by detecting and interrupting dangerous arcing electric discharges that could lead to severe injuries or damage to equipment. Regular maintenance and installation of these breakers, according to the National Electrical Code (NEC) and National Fire Protection Association standards, ensure a safer working environment. Employers should conduct regular electrical safety audits and electric discharge flash studies to identify potential hazards and implement the correct safety measures, including AFCIs.

How Does An AF Breaker Interact with Other Protective Devices?

AF breakers, particularly electric discharge fault circuit interrupters, often work in conjunction with other protective devices in an electrical system. In residential settings, AFCIs and ground fault circuit interrupters (GFCIs) provide comprehensive protection against both electrical fires and shock hazards. While AFCIs prevent fires by detecting arcing conditions, GFCIs protect people from electrical shock by sensing current leakage to the ground. Click here to learn how to prevent an arc flash from happening in your work environment, follow essential safety protocols and precautions.

In industrial applications, AF breakers can be integrated with overcurrent protective devices and personal protective equipment (PPE) to create a layered approach to safety. By detecting and responding to electrical faults early, AF breakers prevent hazardous incidents, thereby ensuring the protection of both equipment and personnel.

AF breakers are a crucial component of modern electrical systems, offering advanced protection against electric discharge faults that could otherwise lead to hazardous electrical fires. Unlike standard arc fault circuit breakers, AFCIs detect smaller electric discharges and de-energize circuits before a fault can escalate. By following National Electrical Code guidelines and incorporating AFCIs into electrical systems, homes and workplaces can significantly reduce the risks associated with electrical faults. In conjunction with other protective devices, whether in a home or an industrial facility, these breakers create a safer and more reliable electrical system.

For more information on identifying and addressing electrical safety in the workplace, visit our dedicated page.

Related Articles:

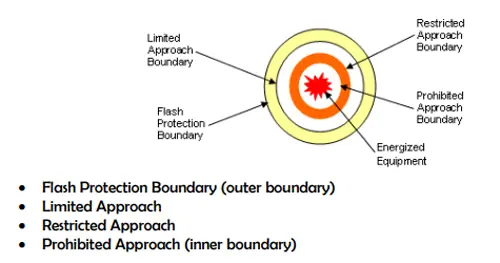

The Three Limits of Approach Boundaries Are

The three limits of approach boundaries are Limited, Restricted, and Prohibited, defining safe distances from energized electrical parts to reduce shock hazards and meet NFPA 70E safety requirements.

What Are The Three Limits of Approach Boundaries?

The three limits of approach are designed to protect workers from electrical hazards, specifically shock and arc flash. These are:

✅ Limited Approach Boundary – minimum safe distance to reduce shock risk for qualified and unqualified persons

✅ Restricted Approach Boundary – closer limit requiring additional protective measures and PPE

✅ Prohibited Approach Boundary – closest limit treated as direct contact with energized parts

Reviewing the arc flash boundary chart can help safety managers compare shock protection distances with thermal hazard limits.

1. Limited Approach Boundary

The limited approach boundary is the outermost zone and marks the distance from an exposed energized conductor or circuit part where a shock hazard exists. While unqualified personnel cannot cross this boundary unless escorted by a qualified person, qualified workers may enter this zone wearing appropriate voltage-rated shock protection equipment. The limited approach boundary is typically determined based on the system's voltage level and specific safety requirements. The Limited Approach Boundary is the outermost shock protection zone, restricting access for unqualified personnel without a qualified escort.

How to determine the limited approach boundary

The limited approach boundary can be calculated using tables provided in NFPA 70E, which consider factors such as voltage level and the presence of insulating materials. In general, the higher the voltage, the greater the distance required for the limited approach boundary.

2. Restricted Approach Boundary

The restricted approach boundary lies within the limited approach boundary and signifies an increased risk of shock due to potential arc-over or inadvertent movement. Only qualified workers may enter this zone, and they must utilize additional shock protection measures, such as insulated tools or equipment, in addition to their voltage-rated PPE. The Restricted Approach Boundary is closer to energized parts, requiring additional PPE and insulated tools for safe entry.

