Latest Arc Flash Articles

OSHA 1910.333: Safety-Related Work Practices

OSHA 1910.333 outlines safety practices for working on or near exposed energized electrical conductors and circuit parts. It ensures proper de-energization, lockout/tagout procedures, and qualified personnel requirements to reduce electrical shock, arc flash, and burn hazards.

What is: "OSHA 1910.333"?

OSHA 1910.333 is a key electrical safety regulation focused on preventing electrical injuries during work on energized systems.

✅ Requires proper de-energization and lockout/tagout procedures

✅ Defines qualifications for authorized electrical workers

✅ Aims to prevent electric shock, arc flash, and burns

Request a Free Training Quotation

OSHA 1910.333, formally known as the Work Practices Standard (29 CFR 1910.333), is a cornerstone of electrical safety in workplaces across the United States. Established by the Occupational Safety and Health Administration, this regulation outlines safety-related work practices to protect workers from electrical hazards like shocks, burns, or injuries from exposed electric parts. Whether you’re an employer, safety manager, or worker, understanding this standard is essential for creating and maintaining a safe work environment. Let’s break down its major sections and explore how it ensures workplace safety through practical measures and compliance. To understand the related procedures, see how 29 CFR 1910.147 outlines OSHA's lockout/tagout requirements.

OSHA 1910.333 Safety-related Work Practices

At its core, regulation 29 CFR 1910.333 requires that safety-related work practices be employed to prevent electrical injuries from direct or indirect contact with energized parts. These work practices must be appropriate for the nature of the work and the piece of equipment involved. Discover the differences between arc flash vs arc blast and how each presents unique hazards.

According to OSHA, live parts must be de-energized before any employee can work on or near them unless doing so would create additional hazards or is infeasible due to equipment design or operational requirements. For example, de-energizing equipment might endanger life support systems or interrupt critical industrial processes.

In the context of electrical safety for general industry, OSHA’s enforcement of 29 CFR 1910.333 emphasizes the importance of clearly distinguishing between qualified persons and unqualified persons when performing tasks near or on live parts. Qualified individuals must receive specific training on safe work practices, including how to recognize electrical hazards, determine minimum approach distances, and implement appropriate protective measures. These practices are critical to ensuring workplace safety, especially when operations involve energized work or proximity to exposed energized conductors and circuit parts.

To mitigate risk, OSHA mandates strict lockout/tagout procedures when servicing or maintaining de-energized circuits. These protocols ensure that energy sources are isolated and secured before work begins. However, when lockout/tagout is not feasible—such as during certain testing or troubleshooting tasks—employers must adhere to additional training requirements and provide enhanced enforcement guidance to ensure all hazards are controlled. By clearly outlining expectations for both routine operations and exceptional cases, OSHA helps organizations maintain consistent compliance and safeguard workers from preventable injuries. For a visual breakdown of approach limits, explore our arc flash boundary chart.

Major Sections

OSHA 1910.333, also known as the "Energized Equipment Work Rules" (29 CFR 1910.333), is a critical regulation established by statute to protect workers from electrical hazards in general industry. Enforced by the Occupational Safety and Health Administration, it outlines safety-related work practices to prevent injuries from exposed electric parts, such as shocks or arc flashes. This standard applies to particular circumstances, ensuring employers address risks without creating circumstances that could introduce additional or increased hazards. Below, we explore its key components, from de-energizing circuits to training workers, to help you comply and prioritize safety. Our NFPA 70E guide provides practical alignment with OSHA 1910.333 to prevent electrical injuries.

De-energizing and Verification

A cornerstone of electrical safety compliance is to ensure that every piece of equipment is de-energized before work begins, eliminating risks from live parts. Employers must shut down electrical systems unless doing so is infeasible, such as in a continuous industrial process where stopping operations could cause additional or increased hazards. Once powered down, a qualified person must verify the absence of voltage using proper test instruments, confirming the system is safe for work. This step is non-negotiable to protect workers from unexpected electrical surges.

Lockout/Tagout Procedures

OSHA 1910.333 mandates robust lockout/tagout (LOTO) procedures to secure de-energized circuits. Workers isolate energy sources and apply locks or tags to prevent accidental re-energization, a critical safeguard in complex industrial settings. Only the authorized employee who placed the LOTO device can remove it, ensuring accountability. Note that our enforcement aligns with related standards like 1910.147, reinforcing consistency across OSHA requirements are set to protect workers.

Working on Energized Systems

When de-energizing isn’t practical—such as during essential maintenance in a continuous industrial process—OSHA 1910.333 permits energized work under strict conditions. Employers must justify the need, avoiding blanket exemptions, and protect workers with safe approach distances and personal protective equipment, such as insulated gloves, arc-rated clothing, or face shields. Only qualified persons, trained to recognize electrical hazards, can perform such tasks, ensuring that safety procedures apply to particular circumstances.

Safe Approach Distances

To shield workers from arc flashes or shocks, the standard establishes minimum approach distances based on voltage levels and the level of worker training. Unqualified persons must maintain greater distances from live parts to avoid accidental contact, while qualified persons follow tailored guidelines. This focus on spatial awareness reduces risks near exposed electric components, emphasizing prevention over reaction.

Personal Protective Equipment

Personal protective equipment is a lifeline for electrical work. When workers face live parts, the OSHA electrical standard requires employers to assess each piece of equipment and task to provide PPE, such as rubber gloves, flame-resistant attire, or eye protection. This proactive measure ensures workers are equipped to handle potential hazards, minimize injury risks, and align with the United States government’s safety priorities. See our article on arc flash PPE requirements to ensure your workers are properly protected.

