Electrical Safety

CSA Z462 Arc Flash Training - Electrical Safety Essentials

Our customized live online or in‑person group training can be delivered to your staff at your location.

- Live Online

- 6 hours Instructor-led

- Group Training Available

Download Our OSHA 4474 Fact Sheet – Establishing Boundaries Around Arc Flash Hazards

- Understand the difference between arc flash and electric shock boundaries

- Learn who may cross each boundary and under what conditions

- Apply voltage-based rules for safer approach distances

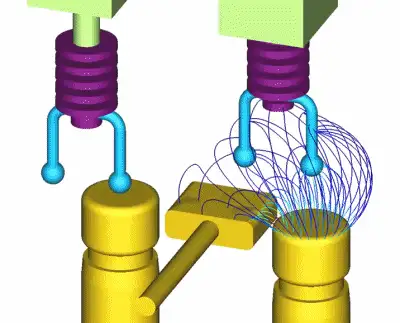

Electrical safety in engineering involves grounding, insulation, PPE, lockout-tagout, and arc flash mitigation to control voltage and current hazards, ensure NFPA 70E and OSHA compliance, and protect personnel, equipment, and facilities.

What Is Electrical Safety?

Engineering controls to prevent shock, arc flash, and fires via standards, grounding, insulation, PPE, and devices.

✅ Implement grounding, bonding, and insulation per IEEE/NFPA.

✅ Apply lockout-tagout, GFCI/RCDs, and circuit protection coordination.

✅ Conduct arc flash studies, PPE selection, and NFPA 70E training.

Electrical Safety is the most important issue in the electrical industry. Electricity is an immediate and essential part of our daily lives, providing power for industrial, commercial and institutional power systems, communications and computerization in homes, offices and industrial plants. It's because electricity is so widely used in every aspect of our lives that every year people come into unsafe contact with electricity and are killed or injured by electric shocks, arc flash burns, and arc blast explosions.

This is because they either were not complelely aware of the relative hazards and did not properly understand the effects of electricity on the body or (as in case of electrical workers) they did understand but had accidental or negligent contact with electricity in high enough voltages to either injure or kill them. This makes electrical safety paramount, whether or not you are an electrical worker. For a deeper introduction to risk controls across plants and facilities, see industrial electrical safety guidance resources that expand on these hazards.

In every company, electrical safety starts with a company's commitment to the health and safety of all it's employees, electrical and non electrical workers. Electrical professionals need to receive periodic but regular training on the proper care, maintenance, inspection and utilization of the electrical systems in industrial, commerical and institutional locations. Safety programs are designed to make sure that electricans work within the guidelines of current Federal (OSHA and CSA), state and provincial, U.S. NFPA 70e and Canadian CSA Z462 regulations. Comprehensive electrical safety in the workplace frameworks outline training cycles and documentation requirements.

Sign Up for Electricity Forum’s Arc Flash Newsletter

Stay informed with our FREE Arc Flash Newsletter — get the latest news, breakthrough technologies, and expert insights, delivered straight to your inbox.

Electrical safety protection programs help employees and companies reduce the risk of personal injury and equipment damage due to operator error. These programs are designed to ensure that, under emergency conditions, the proper steps are taken to restore power in an efficient and safe manner. These programs align task planning with electrical safety work practices that minimize exposure during switching and testing.

In North America, various federal (OSHA, CSA), and state and provincial laws require that employers maintain safe workplace conditions and practices. This means that under the Occupational Electrical Health and Safety Act, employers, supervisors, and workers individually have legal responsibilities to ensure that all work practices are being conducted in a professional and electrically safe manner. Understanding applicable electrical safety requirements helps employers and workers meet their legal duties effectively.

Electrical safety OSHA regulations govern hazards are addressed in specific OSHA standards for the general industry, shipyard employment, and marine terminals. OSHA standards, the Regulatory Agenda (a list of actions being taken with regard to OSHA standards), including Federal Registers (these are rules, proposed rules, and also notices), OSHA directives (these are instructions for persons deemed to be "electrical compliance officers"), standard interpretations (this means official letters of interpretation of the OSHA standards), and national consensus standards which are related to any electrical equipment hazards. For quick reference, curated OSHA electrical safety materials summarize enforcement priorities and common citations.

Electrical Safety Procedures are an essential part of any program. Electrical workers must know where the disconnect switches and electrical panels are located in the workplace so that the electrical equipment can be quickly de-energized when an electrical accident occurs. Posting the location of the electrical panel on servicing equipment is also a great way to enhance safety. Documented electrical safety procedures should also specify verification steps and responsibilities.

Lockout Tagout is a term that refers to specific electrical procedures that are designed to safeguard electrical employees from electrocution in the event of unexpected energization of electrical equipment and machinery during service or electrical maintenance activities. From an engineering perspective, applying electrical engineering safety principles supports effective LOTO design and equipment labeling.

The Electrical Safety Forum is designed to provide electrical workers and non electrical workers with the latests information about standards and regulaions, products and services.