How to determine the restricted approach boundary

The restricted approach boundary is typically determined by the specific task being performed and the associated risk factors. Factors such as the voltage level, equipment configuration, and working conditions are considered when establishing this boundary.

3. Prohibited Approach Boundary

The prohibited approach boundary is the innermost zone, representing the closest distance a person can approach an exposed energized part without making direct contact. Entry into this zone is strictly limited to qualified workers with specific training and authorization, who must follow rigorous safety procedures. Additionally, they must wear appropriate PPE, including arc flash protection equipment, to safeguard against the potential energy released during an arc flash incident. Understanding prohibited approach boundary requirements is critical, as this zone is treated the same as direct contact with live parts.

How to determine the prohibited approach boundary

The prohibited approach boundary is established based on the results of an arc flash hazard analysis. This analysis calculates the incident energy, measured in calories per square centimetre (cal/cm²), at various distances from the exposed live part. The distance at which the incident energy reaches a level that would cause a second-degree burn (typically 1.2 cal/cm²) is considered the flash protection boundary, which often coincides with or is used to establish the prohibited approach boundary.

How to Determine the Limited Approach Boundary?

The limited approach boundary is determined based on the nominal system voltage. NFPA 70E provides tables that specify the distances for different voltage levels. For instance, for systems operating at 50 volts to 750 volts, the limited approach boundary is typically set at 3 feet 6 inches. This boundary ensures that unqualified persons remain safe from energized components, reducing the risk of accidental contact.

How to Determine the Prohibited Approach Boundary?

The prohibited approach boundary is calculated to ensure that no part of the body or conductive object can come in close proximity to the exposed energized conductor or circuit part without adequate protection. This boundary is determined by considering the potential for arc flash hazards and the necessary incident energy calculations. For example, the prohibited approach boundary might be set at 1 inch for systems operating at 750 volts to 15,000 volts. This boundary is critical for ensuring the highest level of protection against direct contact with energized parts.

How to Determine the Restricted Approach Boundary?

The restricted approach boundary is determined based on the shock protection requirements and the nominal system voltage. NFPA 70E outlines specific distances for different voltage levels. For example, for systems operating at 50 volts to 750 volts, the restricted approach boundary is typically set at 1 foot. This boundary is essential for protecting workers from shock hazards, requiring specific PPE and work permits to enter.

Importance of Understanding and Implementing Boundaries

Understanding and properly implementing these approaches is crucial for maintaining electrical safety in the workplace. These zones help in:

-

Preventing Electrical Shocks: By maintaining a safe distance from exposed energized parts, the risk of electrical shocks is significantly reduced.

-

Ensuring Proper Use of PPE: The zone ensures that workers use the appropriate level of personal protective equipment (PPE) based on the incident energy levels.

-

Complying with Safety Standards: Adhering to NFPA 70E standards helps in maintaining compliance with national fire protection regulations and ensures a safe work environment. A thorough arc flash assessment will establish both the arc flash boundary and the appropriate approach boundaries for each piece of equipment.

The concept of approach boundaries is fundamental to electrical safety, providing a structured method for protecting workers from electrical hazards. By understanding the limited, restricted, and prohibited approach zone, workers can ensure their safety and comply with NFPA 70E standards. Proper training, use of PPE, and adherence to these zones are essential for preventing accidents and maintaining a safe working environment around energized electrical components.

Related Articles

Arc Flash Categories by Voltage Chart

Arc flash categories by voltage chart shows required PPE levels based on system voltage and incident energy. This guide helps electrical workers select appropriate protection according to NFPA 70E standards, reducing shock and arc flash risks in industrial and commercial settings.

What are the Arc Flash Categories by Voltage Chart?