Re-energizing Equipment Safely

After maintenance, re-energizing equipment demands care. Workers must remove all temporary protective measures, clear tools, and confirm the system is ready. Only the authorized employee who applied the LOTO device can restore power, preventing errors. This structured process ensures equipment returns to service safely, closing the loop on OSHA’s safety-related work practices.

Training for All Workers

Training underpins OSHA 1910.333’s success. Employers must educate qualified persons on advanced skills for energized work and train unqualified persons to recognize and avoid electrical risks. Covering safe work practices, PPE use, and emergency protocols, training empowers workers to make informed decisions, reinforcing a safety culture. Visit our arc flash training certification page to equip your team with OSHA-compliant safety skills.

OSHA’s Guidance and Enforcement

The Occupational Safety and Health Administration clarifies OSHA 1910.333 through interpretation letters that explain how requirements apply in real-world scenarios. For instance, a letter constitutes an OSHA interpretation when it details PPE needs for a specific task. These interpretation letters clearly explain the requirements, but they cannot create additional employer obligations beyond the standard. Affected by statute standards and regulations, employers must stay vigilant, as OSHA’s enforcement adapts in response to new information, such as emerging technologies. Non-compliance may result in citations, underscoring the importance of adhering to these guidelines.

This comprehensive framework ensures that the OSHA electrical standard protects workers while providing employers with clear, actionable steps. The standard fosters safer workplaces without imposing undue burdens by prioritizing de-energizing, LOTO, PPE, and training. Discover how arc flash hazard analysis enhances risk assessments for energized electrical work.

Understanding OSHA’s Interpretation and Enforcement

The Occupational Safety and Health Administration clarifies regulation 29 CFR 1910.333 through interpretation letters explaining how the standard applies to real-world scenarios. For example, a letter constitutes an OSHA interpretation when it addresses whether certain PPE is required for a specific task. These interpretation letters explain requirements in detail, helping employers comply without guesswork. However, it’s worth noting that letters explain these requirements and their interpretation of them applies to particular circumstances, but they cannot create additional employer obligations beyond the standard itself.

OSHA’s enforcement is responsive to new information, such as emerging technologies or workplace trends. If a company’s practices deviate from the standard, OSHA may issue citations to ensure compliance. Affected by statutory standards and regulations, employers must stay vigilant to maintain a safe workplace and avoid penalties.

Why OSHA 1910.333 Matters

It isn’t just a set of rules—it’s a framework for protecting lives. Electrical hazards are among the leading causes of workplace injuries, and this standard empowers employers to create safer environments. Businesses can reduce risks and build trust with their workforce by prioritizing safety-related work practices, using personal protective equipment, and adhering to lockout/tagout protocols. Plus, compliance demonstrates a commitment to the well-being of employees, aligning with the United States government’s mission to uphold occupational safety.

Employers must ensure that all electrical work complies with the requirements of 1910.333. This means:

-

Training qualified workers on work practices standard 29 CFR 1910.333

-

Providing appropriate personal protective equipment

-

Establishing safe procedures for lockout/tagout

-

Ensuring compliance with documentation and signage rules

-

Maintaining records and justifications for energized work

Interpretation and Enforcement

Understanding the interpretation of the requirements is important. OSHA frequently publishes interpretation letters to help clarify its rules. Each letter constitutes an OSHA interpretation, but OSHA notes that these letters explain these requirements only in the context of the specific scenario presented. They cannot create additional employer obligations or carry the same legal weight as the standard itself.

Additionally, OSHA states:

“Note that our enforcement guidance may be affected by changes to OSHA rules.” This means that interpretations can evolve in response to new information or policy changes.

Employers must remain aware of changes and updates to OSHA regulations. Interpretation letters are useful tools for understanding how regulations may apply to particular circumstances, especially when dealing with complex systems or rare worksite conditions.

Tips for Compliance

To meet OSHA's electrical safety standard requirements, consider these practical steps:

-

Conduct Risk Assessments: Evaluate every piece of equipment for electrical hazards before work begins.

-

Invest in Training: Ensure that all workers, regardless of their qualifications, understand safe work practices and the proper use of PPE.

-

Stay Updated: Monitor OSHA’s interpretation letters for responses to new information that could affect your operations.

-

Implement LOTO: Use robust lockout/tagout systems to secure de-energized circuits.

-

Audit PPE: Regularly check that personal protective equipment meets OSHA standards and is suitable for the task.

OSHA 1910.333 is a vital tool for safeguarding workers from electrical dangers in the general industry. Outlining clear safety-related work practices helps employers navigate the complexities of energized and de-energized systems while minimizing additional or increased hazards. From lockout/tagout to PPE and training, the standard’s major sections work together to create a safer workplace. Stay informed, leverage OSHA’s interpretation letters, and prioritize compliance to protect your team and uphold the values of the Occupational Safety and Health Administration.

Explore More Arc Flash Topics:

Explore our Arc Flash Training Programs or contact us to Request a Free Training Quotation for group safety sessions and PPE consultation.

Sign Up for Electricity Forum’s Arc Flash Newsletter

Stay informed with our FREE Arc Flash Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Arc Flash Study Requirements

Arc flash study requirements define the steps needed to assess electrical hazards, including fault current study, device coordination, and labeling. These studies help ensure NFPA 70E and OSHA compliance to protect workers from arc flash risks and improve electrical safety.

What are Arc Flash Study Requirements?

Arc flash study requirements are essential for ensuring electrical hazard compliance with OSHA and NFPA 70E. They:

✅ Include fault current, equipment labeling, and protective device coordination

✅ Ensure NFPA 70E and OSHA compliance for workplace safety

✅ Protect workers from arc flash and shock hazards

These studies identify safety risks, calculate incident energy, and define boundaries to help protect workers from serious injuries. A properly executed arc flash risk assessment determines PPE categories, short circuit energy levels, and mitigation strategies that reduce exposure during energized work. Conducting regular studies supports electrical safety programs across industrial, commercial, and utility environments. Visit our Arc Flash Study Training Course Page

Request a Free Training Quotation

Understanding Arc Flash

Arc flashes release extreme heat and energy that can cause serious injury or death. While this page explains the requirements for conducting an arc flash study, the detailed process of identifying hazards and evaluating risks is covered in our Arc Flash Hazard Analysis guide. For more on energy levels and hazard thresholds, see our Incident Energy guide.

Regulatory Requirements for Arc Flash Studies

While OSHA does not explicitly require an arc flash study, compliance with OSHA 29 CFR 1910.333 and 1910.269 indirectly mandates the identification and mitigation of hazards. NFPA 70E provides a structured approach to electrical safety risk evaluation, including a proper risk evaluation.

Under NFPA 70E:

-

Risk Assessment

Employers must assess potential arc hazards and implement controls to minimize exposure to them. This includes identifying energized equipment, estimating incident energy, and determining the likelihood of the incident occurring. -

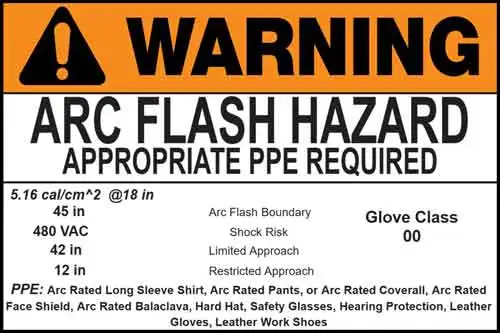

Labeling of Electrical Equipment

All electrical panels and gear likely to require inspection or servicing while energized must be labelled with the arc flash boundary and incident energy level, as per Section 130.5(H). -

Five-Year Review Cycle

NFPA 70E requires a review of studies at least every five years, or more frequently if significant electrical changes occur.

For a deeper breakdown of these requirements, refer to our incident energy analysis resource.

Key Components of an Arc Flash Study

An effective arc flash study includes several interconnected technical steps that comply with NFPA 70E. These steps form the foundation of a documented safety evaluation:

1. Data Collection

-

Purpose: Gather system-specific information to model real-world fault scenarios accurately.

-

Includes: Equipment ratings, protective device settings, transformer data, conductor lengths, and grounding details.

-

Why it matters: Incomplete or outdated data can lead to incorrect incident energy results and ineffective safety labeling.

2. System Modelling

-

Purpose: Digitally represent the facility's electrical distribution system in specialized software like SKM or ETAP.

-

Includes: Development of a one-line diagram showing all critical power distribution paths and components.

-

Why it matters: A clear system model enables the simulation of how electricity flows under both normal and fault conditions.

3. Short Circuit and Coordination Study

-

Purpose: Establish the available fault current and ensure protective devices operate in the correct sequence.

-

Includes: Calculating bolted fault currents and analyzing breaker trip curves.

-

Why it matters: Accurate short circuit study directly impacts incident energy calculations and breaker coordination.

4. Incident Energy and Boundary Calculations

-

Purpose: Quantify the thermal energy that would be released at specific working distances.

-

Includes: Use of IEEE 1584 formulas to calculate calories per square centimetre (cal/cm²).

-

Why it matters: These values determine boundaries and required PPE, forming the basis for all field labelling.

5. Hazard Category Determination

-

Purpose: Assign a PPE category based on the calculated incident energy.

-

Includes: Comparing energy levels to NFPA 70E tables to define if Category 1 (low) or Category 4 (high) PPE is needed.

-

Why it matters: PPE selection must align with risk level to ensure adequate protection during energized work.

6. Recommendations and Mitigation

-

Purpose: Suggest ways to reduce risk and improve system safety.

-

Includes: Adjusting protection settings, improving coordination, installing remote racking systems, or relocating control panels.

-

Why it matters: These proactive steps reduce the likelihood or severity of incidents, lowering the overall electrical hazard severity.

PPE Selection and Arc Flash Boundaries

The results of an arc flash study guide the selection of arc-rated clothing and equipment. Incident energy calculations and hazard category determine proper PPE.

-

Category 1 (4 cal/cm²): Long-sleeved flame-resistant (FR) clothing, hard hat with arc-rated face shield, leather gloves.

-

Category 2 (8 cal/cm²): Adds arc-rated balaclava and heavier FR gear.

-

Category 3–4 (25–40+ cal/cm²): Includes multi-layer protective clothing and insulated gloves.

According to industry data, thousands of arc flash injuries occur each year in North America alone. That's why identifying and mitigating arc flash risk is not only a best practice but an essential safety obligation.