An arc flash categories by voltage chart provides critical safety guidance for selecting personal protective equipment (PPE) based on system voltage and potential incident energy.

✅ Identifies PPE categories by system voltage and task risk level

✅ Aligns with NFPA 70E and CSA Z462 standards

✅ Supports safe work practices and compliance for electrical safety

For a foundational overview of arc flash risks, see our main arc flash guide, which covers causes, hazards, and safety strategies.

This chart categorizes different voltage levels and their associated risks, guiding workers and safety professionals in selecting the appropriate level of protection. Higher voltage levels generally correspond to higher energy releases during an arc event, which means more extensive PPE is necessary. By understanding how categories are influenced by voltage, fault current, and the clearing time of protective devices, professionals can accurately classify hazards and ensure safety in potentially dangerous environments using the voltage chart. Learn how arc flash boundary calculations are influenced by voltage, fault current, and PPE requirements to ensure accurate risk classification.

Request a Free Training Quotation

In electrical safety, understanding the correlation between voltage levels and categories is essential to ensuring proper protection for workers. The potential hazards associated with working on or near energized equipment vary depending on the voltage present, and selecting the correct personal protective equipment (PPE) is crucial for minimizing risk.

Arc Flash Categories by Voltage Chart

| System Voltage | Typical Equipment | Incident Energy (cal/cm²) | PPE Category | Required PPE |

|---|---|---|---|---|

| < 240V | Control panels, lighting panels | < 1.2 | Category 0/1 | FR shirt & pants, safety glasses, hearing protection |

| 240–480V | Motor control centers, switchgear | 1.2 – 8 | Category 2 | FR clothing (min 8 cal/cm²), arc-rated face shield, gloves, hearing protection |

| 480–600V | Large breakers, transformers | 8 – 25 | Category 3 | Arc-rated coveralls, flash hood, gloves, hard hat, face and neck protection |

| 600–1000V | Substation gear, bus ducts | 25 – 40 | Category 4 | Arc-rated suit (≥40 cal/cm²), full-body protection, gloves, hood, balaclava |

| > 1000V | Utility gear, high-voltage gear | Site-specific analysis | Engineering req. | Custom PPE based on incident energy, detailed arc flash study required |

Arc Flash Boundary Table by Incident Energy

See the Arc Flash Boundary Table by Incident Energy for a detailed breakdown of PPE levels at specific energy thresholds.

| Incident Energy (cal/cm²) | Minimum Arc Flash Boundary | PPE Category | Required PPE Examples |

|---|---|---|---|

| 1.2 cal/cm² | 18 inches (typical) | Category 1 | FR shirt and pants, safety glasses, and hearing protection |

| 4 cal/cm² | 24 inches | Category 2 | FR clothing (8 cal/cm² min), arc-rated face shield, leather gloves |

| 8 cal/cm² | 36 inches | Category 3 | Arc-rated coveralls, balaclava, hard hat, face shield |

| 25 cal/cm² | 48 inches | Category 4 | Arc-rated full suit, arc-rated hood, gloves, full-body protection |

| 40+ cal/cm² | >60 inches (engineered) | Special Analysis | Suit rated ≥40 cal/cm², insulated tools, work only if absolutely necessary |

Frequently Asked Questions

What are the different arc flash categories based on voltage levels?

Arc flash categories are classified according to the potential energy release during an electrical fault. The higher the voltage, the greater the likelihood of a severe arc event. Categories range from Category 1 to Category 4, with each representing an escalating level of risk and requiring increasingly protective gear. Low-voltage systems, typically operating at voltages below 240 volts, often fall into Category 1 or 2. These systems present a lower energy release and require less protection. As the voltage increases, so does the potential danger, placing the system in higher categories.