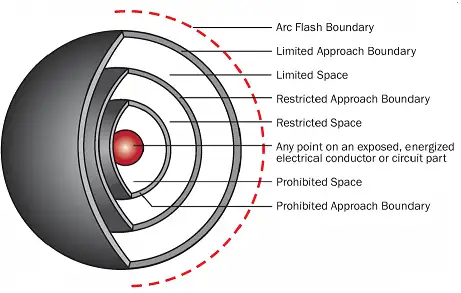

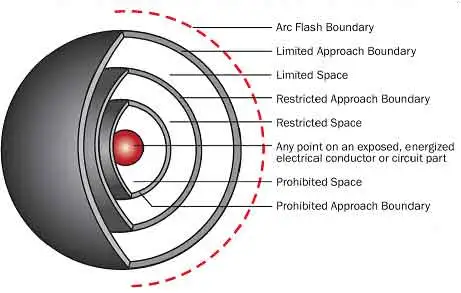

In addition to PPE, an arc flash study defines the approach boundaries:

-

Limited Approach Boundary: Distance where shock hazards require limited access.

-

Restricted Approach Boundary: Closer zone requiring special training and PPE.

-

Arc Flash Boundary: The outer perimeter where exposure exceeds 1.2 cal/cm².

To explore the differences between boundary distances and gear selection, visit our Arc Flash Gear Guide.

Who Can Perform an Arc Flash Study?

It must be conducted by qualified individuals with experience in electrical system modelling and safety compliance:

-

Electrical Engineers: Typically licensed Professional Engineers (PEs) or Certified Electrical Safety Compliance Professionals (CESCP).

-

Consultants: Often possess training in IEEE 1584 modelling and use of SKM/ETAP.

-

Qualified Personnel: Must understand NFPA 70E, OSHA regulations, and utility fault current contribution.

For training and certification opportunities, see our arc flash study training.

How Often Must Arc Flash Studies Be Conducted?

The NFPA 70E standard requires updates to arc flash studies:

-

Every 5 Years: To ensure accuracy and continued compliance.

-

After Major System Changes: Including transformer upgrades, panel additions, or relay setting adjustments.

-

Post-Incident or Fault Event: If a near-miss or arc incident occurs, the study should be revalidated.

A current report ensures an accurate arc flash study, helping reduce insurance risk and liability.

Arc flash study requirements play a pivotal role in safeguarding electrical systems and personnel from hazardous incidents. In conjunction with a proper risk assessment, these studies empower electrical engineering and maintenance professionals to design safer work environments, comply with regulatory standards, and minimize operational disruptions. Adhering to these requirements ensures not only the protection of workers but also the longevity and reliability of electrical equipment, making them a cornerstone of modern electrical safety practices.

Related Articles:

Arc Flash Boundary Explained

An arc flash boundary is the minimum safe distance from energized electrical equipment where a worker could suffer a second-degree burn from an arc flash event. It is calculated based on where incident energy reaches 1.2 calories per square centimeter (cal/cm²) according to NFPA 70E and CSA Z462 standards.

Request a Free Training Quotation

What is an Arc Flash Boundary?

In simple terms, the Arc Flash Boundary can be summarized as follows:

? The minimum safe distance from energized equipment where a worker could suffer a second-degree burn from an arc flash.

? Based on an incident energy level of 1.2 calories per square centimeter (cal/cm²) under NFPA 70E and CSA Z462 standards.

? Determined by factors such as system voltage, available fault current, clearing time, and equipment design.

The arc flash boundary (AFB) is the minimum safe distance from energized electrical equipment where a worker could suffer a second-degree burn from an arc flash event. It is calculated based on where the incident energy reaches 1.2 calories per square centimetre (cal/cm²). Defined by NFPA 70E and guided by IEEE 1584, the arc flash boundary determines required personal protective equipment (PPE), informs safe work practices, and restricts personnel entry into hazardous zones during energized tasks such as maintenance, testing, or troubleshooting.

For more details on calculated distances, see our arc flash boundary chart.

Purpose and Benefits of Establishing the AFB

This protection zone serves multiple safety functions:

-

Identifies zones of elevated thermal risk

-

Helps determine required PPE levels

-

Defines access control perimeters for qualified and unqualified personnel

-

Promotes planning for safe electrical work procedures

Visual indicators such as floor tape and posted signage help communicate the zone clearly to all workers, reinforcing situational awareness on the job site.

Who Determines the Arc Flash Boundary?

Qualified engineers or safety professionals conduct arc flash studies using data on system voltage, available fault current, protective device clearing times, and equipment configuration. These studies follow standardized calculation methods found in IEEE 1584, with applications enforced through NFPA 70E guidelines. While OSHA does not directly define arc flash parameters, it mandates the use of recognized industry standards, such as NFPA 70E, to maintain a safe working environment.

When working on or near any energized equipment, there is a serious risk of an arc flash. This risk highlights the importance of restricting access to only qualified workers who have been trained in proper procedures and are equipped with the appropriate personal protective equipment (PPE). Without these precautions, anyone crossing the AFB could receive second-degree burns, which is why this zone exists—to define the minimum safe distance from the hazard.

How Is the AFB Calculated?

The boundary distance varies depending on several key factors:

-

System voltage

-

Available fault current

-

Duration of arc exposure (based on breaker/fuse clearing time)

-

Configuration of the equipment (open air vs. enclosed)

For example, in a 480V motor control center (MCC), the required safe distance may be 36 inches at an incident energy of 8 cal/cm². See: what is the arc flash boundary for 8 cal/cm².

Calculations can be performed manually using IEEE 1584 formulas or with specialized arc-flash analysis software. To see common calculated distances, refer to our arc flash boundary table by incident energy.

Approach Boundaries: Complementary Protection Zones

In addition to the AFB, NFPA 70E defines three approach boundaries for shock protection:

-

Limited Approach Boundary: The distance from exposed, energized parts where unqualified persons must be accompanied.

-

Restricted Approach Boundary: Area requiring additional PPE and safety documentation. Only qualified personnel can enter.

-

Prohibited Approach Boundary (no longer used in recent editions): Previously defined areas requiring same protection as direct contact.

To better understand these zones, visit our articles on the limited approach boundary, restricted approach boundary, and prohibited approach boundary.

These boundaries work in tandem with the AFB to ensure a layered approach to electrical safety.

Marking the AFB in the Workplace

To ensure arc flash boundaries are respected and understood, workplaces must make them clearly visible. Best practices include:

-

Applying floor marking tape to show calculated distances

-

Posting warning signs near electrical panels or switchgear

-

Labeling equipment with arc flash labels that include the distance and required PPE

-

Using temporary barriers or barricades during energized work

-

Training all staff to recognize these visual indicators and understand their meaning

Effective zone marking helps prevent accidental entry into high-risk zones and reinforces safe behavior throughout the facility.

Real-World Applications and Protective Value

In practical terms, this critical hazard zone is more than a theoretical line — it shapes real jobsite behavior. For example, a 480V panel with 8 cal/cm² of incident energy might require a boundary of 36 inches. Workers crossing this line must wear appropriate PPE, including an arc-rated suit, face shield, gloves, and hearing protection.

Arc flash boundaries also help define safe zones for unqualified personnel, guide pre-job briefings, and support lockout/tagout planning. By enforcing these boundaries, employers minimize the risk of injury and build a safety culture grounded in prevention and preparedness.

To minimize the risk of an arc-flash incident, facilities must calculate the incident energy at various points within the system and apply the appropriate NFPA 70E threshold limits. These boundaries are not arbitrary—they serve as part of a layered electrical safety perimeter that includes clearly marked approach boundaries for shock protection. Only qualified electrical workers, trained in hazard recognition and PPE requirements, are permitted to enter these zones when energized work is necessary, thereby reinforcing a structured and compliant safety protocol.

Enforcing Calculated Limits

Establishing and enforcing these calculated limits is not just a matter of compliance—it’s a matter of safety culture. The zone reflects a facility's commitment to preventing life-altering injuries and maintaining high standards for electrical work. It also supports the development of consistent arc flash training, pre-job briefings, and hazard awareness.

This minimum safe distance is crucial for protecting workers from the thermal hazards associated with arc-flash incidents. It defines the danger zone, informs PPE selection, and guides safe work practices. Organizations create safer work environments and meet their legal obligations by adhering to NFPA 70E, implementing zone signage, and conducting proper arc flash studies.

Frequently Asked Questions

What are the 3 boundaries for arc flash?

The three boundaries include the Limited Approach Boundary, the Restricted Approach Boundary (both related to electric shock protection), and the Arc Flash Boundary. Each boundary sets specific requirements under NFPA 70E, including the type of PPE required and the qualifications workers must possess to enter each zone safely.

What is the minimum arc flash boundary?

The arc flash boundary is the minimum distance from an energized conductor or circuit where the incident energy equals 1.2 cal/cm² (5.02 J/cm²). At this distance, a worker without proper PPE could suffer second-degree burns from an arc flash.

What is the boundary of arc flash 480v?

The arc flash boundary for 480V equipment is the distance from the potential arc source at which the incident energy reaches 1.2 cal/cm², sufficient to cause second-degree burns. This distance depends on factors such as fault current, system configuration, and protective device clearing time.

How to calculate the arc flash boundary?

The arc flash boundary is calculated by determining the distance from an exposed energized conductor at which the incident energy reaches 1.2 cal/cm² (5.02 J/cm²), as specified in NFPA 70E. This marks the point where a worker without proper PPE could suffer second-degree burns.

Compliance Note

Note: The Prohibited Approach Boundary was removed in recent NFPA 70E revisions; however, it still appears in some legacy documentation and training materials. Facilities should align current practices with the latest edition of the standard.

Related Articles:

Arc Flash Boundary Chart - Safe Approach Distances

An Arc Flash Boundary Chart outlines the minimum safe distance from energized equipment where a person could be exposed to a thermal incident. This boundary is defined by NFPA 70E and helps determine the required PPE level to reduce the risk of injury.

Request a Free Training Quotation

What is an Arc Flash Boundary Chart?

An Arc Flash Boundary Chart is a visual safety reference that outlines critical zones around energized electrical equipment where workers face potential thermal exposure from an arc flash event. These zones are defined by the amount of thermal energy, known as incident energy, that could be released during an electrical explosion. The boundary distance is typically measured in calories per square centimetre (cal/cm²) and directly influences the level of protection required.

✅ Establishes Protection Zones – The chart identifies threshold distances where arc flash hazards begin, helping planners designate safe work limits around equipment.

✅ Supports Risk Assessment – It assists safety professionals in evaluating job site hazards and determining when additional safety controls or energized work permits are required.

✅ Promotes Standardized Safety Practices –The chart helps enforce consistent protection measures across facilities by referencing NFPA 70E and CSA Z462 guidelines.