Categories 3 and 4 are typically reserved for systems with higher voltage, where the risk of a more severe arc is present. These categories require extensive protection, including flame-resistant clothing, gloves, and face shields. The exact category for a specific task will depend not only on the voltage but also on other factors, such as the available fault current and the distance from the energy source. To ensure proper protection for each hazard category, refer to our detailed Arc Flash PPE Requirements Chart, which outlines the specific clothing and equipment required by incident energy level.

How does voltage impact the arc flash category assigned to a task?

The relationship between voltage and the assigned category is direct but not absolute. As voltage levels rise, the energy that can be released during an electrical explosion increases. However, voltage is not the only factor that determines the hazard level. The available fault current and clearing time of protective devices also play a significant role.

For example, a system operating at 480 volts may fall into a higher category than one operating at 240 volts, but if the available fault current is low, the overall energy release might still place it in a lower category. The combination of voltage, fault current, and protective device clearing time will dictate the category, making the use of a voltage chart essential for accurate classification. To dive deeper into voltage-specific hazards, our 480V arc flash guide explains how moderate voltage levels can still pose serious risks if not properly assessed.

What PPE is required for each arc flash category by voltage level?

PPE is designed to provide protection against the thermal energy released during an arc event. Each category corresponds to a specific level of PPE, which includes clothing and equipment rated for the hazard. For Category 1, basic PPE, such as flame-resistant shirts, pants, and safety glasses, is typically required. As the categories increase, so does the protection level. Explore the differences between Category 1 PPE and Category 4 suits like the 40 cal arc flash suit to understand how protective gear scales with risk.

For Category 2, additional PPE, such as arc-rated gloves and a face shield, may be necessary. In Categories 3 and 4, full-body protection is required, including arc-rated coveralls, gloves, helmets, and face shields. The voltage chart and the corresponding hazard category for the task at hand should guide the choice of PPE.

How do you determine the arc flash category using a voltage chart?

A voltage chart provides a visual reference for determining the appropriate arc flash category based on the system’s operating voltage. It helps in evaluating the potential energy release and selecting the correct PPE. The chart is typically organized by voltage levels, with different columns or sections indicating the corresponding category. To use the chart, identify the operating voltage of the system and then cross-reference it with the available fault current and protective device clearing time to determine the appropriate category.

It is important to remember that the voltage chart is not a stand-alone tool; it must be used in conjunction with a thorough hazard assessment. Other variables, such as the proximity of workers to the energized equipment, must also be considered when assigning a category.

Are higher voltage systems always in higher arc flash categories?

While higher voltage systems generally pose a greater risk, they are not always assigned to higher categories. The actual category is determined by the total energy released during an arc event, which is influenced by factors beyond just voltage. Systems with high voltage but low fault current might be placed in a lower category than systems with lower voltage but high fault current.

Thus, it is essential to conduct a full analysis of all the factors involved, including voltage, available fault current, and the clearing time of protective devices, when determining the category.

Understanding arc flash categories by the voltage chart is crucial for protecting workers from electrical hazards. By using a voltage chart and considering all relevant factors, such as fault current and the clearing time of protective devices, organizations can accurately determine the appropriate category for each task. Selecting the correct PPE based on these categories is vital for ensuring the safety of personnel working with energized equipment. Discover common mistakes in assessments with our article on the 10 most frequent arc flash analysis errors and how to avoid them.

Related Articles

What is an arc flash boundary?

What is an arc flash boundary? It is the NFPA 70E-defined safe working distance where incident energy reaches 1.2 cal/cm², dictating PPE selection, approach limits, arc flash labeling, and electrical safety procedures for energized equipment.

What Is an Arc Flash Boundary?

The arc flash boundary is the NFPA 70E distance where 1.2 cal/cm² incident energy requires PPE and controls.

✅ Defined by NFPA 70E based on incident energy analysis

✅ Requires PPE, signage, and energized work permits inside boundary

✅ Adjusted by fault current, clearing time, and working distance

The term arc flash boundary may sound like technical jargon, but its meaning and evolution have been crucial in shaping modern electrical safety practices. While it’s now a defined safety zone in NFPA 70E and CSA Z462, its origins and significance have a deeper story rooted in the effort to prevent catastrophic workplace injuries. For a plain-language primer on concepts and terminology, the Arc Flash Boundary overview outlines definitions, history, and key safety implications.