Each boundary distance shown in the chart corresponds to a specific incident energy exposure level. The farther a worker is from the source, the less energy they are exposed to, meaning reduced PPE requirements. Conversely, close proximity to energized equipment demands more robust arc-rated protective gear.

The arc flash boundary is sometimes called the “protection boundary” or “minimum safe approach distance.” This distance must be calculated individually for each piece of electrical equipment, based on its configuration, voltage level, and available fault current. The boundary is not fixed; it can vary widely between systems, making accurate analysis essential.

Using an Arc Flash Boundary Chart as part of a comprehensive electrical safety strategy ensures that hazard zones are clearly marked, appropriate PPE is used, and only properly trained personnel enter high-risk areas. When integrated with energy assessments and worker training, the chart becomes a practical tool for minimizing injuries and meeting regulatory safety standards.

To delve deeper into the specifics of boundaries, consult our article on Arc Flash Boundary.

Sample Arc Flash Boundary Chart

| System Voltage | Available Fault Current (kA) | Clearing Time (s) | Incident Energy (cal/cm²) | Arc Flash Boundary (AFB) |

|---|---|---|---|---|

| 208V | 15 | 0.1 | 1.5 | 18 inches (1.5 ft) |

| 480V | 10 | 0.1 | 2.8 | 36 inches (3 ft) |

| 600V | 25 | 0.2 | 8.0 | 60 inches (5 ft) |

| 480V | 35 | 0.5 | 12.0 | 96 inches (8 ft) |

| 13.8kV | 5 | 0.1 | 4.0 | 48 inches (4 ft) |

What are AF Boundaries?

The protection zone is the minimum safe distance from energized equipment that an unqualified worker can approach without wearing personal protective equipment (PPE). The NFPA 70E and CSA Z462 standards guide the minimum distances that should be maintained between energized electrical equipment and workers based on the incident energy levels.

Three protection boundaries are defined by the NFPA 70E and CSA Z462 standards:

Limited Approach Boundary (LAB)—The LAB is the minimum distance from the energized equipment that an unqualified person can approach. This zone is generally marked with a yellow line and is intended to prevent unqualified personnel from entering the hazard zone.

Restricted Approach Boundary (RAB) - The RAB is the minimum distance from the energized equipment a qualified worker can approach without wearing the appropriate PPE. This zone is marked with a red line indicating where a worker must begin wearing the appropriate PPE to prevent injury.

Prohibited Approach Boundary (PAB) - The PAB is the closest distance to the energized equipment considered safe for any person to approach, regardless of PPE. This zone is marked with a black line and indicates the most hazardous area.

What is the Minimum Arc Flash Boundary?

The minimum arc flash boundary is determined by the incident energy level that could be released during an electrical explosion. The incident energy level is calculated using complex mathematical formulas that consider the system voltage, available fault current, and the time it takes for the protective devices to clear the fault.

The NFPA 70E and CSA Z462 standards provide tables and formulas to help calculate the incident energy and the minimum distance. The minimum approach distance is the distance from the energized equipment where the incident energy is below 1.2 cal/cm², which is the level of thermal energy that can cause second-degree burns to unprotected skin. For a breakdown of boundary distances by energy level, refer to our Arc Flash Boundary Table by Incident Energy.

What is the Arc Flash Boundary for 480V?

The protection zone for 480V arc flash equipment can vary depending on the incident energy level. However, the NFPA 70E and CSA Z462 standards provide a table that specifies the minimum distance for 480V equipment based on the available fault current and the clearing time of the protective device.

For example, if the available fault current is 10,000 A and the protective device clearing time is 0.1 seconds, the minimum approach distance for 480 V equipment is 3 feet for a Category 1 PPE level. If you’re working with high-risk levels like 8 cal/cm², see What Is the Arc Flash Boundary for 8 cal/cm²? to ensure proper distance and PPE selection.

It's important to note that the minimum approach distance can vary depending on several factors, including system voltage, available fault current, and protective device settings. Therefore, it's essential to accurately calculate the proper working distance for each piece of equipment to ensure that workers are adequately protected.

How the Arc Flash Boundary Chart Is Used in the Field

The chart serves as a visual reference, enabling safety managers, engineers, and qualified electrical workers to determine safe working distances based on incident energy levels quickly. Typically, the chart displays boundary distances for various voltages, fault clearing times, and working distances. It’s used during risk assessments and job planning to determine the safe distance personnel can be positioned from energized equipment without exceeding the 1.2 cal/cm² threshold. By consulting the chart, professionals can select the appropriate PPE and ensure that labelling and signage accurately reflect the hazard zones. Learn more about Incident Energy and how it affects arc flash risk and PPE requirements.

How to Calculate Boundaries

The chart can be used to calculate the minimum approach distance, but it requires an understanding of the electrical system and its potential hazards. The process involves a detailed analysis of the electrical system and the potential fault currents that could occur.

The NFPA 70E and CSA Z462 standards outline the calculation of the protection zone using various methods, including the incident energy analysis method and the PPE category method.

The incident energy analysis method involves conducting a detailed analysis of the electrical system to determine the potential incident energy levels at various points within the system. This method requires complex calculations and detailed information about the system components, such as the available fault current and protective device settings.

The PPE category method determines the minimum PPE level required for a specific task based on the incident energy level. This method involves using tables to determine the required Personal Protective Equipment (PPE) level for a specific incident energy level and selecting the appropriate PPE based on the task.

Regardless of the method used, accurately calculating this safe distance is critical to ensuring adequate worker safety.

Can an Unqualified Person Cross the AFB?

An unqualified person should never cross the LAB of an energized piece of electrical equipment. The LAB is the minimum distance from the energized equipment that an unqualified person can approach, and it's intended to keep unqualified personnel from entering the hazard zone.

Only a qualified electrical worker who has received specialized training and is authorized to work on or near energized electrical equipment should cross the RAB. Crossing the RAB without appropriate PPE is dangerous and can result in severe burns, injuries, or even death.

Related Pages

CSA Z462 Tables Explained

CSA Z462 tables outline arc-flash PPE categories, shock protection boundaries, and task-based risk assessment criteria, guiding electrical safety, incident energy estimation, and approach limits for low- and medium-voltage systems during maintenance and troubleshooting.

Understanding CSA Z462 Tables in Electrical Safety

CSA Z462 Tables For a comprehensive overview of CSA Z462, the guidance in this CSA Z462 resource explains how tables are structured for practical field use.

Recent revisions are summarized in the CSA Z462 2024 update, highlighting clarifications to table selection and risk assessment.

Because table use depends on control of hazardous energy, consult CSA Z460 lockout/tagout guidance to ensure equipment is de-energized before verification.

For cross-compatibility, compare with the NFPA 70E arc flash table to align PPE categories and approach boundaries.

Your jurisdiction may reference applicable electrical safety regulations when enforcing table-based work practices.

When tables are insufficient for specific equipment conditions, arc flash analysis and labeling solutions provide incident energy values for precise PPE selection.

Integrate table use within electrical safety requirements that address training, procedures, and documentation.

Related Articles

At what voltage can an arc flash occur?

At what voltage can an arc flash occur depends on system design, incident energy, fault current, and clearing time; NFPA 70E, OSHA, PPE, low- and medium-voltage equipment, and arc fault mitigation all influence risk.

Quick Reference: At What Voltage Can an Arc Flash Occur

Arc flashes can occur at voltages as low as 120 volts or even lower, especially when conductors are in close proximity and fault conditions exist. While higher voltages increase severity, low-voltage systems can still generate dangerous arcs capable of causing fires, injuries, or explosions. For a deeper look at the initiating conditions, see how an arc develops in the guide at how arc flashes occur and why conductor spacing matters.

Arc flashes, a dangerous electrical hazard, are often associated with high-voltage systems, typically 120 volts and above. However, it's crucial to understand that even lower voltages can trigger an arc flash under certain conditions, particularly when conductors are in close proximity. If the concept is unfamiliar, this overview on what an arc flash is clarifies key terms used in low- and high-voltage discussions.

The misconception that low-voltage arc flashes are harmless can have devastating consequences. While they may not cause immediate severe injuries, the resulting sparks or arcs can easily ignite flammable materials like dust, sawdust, or gasoline, leading to catastrophic fires. Furthermore, the presence of an arc flash, regardless of voltage, often signals underlying issues within the electrical system that could escalate into more serious problems. Practical examples of typical equipment and locations are outlined in where arc flashes commonly occur for context on facility risks.

As the voltage in a system increases, so does the severity of potential arc flashes. The energy intensifies, expanding the arc flash's reach and destructive power. In high-voltage scenarios, arc flashes can span several feet, generating temperatures exceeding tens of thousands of degrees. These extreme conditions can trigger explosions, causing extensive damage to both infrastructure and human life. Thermal and pressure effects at these energy levels are documented in this primer on electrical arc flash phenomena and incident energy.

Some resources refer to the event as an electric flash, a term you may encounter in standards and maintenance guides.

Prioritizing electrical safety is paramount in mitigating these risks. Regular maintenance of electrical systems is crucial to identify and address potential faults before they escalate into arc flash incidents. Additionally, equipping systems with appropriate safety measures like circuit breakers is essential. These devices can rapidly cut off the electrical current in the event of a fault, significantly reducing the arc flash's duration and impact, ultimately saving lives and minimizing property damage. Understanding initiating faults helps select protective devices, as explained in why arc flashes happen and how mitigation strategies are applied.

Understanding the potential for arc flashes across various voltage levels is vital for creating a safe working environment. By implementing comprehensive safety protocols and maintaining electrical systems diligently, we can significantly reduce the risk of these dangerous incidents. Safety planning benefits from knowing fault progression, detailed in how an arc flash happens and the stages leading to escalation.

Related Articles

Arc Flash Gear Explained

Arc flash gear provides PPE compliant with NFPA 70E and CAT ratings, including arc-rated clothing, face shields, FR gloves, and balaclavas, to safeguard electrical workers during switchgear operations and high incident energy tasks.

Essential Guide to Arc Flash Gear for Electricians

Arc flash gear is specialized personal protective equipment (PPE) designed to safeguard workers against the devastating effects of arc flash (AF) incidents. These incidents can generate intense heat, light, and pressure, leading to severe burns and other injuries. Understanding the intricacies of PPE is crucial for ensuring the safety of electrical workers. For a concise overview of key terms and selection basics, consult this arc flash PPE resource to align training with best practices.

Understanding AF Ratings and PPE Categories

The National Fire Protection Association (NFPA) 70E standard provides guidelines for selecting appropriate PPE based on the anticipated incident energy level. If you need help interpreting cal/cm² and hazard categories, see an explanation of arc flash ratings for real-world examples.

The incident energy is measured in calories per square centimeter (cal/cm²) and indicates the amount of heat energy released during an AF.