Historical Development of the Term

Before the adoption of NFPA 70E, the concept of arc flash hazards received little formal recognition in workplace safety programs. Electrical safety focused primarily on shock hazards, with boundaries defined only in terms of approach distances to energized conductors. To understand how both thermal and shock boundaries are set, see the guide to determining arc flash and electric shock protection boundaries for methodology and examples.

That began to change in the 1990s, as awareness grew around the dangers of arc flash — high-energy explosions caused by electrical faults. Researchers, particularly those involved in IEEE 1584, helped quantify the risks and the amount of incident energy workers could be exposed to during such events. For engineers performing studies, the arc flash boundary calculation resource details equations, assumptions, and data inputs.

With the 2000 publication of NFPA 70E, the arc flash boundary was formally introduced as a critical protection zone — defined as the distance at which a worker could receive 1.2 cal/cm² of incident energy, the threshold for a second-degree burn. In 2015 and later updates, this definition was refined, and emphasis shifted from rigid tables to calculated boundaries based on incident energy analysis, incorporating real-world equipment and system data. When quick lookups are needed, the incident energy boundary table can help verify results and inform PPE selection.

CSA Z462, Canada's parallel standard, adopted similar language and principles, aligning the term across North America and reinforcing its use in both industrial and commercial environments. This alignment also clarifies distinctions from the Limited Approach Boundary, which addresses shock hazards under separate criteria.

Why Does It Matter?

For electrical workers, knowing where the arc flash boundary lies is not theoretical — it’s life-saving. This boundary determines when and where personal protective equipment (PPE) is required and defines safe work distances. It shapes:

-

Job planning and risk assessment

-

The selection of arc-rated clothing and equipment

-

Decisions about energized vs de-energized work

-

Signage, labeling, and physical barriers in the field

In day-to-day tasks like opening panels or performing diagnostics, the arc flash boundary informs whether a worker must don a full arc-rated suit or can proceed with minimal PPE. It also supports supervisors and safety coordinators in enforcing compliant work procedures. For field implementation, the guidance on marking off arc flash boundaries covers labeling, barricades, and temporary controls.

In short, it translates complex hazard calculations into clear, actionable field instructions that protect lives.

Common Misconceptions About Arc Flash Boundaries

Despite its widespread use, the term still carries confusion. Here are a few common misconceptions:

-

“It’s the same as the Limited Approach Boundary.”

False. The Limited Approach Boundary addresses shock hazards. The Arc Flash Boundary relates specifically to thermal energy exposure. -

“All arc flash boundaries are 18 inches.”

Not true. While 18 inches is a common working distance for calculating incident energy, arc flash boundaries vary depending on system voltage, fault current, clearing time, and equipment condition. Practitioners often consult the arc flash boundary chart to visualize how these variables shift distance across equipment types. -

“If I’m outside the arc flash boundary, I don’t need to worry.”

That’s misleading. While PPE may not be required beyond the boundary, awareness and training are still critical. Arc blast pressure, flying debris, and indirect injuries remain possible. -

“Once labeled, a boundary never changes.”

Incorrect. Labels must be updated after system changes, new hazard analyses, or NFPA/CSA standard updates. Assumptions based on outdated data can be dangerous.

The arc flash boundary is more than a technical term — it is a dynamic tool born out of decades of research and tragedy. Its importance continues to grow as electrical systems evolve and safety regulations adapt. By understanding where it came from, what it means, and how to apply it, we can bridge the gap between compliance and true workplace safety.

Would you like a new meta title and description for this updated version?

Visit our Arc Flash Boundary main page for more detailed information on calculating boundaries, protection zones, compliance requirements, and real-world application examples.