Arc flash gear is categorized into different PPE categories, ranging from 1 to 4, with each category corresponding to a specific arc rating. For instance, Category 2 PPE is suitable for tasks with an incident energy level of 8 cal/cm², while Category 4 PPE is designed for higher incident energy levels exceeding 40 cal/cm².

Selecting the Right Arc Flash Gear: The Most Important Criterion

The most critical factor in choosing PPE is ensuring its arc rating matches or exceeds the anticipated incident energy level of the task. This requires conducting an AF hazard analysis to determine the potential energy levels at various points in the electrical system. A practical purchasing checklist is outlined in this safety gear guide to help match tasks and environments.

Components of Arc Flash Gear

PPE typically includes a combination of flame-resistant clothing, such as bib overalls, jackets, and coveralls. It may also include additional protective items like hoods, gloves, and face shields. These components work together to provide comprehensive protection against the thermal hazards of an electrical explosion. For garment selection, laundering tips, and layering strategies, reference this guide to arc-rated clothing to optimize protection and comfort.

It may also include additional protective items like hoods, gloves, and face shields. These components work together to provide comprehensive protection against the thermal hazards of an electrical explosion. For a broader view of tools, barriers, and supporting devices, consult this arc flash safety equipment overview to round out your protection strategy.

The Lifespan of Arc Flash Gear

The lifespan of PPE depends on various factors, including the frequency of use, exposure to contaminants, and proper care and maintenance. Regular inspections are essential to identify any signs of wear and tear, such as holes, tears, or discoloration. Damaged gear should be replaced immediately to ensure continued protection.

The Highest Rated PPE for Arc Flash Gear

The highest rated PPE is typically Category 4, designed to withstand incident energy levels exceeding 40 cal/cm². This category includes specialized suits that provide head-to-toe protection, including hoods, gloves, and face shields.

The Primary Goal of Arc Flash Gear

The primary goal of PPE is to minimize the risk of injury or death from an incident. By creating a barrier between the wearer and the intense heat and flames, ppe can significantly reduce the severity of burns and other injuries.

What is the Most Important Criteria for Choosing PPE for Arc Flash Gear?

The most important criteria for choosing PPE is the arc rating. The arc rating measures the protective performance of the clothing and indicates the level of incident energy that the gear can withstand. It is typically measured in calories per square centimeter (cal/cm²). For example, PPE with a 12 cal/cm² rating can protect against lower energy exposures, while gear with a 40 cal/cm² rating provides higher protection for more intense incidents.

Additionally, selecting PPE that complies with NFPA 70E standards is crucial. NFPA 70E outlines the requirements for electrical safety in the workplace, including the specifications for protection. Ensuring that PPE meets these standards guarantees that the gear is designed and tested to protect against hazards effectively. For specific employer obligations, selection steps, and labeling rules, review the arc flash PPE requirements to verify compliance efforts.

How Long is Arc Flash Gear Good For?

The longevity of ppe depends on several factors, including the frequency of use, the conditions under which it is used, and how well it is maintained. Generally, ppe should be inspected regularly for signs of wear and tear. Flame resistant (FR) clothing, for instance, may need to be replaced after about 1 to 2 years of regular use, but this can vary based on the manufacturer's recommendations and the intensity of the work environment.

Storage bags play a crucial role in extending the life of ppe. Proper storage can prevent damage from environmental factors such as moisture, dust, and UV light, which can degrade the protective properties of the gear over time.

What is the Highest Rated PPE for Arc Flash Gear?

The highest rated PPE for ppe is typically found in the PPE Category 4 as defined by NFPA 70E. This category includes gear with an arc rating of at least 40 cal/cm². An arc flash suit in this category often comprises multiple layers, including a flame-resistant outer layer, arc-rated bib overalls, and a hood with a face shield.

PPE in this category is designed to provide maximum protection for workers exposed to high incident energy levels, ensuring they remain safe during even the most severe incidents.

What is the Primary Goal of Arc Flash Gear?

The primary goal of ppe is to protect workers from the thermal and physical hazards. This includes protecting against burns from intense heat, injuries from molten metals, and impacts from the pressure wave generated by an electrical explosion. Properly designed arc flash gear minimizes the risk of severe injury or death, allowing workers to perform their duties safely in hazardous environments.

PPE aims to:

- Prevent Burns: The heat from an electrical explosion can cause severe burns. Flame resistant clothing helps to prevent these burns by providing a barrier between the worker and the heat source.

- Protect Against Molten Metals: During an arc blast, metals can melt and splatter. PPE is designed to withstand and repel these molten materials.

- Shield from Pressure Waves: The pressure wave can cause physical injuries. Sturdy, well-fitted gear helps to protect against the force of these blasts.

Additional Considerations

When selecting PPE, consider factors such as comfort, fit, and ease of movement. Ill-fitting gear can hinder the wearer's ability to perform tasks safely. Additionally, ensure the gear is compatible with other PPE, such as hard hats and safety glasses.

Proper storage of PPE is also important to maintain its integrity. Consider using storage bags or containers to protect the gear from dust, moisture, and other contaminants.

PPE is a critical component of electrical safety. By understanding the importance of arc ratings, PPE categories, and proper selection criteria, workers and employers can make informed decisions to protect themselves from the devastating effects of incidents. Remember, investing in high-quality PPE is an investment in the safety and well-being of electrical workers. For selection, care, and training considerations in one place, see this PPE for arc flash summary as you develop or update your program.